A high-efficiency and energy-saving split suction roller

A high-efficiency, energy-saving, split-type technology, used in textiles and papermaking, non-woven fabrics, acupuncture machines, etc., can solve the problems of small working area diameter, large thickness of deflector 2, low suction efficiency, etc. The effect of high degree of sealing, good sealing performance and high suction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

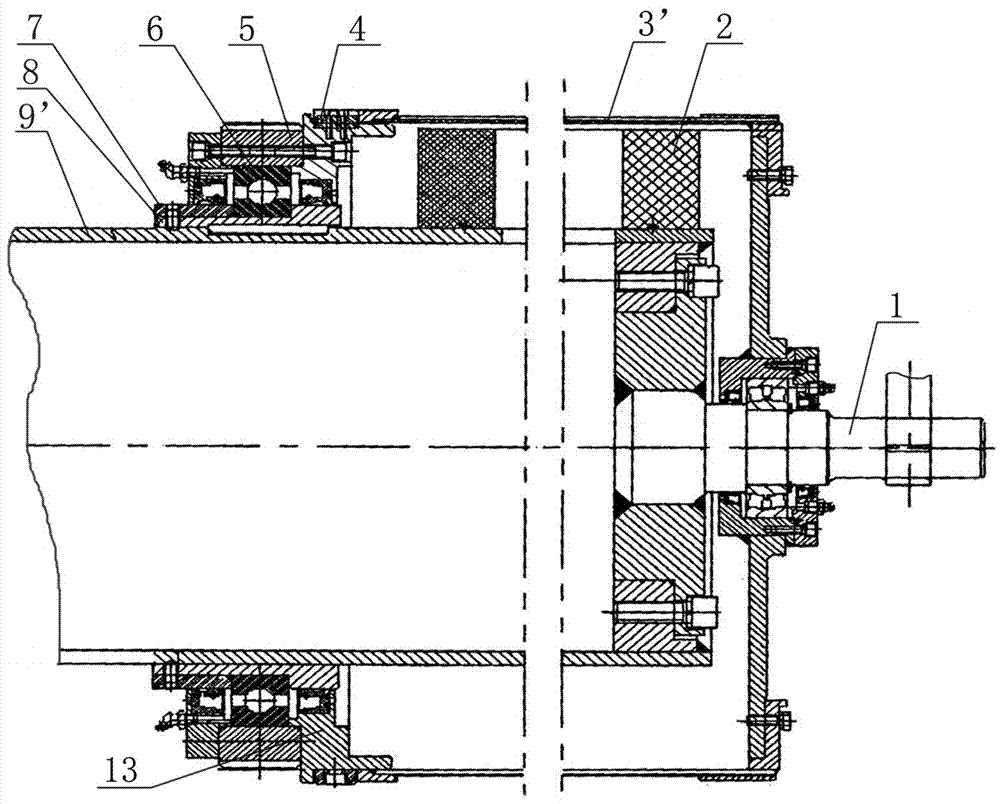

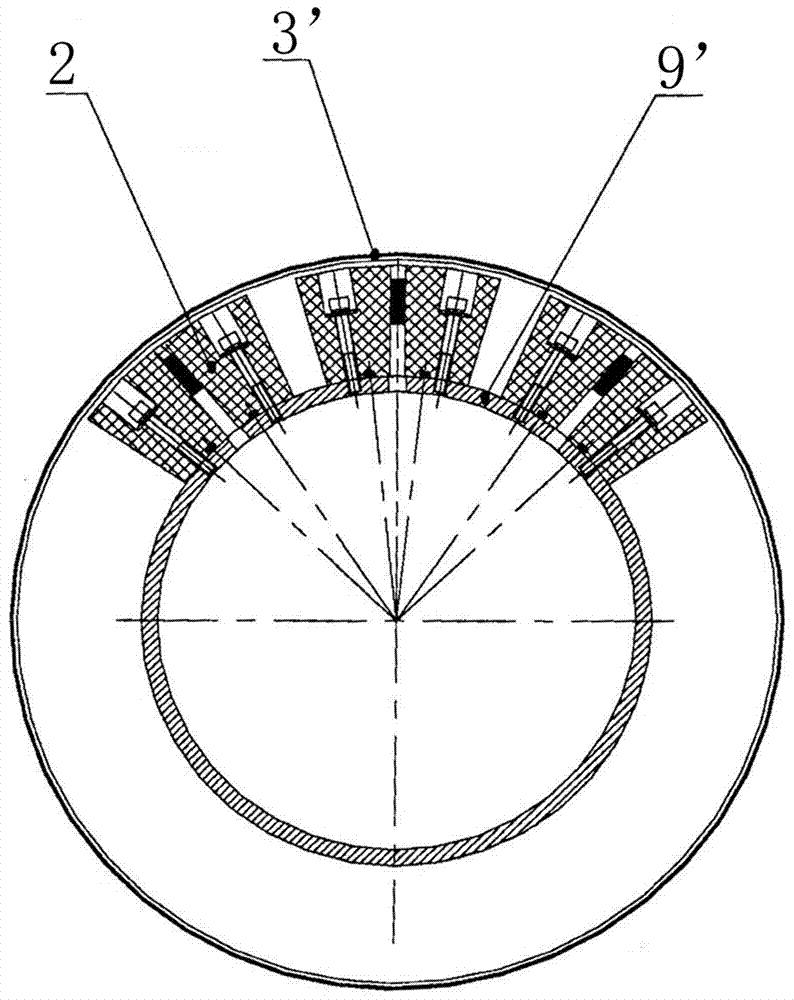

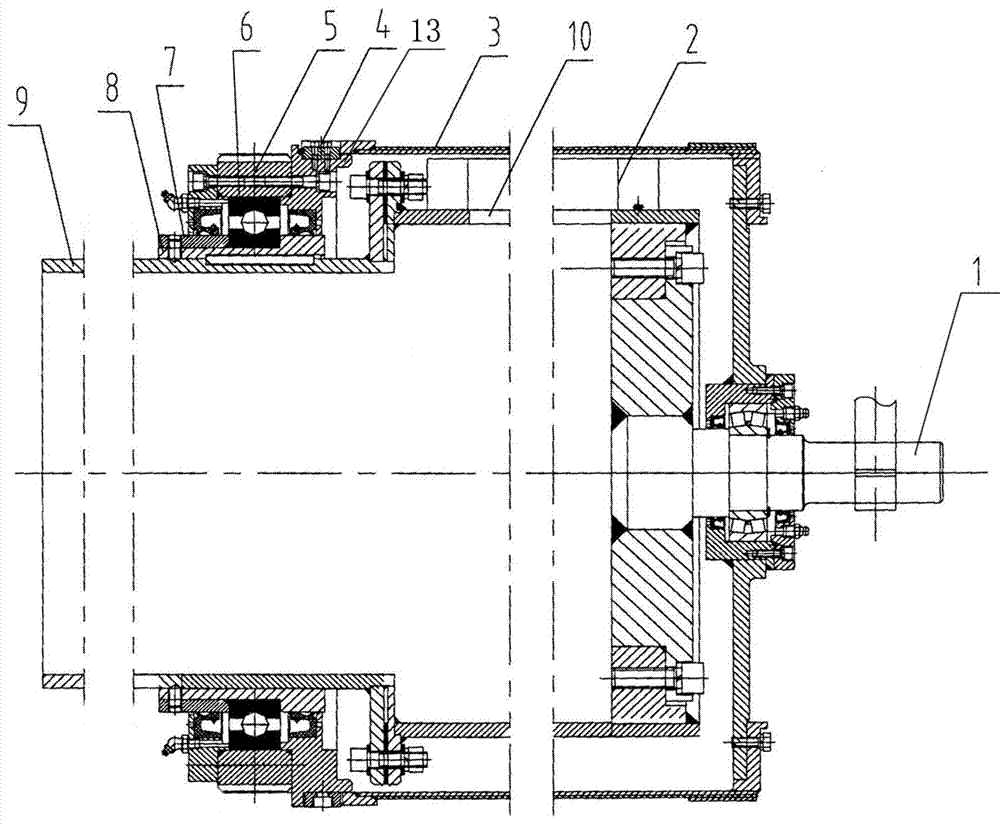

[0022] like image 3 , 4 , 5, the high-efficiency energy-saving split suction roller of the present invention includes a large-diameter stainless steel suction pipe 10 and a small-diameter stainless steel suction pipe 9 that are butted together in a coaxial manner through a connecting flange. The extension end of the diameter stainless steel suction pipe 9 is connected with the negative pressure suction device, and the extension end of the large diameter stainless steel suction pipe 10 is fixedly connected with the shaft head 1 through the sealing end plate; the shaft head 1 The extension end of the pipe is fixedly connected to the shaft end sealing end plate for installing the outer composite cylinder 3 through bearings and bearing seats; the pipe at the butt joint end of the small diameter stainless steel suction pipe 9 and the large diameter stainless steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com