Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

250results about How to "High plasticizing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

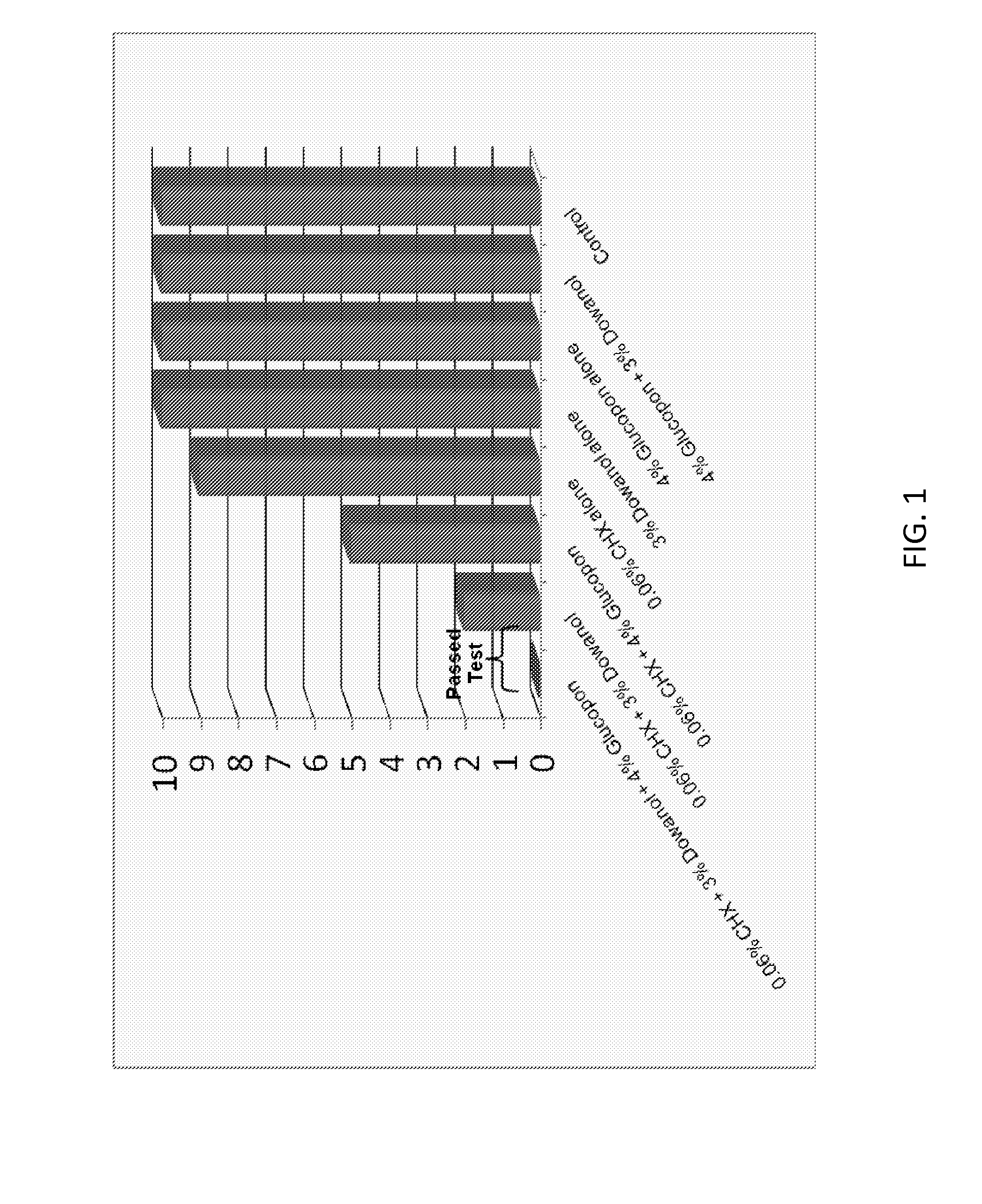

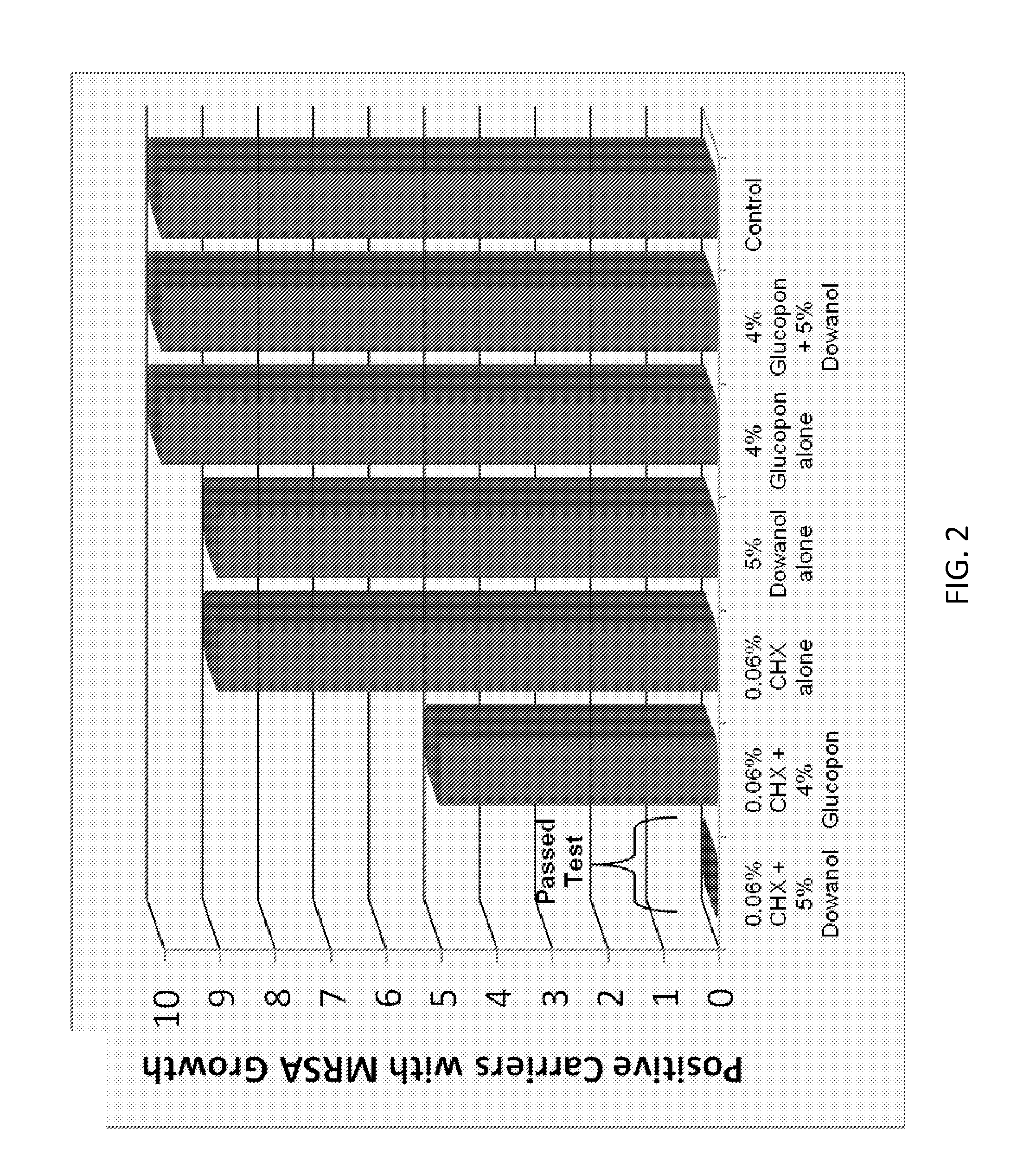

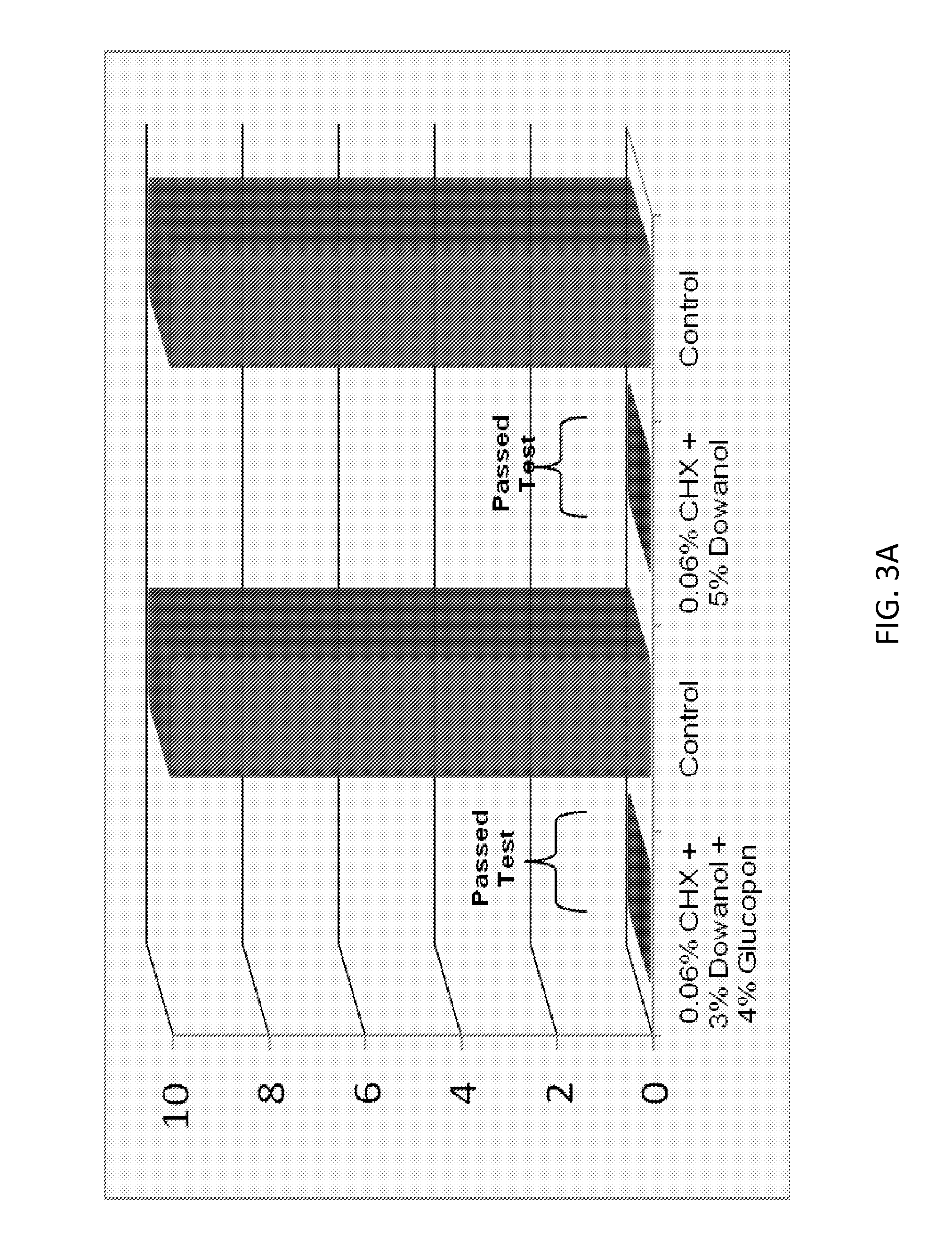

Antimicrobial solutions

ActiveUS20130231302A1Excellent surface tension lowering activityImprove film qualityOrganic active ingredientsBiocideAlcoholMedicine

The present invention provides antimicrobial solutions that in certain cases comprise a biguanide and a glycol ether and, in some cases, optionally also includes combinations of at least one an alcohol, at least one chelator, glycerol, deoxycholate, and / or at least one alkylpolyglucoside. In certain aspects the invention comprises a biguanide and deoxycholate or a combination of chelator, ethanol, and alkylpolyglucoside. Also provided are methods for rapidly killing and / or reducing bacteria, fungi, or virus from surfaces, for example, including surfaces of indwelling medical devices and organic surfaces such as skin and sutures, and inorganic surfaces such as medical equipment, pipelines etc.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Environment-friendly composite plasticizer and preparation method

The invention discloses a plasticizer and a preparation method, in particular an environment-friendly composite plasticizer which is based on a diethylene glycol dibenzoate type plasticizer and di(2-ethylhexyl) terephthalate and can comprise epoxy compounds, adipate compounds, dicaprate compounds and trimellitate compounds. The environment-friendly composite plasticizer can be used as a main plasticizer of polyvinyl chloride resin and other resins. The invention also relates to a preparation method of the environment-friendly composite plasticizer and ingredients thereof, namely the diethylene glycol dibenzoate type plasticizer and the di(2-ethylhexyl) terephthalate. The environment-friendly composite plasticizer has the characteristics of high intermiscibility, plasticizing efficiency, cold resistance, heat resistance, pollution resistance, extraction resistance, migration, electric insulation, light and heat stability and the like, and is widely applied in plasticizing industry.

