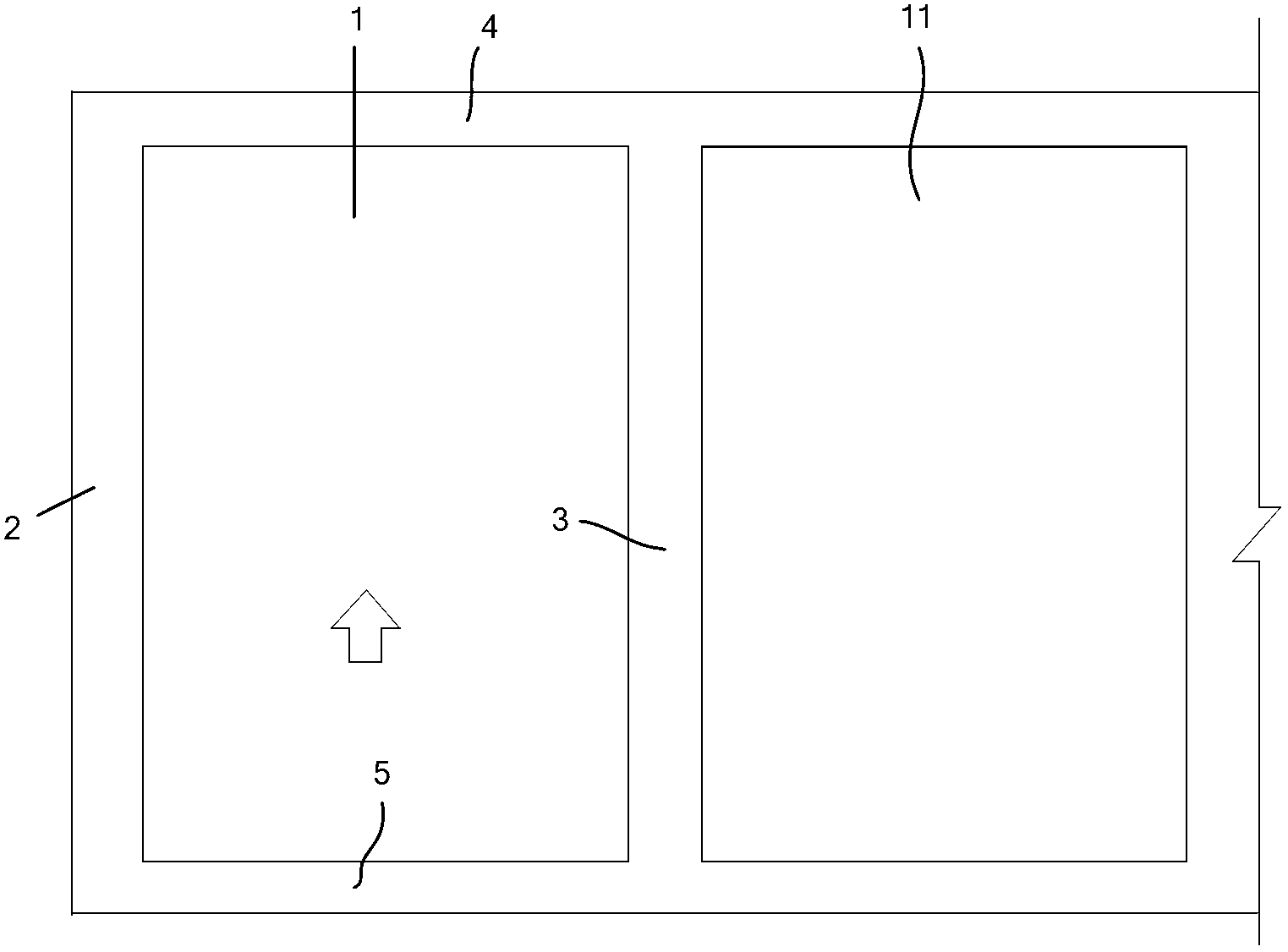

Top-cutting roadway coal-pillar-free mining method of close-range thin coal seam

A mining method and technology for thin coal seams, which are applied in surface mining, earthwork drilling, underground mining, etc., can solve problems such as the inability to achieve coal pillar-free mining, and achieve the effects of stable gob-side tunnels, low cost, and small deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

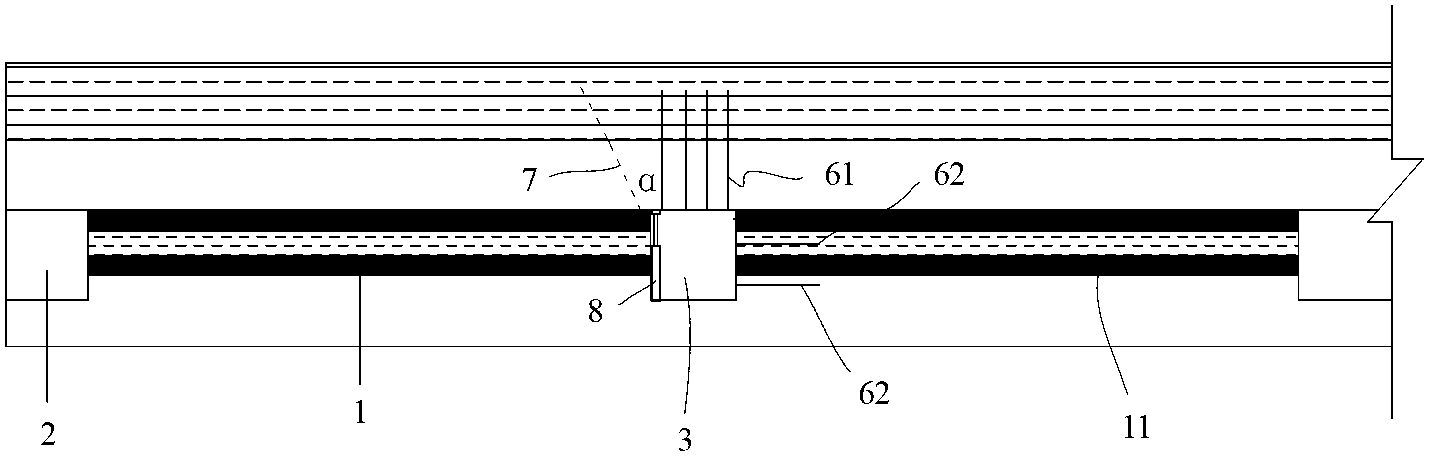

[0053] The coal seam inclination angle of the working face is 0-8 degrees, the working face has a dip length of 164 meters, a strike length of 1050 meters, and a buried depth of 600 meters. It belongs to the coal of the Upper Triassic Xujiahe Formation. The coal mining height is 0.8m, the working face is directly topped by 1.2-2.0m medium-hard argillaceous sandstone, and the immediate upper part is composed of 5-7m thick sandstone and mudstone. The long-wall retreating comprehensive mechanized mining is adopted, and the roof is managed by the caving method. Among them, the machine lane is 1,050 meters long, with a large section reserved for special shapes, with a height of 2.5 meters and a width of 4.4 meters. During the test period, the working face was mined twice for 1,000 meters. After experiencing multiple occurrences of mine pressure, a total of 250 meters of roadway was formed. The average width is 2.8 meters, and the on-site observation shows that the gangue cut from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com