Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

276results about How to "Convenient heat treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

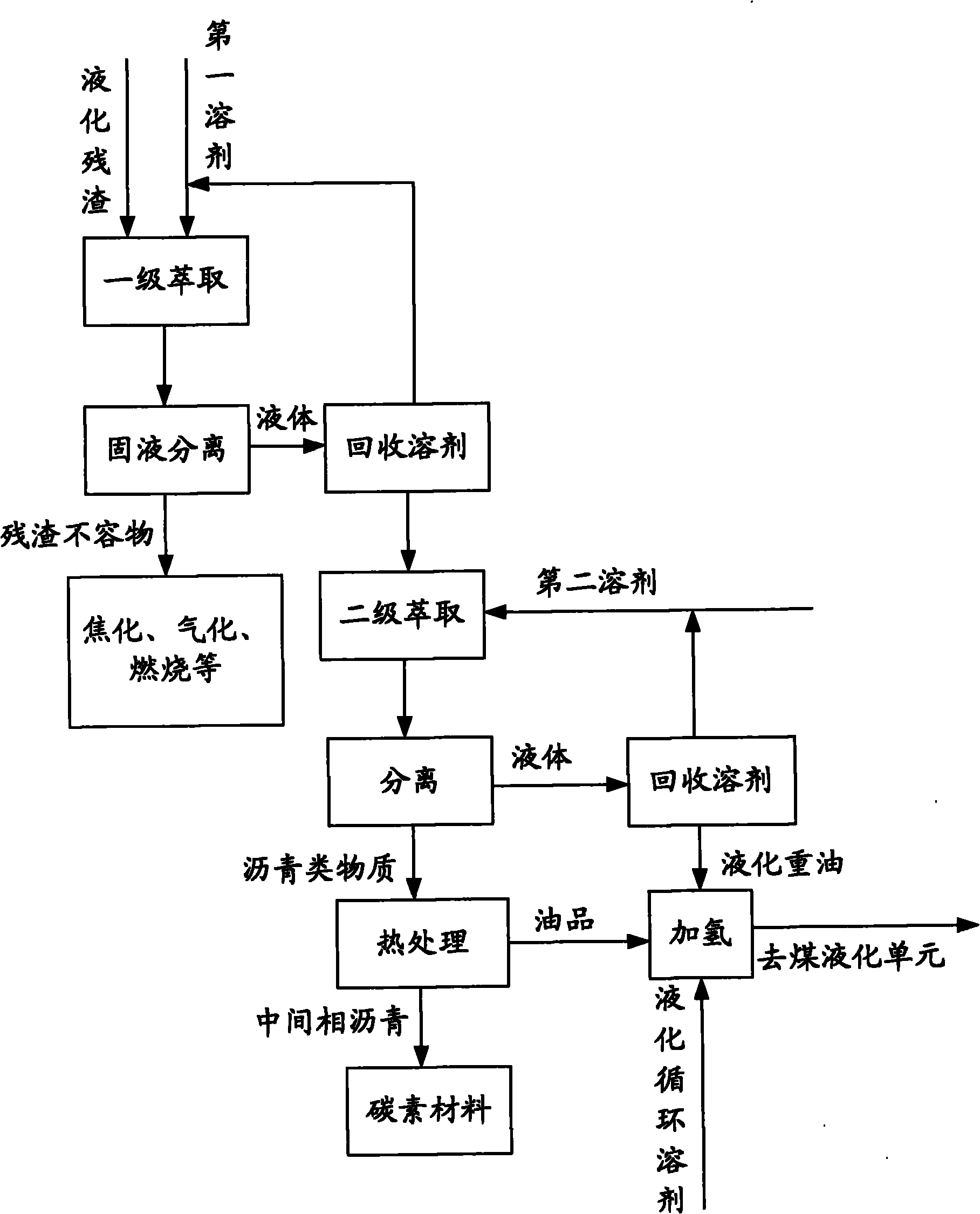

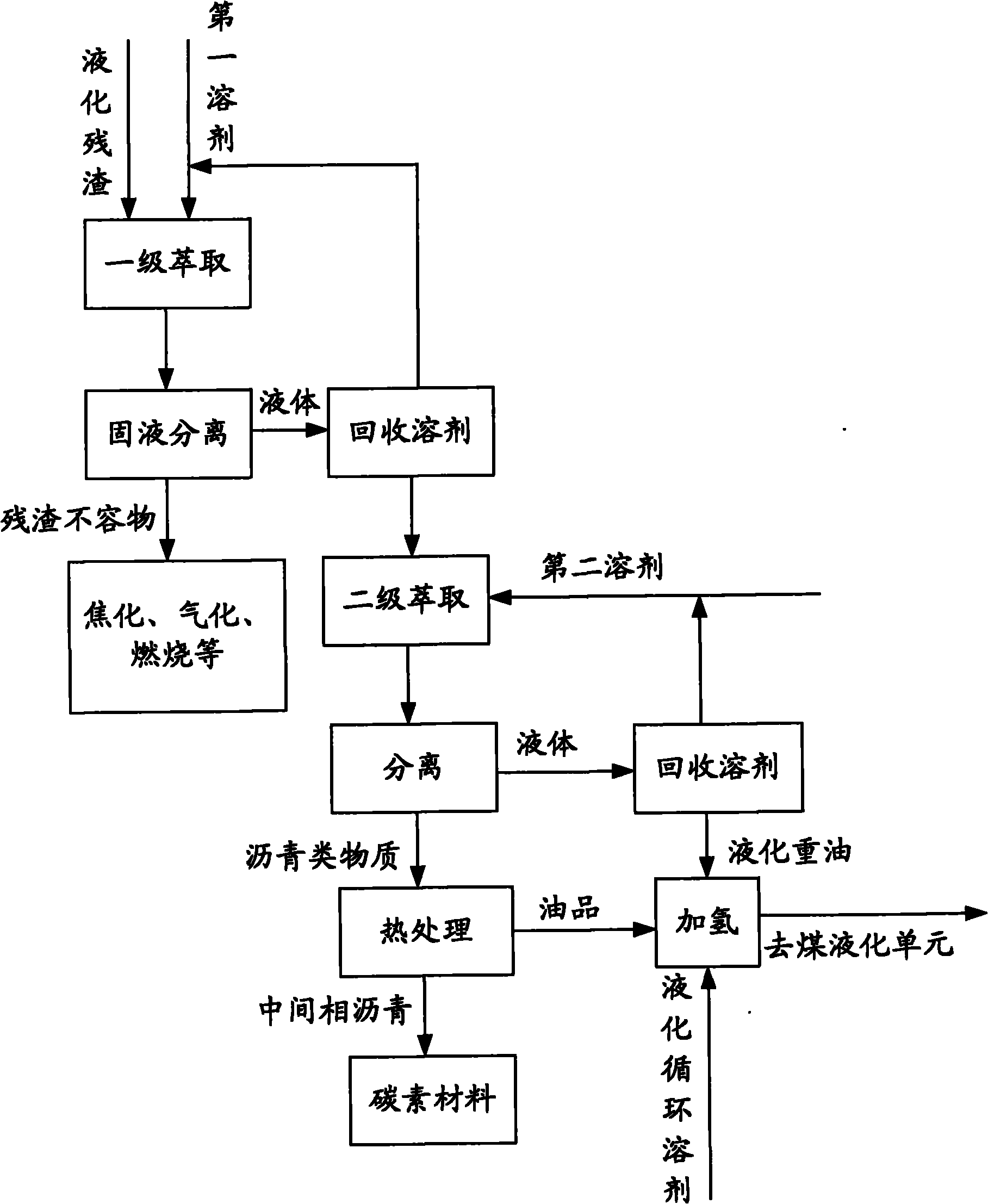

Extraction method of direct coal liquefaction residues and application of extracts

ActiveCN101962561AMake full use ofSimple processWorking-up pitch/asphalt/bitumen by selective extractionLiquid hydrocarbon mixture productionSolventThermal treatment

The invention relates to an extraction method of direct coal liquefaction residues and application of extracts. The extraction method comprises the following steps: a) adding coal liquefaction residue powder and a first extraction solvent to a stirred tank to undergo primary extraction; b) carrying out solid-liquid separation on the extracted mixture obtained in the step a) and recovering the first extraction solvent from the obtained liquid in a solvent recovery unit and recycling the first extraction solvent; c) obtaining extracts after recovering the first solvent and mixing the extracts with a second extraction solvent to undergo secondary extraction; d) carrying out solid-liquid separation on the extracted mixture obtained in the step c), obtaining heavy liquefied oil after recovering the second extraction solvent from the obtained liquid in the solvent recovery unit and then carrying out moderate hydrogenation on the heavy liquefied oil and other recycled solvents in a coal liquefaction solvent hydrogenation unit and using the product as the recycled solvent in the coal liquefaction process; and e) carrying out heat treatment on the asphaltic substances obtained in the step d) by heating and carbonizing to obtain mesophase asphalt and oils.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

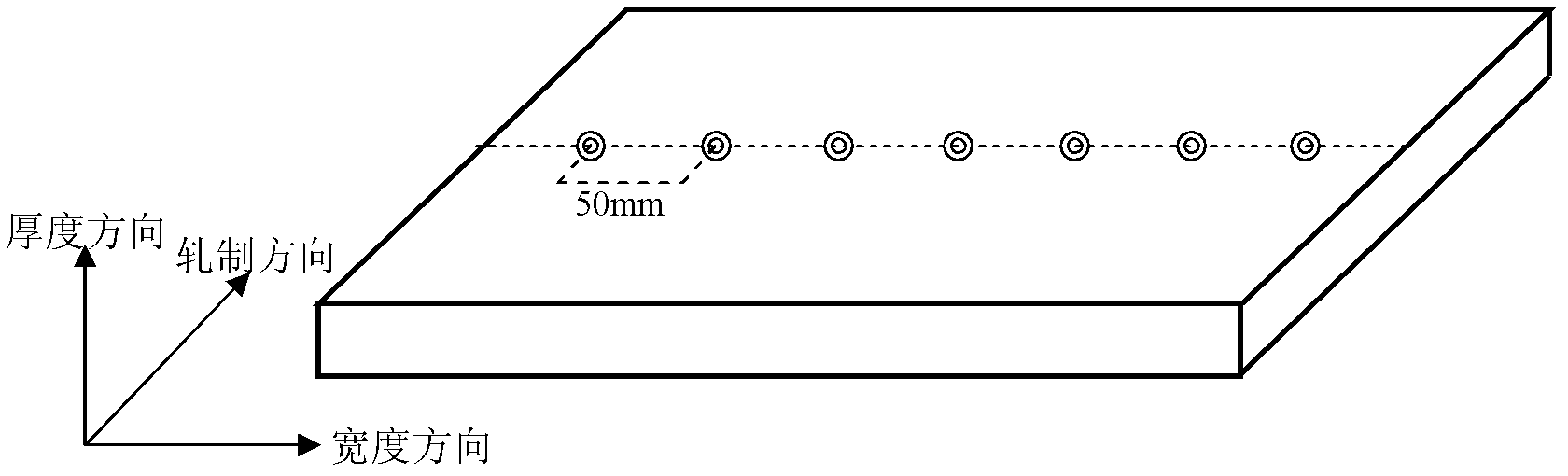

Method for determining precision of blind-hole method residual stress testing system

InactiveCN102608169AEasy to get materialsSimple heat treatmentApparatus for force/torque/work measurementMaterial resistanceStrain gaugeEnvironmental geology

The invention belongs to the technical field of precision determination, and relates to a method for determining the precision of a blind-hole method residual stress testing system. The method comprises the specific technologies of sample plate sampling, stress-relieving annealing, sample surface preparing and strain gauge adhering, data line connection, testing parameter configuring, hole drilling, data collecting, data processing, and precision determining. The method is advantaged in stable technology and accurate result. With the method, deviations of a testing system can be visually, rapidly, and quantitatively determined. Therefore, testing errors caused by influencing factors such as strain gauge quality, hole drilling eccentricity, and additional strain can be conveniently adjusted. Thus, the accuracy of the residual stress testing before and after hot rolled coil decoiling can be ensured.