Owner:浙江嘉澳环保科技股份有限公司

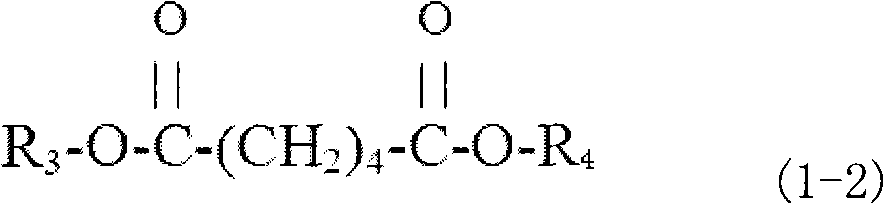

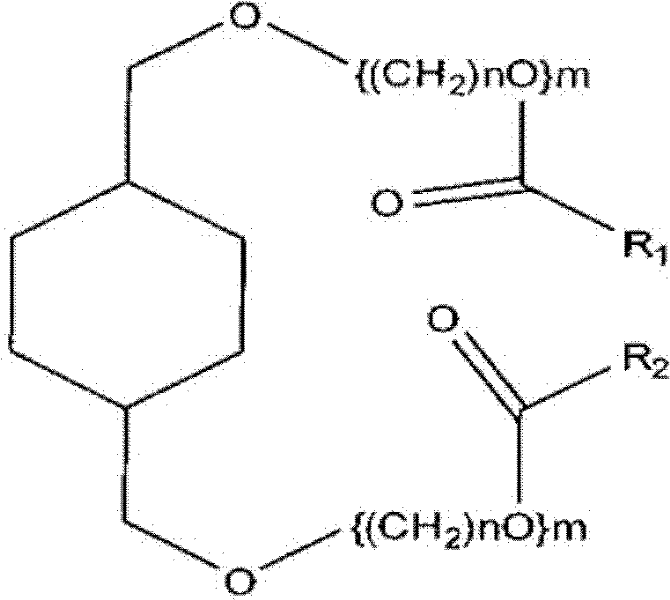

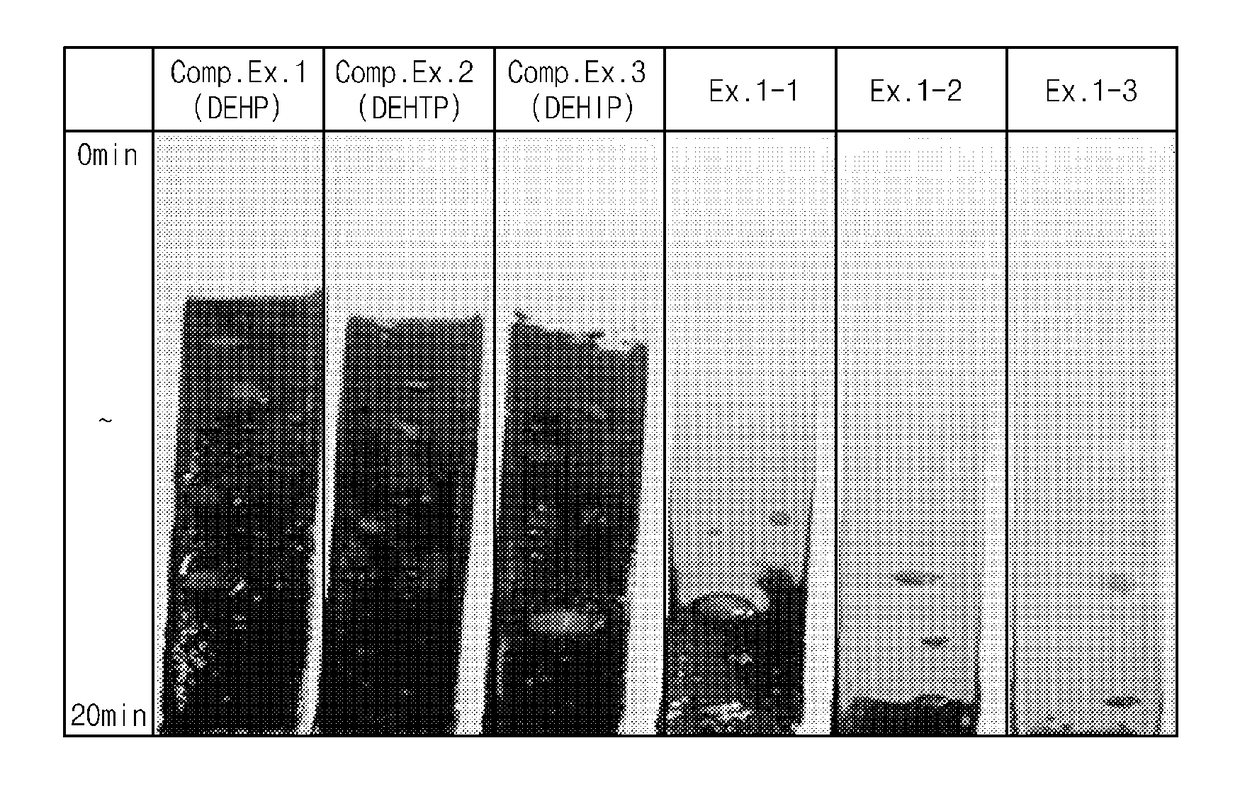

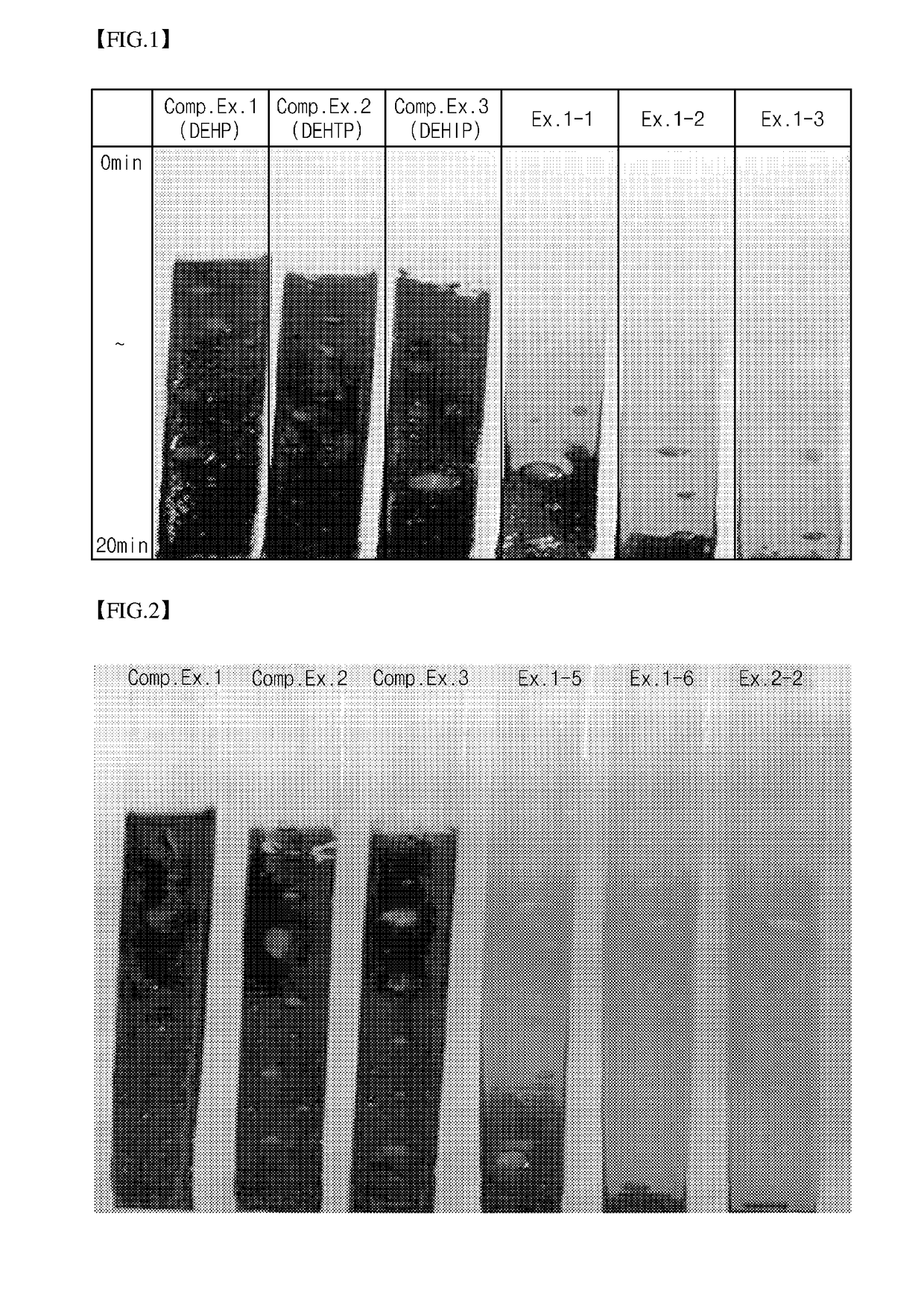

Plasticizer composition and resin composition, and preparation method thereof

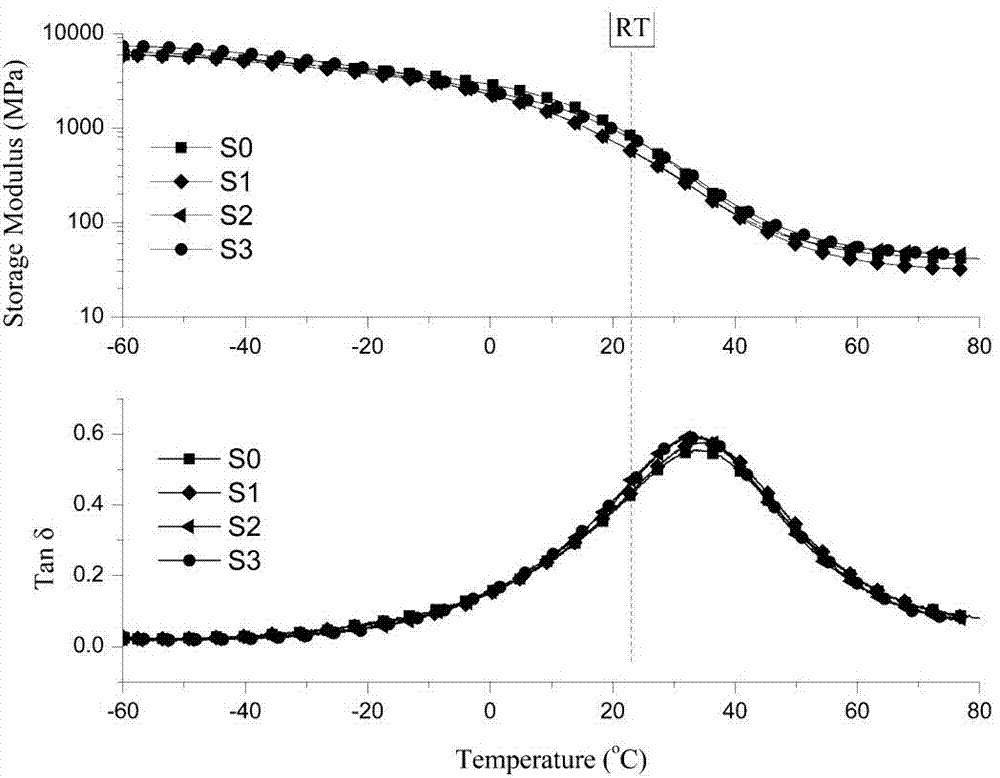

Provided are a plasticizer composition and a resin composition, and a preparation method thereof, wherein the present invention may provide a plasticizer, which may improve physical properties, such as plasticizing efficiency, migration, tensile strength, elongation rate, stress resistance, and light resistance, required for a sheet formulation when used as a plasticizer of a resin composition, by improving poor physical properties that have been ascribed to structural limitations, and a resin composition including the plasticizer.

