Hydroxyl polyester resin for high-gloss powder coating, and preparation method and application thereof

A polyester resin and powder coating technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of affecting gloss performance, difficulty, and reducing the gloss of the final coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

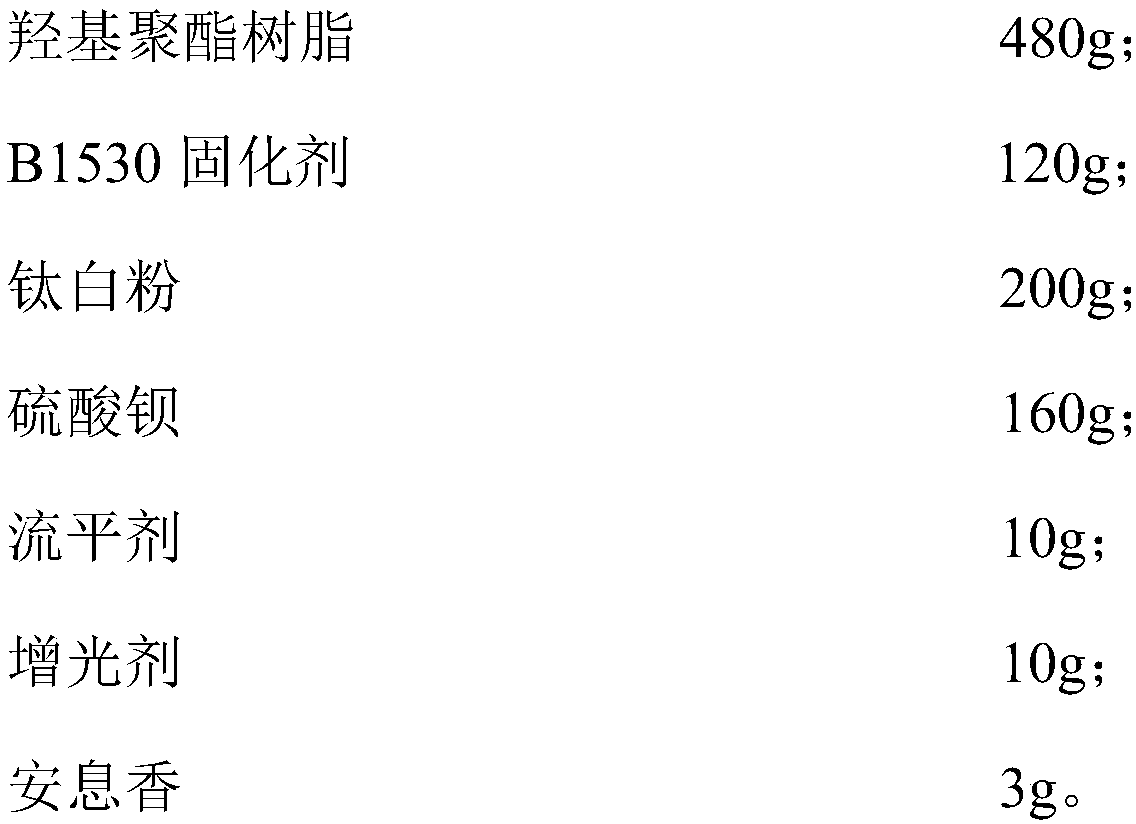

Examples

Embodiment 1

[0042] The hydroxyl polyester resin for high-gloss powder coatings described in this embodiment, based on the total amount of raw materials for preparing the hydroxyl polyester resin, includes the following raw material components in molar percentages:

[0043] Terephthalic acid 21mol;

[0044] 6-aminocaproic acid 12mol;

[0045] Domoic acid 10mol;

[0046] 3,6-dithia-1,8-octanediol 17mol;

[0047] 2-Acrylic acid-2,18-dihydroxy-4,7,10,13,16-pentaoxanonadecane-1,19-diyl ester 10mol;

[0048] Neopentyl glycol 12mol;

[0049] 3-(2,3-epoxypropoxy)propyltrimethoxysilane 6mol;

[0050] 3,5-di-tert-butyl-4-hydroxybenzyl alcohol 12mol;

[0051] Dimethyl tin oxide 0.3mol;

[0052] Antioxidant 300 0.2mol.

[0053] The method for preparing high-gloss powder coating hydroxy polyester resin described in the present embodiment may further comprise the steps:

[0054] (1) Take a selected amount of the 3,6-dithia-1,8-octanediol, 2-acrylic acid-2,18-dihydroxy-4,7,10,13,16-pentoxadecyl M...

Embodiment 2

[0061] The hydroxyl polyester resin for high-gloss powder coatings described in this embodiment, based on the total amount of raw materials for preparing the hydroxyl polyester resin, includes the following raw material components in molar percentages:

[0062] Terephthalic acid 25mol;

[0063] 6-aminocaproic acid 15mol;

[0064] Domoic acid 5mol;

[0065] 3,6-dithia-1,8-octanediol 16mol;

[0066] 2-Acrylic acid-2,18-dihydroxy-4,7,10,13,16-pentaoxanonadecane-1,19-diyl ester 6mol;

[0067] Neopentyl glycol 15mol;

[0068] 3-(2,3-epoxypropoxy)propyltrimethoxysilane 3mol;

[0069] 3,5-di-tert-butyl-4-hydroxybenzyl alcohol 15mol;

[0070] Dimethyl tin oxide 0.1mol;

[0071] Antioxidant 300 0.5mol.

[0072] The method for preparing the hydroxyl polyester resin for high-gloss powder coatings described in this example is the same as that in Example 1.

[0073] After testing, the hydroxyl value of the hydroxyl polyester resin prepared in this example is 44 mgKOH / g, the softeni...

Embodiment 3

[0075] The hydroxyl polyester resin for high-gloss powder coatings described in this embodiment, based on the total amount of raw materials for preparing the hydroxyl polyester resin, includes the following raw material components in molar percentages:

[0076] Terephthalic acid 25mol;

[0077] 5mol of 6-aminocaproic acid;

[0078] Domoic acid 12mol;

[0079] 3,6-dithia-1,8-octanediol 18mol;

[0080] 2-Acrylic acid-2,18-dihydroxy-4,7,10,13,16-pentaoxanonadecane-1,19-diyl ester 12mol;

[0081] Neopentyl glycol 15mol;

[0082] 3-(2,3-epoxypropoxy)propyltrimethoxysilane 8mol;

[0083] 3,5-di-tert-butyl-4-hydroxybenzyl alcohol 5mol;

[0084] Dimethyl tin oxide 0.4mol;

[0085] Antioxidant 300 0.2mol.

[0086] The method for preparing the hydroxyl polyester resin for high-gloss powder coatings described in this example is the same as that in Example 1.

[0087] After testing, the hydroxyl value of the hydroxyl polyester resin prepared in this example is 32 mgKOH / g, the soft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com