Owner:SHOUGANG CORPORATION

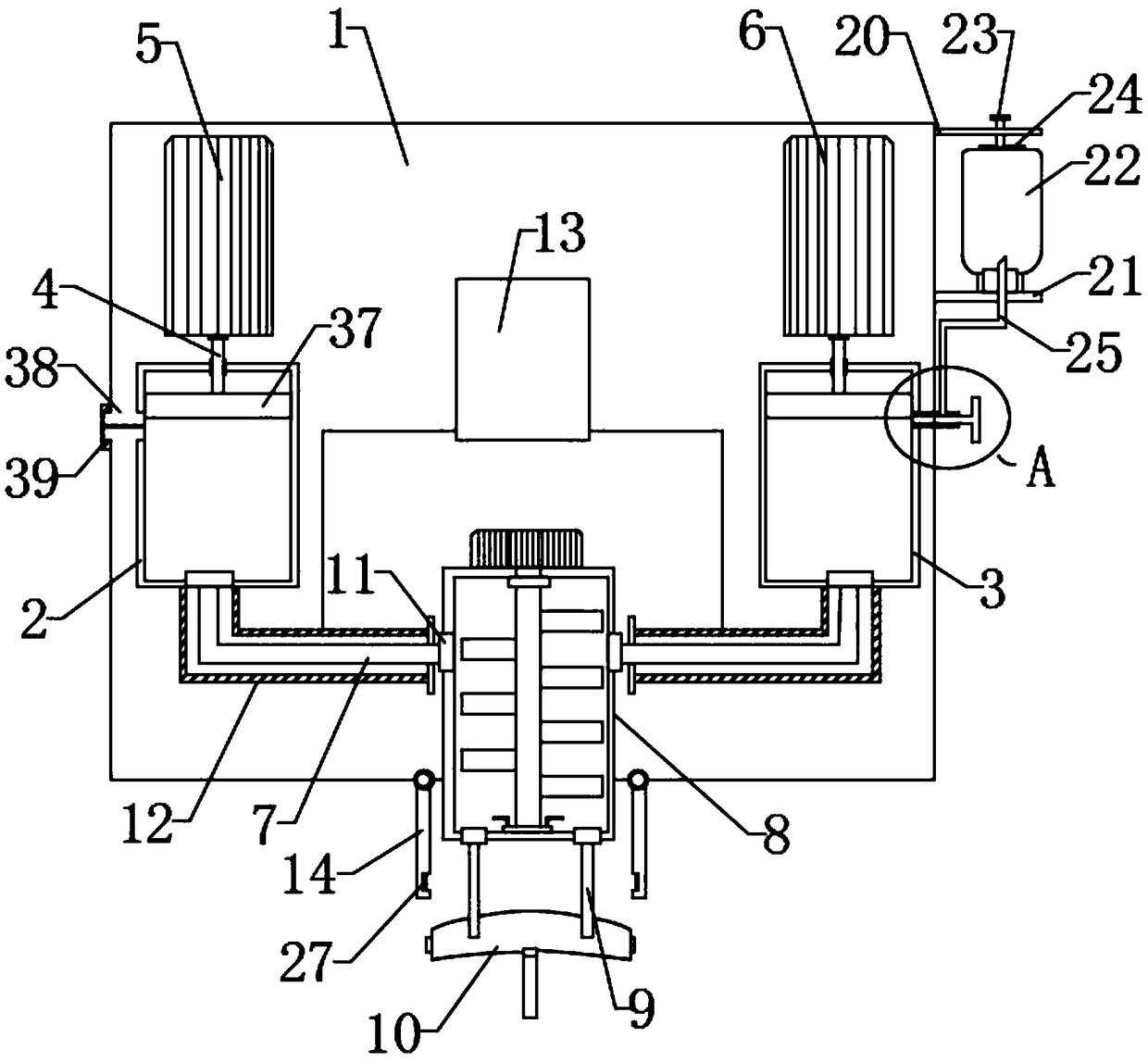

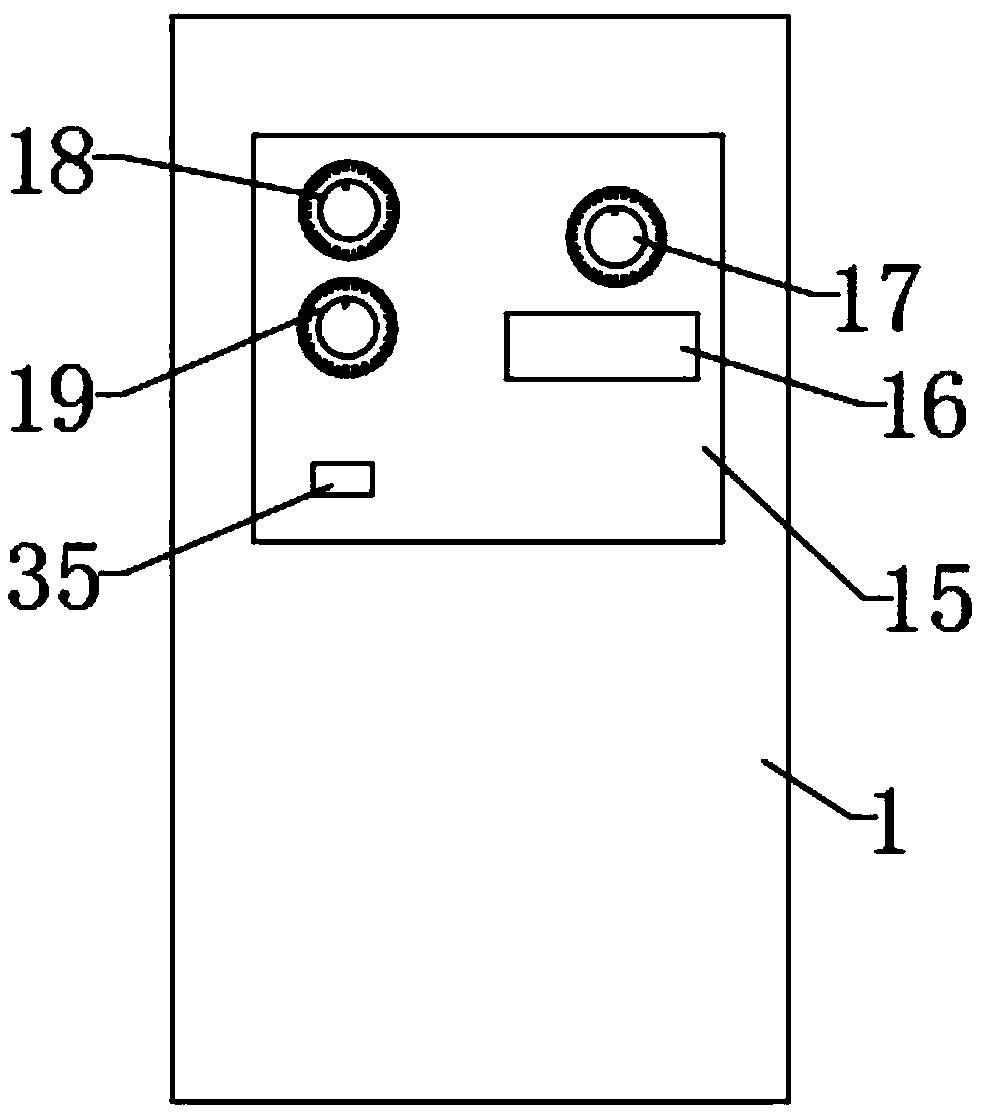

Anesthesiology concentration adjustment anesthesia device

ActiveCN108744215ARealize atomization workAchieve sealing workRespiratory masksMedical devicesAnesthetic AgentAnesthesiology

The invention discloses an anesthesiology concentration adjustment anesthesia device, and belongs to the technical field of the technical field of medical anesthesia appliances. The anesthesia devicecomprises a body, a diluent extrusion cavity and an anesthetic extrusion cavity are formed in two sides in the body, a first electric cylinder and a second electric cylinder are connected at the topsof the diluent extrusion cavity and the anesthetic extrusion cavity through pushing rods, liquid guide pipes are communicated with the bottoms of the diluent extrusion cavity and the anesthetic extrusion cavity, the other end of each liquid guide pipe is connected with a mixing cavity, anesthesia masks are connected at the bottoms of the mixing cavities through telescopic pipes, atomizers are mounted at connecting ends among the liquid guide pipes and the mixing cavities, and heating pipes are connected on the outer side walls of the liquid guide pipes in a sleeving manner and connected with acontrol plate through leads. The anesthesia device is simple in structure and convenient to use, drugs are preheated by a reasonable spraying and mixing mode, and the medical effect of the device isconveniently improved.