Owner:LG CHEM LTD

Environment-friendly soft polyvinyl chloride granules

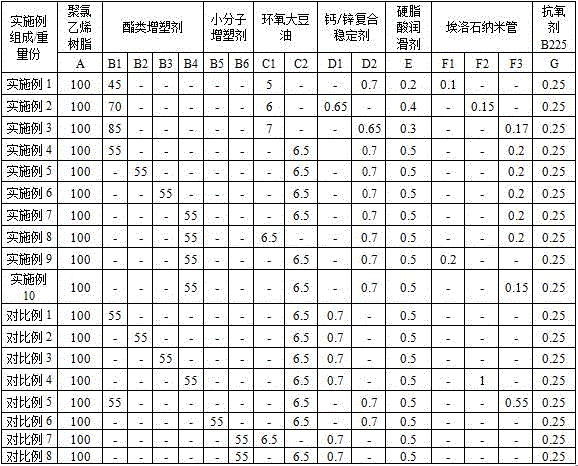

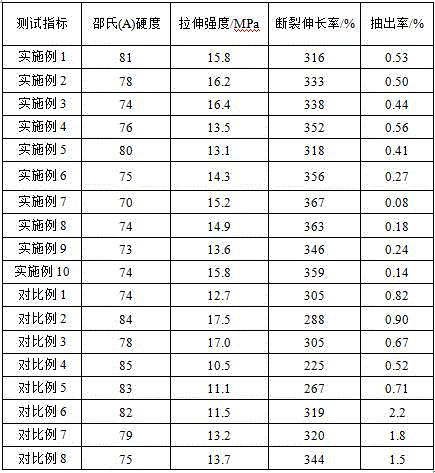

The invention provides environment-friendly soft polyvinyl chloride granules. The environment-friendly soft polyvinyl chloride granules are prepared from the following raw materials: 100 parts of polyvinyl chloride resin, 30-130 parts of ester plasticizer, 5-10 parts of epoxidized soybean oil, 0.1-2 parts of calcium / zinc compound stabilizer, 0.1-1 part of lubricating agent and 0.01-0.5 part of halloysite nanotube. The soft polyvinyl chloride granules have high plasticizing efficiency, superior toughness, extremely low precipitation rate, and safety protection of the environment and body health are facilitated.

Owner:浙江天原医用材料有限公司

Polyester plasticizer and chlorine-containing resin compositions

The polyester-based plasticizer of the present invention is obtained by reacting (a) a diol component, (b) an organic dicarboxylic acid component, and (c) a terminal terminator, and the average molecular weight of the polyester-based plasticizer is 500-5000, wherein, the (a) diol component is composed of 100 mole parts of 2-methyl-1,3-propanediol, 10-1000 mole parts of 3-methyl-1,5-pentanediol and 0-1000 mole parts of other aliphatic diols; the (b) organic dicarboxylic acid component is composed of 100 mole parts of adipic acid and 0 to 100 mole parts of other organic dicarboxylic acids; the (c) terminal The terminator is composed of monohydric aliphatic alcohol or monohydric aliphatic organic acid. The polyester plasticizer of the present invention has excellent plasticizing efficiency and can impart excellent oil resistance to synthetic resins such as chlorine-containing resins.

Owner:ADEKA CORP

Sole material and preparation method thereof

The invention discloses a sole material. The sole material is characterized in that the sole material is prepared from 50-150 parts of TPU, 10-50 parts of PVC, 10-30 parts of a plasticizer, 3-6 parts of a stabilizer, 2-20 parts of a compatilizer, 0-1 part of a crosslinking agent, 0-50 parts of a filler, and 0-1 part of a lubricant, wherein the compatilizer is one of chlorinated polyethylene and ethylene-vinyl acetate grafted maleic anhydride. According to the invention, after adopting above technical scheme, the compatibility of a blend of the TPU and the PVC is improved, so a problem of bad compatibility of blends treating the TPU as a primary material and the PVC as an auxiliary material in the prior art is solved, thereby the utilization of excellent characteristics of the TPU and the PVC makes the sole material of the invention have the advantages of good wear resistance and low production cost.

Owner:QUANZHOU XINTAI SHOES MATERIAL

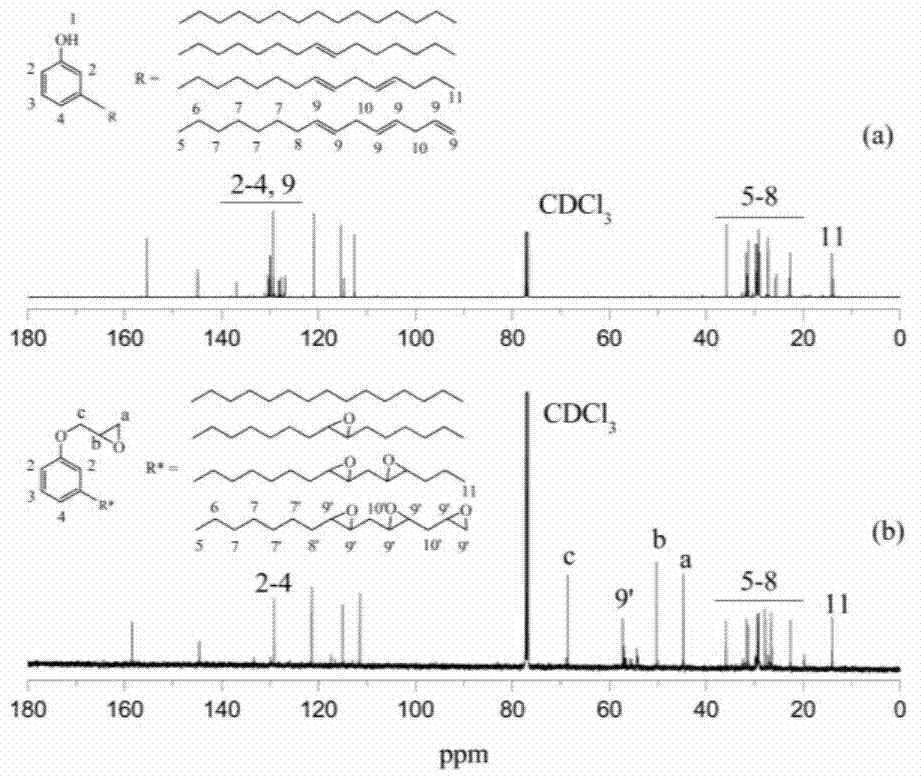

Epoxy cardanol-based glycidyl ether as well as preparation method and application thereof

InactiveCN104710388AEmission reductionSimple production processOrganic chemistryOrganic acidGlycidyl ethers

The invention discloses an epoxy cardanol-based glycidyl ether plasticizer as well as a preparation method and application thereof. The preparation method comprises the following steps: taking cardanol and epoxy chloropropane as main raw materials and carrying out ring-opening addition reaction and ring-closure reaction to synthesize an intermediate product cardanol-based glycidyl ether; and further uniformly mixing the intermediate product with organic acid and a catalyst, heating to a certain temperature, dripping a peroxide source to carry out epoxidation reaction to obtain a crude product, leaving the crude product to stand, layering, performing neutralization and dehydration on the crude product after the reaction so as to obtain an epoxy cardanol-based glycidyl ether plasticizer. The plasticizer is non-toxic, has relatively high plasticizing efficiency and can endowing resin products with favorable thermal stability and mechanical property; and moreover, by taking the cardanol which is low in cost and easy to get as raw material, the epoxy cardanol-based glycidyl ether plasticizer integrates the advantages of being environment-friendly and being reproducible, complies with the developing trend of the plastic additive industry and has wide application and favorable application prospect.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

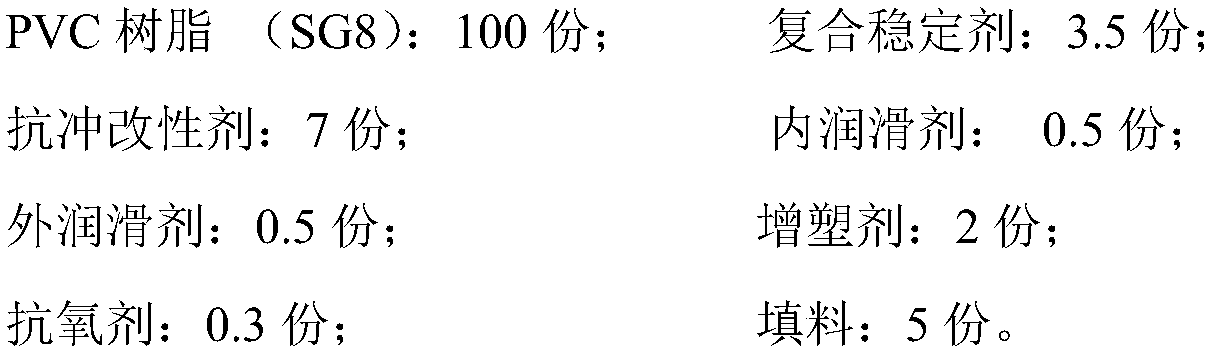

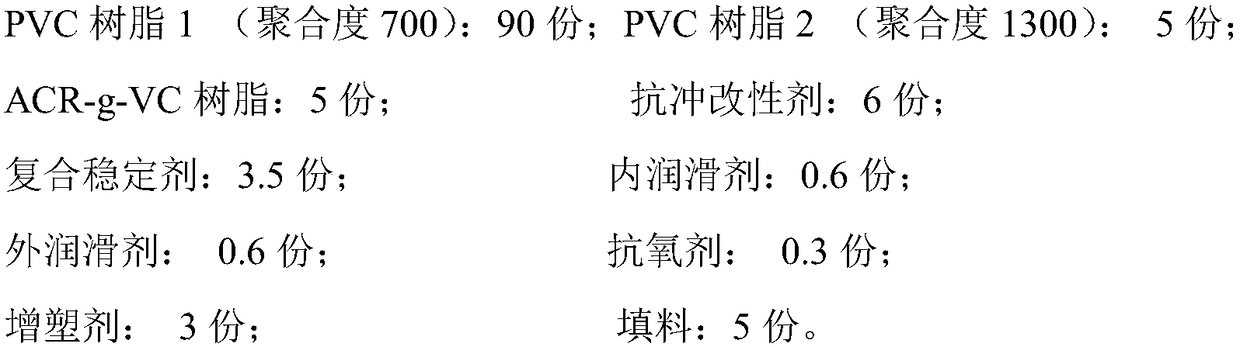

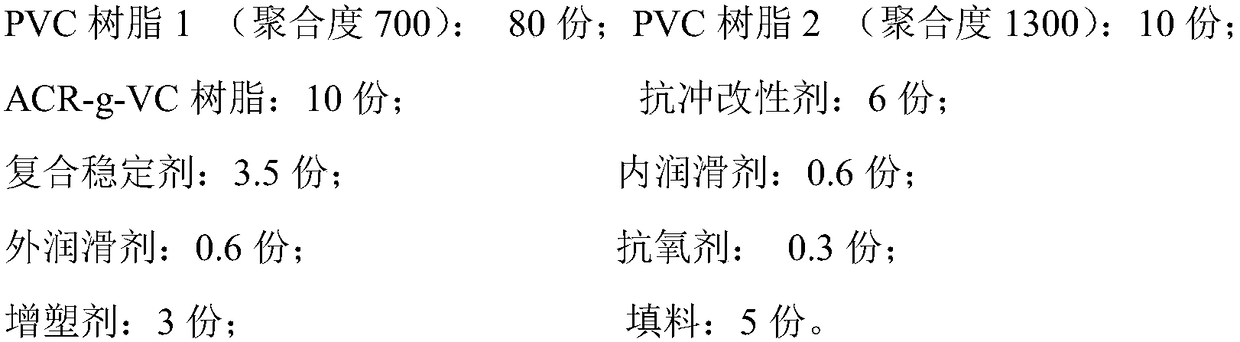

High-strength and high-toughness polyvinyl chloride injection molded composition and preparation method thereof

The invention discloses a high-strength and high-toughness polyvinyl chloride injection molded composition and a preparation method thereof. The composition comprises, by weight, 50-90 parts of PVC (polyvinyl chloride) resin 1, 5-20 parts of PVC resin 2, 5-40 parts of ACR-g-VC (acrylic graft vinyl chloride) resin, 3-10 parts of parts of impact modifier, 4-6 parts of compound stabilizer, 0.5-2 parts of internal lubricant, 0.5-1.2 parts of external lubricant, 1-5 parts of fillers, 1-3 parts of plasticizer and 0.1-1 part of antioxygen. The preparation method includes: weighing the ingredients according to a formula about weight ratios, placing in a high-speed mixer, mixing to obtain a polyvinyl chloride mixture, adding the polyvinyl chloride mixture into a tapered double-screw extruder, melting, extruding, pelletizing and packaging. Compared with a product prepared according to a formula adopting normal SG8 type PVC resin, the high-strength and high-toughness polyvinyl chloride injectionmolded composition has the advantages that plasticizing time can be shortened by more than 20%, and impact strength can be enhanced by more than 10 times.

