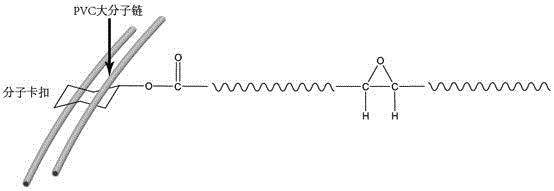

Environment-friendly migration-resistant epoxy fatty acid cyclohexyl plasticizer and preparation method thereof

A technology of epoxy fatty acid methyl ester and epoxy fatty acid, which is applied in the field of epoxy fatty acid cyclohexyl ester plasticizer and its preparation, can solve slow volatilization, migration or extraction, intolerance to migration, and affect the performance and life of PVC products And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Mix 100 parts of oleic acid, 40 parts of cyclohexanol, 0.5 parts of concentrated sulfuric acid, and 10 parts of cyclohexane evenly, and esterify at 85°C for 3 hours in a reactor equipped with a water separator. The oil after esterification With a mass fraction of 5% NaHCO 3 The solution was washed until neutral, and finally the water and unreacted cyclohexanol were distilled off under reduced pressure to obtain cyclohexyl oleate.

[0020] Take 50 parts of hydrogen peroxide with a mass fraction of 35%, 8 parts of formic acid, 1 part of concentrated sulfuric acid, and 0.5 part of urea and mix them evenly to obtain an active peroxyacid, which is then added dropwise to 100 parts of cyclohexyl oleate , the reaction temperature is 60°C, and the dropping time is controlled within 1 hour. After the dropping is completed, the reaction is continued for 4 hours with insulation and stirring. 3 The solution was washed to neutrality, and finally dehydrated by vacuum distillation to ...

Embodiment 2

[0023] Mix 100 parts of linoleic acid, 45 parts of cyclohexanol, 1.5 parts of concentrated sulfuric acid, and 12 parts of toluene evenly, and esterify at 90°C for 3.5 hours in a reactor equipped with a water separator. The mass fraction is 5% NaHCO 3 The solution was washed until neutral, and finally the water and unreacted cyclohexanol were distilled off under reduced pressure to obtain cyclohexyl linoleate.

[0024] Take 65 parts of hydrogen peroxide with a mass fraction of 35%, 9 parts of acetic acid, 1.2 parts of benzenesulfonic acid, and 0.7 parts of urea and mix them evenly to obtain an active peroxyacid, and then add it dropwise to 100 parts of linoleic acid cyclohexyl In the ester, the reaction temperature is 60°C, and the dropping time is controlled within 1.5 hours. After the dropping, continue to keep warm and stir for 5.5 hours. 3 The solution was washed to neutrality, and finally dehydrated by vacuum distillation to obtain epoxy linoleic acid cyclohexyl ester pla...

Embodiment 3

[0027]Mix 40 parts of oleic acid, 60 parts of linoleic acid, 45 parts of cyclohexanol, 1.7 parts of concentrated sulfuric acid, and 15 parts of toluene evenly, and esterify at 100°C for 4 hours in a reactor equipped with a water separator. The liquefied oil is 5% NaHCO with mass fraction 3 The solution was washed until neutral, and finally the water and unreacted cyclohexanol were distilled off under reduced pressure to obtain unsaturated fatty acid cyclohexyl ester.

[0028] Take 70 parts of hydrogen peroxide, 11 parts of acetic acid, 1.5 parts of sodium bisulfate, and 0.8 parts of urea with a mass fraction of 35% and mix them uniformly to obtain an active peroxyacid, which is then added dropwise to 100 parts of unsaturated fatty acid cyclohexane In the ester, the reaction temperature is 60°C, and the dropping time is controlled within 1.5 hours. After the dropping, continue to keep warm and stir for 6 hours. 3 The solution was washed to neutrality, and finally dehydrated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com