Owner:JILIN UNIV

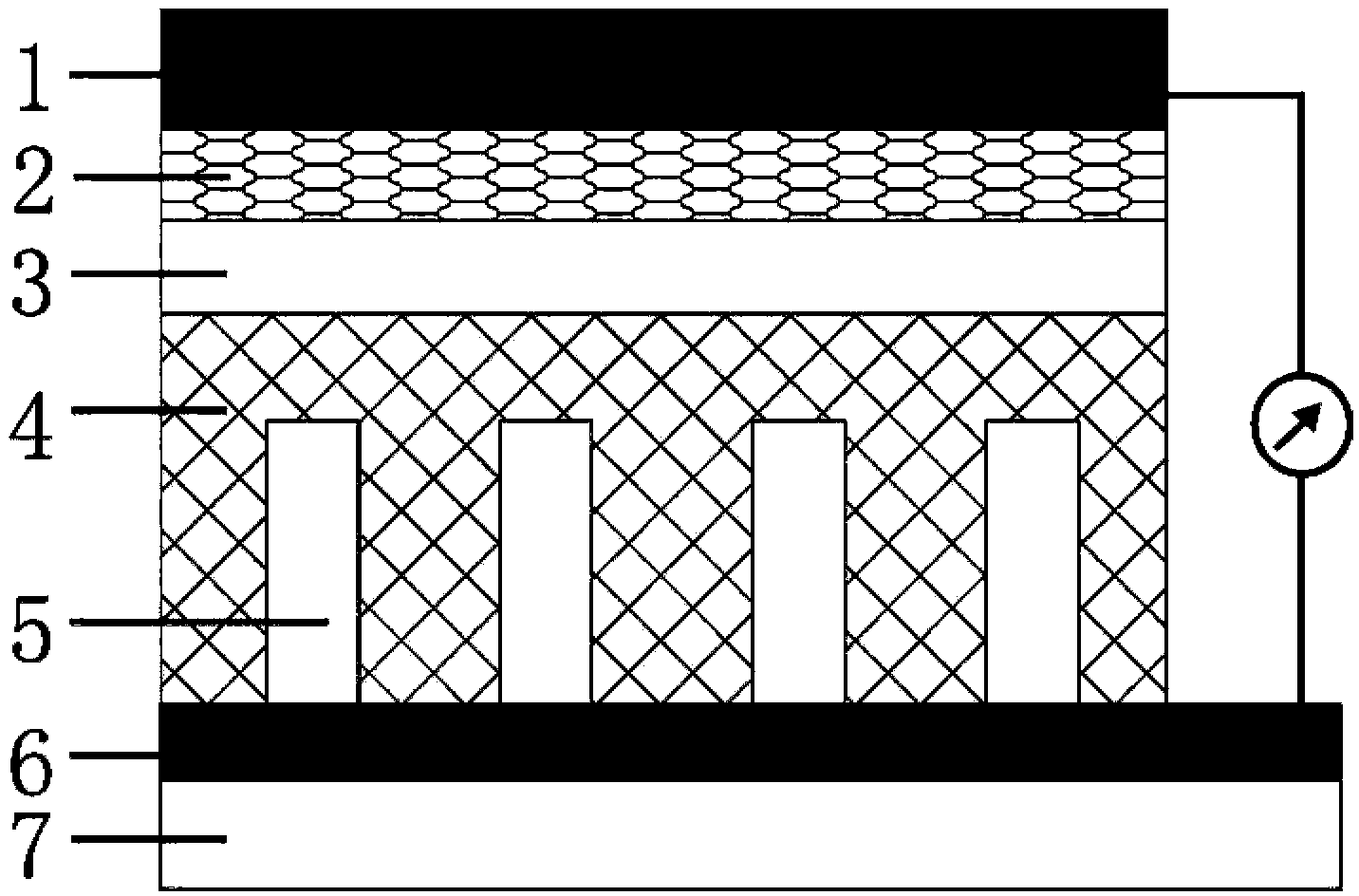

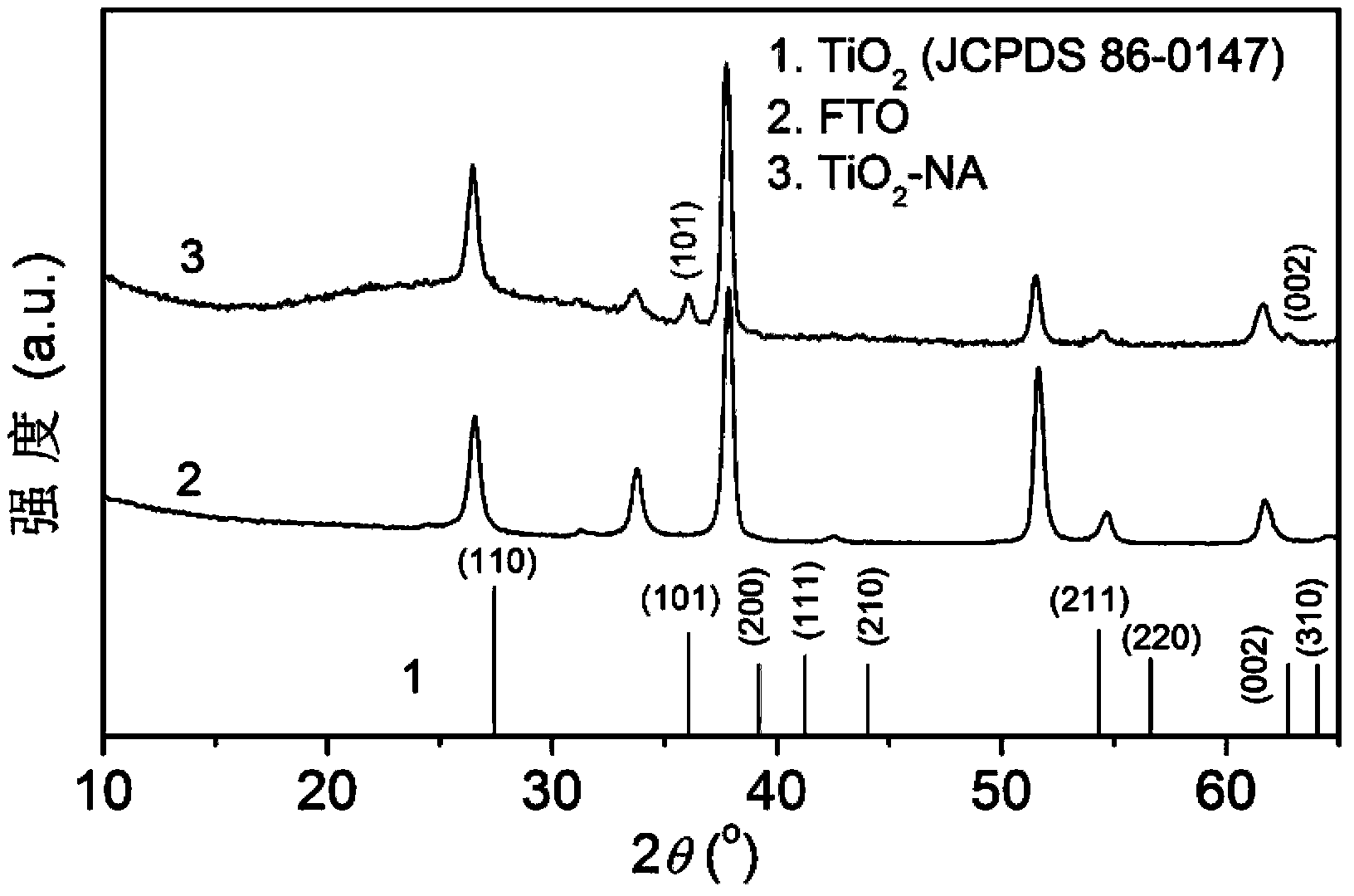

Solar battery based on inorganic bulk heterojunction and preparation method thereof

InactiveCN103367512AEasy to prepareLow equipment requirementsFinal product manufacturePhotovoltaic energy generationTitanium dioxideFluorine doping

The invention discloses a solar battery based on an inorganic bulk heterojunction and a preparation method thereof. The battery comprises a glass substrate, an FTO (fluorine-doped tin oxide) layer which is used as a positive electrode, a heterojunction composite film layer consisting of an Sb2S3 (stibnite) block and a TiO2 (titanium dioxide) nano-bar array, a polymer MEH-PPV electron barrier layer, a PEDOT: PSS hole transferring layer and an Au (gold) film layer as a battery negative electrode. The preparation method of the battery is simple, and the battery has a spectrum response range of 300 nm to 750 nm; and when an optical active layer of the battery stays at an illumination state, conversion efficiency of the battery can reach 5.58 percent.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