Owner:YIBIN TIANYUAN GRP CO LTD

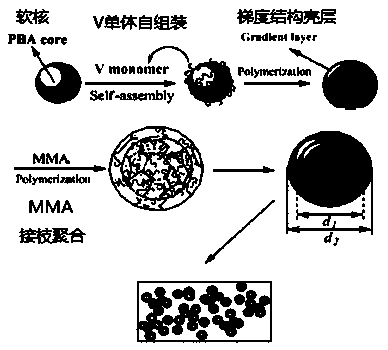

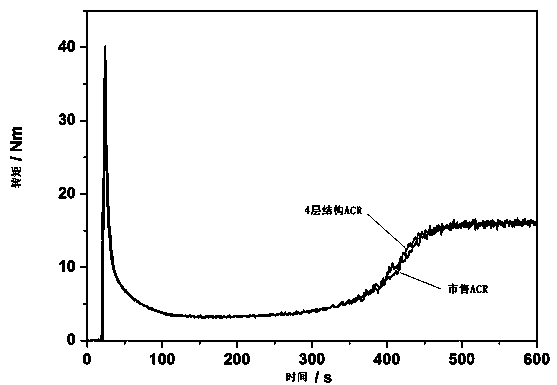

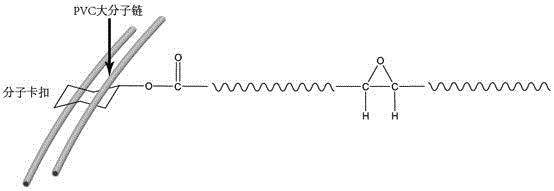

Preparation method of acrylic ester type processing aid with multilayer gradient core-shell structure

ActiveCN103467663AProcess parameters are reasonableReduce material and process costsEmulsionSolubility

The invention relates to a preparation method of an acrylic ester type processing aid with a multilayer gradient core-shell structure, belonging to the field of modification of functional macromolecular materials. The preparation method comprises the following process steps: (1) under the condition of stirring at 30 DEG C, adding deionized water, an initiator A, an emulsifier, a co-emulsifier, a dispersant, a soft monomer and a crosslinking agent into a reaction kettle, and performing pre-emulsification to obtain a pre-emulsion; (2) heating the pre-emulsion to a temperature less than or equal to 90 DEG C, and performing a thermal reaction to obtain a soft monomer core layer emulsion; and (3) adding an initiator B, alpha olefin and a monomer which has a solubility parameter similar to that of PVC (polyvinyl chloride) into the soft monomer core layer emulsion, and sequentially polymerizing 1-5 layers of rigid polymer shells with a solubility parameter similar to that of polyvinyl chloride to obtain the acrylic ester type processing aid. The obtained PVC processing aid has the advantages of low price, good effect of promoting plasticization, excellent weathering resistance, capability of improving impact properties of a product and the like, and can be widely applied to the fields of PVC building door and window profiles, pipes, wires, cables, small-scale household appliances and the like.

Owner:乌鲁木齐市华泰隆化学助剂有限公司

Preparation of polychloroethylene film for jet drawing

InactiveCN101298508AImprove precipitation effectDoes not affect the inkjet effectFlat articlesCoatingsEpoxyProduction line

A preparation method of polyvinyl chloride film for spray painting relates to a preparation method of a polyvinyl chloride film. The method resolves problems of complex technology, high cost, and low plasticizing efficiency of plasticizer and poor spray painting effect of polyvinyl chloride film for spray painting of polyvinyl chloride film precipitated from low plasticizer of existing preparation. The method is that: 1. Inorganic nano-particles and epoxy soybean oil are mixed to gain a mixture; 2. Polyvinyl chloride resin, triethyl trimellitate (2-ethyl), antioxidant, titanium pigment and ultraviolet absorber are added into the mixture to gain mixing materials; 3. The mixing materials are filled into a PVC calendaring production line to produce polyvinyl chloride film, namely, the polyvinyl chloride film for spray painting. The invention is characterized by simple technology, low cost, high plasticizing efficiency and good effect of spray painting.

Owner:HARBIN INST OF TECH

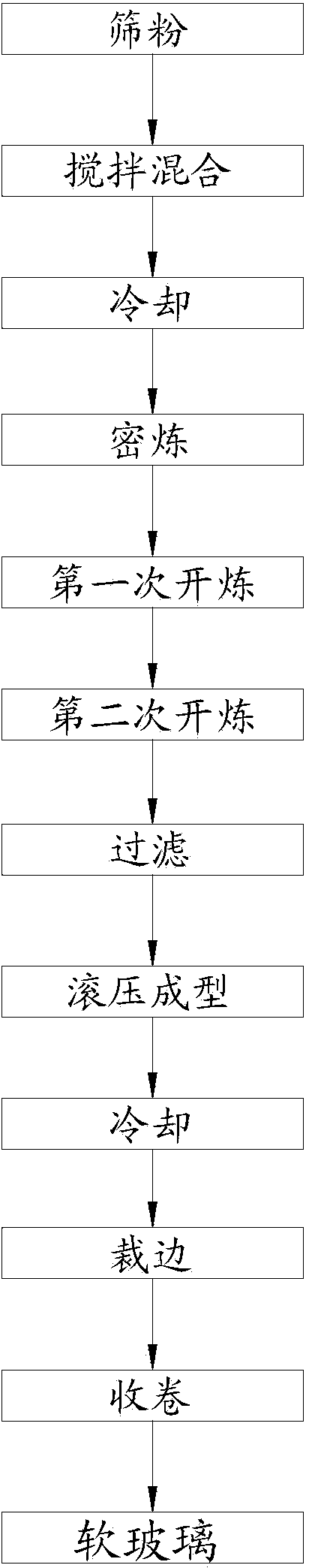

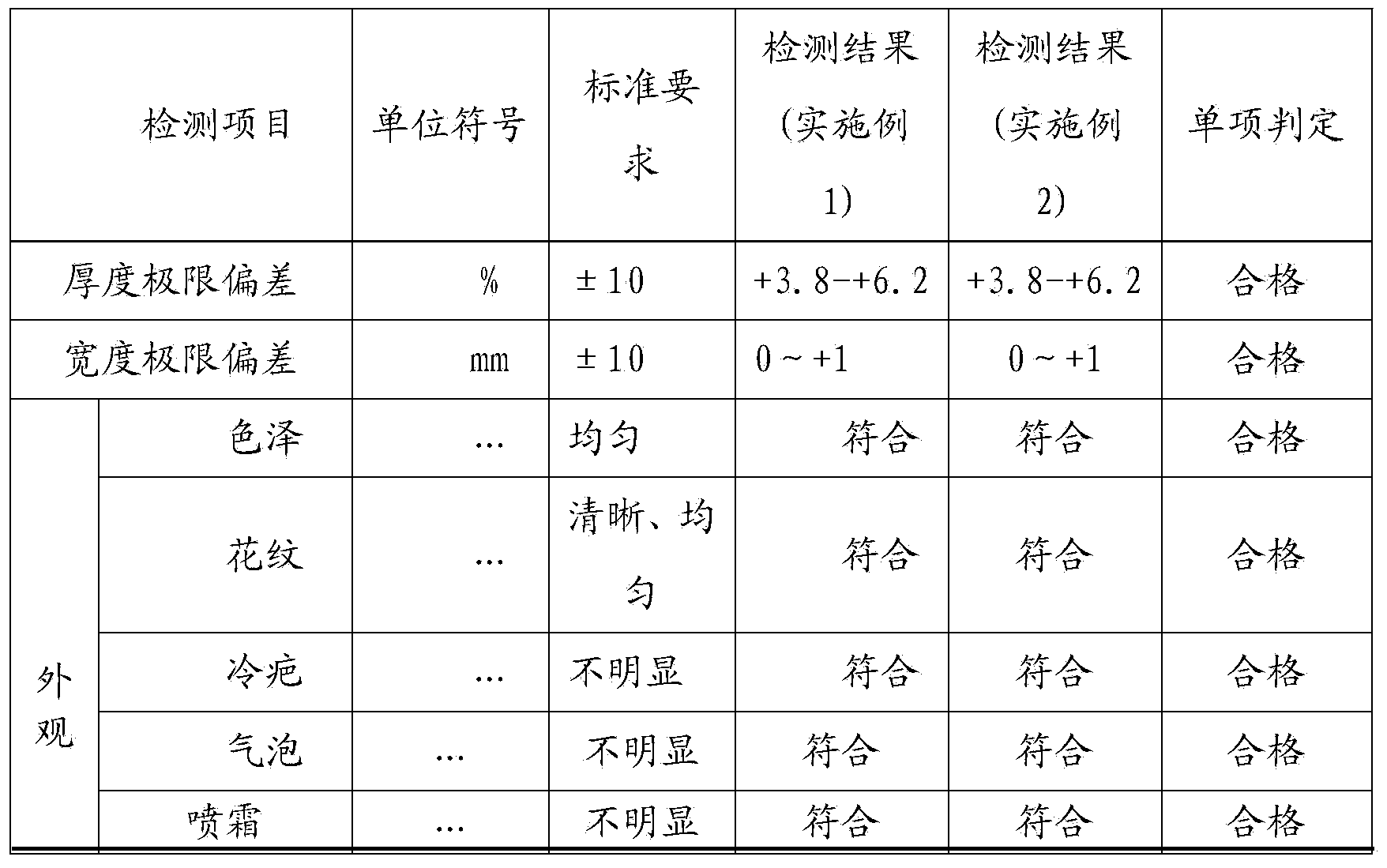

Production method of super-transparent soft PVC (polyvinyl chloride) film

The invention discloses a production method of a super-transparent soft PVC (polyvinyl chloride) film, which comprises the following steps: 1) screening a PVC resin powder to obtain a powder A; 2) stirring the powder A with a plasticizer, a stabilizer, a lubricant and a pigment to obtain a mixed powder B; 3) cooling the mixed powder B by stirring to obtain a mixed powder C; 4) carrying out pressurized banburying on the mixed powder C by a Banbury mixer to obtain a colloid D; 5) carrying out roll plastification on the colloid D to obtain a colloid E; 6) secondary open milling: carrying out roll plastification on the colloid E to obtain a colloid F; 7) adding the colloid F into a filtering machine to obtain a melting charge G; and 8) carrying out roll forming on the melting charge G, cooling, carrying out edge trimming and rolling to obtain the super-transparent soft PVC film. The method can avoid the problem of insufficient plastification and ensure the plastification degree of the product, thereby obtaining the super-transparent soft glass; and the super-transparent soft PVC film has the characteristics of smooth surface, no crack, no bubble, uniform color, high heat resistance, high cold resistance, high aging resistance, high load resistance, strong acid / alkali resistance and favorable light transmittance.

