Prestressed drilling, anchoring and grouting anchor cable and support method

A technology of prestressing and injecting anchor cables, which is applied in the direction of earthwork drilling, installation of anchor rods, mining equipment, etc., can solve the problems of anchor cable installation, drilling downtime, cumbersome construction, etc., achieve simple structure, improve bearing capacity, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention is further described below in conjunction with accompanying drawing:

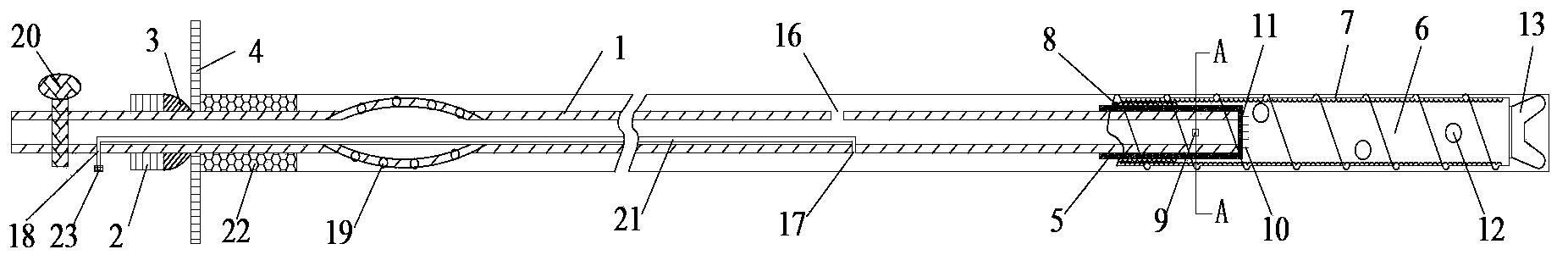

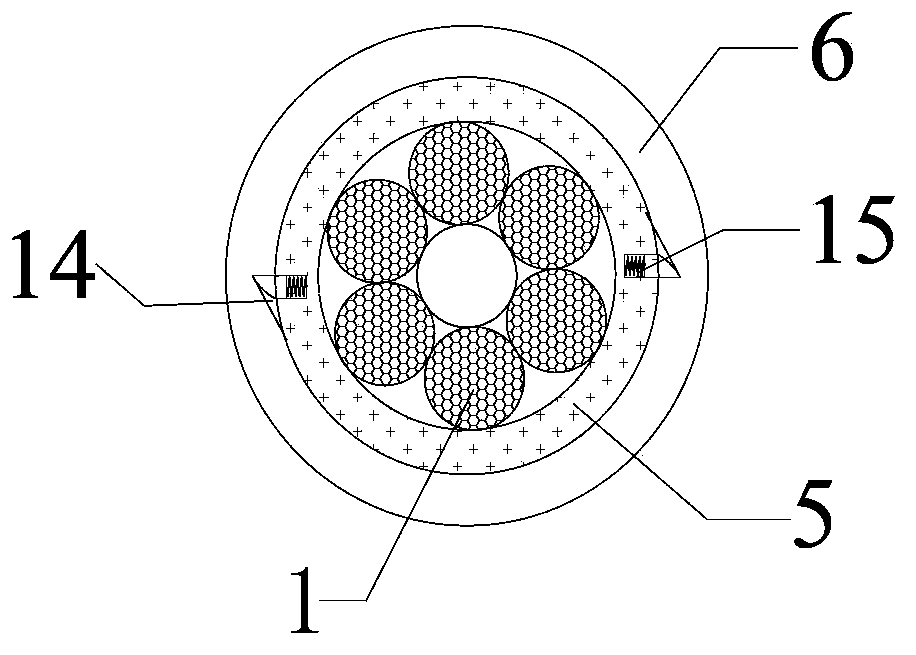

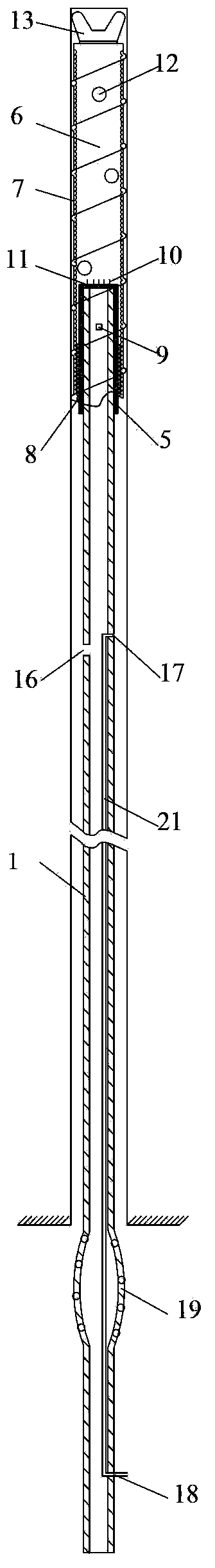

[0017] Such as figure 1 figure 2 As shown, the prestressed anchor cable of the present invention is mainly composed of a hollow grouting anchor cable 1, a lock 2, a gasket 3, a tray 4, and a grouting valve 20 which are successively arranged at the tail of the hollow grouting anchor cable 1; The front end of the slurry anchor cable 1 is equipped with a sleeve 5, the front end of the sleeve 5 is screwed with the tail end of the sleeve 6, the front end of the sleeve 5 is provided with an external thread 8 matching the internal thread 7 at the tail end of the sleeve 6, and the sleeve 5 and the sleeve A self-locking lock 9 is provided in the inner hole of the matching end of the barrel 6, and a metal nail 10 is welded on the inner wall circumference of the sleeve head 5, and a slidable anchoring agent baffle 11 is installed on the metal nail 10; the sleeve 6 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com