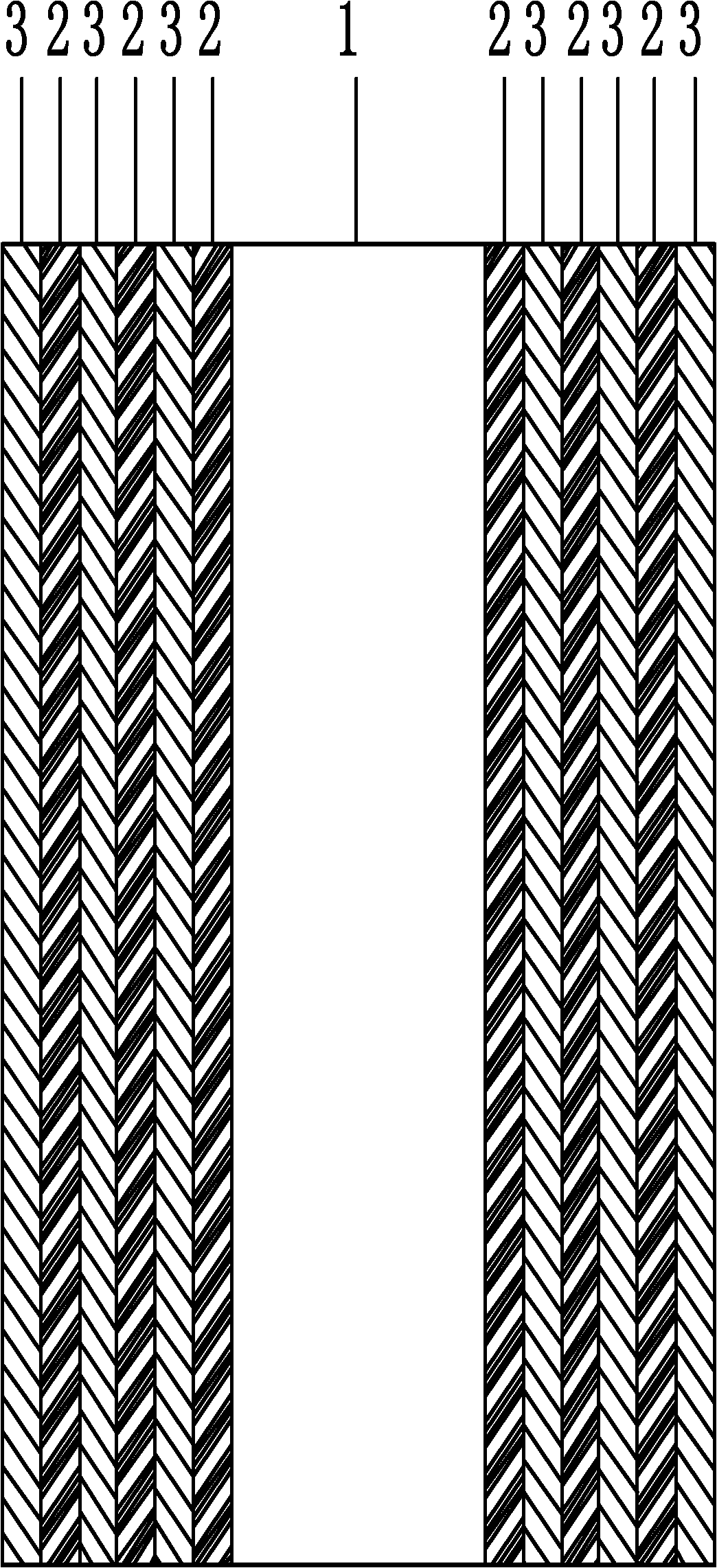

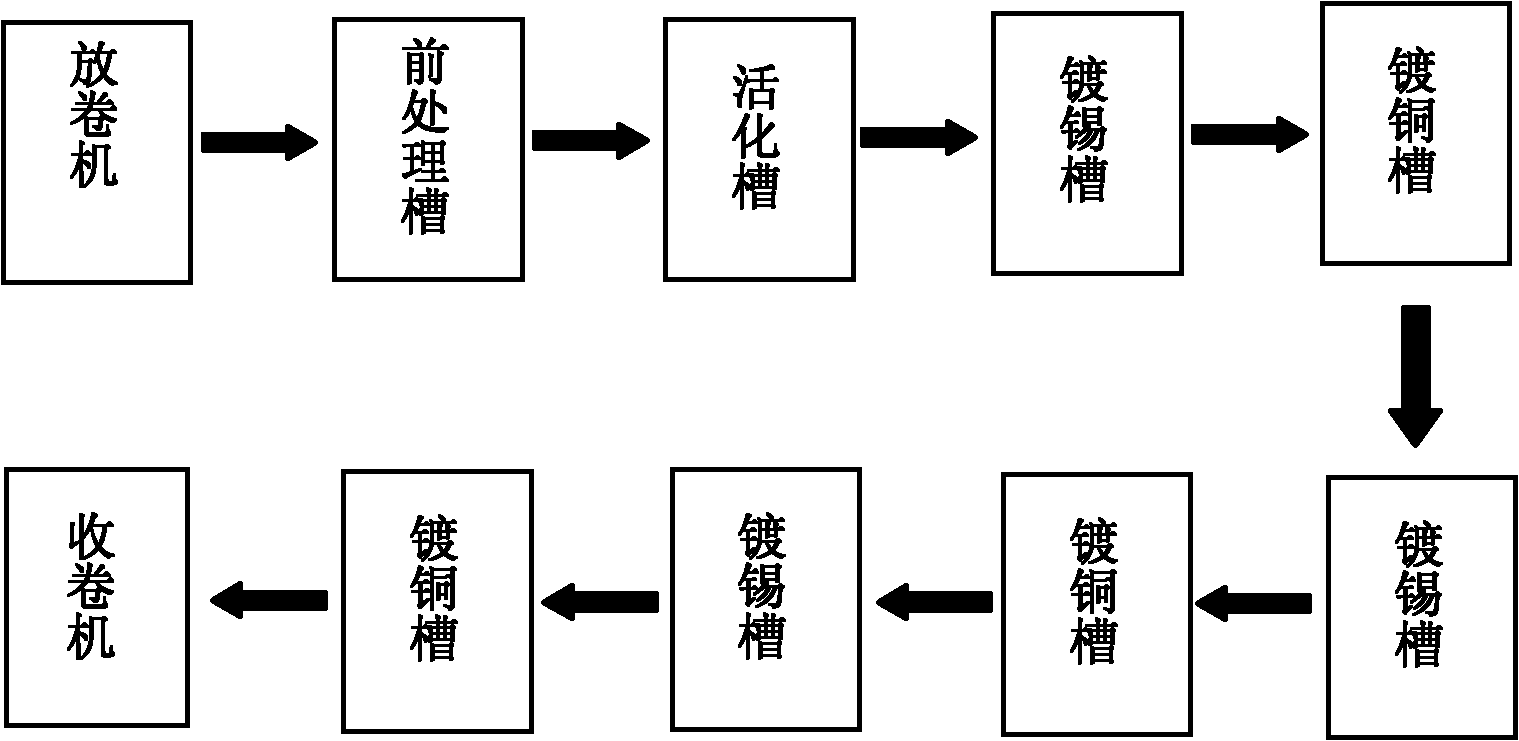

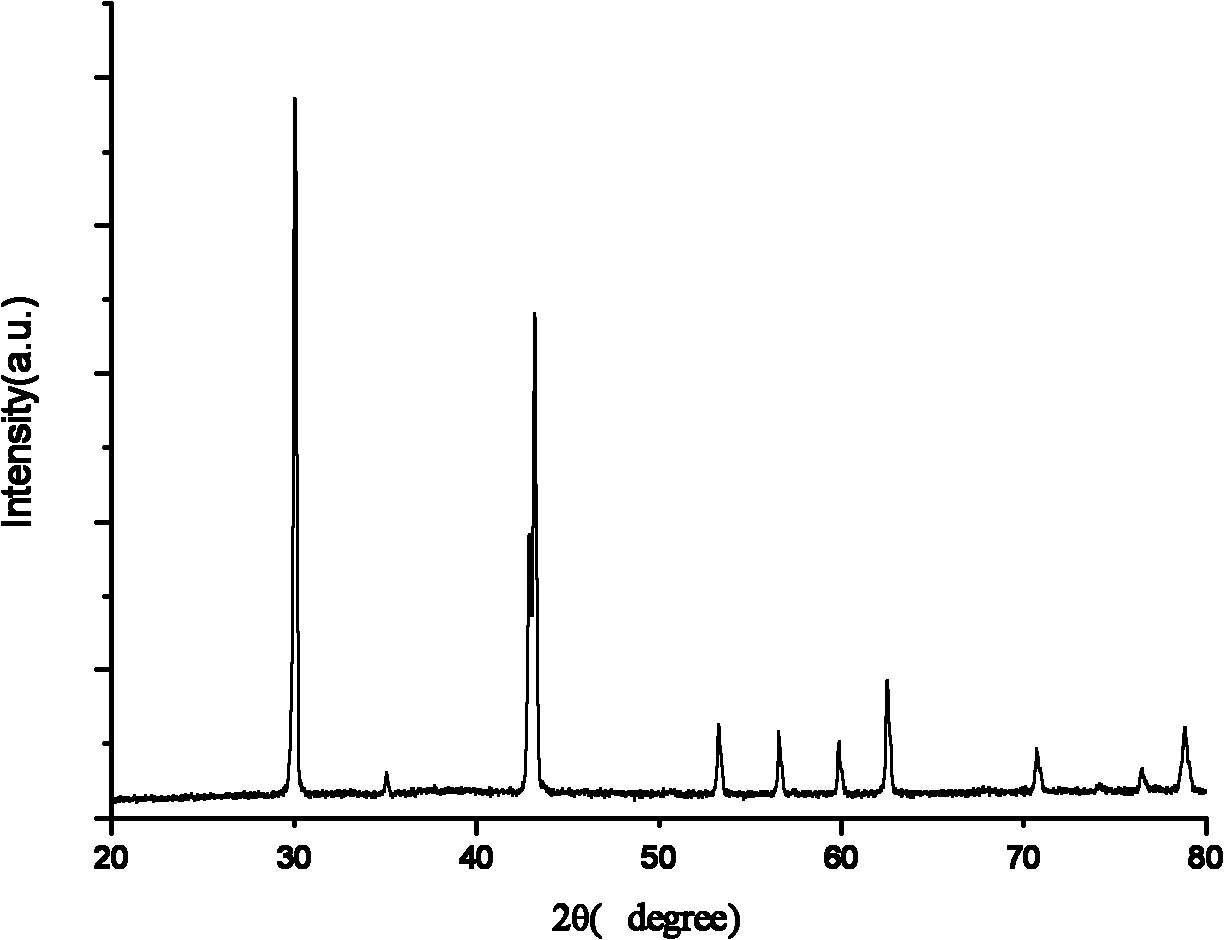

Tin/copper foam alloy cathode material for lithium ion cells and preparation method thereof

ActiveCN102013488AImprove conductivityImprove cycle performanceCell electrodesCopper coatingMicrometer

The invention discloses a tin / copper foam alloy cathode material for lithium ion cells and a preparation method thereof. In the invention, foam copper serving as a substrate is coated and plated with tin / copper alternate multilayer lamination structure; and then the tin / copper alloy cathode material is obtained by heat treatment. A tin coating is formed directly on the foam copper strip substrate, and a copper coating is formed on the outmost layer; in the multilayer lamination structure, each coating is 0.1 to 1.0 micrometer thick, and the thicknesses of all coatings are the same; the thickness ratio of each tin coating to each copper coating is 1:1.7-1:2.1; and the heat treatment temperature is 150 to 400 DEG C and the heat treatment time is 0.5 to 6 hours. The tin / copper foam alloy cathode material prepared by the method has a high charge-discharge specific capacity and high cycle performance; and the maximum primary discharge specific capacity is up to 610mAh / g, and after 50 circles, the specific capacity reduces only by 1 to 3 percent. In the invention, the preparation process is simple, and large-scale industrial production can be performed.

Owner:HUNAN YONGSHENG NEW MATERIALS

Process for preparing nickel-base superalloy

ActiveCN102808113AElimination of lateral grain boundariesImprove organizationPolycrystalline material growthSingle crystal growth detailsSmelting processRoom temperature

The invention discloses a process for preparing nickel-base superalloy. The superalloy consists of the following components in percentage by weight: 22.5 to 24.5 percent of Cr, 7.0 to 8.0 percent of Co, 6.5 to 7.5 percent of W, 3.0 to 4.0 percent of Mo, 1.2 to 1.8 percent of Al, 1.5 to 2.5 percent of Ti, 2.0 to 3.0 percent of Nb, 1.0 to 2.0 percent of Mn, 2.0 to 4.0 percent of Fe, 0.02 to 0.08 percent of B, 0.5 to 1.5 percent of Ce, less than or equal to 0.1 percent of C, less than or equal to 0.2 percent of Si, less than or equal to 0.008 percent of P, less than or equal to 0.008 percent of S and the balance of Ni. The process for preparing the nickel-base superalloy comprises a smelting process and a heat treatment process, wherein the smelting process comprises the steps of: smelting master alloy by using a vacuum induction furnace, and performing directional solidification in a liquid metal directional furnace to prepare directional column crystal alloy, wherein the vacuum degree of the directional furnace is about (1-5)*10<-4>mmHg, the pouring temperature is 1,580 to 1,600 DEG C, the drawing speed is 4 to 8mm / min, the temperature gradient is 75 to 85 DEG C / cm, and the temperature of liquid tin is 250 to 350 DEG C; the heat treatment process comprises the following steps of: heating the column crystal alloy obtained through smelting to 1,240 to 1,260 DEG C, preserving heat for 3 to 5 hours, and performing air cooling to room temperature; heating to 1,150 to 1,170, preserving heat for 3 to 5 hours, and performing air cooling to room temperature; and heating to 930 to 950 again, preserving heat for 8 to 12 hours and performing air cooling to room temperature.

