Finite element analysis method for temperature action on prestressed reinforced concrete continuous rigid frame bridge

An analysis method and temperature effect technology, applied in the field of prestress analysis, can solve the problems of lengthy calculation, heavy workload, lack of calculation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0175] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be noted that the following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

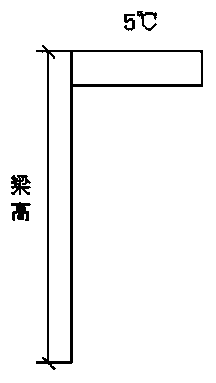

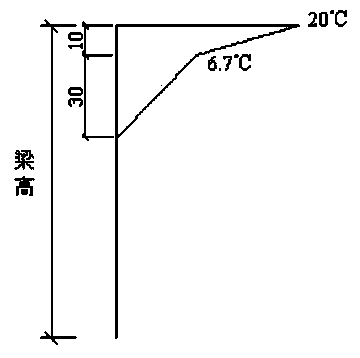

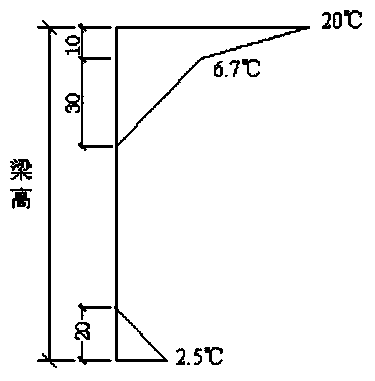

[0176]The computational physical model involved in the present invention is the Shuimowan Super Bridge in the engineering example. The bridge is located at K21+910m from Shaolin Temple to Luoyang Expressway. The main bridge is a prestressed concrete continuous rigid frame bridge with a span of 65+110+65 =240m, hollow thin-walled piers, bored pile foundation. The superstructure is a single-box single-chamber section, with a roof width of 12.75m and a floor width of 6.5m. Parabolic change. The main girder of the main bridge adopts a three-way prestressing system: three types...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com