Owner:佛山龙塑工业塑胶有限公司

Environment-friendly migration-resistant epoxy fatty acid cyclohexyl plasticizer and preparation method thereof

InactiveCN105085982AHigh plasticizing efficiencyIncrease investmentOrganic chemistryEpoxyPolymer science

The invention discloses an environment-friendly migration-resistant epoxy fatty acid cyclohexyl plasticizer and a preparation method thereof. The plasticizer is prepared from unsaturated fatty acid and cyclohexanol through esterification and epoxidation, the technological process is simple, strong continuity and high yield are realized, and the situation that a plasticizer manufacture factory adjusts the process route greatly and increases additional mechanical equipment input is avoided since the process of the plasticizer disclosed by the invention is completely compatible with the synthesis process of a conventional epoxy fatty acid methyl ester plasticizer. Under the same conditions, the migration rate of the plasticizer prepared through the method is only about 1 / 5 of that of the conventional epoxy fatty acid methyl ester plasticizer in PVC, the flash point of the plasticizer prepared through the method is 20-30 DEG C higher than that of the conventional epoxy fatty acid methyl ester plasticizer, and meanwhile, the plasticizer disclosed by the invention has the advantages of no toxicity, environment friendliness, good compatibility with polyvinyl chloride resin, high plasticizing efficiency and the like, can replace or partially replace phthalate plasticizers to be used for manufacturing polyvinyl chloride artificial leather, food-grade hoses, fresh-keeping films, infusion apparatuses, blood transfusion bags, medical gloves, children's toys, cables and wires and the like and has a wide application prospect.

Owner:SICHUAN UNIV

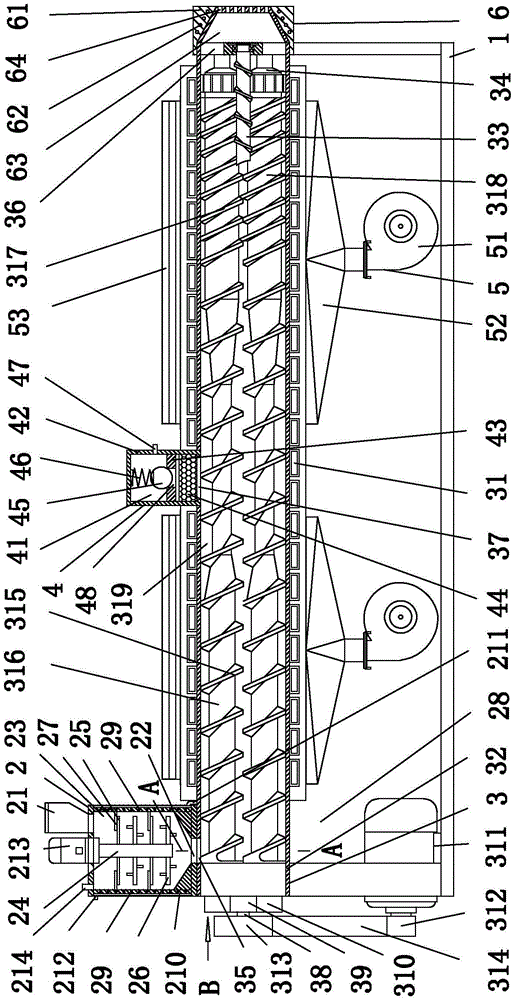

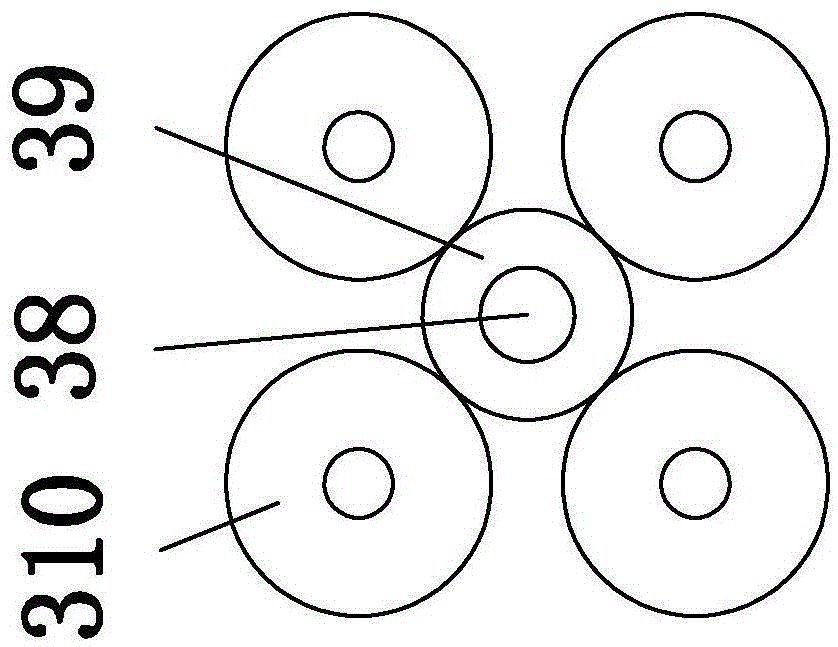

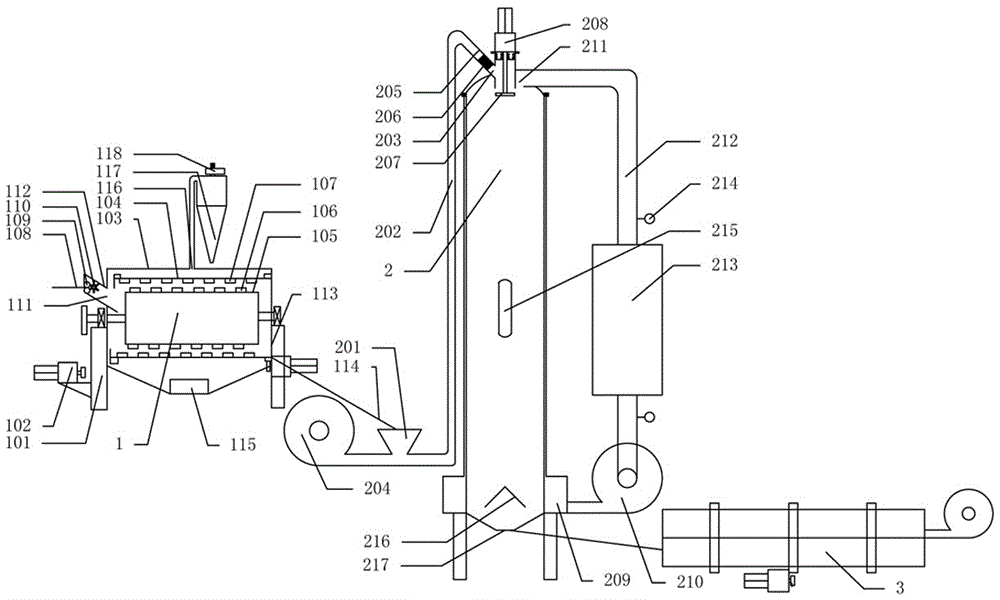

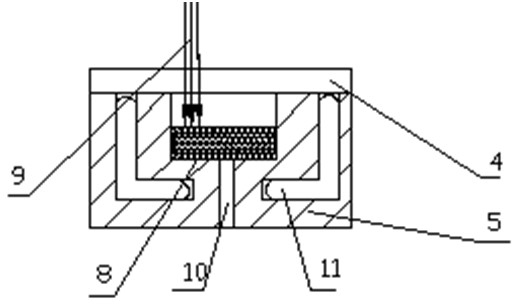

Film crushing plasticator

ActiveCN105710985AImprove the mixing effectImprove toughnessPlastic recyclingMechanical material recoveryAir filterEngineering

The invention relates to the field of recycling of waste plastics and provides a film crushing plasticator. The film crushing plasticator comprises a machine frame and further comprises a crushing, stirring and preplasticizing device, a plasticizing and toughening device and an exhaust air filter device, wherein the crushing, stirring and preplasticizing device is provided with a feeding hopper and a discharging outlet; the plasticizing and toughening device comprises a barrel provided with a barrel heating device and connected with the machine frame, a middle spiral push rod connected with the barrel in a pivoted mode, a plurality of outer spiral push rods distributed in the circumferential direction of the middle spiral push rod and connected with the barrel in a pivoted mode, and a spiral push rod drive device; and the barrel is provided with a plasticizing inlet located at the rear portion of the side body of the barrel and communicating with the discharging outlet, a plasticizing outlet located in the front end of the barrel, and an exhaust hole communicating with an inlet of the exhaust air filter device. The film crushing plasticator is good in effect of mixing, extruding and rubbing of plasticized raw materials in the plasticizing process, gas is exhausted easily, and prepared plastic renewable raw materials are good in toughness.

Owner:NINGBO LVHUA RUBBER & PLASTIC MACHINERY IND & TRADE

Method for preparing plant fiber-based foamed thermoplastic masterbatch

The invention discloses a method for preparing plant fiber-based foamed thermoplastic masterbatch. The method comprises the following specific steps: (A) crushing plant fibers, adding an alkali liquor swelling agent, soaking the processed plant fibers, and drying the soaked plant fibers after carrying out ultrasonic reaction; (B) adding a modified plasticizer, carrying out heating reaction for 30-90min, carrying out filtration after cooling, cleaning filter residues, and drying the cleaned filter residues; and (C) mixing plasticized plant fiber powder, a plastic matrix and auxiliaries, adding the mixture in an extruder, carrying out squeezing granulation to obtain the plant fiber-based foamed thermoplastic masterbatch. By the adoption of the invention, the glass transition temperature of natural plant fibers is optimized, the hot melting flowing property of the natural plant fibers is improved after being modified by the composite modified plasticizer, the wood-plastic plasticizing torsional force is effectively reduced, the energy consumption is greatly reduced, the cost is reduced, meanwhile, the mechanical property of the foamed thermoplastic masterbatch product can be improved by more than 25%, the impact resistance and the ductility are greatly improved, the material density is reduced, and thus the method has relatively high promotion and application values.

Owner:JIANGSU ACAD OF AGRI SCI

High-elasticity glove and production process thereof

The invention specifically relates to a high-elasticity glove and a production process thereof, belonging to the field of production of plastic gloves. The high-elasticity glove uses DOTP, epoxidized fatty acid methyl ester and a hot melt adhesive as a compound plasticizer and is prepared from the following raw materials by weight: 100 parts of PVC powder, 45 to 55 parts of DOTP, 35 to 55 parts of epoxidized fatty acid methyl ester, 0.8 to 1.2 parts of the hot melt adhesive, 0.1 to 0.3 part of an anti-oxidant, 8 to 12 parts of DBE, 0.8 to 1.8 parts of a calcium zinc stabilizing agent, 25 to 35 parts of a viscosity reducer and 0.5 to 0.7 part of waterborne PU glue. According to the invention, on the basis of a conventional basic formula for a PVC glove, the DOTP, epoxidized fatty acid methyl ester and hot melt adhesive are added as a compound plasticizer, so the indexes including elongation, tensile strength and the like are effectively improved, hand feeling of the PVC glove is enhanced, and the produced glove reaches an advanced level in China; and the production process is simple and can be easily realized.