Owner:南通大地电气股份有限公司

Wiper blade for a window wiper and method for the production of said wiper blade

InactiveUS8893348B2Improved flipping-over characteristicAvoids being weak pointCeramic shaping apparatusWindow cleanersElastomerEngineering

The invention relates to a wiper blade for a window wiper, in particular a window wiper for a motor vehicle, comprising a wiper rubber (1) made from an elastomer material with a base section (3) and a lip section (5), wherein the elastomer material at least partially surrounds a fabric insert (13). The base section (3) and the lip section (5) are connected to each other by the fabric insert (13), wherein the fabric insert (13) serves as a joint (7), and / or a part (17) of the fabric insert (13) protrudes out of the base section (3) on the side facing away from the lip section (5). Furthermore, the invention relates to a method for producing a wiper blade, in which a fabric strip is guided through an extruder die in order to form a fabric insert (13), the fabric strip is surrounded by an elastomer material in order to produce an extruded profile, and the extruded profile is cut into individual wiper rubbers (1).

Owner:ROBERT BOSCH GMBH

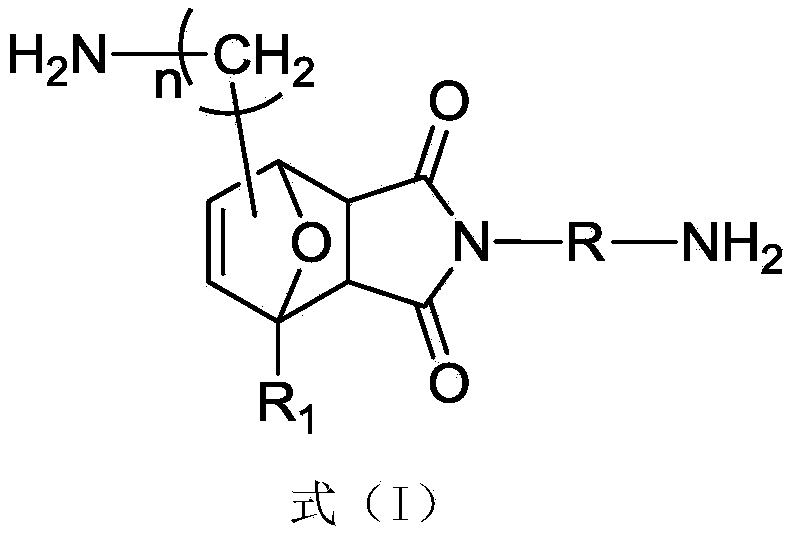

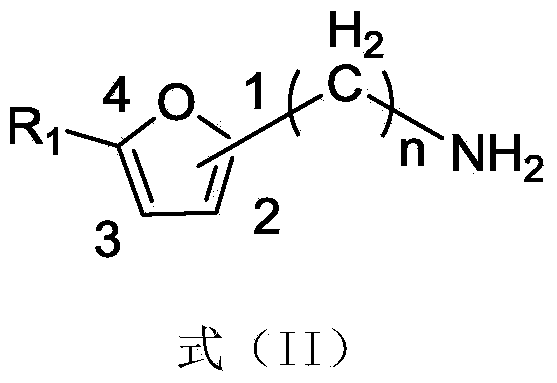

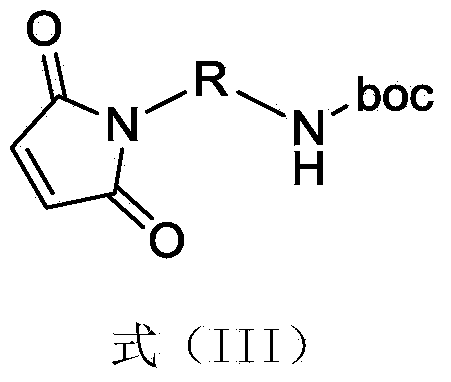

Diamine addition crosslinking agent and preparation method thereof, as well as composition for preparing thermal reversible crosslinking epoxy resin and composite material of thermal reversible crosslinking epoxy resin

The invention belongs to the technical field of epoxy resin based chemical crosslinking material preparation, and particularly relates to a diamine addition crosslinking agent and a preparation method thereof, as well as a composition for preparing thermal reversible crosslinking epoxy resin and a composite material of the thermal reversible crosslinking epoxy resin. The structure of the diamine addition crosslinking agent is as shown in the formula (I), wherein R1 is methyl or H, and n is 1-3; and R is non-aromatic radical. The epoxy resin and the composite material prepared from the composition containing the crosslinking agent have all excellent performance of traditional chemical crosslinking epoxy resin at a low temperature, have re-processing forming performance of thermoplastic materials at a high temperature, restore crosslinking characteristics after being cooled, and are called 'thermosetting-thermoplastic' materials. The reversible crosslinking epoxy resin and the composite material thereof have a self-recovery capability, and the performance of the re-processing forming material can be regulated by means of thermal treatment, so that the diamine addition crosslinking agent is applicable to preparation of self-restoring paint, electronic packaging materials, thermal reversible adhesives and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Fine Spheroidized Steel Sheet with Excellent Heat Treatment Characteristic and Method for Manufacturing the Same

ActiveUS20110259483A1Improve productivityConvenient heat treatmentFurnace typesHeat treatment furnacesSheet steelReduction ratio

A method for manufacturing a fine spheroidized steel sheet having an excellent heat treatment characteristic, the method including: i) manufacturing a high carbon slab that is formed of 0.3 to 1.0 wt % C, 0.1 to 1.2 wt % Mn, 0 to 0.4 wt % Si, 0.01 to 0.1 wt % Al, 0 to 0.01 wt % S, and balance Fe and an inevitably added impurity as residuals; ii) reheating the slab to a temperature of Ar3 transformation point or more; iii) roughing rolling the slab, and manufacturing a thin plate by performing finish rolling in an austenite region; iv) cooling the thin plate at a cooling speed of 50 to 300° C. / sec; v) finishing the cooling of the thin plate at a temperature region of 400 to 650° C. and maintaining the temperature; vi) winding the thin plate at a temperature region of 450 to 700° C.; vii) performing cold rolling at a reduction ratio of 30% or more; and viii) spheroidizing annealing the cold rolled thin plate.

Owner:POHANG IRON & STEEL CO LTD

Dimmable LED constant current source driver with wide voltage range

InactiveCN101626652AConvenient heat treatmentLow costPoint-like light sourceElectric circuit arrangementsElectrical resistance and conductanceVoltage range

The invention discloses a dimmable LED constant current source driver with wide voltage range, belonging to an LED light source driver in the illuminating field. The driver comprises a voltage identification circuit, a light compensation circuit, an MCU control circuit, a temperature compensation circuit and a dimmable constant current source circuit, wherein the output ends of the voltage identification circuit, the light compensation circuit and the temperature compensation circuit are all connected with the input end of the MCU control circuit, the PWM output end of the MCU control circuit is connected with the input end of the dimmable constant current source circuit, the voltage identification circuit and the dimmable constant current source circuit are both connected into direct-current or alternating-current input voltage, the light compensation circuit is connected with a photosensitive device, the temperature compensation circuit is connected with a thermistor, and the output end of the dimmable constant current source circuit is connected with an LED light source. The invention has low cost, small volume, stable and reliable working of a system and prolongs the service life of an LED.

Owner:JIANGSU YINJIA GROUP

Natural anticorrosion fresh-keeping composite prescription for beef ham slices

InactiveCN1653966ALong shelf lifeLow costFood preservationFood preparationFood additivePutrefying bacteria

The present invention is one kind of re-compounded natural preservative preparation for preventing putrefying bacteria from generating in beef ham slices effectively. The re-compounded natural preservative preparation consists of Nisin and tea polyphenol in the weight ratio of 1 to 12.5-200. The present invention has expanded bacteriostasis spectrum and optimized effect, and may be used to replace available synthetic preservative.

Owner:NANJING YURUN FOOD

Mixing stirrer with double feed inlets

InactiveCN106040067AImprove mixing efficiencyQuality improvementRotating receptacle mixersTransportation and packagingEngineering

Owner:HARBIN HUAZAO BIOTECH DEV

Semi-steel roll and preparation method thereof

InactiveCN101537428AReasonable compositionEasy to shapeFurnace typesRollsChemical compositionCarbide

The invention relates to a semi-steel roll and a preparation method thereof, belonging to the technical field of steel rolling. The semi-steel roll contains the following chemical components according to the mass percent: 1.65-1.90 of C, 0.80-1.15 of Cr, 0.35-0.65 of Si, 0.60-1.00 of Mn, 0.30-0.60 of Mo, 0.20-0.80 of Ni, 0.05-0.10 of K, 0.05-0.10 of Na, 0.05-0.15 of Ti, 0.05-0.15 of Nb, 0.08-0.15 of Y, 0.03-0.08 of Mg, 0.02-0.04 of Zn, 0.06-1.00 of Al, less than 0.04 of P, less than 0.03 of S, and the balance of Fe. The semi-steel roll has reasonable chemical component, prolonged service life, the hardness of 55-58 HS and the tensile strength of 900-950 MPa and the impact toughness of 10-12 J / cm2; the invention can save the nickel resource, reduce the cost, simplify the heat treatment, shorten the production period, improve the heat treatment efficiency, save the energy, thin the solidified organization, improve the forms and the distribution uniformity of carbides and inhibit the aliquation of alloy elements;.

