Lanthanum lithium titanate doped composite negative electrode material of lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor electronic conductivity of lithium titanate and limit high-rate performance, shorten heat treatment time, and facilitate migration and migration output and increase productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Disperse 28.4ml of isopropyl titanate in 60ml of deionized water; disperse 4.2g of lithium nitrate in 40ml of deionized water, and keep the molar ratio of lithium and titanium n Li :n Ti =1:1, mix the two liquids, stir for 30min;

[0025] 2) According to 1‰ of the product mass (total mass of lithium source and titanium source material), add 0.07ml of lanthanum source solution with a lanthanum ion concentration of 1mol / L; magnetically stir for 1h, pour the mixed solution into a hydrothermal reaction kettle, Then place it in an oven at 200°C to react for 5 hours. After the reaction, cool naturally to room temperature, then perform suction filtration, wash with deionized water, and dry at 60°C to obtain a lanthanum-doped lithium titanate precursor;

[0026] 3) The obtained precursor was sintered at 800°C for 2 h in a nitrogen atmosphere, and the obtained product was a nanoscale lanthanum-doped lithium titanate material.

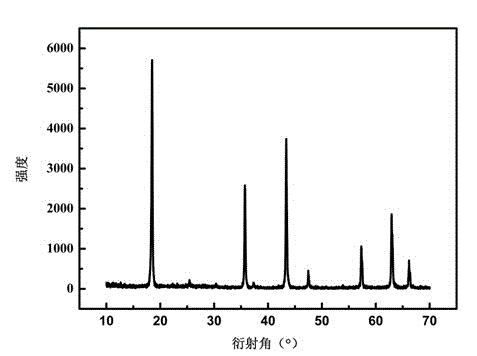

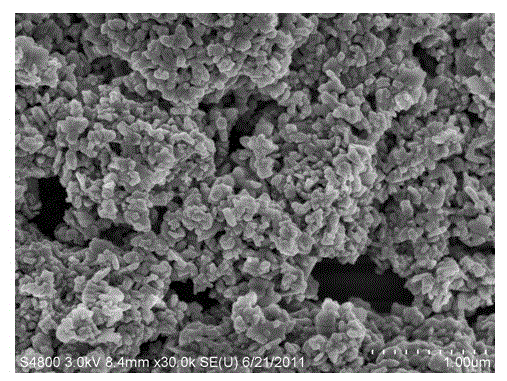

[0027] The sample was analyzed by D\max-2550 X...

Embodiment 2

[0031] 1) Add 10g of amorphous TiO 2 Disperse in 50ml deionized water; disperse 12.14g lithium acetate in 50ml deionized water, and keep the molar ratio of lithium and titanium n Li :n Ti =1:1.05, mix the two liquids, stir for 30 minutes;

[0032] 2) Add 0.86ml of lanthanum nitrate solution with a concentration of 1mol / L according to 1% of the product weight; magnetically stir for 1 hour, pour the mixed solution into a hydrothermal reaction kettle, and then place it in an oven at 120°C for 24 hours. , naturally cooled to room temperature, then suction filtered, washed with deionized water, and dried at 120°C to obtain a lanthanum-doped lithium titanate precursor;

[0033] 3) The obtained precursor is sintered at 1000° C. for 1 hour under a nitrogen atmosphere, and the obtained product is a nanoscale lanthanum-doped lithium titanate material.

[0034] Its test method is the same as that of Example 1, and the first discharge specific capacity reaches 195mAh g -1 . The speci...

Embodiment 3

[0036] 1) Disperse 28.46ml of isopropyl titanate in 30ml of deionized water; disperse 6.26g of lithium hydroxide monohydrate in 20ml of deionized water, and keep the molar ratio of lithium and titanium n Li :n Ti =1:1.1; Mix the two liquids and stir for 30 minutes;

[0037]2) Pour the mixed solution into a hydrothermal reaction kettle, and then place it in an oven at 160°C for 10 hours to react. After the reaction, cool down to room temperature naturally, then perform suction filtration, wash with deionized water, and dry at 100°C to obtain lithium titanate Precursor: Add 0.5g of precursor and 0.015g of lanthanum sulfate into a 50ml reaction kettle, react at 200°C for 5 hours, and then cool naturally. Then perform suction filtration, wash with deionized water, and dry at 100°C to obtain a lanthanum-doped lithium titanate precursor;

[0038] 3) The obtained precursor was sintered at 600° C. for 5 h under a nitrogen atmosphere, and the obtained product was a nanoscale lanthanu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com