Owner:BLUE SAIL MEDICAL +1

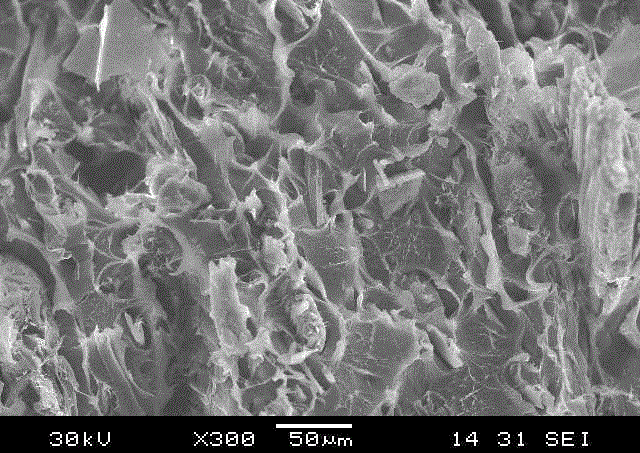

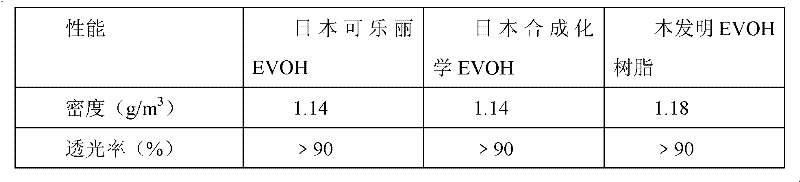

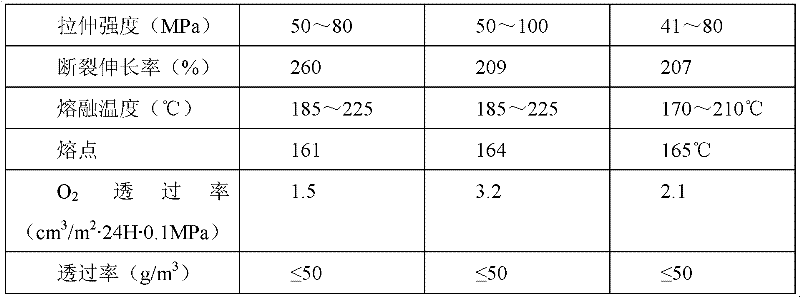

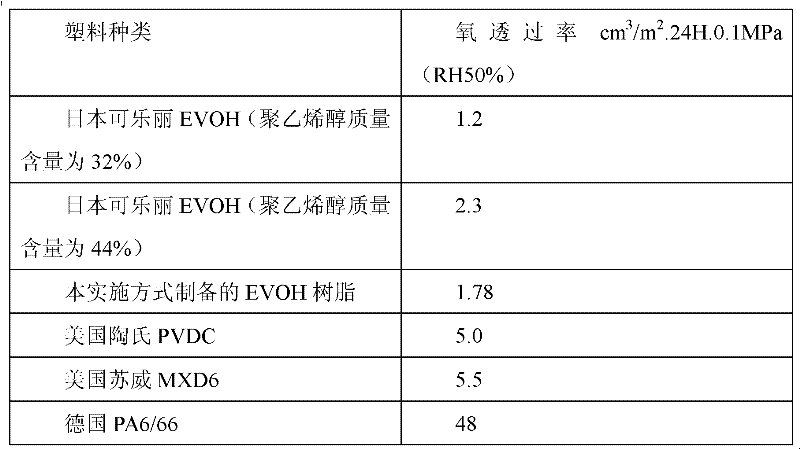

EVOH (ethylene vinyl alcohol) resin and preparation method thereof

The invention discloses an EVOH (ethylene vinyl alcohol) resin and a preparation method thereof and relates to a resin and a preparation method thereof, and the method provided by the invention can be used for solving the problems of complex process for the production of the EVOH resin and large production difficulty in traditional methods. The EVOH resin is prepared through the following steps: stirring polyvinyl alcohol, a plasticizer, an ethylene unsaturated monomer, maleic anhydride graft polypropylene resin, an initiator, a catalyst, an anti-yellowing agent and a surfactant, and then pelletizing the mixture in a double-screw extruder. The method provided by the invention is simple in process and small in equipment investment, and the EVOH resin has the advantage of stable quality.

Owner:WEIFANG HUAWEI MATERIALS TECH CO LTD

Self-sticky modified asphalt waterproof coil and production method thereof

InactiveCN107984823AGood resistance to mold reproductionImprove water resistanceLamination ancillary operationsRoof covering using flexible materialsDispersityBituminous waterproofing

The invention relates to a self-sticky modified asphalt waterproof coil. The waterproof coil has a five-layer type structure which comprises an upper surface isolation layer, an upper modified asphaltself-sticking layer, an tire-based layer, a lower modified asphalt self-sticking layer and a lower surface isolation layer from top to bottom; the upper modified asphalt self-sticking layer and the lower modified asphalt self-sticking layer are prepared from modified asphalt. After asphalt is modified through adopting materials such as butadiene styrene rubber, an SIS (styrene-isoprene-styrene) segmented copolymer and a trimethoxysilyl propyl diethylenetriamine tackifier, obtained modified asphalt has stable performance, added modified nano calcium carbonate has high dispersity, and the storage stability of a modified asphalt system is effectively improved; the modified asphalt is used for making the waterproof coil, the properties such as tearing strength, stickiness, water resistance and ageing resistance of the waterproof coil, which is obtained via production, are all improved, and the service life of the waterproof coil is prolonged.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

Plasticizer and polyvinyl chloride resin composition containing same

InactiveCN102177131AHigh plasticizing efficiencyGood physical propertiesOrganic chemistryOrganic acidPlasticizer

Owner:SK INNOVATION CO LTD +1

Single-component reaction-type polyurethane hot melt adhesive and preparation method thereof

ActiveCN109666441AHigh plasticizing efficiencyReduce volatilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPrepolymerHot-melt adhesive

The invention discloses single-component reaction-type polyurethane hot melt adhesive. The single-component reaction-type polyurethane hot melt adhesive is prepared from the following raw materials: polyurethane prepolymer, a chain extender, tackifying resin, a latent curing agent and filler, wherein the polyurethane prepolymer is formed by polymerizing polyalcohol with a molecular weight of 500 to 3000, polyisocyanate and a catalyst; and the raw material composition also comprises a plasticizer, wherein the plasticizer is dioctyl phthalate and / or diethylene glycol dibenzoate. The components of the single-component reaction-type polyurethane hot melt adhesive of the invention are mixed with plasticizers, the plasticizers are dioctyl phthalate and / or diethylene glycol dibenzoate, the two substances have high plasticizing efficiency for the polyurethane and low volatility and have good low-temperature flexibility; and by adding the plasticizers, the interaction between polymer macromolecular chains can be weakened, the elasticity and flexibility of the polymer materials of the polyurethane hot melt adhesive can be improved, and the high-temperature and low-temperature resistance of the hot melt adhesive can be improved.

Owner:JIANGSU RUIDE NEW ENERGY TECH

Ester-based plasticizer

InactiveCN102471227AHigh plasticizing efficiencyImprove physical propertiesOrganic compound preparationCarboxylic acid esters preparationAlcoholPolyol

The present invention relates to a novel ester-based plasticizer, and more specifically to one which is produced by means of an esterification reaction between a polyhydric alcohol, alkylene oxide and a fatty-acid or aromatic carboxylic acid. When the plasticizer according to the present invention is used to produce a poly(vinyl chloride) resin, there are advantageous effects in that it is possible to obtain products with outstanding plasticization efficiency, and physical properties such as hardness and tensile strength are also improved.

Owner:SK INNOVATION CO LTD +1

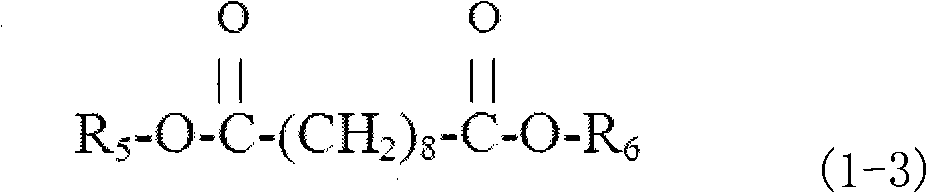

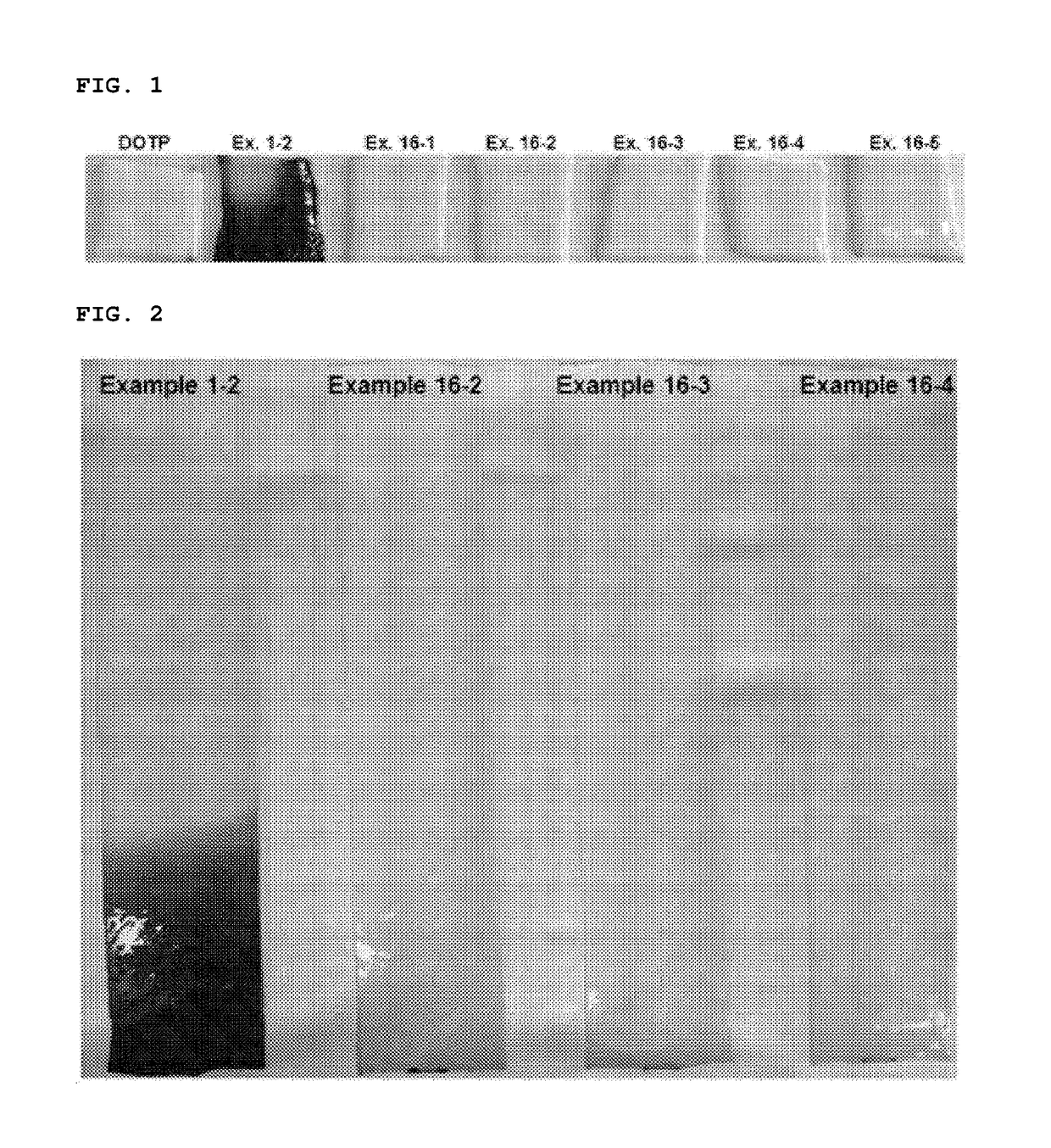

Plasticizer composition, resin composition and method of preparing the same

ActiveUS20180066124A1Maintain good propertiesHigh plasticizing efficiencyOrganic chemistryPlasticizerPolymer chemistry

The present invention relates to a plasticizer composition, a resin composition, and a method of preparing the plasticizer composition. A plasticizer composition capable of improving properties such as tensile strength, migration resistance, volatile loss and the like, which are required when used as a plasticizer of a resin composition, by improving poor properties occurring due to structural limitations, and a resin composition including the same may be provided.