Owner:江苏环立板带轧辊有限公司

Greasy dirt cleaning device for surface of metal part before heat treatment

InactiveCN107899983AConducive to closed cleaningEasy to cleanDrying gas arrangementsCleaning using toolsHydraulic ramImpurity

The invention discloses a greasy dirt cleaning device for the surface of a metal part before heat treatment. The greasy dirt cleaning device comprises a hydraulic pushing rod, a mounting seat, an electric pushing rod, a bearing round plate, a mounting hole, a rotating rod, a motor, a sealing cover, a water spraying head, a fixing plate, an outer threaded pipe, a cross-type brush, a gas spraying head, a cylinder body, a fluid flowing hole, arc-shaped blocks and a rubber block. According to the greasy dirt cleaning device for the surface of the metal part before heat treatment, the design is reasonable, closed cleaning treatment is conducted on the metal part advantageously, dust impurities are avoided from falling in, the metal part is cleaned and air-dried again advantageously, and the greasy dirt cleaning device is suitable for greasy dirt cleaning of metal parts of various kinds of different specifications; the cleaning effect is improved, artificial operation is reduced, and subsequent heat treatment of the metal parts is facilitated; the rotating metal part is subjected to greasy dirt cleaning through the cross-type brush with cleaning fluid, and full using and saving of cleaning are facilitated; and through the four arc-shaped blocks located the same plane and arranged between the fixing plate and a placing round plate, the four arc-shaped blocks clamp the metal part through the electric pushing rod advantageously.

Owner:张粉银

Electro-static dissipative ceramic products and methods

InactiveUS20040242401A1Economical and simpleConvenient heat treatmentConductive materialOxide conductorsDopantWorking temperature

The invention provides partially stabilised zirconia and alumina based electro-static dissipative or ESD ceramic compositions. The proposed ceramic compositions include specific amounts of dopants comprising one or more metal oxides selected from iron oxide, chromium oxide and titanium oxide. The proposed ESD ceramic materials are made into useful industrial products by injection moulding and sintering technology. A novel binder system may optionally be used to make injection mouldable feedstock. Useful products produced by the invention include, for example, ESD ceramic tweezers tips, ESD ceramic dispensing needles, ESD ceramic scissors and blades and ESD ceramic wire bonding capillaries which retain their ESD properties at relatively low temperatures, for example, service temperatures from 25 to 500° C.

Owner:JESSIE DARRYL +1

Manufacturing method of ultra low temperature and high intensity fine grain simple steel flange

ActiveCN101254577AHigh strengthImprove impact performanceMetal-working apparatusFurnace typesQuenchingImpurity

The invention relates to the manufacture method of micro-alloy fine-grain low-carbon steel flange with ultralow temperature and high strength performance, which can manufacture micro-alloy fine-grain low-carbon steel flange from low-carbon micro-alloy fine-grain high-strength steel by forging and heat treatment processes. The steel contains following chemical components (by weight percentage): C 0.12 to 0.18%, Si 0.15 to 0.35%, Mn 1.2 to 1.6%, and trace elements V 0.02 to 0.06%, Al 0.025 to 0.040%, N 0.001 to 0.002%, Fe in balance, and inevitable impurities. The method comprises the following steps: temperature-controlled forging, heat treatment of semi-product and cutting of final product, wherein the beginning temperature of forging is 1,050 DEG C plus or minus 20 DEG C, the final temperature of forging is 900 DEG C plus or minus 20 DEG C, and the semi-product is air-cooled after forging; the heat treatment of the semi-product is executed by adopting quenching and high-temperature tempering process; and a workpiece is subjected to metal cutting after the heat treatment. The method of the invention can obviate the use of expensive Ni alloy steel, and can meet the requirement for -50 DEG C low-temperature toughness and high strength.

Owner:JIANGYIN HENGRUN HEAVY IND

Vacuum heat treatment surface modification technology

InactiveCN107326157AImprove corrosion resistanceSo as not to damageSolid state diffusion coatingHeat treatment process controlMegasonic cleaningNitrogen

The present invention is a vacuum heat treatment surface modification process, which includes the following steps: (1) casting the alloy first, then grinding the surface of the alloy, immersing the smooth polished alloy in a solvent for rinsing; (2) Put the alloy after rinsing into a chemical solvent tank to remove surface oil, and ultrasonically clean the alloy during the process of removing oil; (3) Send the cleaned alloy into a vacuum annealing furnace for the first heating, When the heating temperature reaches 600-650°C, keep it warm for 60-80min, then quickly cool to 300-350°C and then heat it for the second time; (4) Pre-oxidize the alloy sent out of the furnace, and then send the alloy into vacuum (5) Send the alloy into the quenching furnace to complete the quenching; (6) Send the quenched alloy into the tempering furnace, heat it to 200-230°C, and keep it warm for 1- Allow to cool naturally after 3 hours.

Owner:JIANGSU FENGDONG HEAT TREATMENT & SURFACE MODIFICATION ENG & TECH RES CO LTD

Carbon Steel Sheet Superior in Formability and Manufacturing Method Thereof

ActiveUS20080295923A1Good for heat treatmentConvenient heat treatmentFurnace typesHeat treatment furnacesCarbon steelCrystallite

A carbon steel sheet having high formability due to a microscopic and uniform carbide distribution and having a good characteristic of final heat treatment, and a manufacturing method thereof. The carbon steel sheet having excellent formability, includes, in wt %, C at 0.2-0.5%, Mn at 0.1-1.2%, Si at less than or equal to 0.4%, Cr at less than or equal to 0.5%, Al at 0.01-0.1%, S at less than or equal to 0.012%, Ti at less than or equal to 0.5×48 / 14×[N]% when the condition of B(atomic %) / N(atomic %)>1 is satisfied or by 0.5×48 / 14×[N]% to 0.03% when the condition of B and N is not satisfied, B at 0.0005-0.0080%, N at less than or equal to 0.006%, Fe, and extra inevitable elements; an average size of carbide is less than or equal to 1 μm; and an average grain size of ferrite is less than or equal to 5 μm.

Owner:POHANG IRON & STEEL CO LTD

Copper oxide/graphene composite material, preparation method thereof and application of composite material

ActiveCN107413161AGood dispersionAvoid gatheringGas treatmentOther chemical processesFreeze-dryingOxide composite

The invention discloses a copper oxide / graphene composite material, a preparation method thereof and an application of the composite material, and belongs to the technical field of composite materials and air purification. According to the preparation method, graphene oxide acquired by a modified Hummers method serves as a carrier, copper oxide is slowly precipitated on the graphene oxide from pre-prepared copper ammonia solution and combined with an oxygen-containing group on the graphene oxide to form a stable copper oxide / graphene oxide composite material, hydrothermal reaction of the copper oxide / graphene oxide composite material is performed, so that the graphene oxide is reduced into graphene, and the grapheme is filtered, washed, freeze-dried and calcined to prepare the copper oxide / graphene composite material. The preparation method has good application prospect and the advantages that price of raw materials is low, preparation process is simple, the composite material can be repeatedly used and the like. The copper oxide / graphene composite material is applied to removing of formaldehyde and can be repeatedly used after simple heat treatment of the composite material is performed at the temperature ranging from 100 DEG C to 150 DEG C.

Owner:厦门捌斗新材料科技有限公司

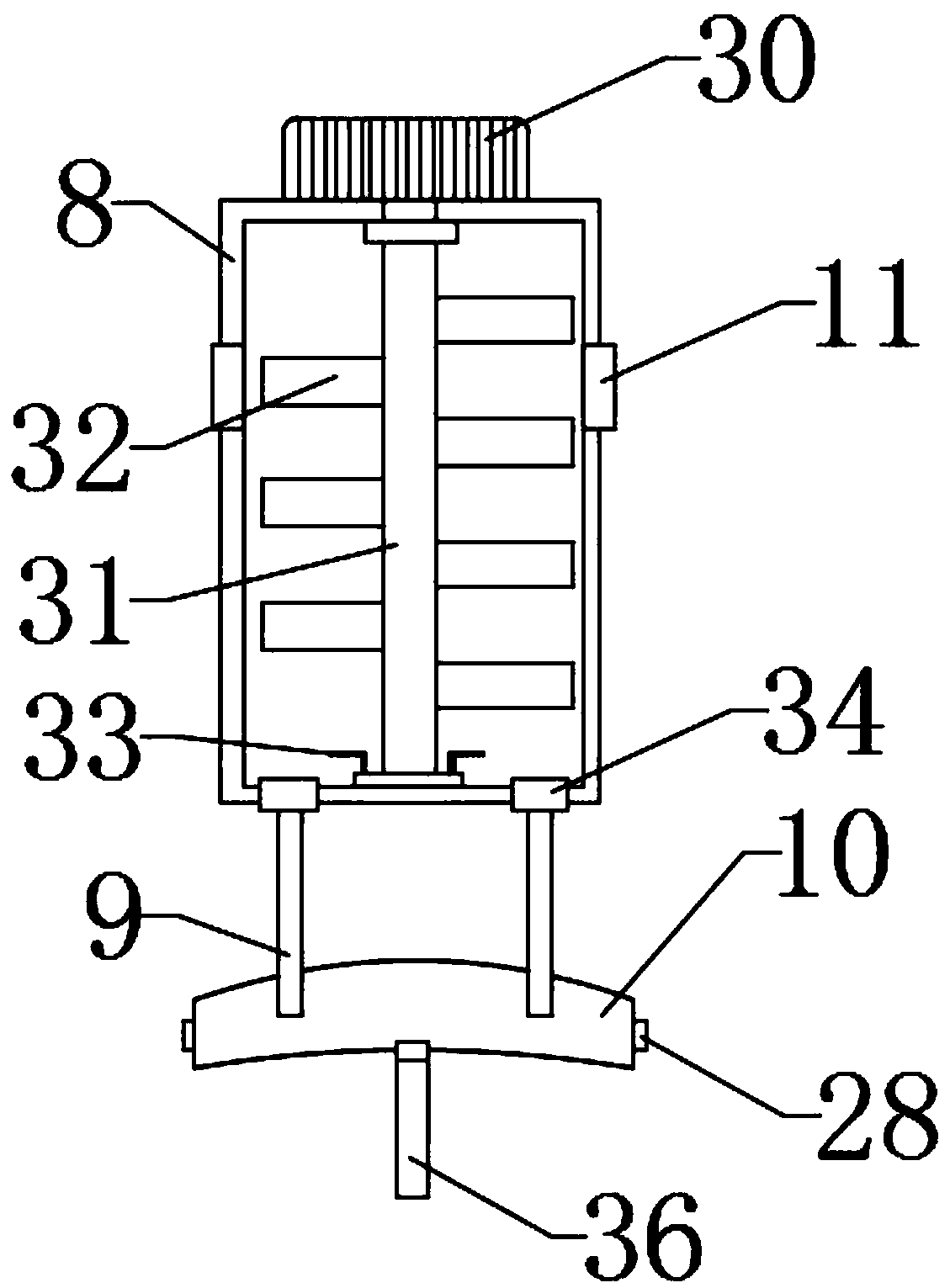

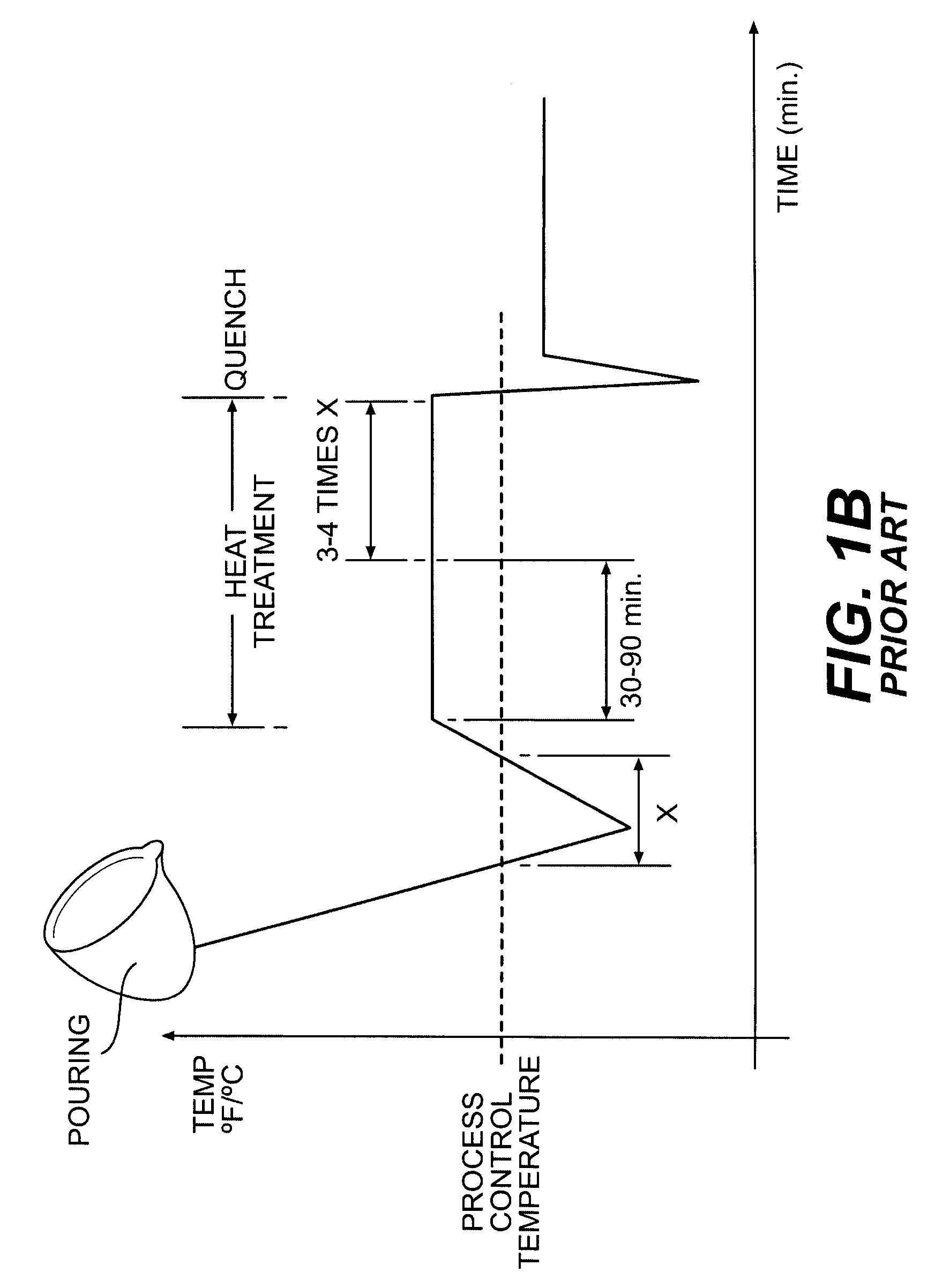

Vertical heat treatment system

InactiveUS20080236779A1Convenient heat treatmentSmall footprintCasting plantsFoundry mouldsEngineeringHeat treated

A system and method for forming and heat treating metal castings is provided with a vertical heat treatment unit positioned adjacent and downstream from a pouring station at which a series of molds are filled with a molten metal to form the castings. The vertical heat treatment unit includes a vertically oriented furnace chamber in which the castings are received, and which has a reduced footprint to reduce the manufacturing floor space required for the vertical heat treatment unit, and to enable the vertical heat treatment unit to be positioned in close proximity to the pouring station.

Owner:CONSOL ENG

Novel electric motor

InactiveCN101582606AEasy to processConvenient heat treatmentToothed gearingsMechanical energy handlingReduction driveGear wheel

The invention discloses a speed reduction electric motor, namely a novel electric motor integrating an epicyclic gear train and an electric motor. The novel electric motor comprises a stander, a stator, a rotor, an internal end cover, a planet carrier, an internal gear, a sun wheel, a big end cover, a supporting bearing, an output shaft, a planetary wheel axle and a planetary wheel. The invention arranges an epicyclic gear train reducer in the stander, uses the internal end cover to separate the epicyclic gear train from an electromagnetic starter and arranges the sun wheel of the epicyclic gear train on a rotor shaft, wherein the epicyclic gear train is a quasi-planet transmission or enclosed planet differential combined gear train. The beneficial effects of the electric motor include light weight, material saving, low cost, high efficiency, small shape, simple installation and other marked advantages.

Owner:吴声震

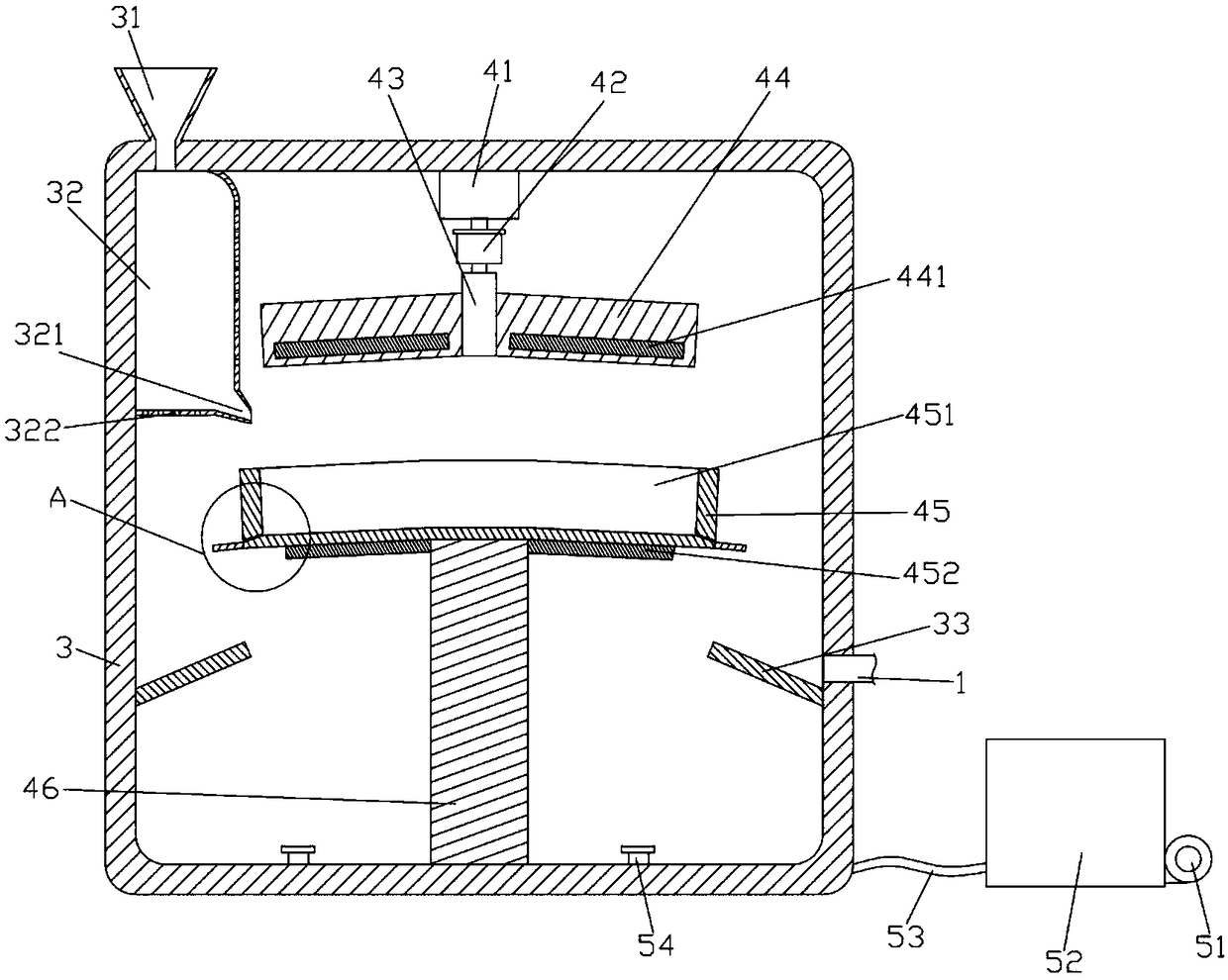

Plastifying machine

InactiveCN108656394AImprove grinding effectConvenient heat treatmentCocoaGrain treatmentsEngineeringMillstone

The invention discloses a plastifying machine. The plastifying machine comprises a box body, a plastifying device arranged in the box body, and a heating device arranged on one side of the box body. Afeed port is formed in the top of the box body, receiving plates are arranged on the side wall of the box body, and a discharge pipe is arranged on the side wall of the box body. The plastifying device comprises a supporting rod arranged at the bottom of the box body, a lower millstone arranged on the supporting rod,, and an upper millstone cooperating with the lower millstone. First heating pipes are arranged on the upper millstone, and second heating pipes are arranged at the bottom of the lower millstone. The grinding effect of plastic is improved through the cooperative effect of grindingof the upper millstone and the lower millstone, through the cooperation of the heating pipes in the upper millstone and the lower millstone and the heating device on one side of the box body, the plastic in the box body is well heated, the plastifying efficiency of the plastic is improved, the time needed by plastifying is shortened, the production efficiency of the plastic is improved, and production and processing use in a factory is promoted.