Owner:LG CHEM LTD

Octadecanoyl tributyl citrate plasticizer and preparation thereof

InactiveCN101255240AIncrease the relative molecular massHigh plasticizing efficiencyCarbonyl chlorideStearic acid

The invention provides octade carbonyl tributyl citrate plasticizer and preparation method thereof. The composition of octade carbonyl tributyl citrate plasticizer (in mass percent): tributyl citrate 43.5-53.8%, octade carbonyl chloride 45.2-55.0%, catalyst 1.0-1.5%. The preparation method comprises: (1) adding citric acid, butylalcohol, water-carrying agent and catalyst into reaction kettle, stirring, heating up until reflowing to obtain tributyl citrate; (2) adding stearic acid into reaction kettle, stirring, heating up to 50 degree and then adding phosphorous trichloride and heating up to 75 degree to perform thermal insulating reaction for 3 hours and layering to obtain octade carbonyl chloride; (3) adding tributyl citrate and catalyst in the reaction kettle, stirring, heating up to 70 degree and then adding octade carbonyl chloride to obtain chlorine hydride and the chlorine hydride being absorbed in water containing soda in drier, when the pH of the water containing soda is constant, the reaction being stopped and the product being subjected to neutralizing, cleaning, pump filtering under reduced pressure to obtain octade carbonyl tributyl citrate.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Waste plastic film recovery processing system and method

InactiveCN106217691AHigh plasticizing efficiencySimple structurePlastic recyclingMechanical material recoveryPlastic filmEngineering

The invention provides a waste plastic film recovery processing system and method. The waste plastic film recovery processing system comprises a crushing dry washer, a pelleting system and a cooling device, wherein the crushing dry washer is used for crushing waste plastic film into plastic film chips and separating out dust and impurities carried by the plastic film chips in a dry washing mode; the pelleting system is used for plastifying the purified plastic film chips into plastic grains through hot wind; and the cooling device is used for cooling the plastified plastic grains into a normal temperature state to be discharged. The waste plastic film recovery processing method comprises the steps of crushing and purifying of the waste plastic film, pelleting and cooling, so that the plastic grains are obtained. According to the waste plastic film recovery processing system and method, renewable resources are effectively recycled, the automation degree is high, the processing steps are fewer, the energy consumption is low, and the efficiency is high; no waste water or smoke or odor is generated in the plastic film recovery processing process; and good environmental benefits and economic benefits are achieved, and the application prospects are broad.

Owner:韩吉生

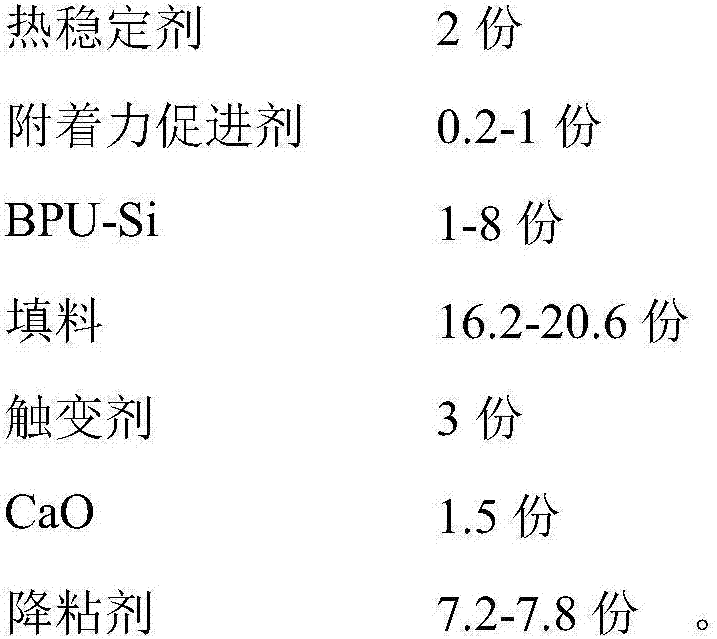

Environment-friendly low-temperature curing PVC plastisol and preparation method thereof

InactiveCN107474445AReduce volatilityHigh plasticizing efficiencyLow temperature curingMechanical property

The invention discloses environment-friendly low-temperature curing PVC plastisol and a preparation method thereof. The environment-friendly low-temperature curing PVC plastisol uses PVC paste resin, chloride vinyl acetate copolymerized paste resin, a plasticizer, a heat stabilizer, an adhesion promoter, BPU-Si, filler, a thixotropic agent, CaO, a viscosity reducer and the like as raw materials. The tensile strength of the prepared PVC plastisol can be up to 6-8 MPa, and the elongation at break can be up to 210%-270%. The adopted plasticizer is the novel environment-friendly plasticizer and has the advantages of being biodegradable, low in volatility, high in plastifying effect and the like. Under the synergistic effect of end-capped polyurethane and an adhesion promoter, the plastifying temperature (120-130 DEG C) of the plastisol can be effectively reduced, and the mechanical properties, elasticity and adhesion of the PVC plastisol are remarkably improved.

Owner:ANHUI UNIVERSITY

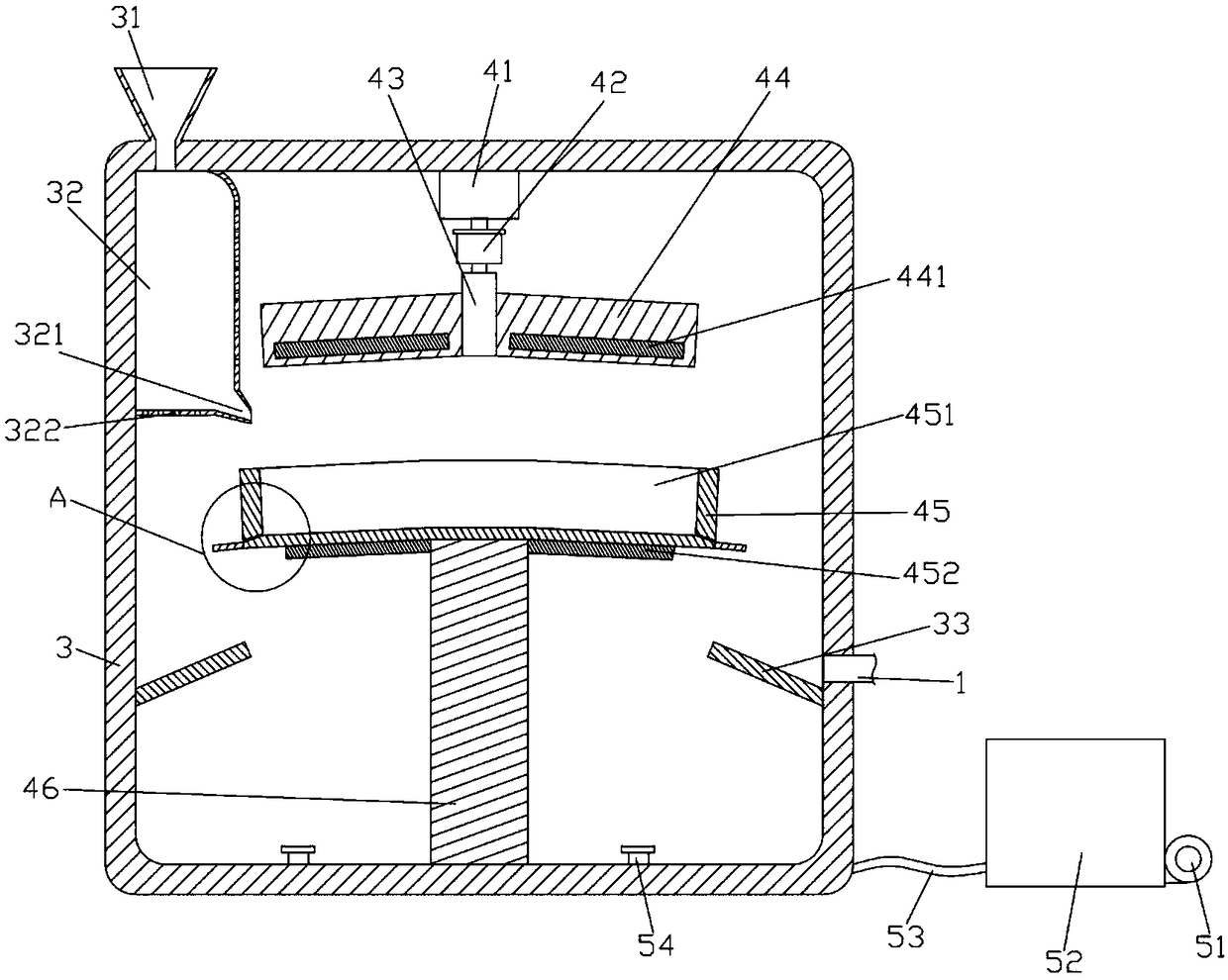

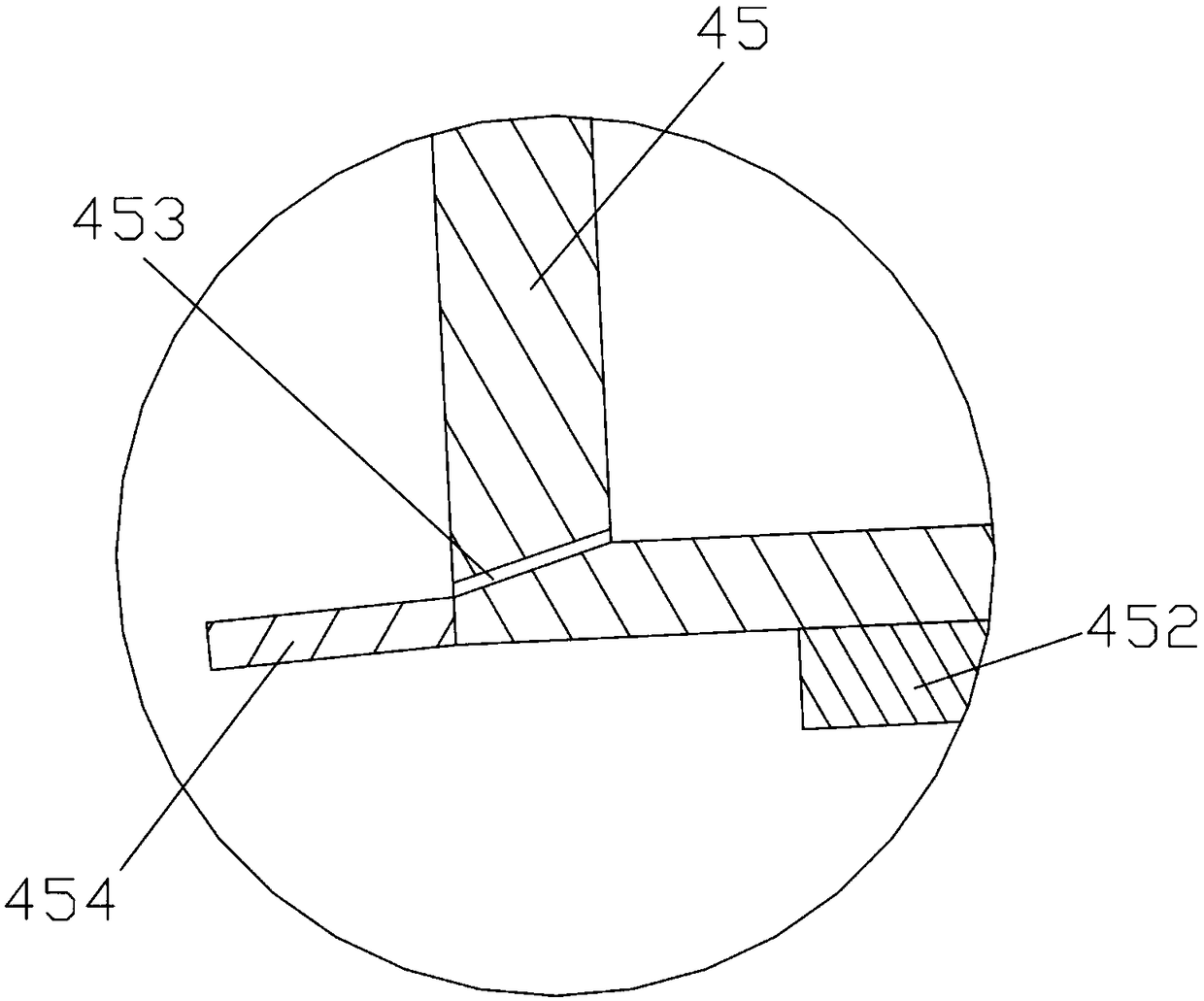

Plastifying machine

InactiveCN108656394AImprove grinding effectConvenient heat treatmentCocoaGrain treatmentsEngineeringMillstone

The invention discloses a plastifying machine. The plastifying machine comprises a box body, a plastifying device arranged in the box body, and a heating device arranged on one side of the box body. Afeed port is formed in the top of the box body, receiving plates are arranged on the side wall of the box body, and a discharge pipe is arranged on the side wall of the box body. The plastifying device comprises a supporting rod arranged at the bottom of the box body, a lower millstone arranged on the supporting rod,, and an upper millstone cooperating with the lower millstone. First heating pipes are arranged on the upper millstone, and second heating pipes are arranged at the bottom of the lower millstone. The grinding effect of plastic is improved through the cooperative effect of grindingof the upper millstone and the lower millstone, through the cooperation of the heating pipes in the upper millstone and the lower millstone and the heating device on one side of the box body, the plastic in the box body is well heated, the plastifying efficiency of the plastic is improved, the time needed by plastifying is shortened, the production efficiency of the plastic is improved, and production and processing use in a factory is promoted.

Owner:杭州大橙知一科技有限公司

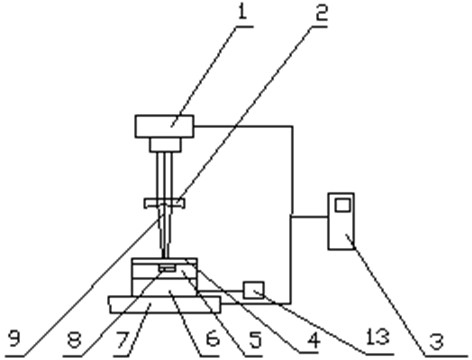

A plastic plasticizing method and device based on co2 laser

The invention discloses a plastic plasticizing method and device based on a CO2 laser, and relates to the field of laser plasticizing molding processing. The invention is based on the photothermal effect of the interaction between the laser and the polymer. For the light energy generated by the CO2 laser, most plastics almost completely absorb it. Through precise control of laser parameters: wavelength, spot size, energy, and irradiation method, the temperature rise range of laser irradiated plastics is controlled, and the plastic solid is heated and plasticized by laser to realize the polymer from glass state to high elastic state to viscous flow state. The plasticizing process, and finally complete the polymer molding process. The invention has the advantages of short plastic melting time, uniform plasticization and good plasticization stability, overcomes the problems of low plasticization efficiency and uneven plasticization in the traditional plasticization process, is suitable for plastic micro-molding processing, and has high application value.

Owner:JIANGSU UNIV

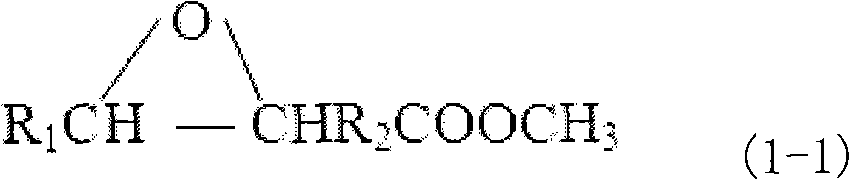

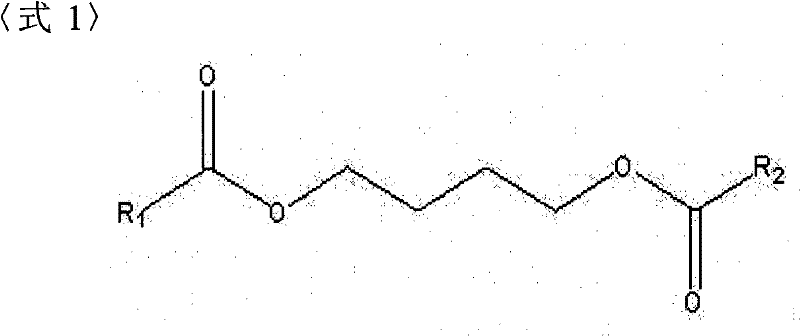

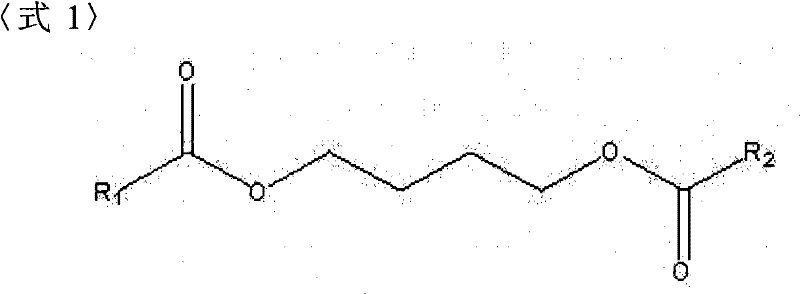

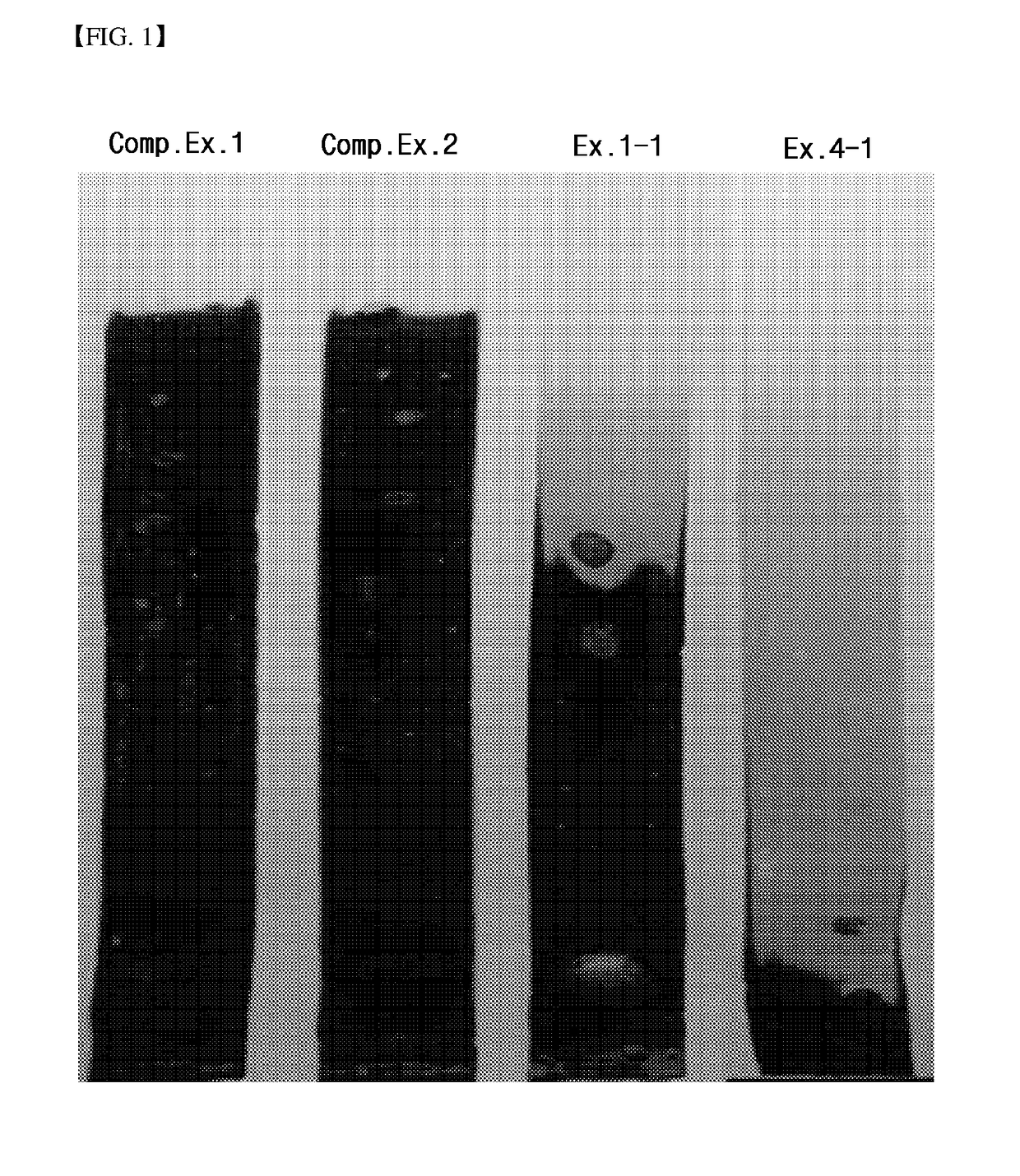

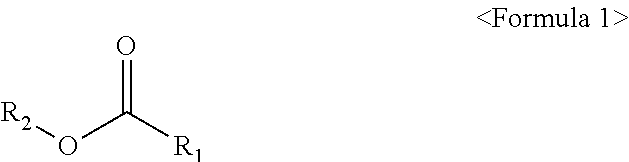

Plasticizer composition, resin composition, and method of preparing the same

Provided herein are a plasticizer composition, a method of preparing the same, and a resin composition including the plasticizer composition, the plasticizer composition including: a terephthalate-based material; and an epoxy-based alkyl ester compound represented by Formula 1 below, wherein a weight ratio of the terephthalate-based material to the epoxy-based alkyl ester compound is 99:1 to 1:99, and the epoxy-based alkyl ester compound is a single compound or a mixture of two or more compounds (In Formula 1, R1 is a C8-C20 alkyl group or an alkyl group containing one or more epoxy groups, and R2 is a C4 or C8 alkyl group). A plasticizer composition capable of enhancing poor physical properties occurring due to structural limitations and enhancing physical properties such as tensile strength, migration resistance, volatile loss, and the like, which are required when used as a plasticizer of a resin composition, and a resin composition including the same may be provided.

Owner:LG CHEM LTD

Cold-resistant plastic bucket and preparation method thereof

ActiveCN108822385AImprove cold resistanceImprove heat resistanceLinear low-density polyethylenePolymer science

The invention discloses a cold-resistant plastic bucket and a preparation method thereof, and belongs to the technical field of a plastic packaging container. The cold-resistant plastic bucket is characterized in that the cold-resistant plastic bucket is prepared from the components in parts by weight: 60 to 80 parts of high-density polyethylene, 15 to 25 parts of linear low-density polyethylene,10 to 20 parts of maleic anhydride grafted high-density polyethylene, 5 to 7 parts of high-polymerization-degree polyvinyl chloride, 6 to 8 parts of ethylene-vinyl acetate copolymer, 0.5 to 1.0 part of ultraviolet absorption agent, 1 to 1.5 parts of antioxidant, 2 to 3 parts of plasticizer and 5 to 7 parts of silica power; the high-density polyethylene has a density of 0.936 g / cm<3> and a melt index of 1.4 g / 10 min; the linear low-density polyethylene has a density of 0.920 g / cm<3> and a melt index of 1.0 g / 10 min. The invention reaches the technical effect of enabling the polyethylene plasticbucket to also have excellent printing performance when having cold resistance.

Owner:青岛邦德化工有限公司

Halogen-free rubber-plastic product and preparation method thereof

The invention relates to a halogen-free rubber-plastic product and a preparation method thereof. The halogen-free rubber-plastic product comprises the following components by weight: a dispersing agent HT-5168, calcium stearate, polyethylene glycol, an anti-aging agent 4020, activated zinc oxide, sulfur powder, solid paraffin, antimony trioxide, zinc borate, nitrile rubber, aluminum hydroxide, polyvinyl chloride resin, dioctyl ester, epoxidized soybean oil, carbon black N550, azodicarbonamide and rubber accelerating agent. The halogen-free rubber-plastic product is simple and convenient in preparation process and low in production cost, and the rubber-plastic product performance, the flame-retardant performance and the using safety performance can be combined.

Owner:WINCELL INSULATION CO LTD

Preparation method and product of adipate epoxy plasticizer

ActiveCN104059032AAchieve recyclingLow costOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyVegetable oil

The invention discloses a preparation method of adipate epoxy plasticizer, which comprises the following steps: (1) extracting fatty acid in vegetable oil leftovers; (2) performing reduction reaction on the obtained long-chain fatty acid under the catalytic reduction action of lithium aluminum hydride, thus obtaining long-chain fatty alcohol; (3) mixing the long-chain fatty alcohol and adipic acid, and adding a reverse micelle nano aluminum oxide catalyst, thus obtaining a system solution containing adipic acid di(long-chain fatty ester); (4) performing epoxy reaction, thus obtaining a finished product solution; and (5) introducing chlorine gas into the epoxy finished product solution, simultaneously performing ultraviolet irradiation until the chlorination reaction is completed, and then treating to obtain the modified epoxy plasticizer. The invention also discloses the epoxy plasticizer prepared by the method. According to the invention, the long-chain alcohol group is introduced into the molecular structure of the adipic acid, so that the plasticizing efficiency of the product is greatly improved, the raw material cost is low, and the comprehensive recovery of the vegetable oil leftovers is realized; and meanwhile, the epoxy group in the plasticizer enhances the heat resistance, stability and compatibility of the product.

Owner:浙江嘉澳环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com