Owner:杭州大橙知一科技有限公司

Method for controllably preparing supported and non-supported Ni2P under mild conditions

ActiveCN102030317AImprove catalytic performanceThe preparation process is safe and simplePhosphidesSodium Hypophosphite MonohydrateHydrogenation reaction

The invention provides a new method for controllably preparing supported and non-supported Ni2P under mild conditions. In the method, two tube furnace reactors connected in series are adopted; and sodium hypophosphite aqueous solution is subjected to thermal decomposition in the first reactor to generate phosphine gas, and later, carried by argon, the phosphine gas is dried and then enters into the second reactor to react with nickel salt to generate the required Ni2P. The invention is characterized in that the preparation process is safe and concise; the preparation conditions are mild and controllable; simple thermal treatment under normal pressure is only needed in the preparation process; and the supported and non-supported Ni2P can be controllably prepared by controlling the amount of the sodium hypophosphite. With excellent catalytic performances, such type of phosphides can be widely applied to various hydrogenation reactions.

Owner:NANKAI UNIV

Suspension component having localized material strengthening

InactiveUS20050236794A1Improve ductilityImprove fracture toughnessInterconnection systemsEngine componentsEngineeringHigh stress

Owner:VISTEON GLOBAL TECH INC

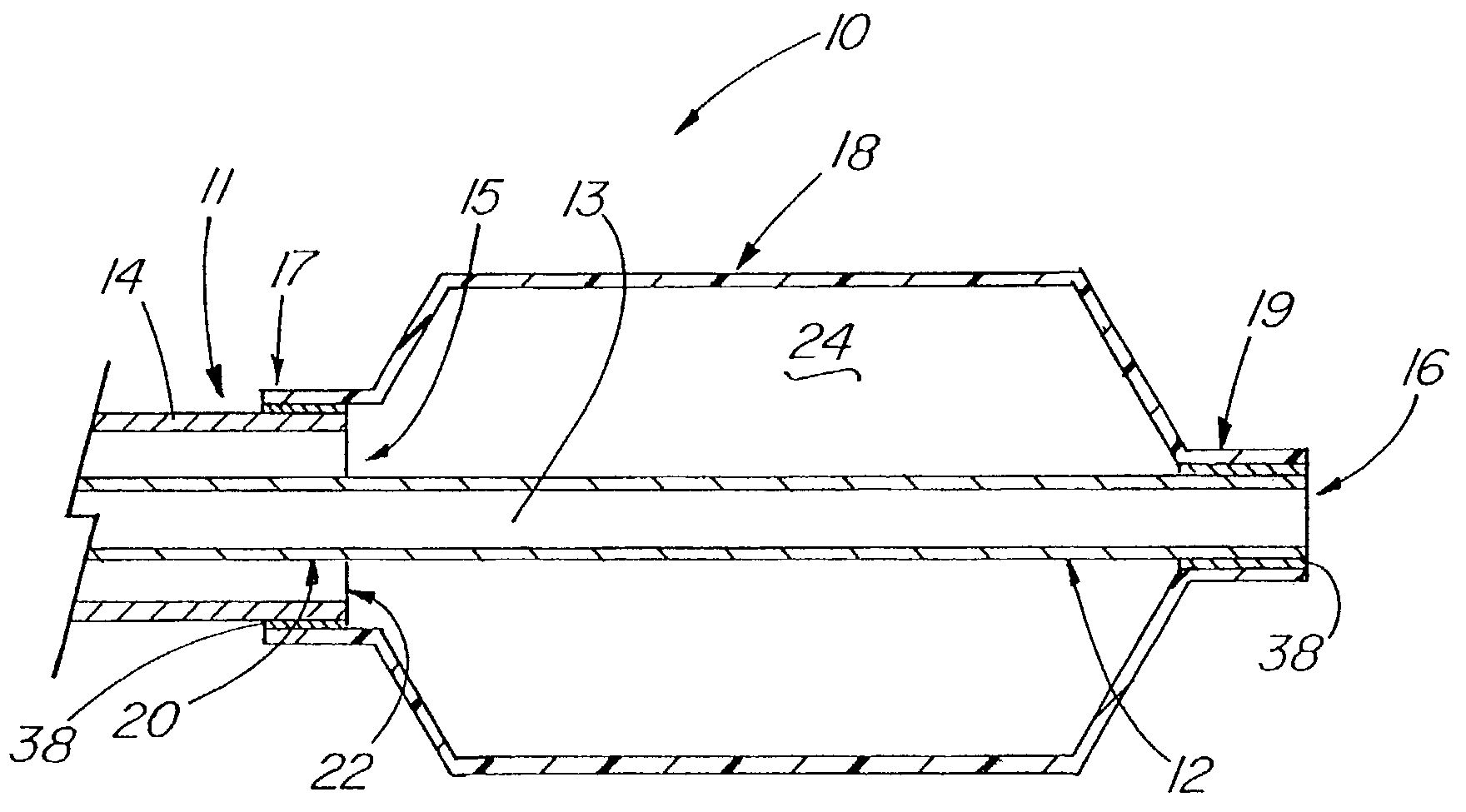

Medical device including improved expandable balloon

InactiveUS7485250B2Point becomes highLess reactiveElectric discharge tubesSynthetic resin layered productsElastomerPolyester

A medical device (10) includes a catheter shaft (11) including inner and outer catheter shafts (12 and 14), and an expandable balloon (18) carried by the catheter shaft (11). The balloon (18) is made from an irradiation cross-linked mixture of a polyamide elastomer and at least one additional cross-linking reactant. The polyamide elastomer can be a polyester amide, a polyether ester amide or a polyether amide, and is preferably a nylon block copolymer. The cross-linking reactant can be: (a) a difunctional material, (b) a trifunctional material, (c) a tetrafunctional material, or (d) an aromatic molecule containing at least two ring substituents, each of the ring substituents having labile hydrogens at a benzylic site therein. The cross-linking reactant can also be diallyl phthalate or meta-phenylene dimaleimide. Irradiation is carried out by exposure to an electron beam or to ultraviolet, X- or gamma radiation, preferably at a total fluence of about 0.5 to about 20 megarads. The amount of the cross-linking reactant is selected to avoid the formation of gelling during the process by which the balloon (18) is made, and the amount of the cross-linking agent and the irradiation fluence are selected to give the balloon a strength generally about equal to that which would be obtained by mere irradiation.

Owner:COOK MEDICAL TECH LLC

Fe-BASED AMORPHOUS ALLOY, POWDER CORE USING THE SAME, AND COIL ENCAPSULATED POWDER CORE

ActiveUS20120092111A1Optimum heat treatment temperatureImprove power efficiencyTransformers/inductances casingsInorganic material magnetismVitrificationMagnetization

An Fe-based amorphous alloy of the present invention has a composition formula represented by Fe100-a-b-c-x-y-z-tNiaSnbCrcPxCyBzSit, and in the formula, 0 at %≦a≦10 at %, 0 at %≦b≦3 at %, 0 at %≦c≦6 at %, 6.8 at %≦x≦10.8 at %, 2.2 at %≦y≦9.8 at %, 0 at %≦z≦4.2 at %, and 0 at %≦t≦3.9 at % hold. Accordingly, an Fe-based amorphous alloy used for a powder core and / or a coil encapsulated powder core having a low glass transition temperature (Tg), a high conversion vitrification temperature (Tg / Tm), and excellent magnetization and corrosion resistance can be manufactured.

Owner:ALPS ALPINE CO LTD

Protective atmosphere short-period roll bottom type continuous annealing furnace production line

InactiveCN108823374AMeet the standard of heat treatmentConvenient heat treatmentFurnace typesHeat treatment process controlAutomatic controlAtmosphere

The invention discloses a protective atmosphere short-period roll bottom type continuous annealing furnace production line. The protective atmosphere short-period roll bottom type continuous annealingfurnace production line comprises a feeding table, a feeding vacuum chamber, a pre-heating chamber, a heating chamber, a thermostable chamber, a slow cooling chamber, a discharging vacuum chamber anda discharging table. The protective atmosphere short-period roll bottom type continuous annealing furnace production line is mainly suitable for spheroidizing annealing, softening annealing, full annealing, distressing, normalization, carbon restoration and other heat treatment processes of low-carbon steel, low alloy steel, bearing steel and other wires, discs, bars, steel pipes and forged casting. The protective atmosphere short-period roll bottom type continuous annealing furnace production line is automatically controlled through a computer and a PLC program, so that all equipment is closely connected, and continuity of feeding is achieved. Meanwhile, the whole device is good in sealing performance, low in energy consumption and high in safety. Intellectualization and automation of production are achieved, and production efficiency and product quality are improved.

Owner:杭州赤热工业炉科技有限公司

N-C-Cr-V-RE multi-element co-diffusion material for 45 steel surface strengthening

ActiveCN105331926AShort processing cycleImprove corrosion resistanceSolid state diffusion coatingMechanical componentsHardness

The invention discloses an N-C-Cr-V-RE multi-element co-diffusion material for 45 steel surface strengthening. The co-diffusion material comprises the following two parts including a J-2 base salt material and a Cr-V-RE co-diffusion material, wherein the Cr-V-RE co-diffusion material is prepared from borax, NaF, K2CO3, V2O5, Cr2O3, aluminum powder and RE. After being subjected to 570 DEG C*4h N-C pre nitrocarburizing, 950 DEG C*6h Cr-V-RE co-diffusion and 550 DEG C*2h tempering, the diffusion layer structure of 45 steel is compact and continuous and high in corrosion resistance and hardness, and surface strengthening properties of corrosion resistance and abrasion resistance of plastic molds and various mechanical parts are guaranteed. The process is simple; the operation is convenient; the heat treatment period is short; the controllability is high; the property defects of unit diffusion metal or nonmetal are overcome; the application prospects are quite wide.

Owner:GUANGXI UNIV

Cast steel material and manufacturing method for castings of cast steel material

ActiveCN106282787AIncrease load capacityExtended service lifeProcess efficiency improvementManufacturing cost reductionElement analysis

The invention provides a cast steel material with high strength, good toughness and low cost. The cast steel material is composed of, in weight percentage, 0.32-0.40% of C, 0.25-0.45% of Si, 0.50-0.80% of Mn, smaller than or equal to 0.035% of P, smaller than or equal to 0.035% of S, 0.02-0.03% of N, 0.020-0.060% of Al, smaller than or equal to 0.10% of Mo, smaller than or equal to 0.05% of V, smaller than or equal to 0.20% of Ni, smaller than or equal to 0.20% of Cu, smaller than or equal to 0.25% of Cr and the balance Fe and inevitable impurities. According to the cast steel material, on the premise of not increasing the wall thickness and the section ratio of engineering vehicle axle housings and suspensions and not increasing the manufacturing cost, the strength and the toughness of the axle housings and suspension supports are improved, and therefore the bearing capacity can be improved; and according to finite element analysis, the thickness of castings of products can be reduced appropriately, the purpose of light weight can be realized, and the manufacturing cost can be lowered.

Owner:卢森加

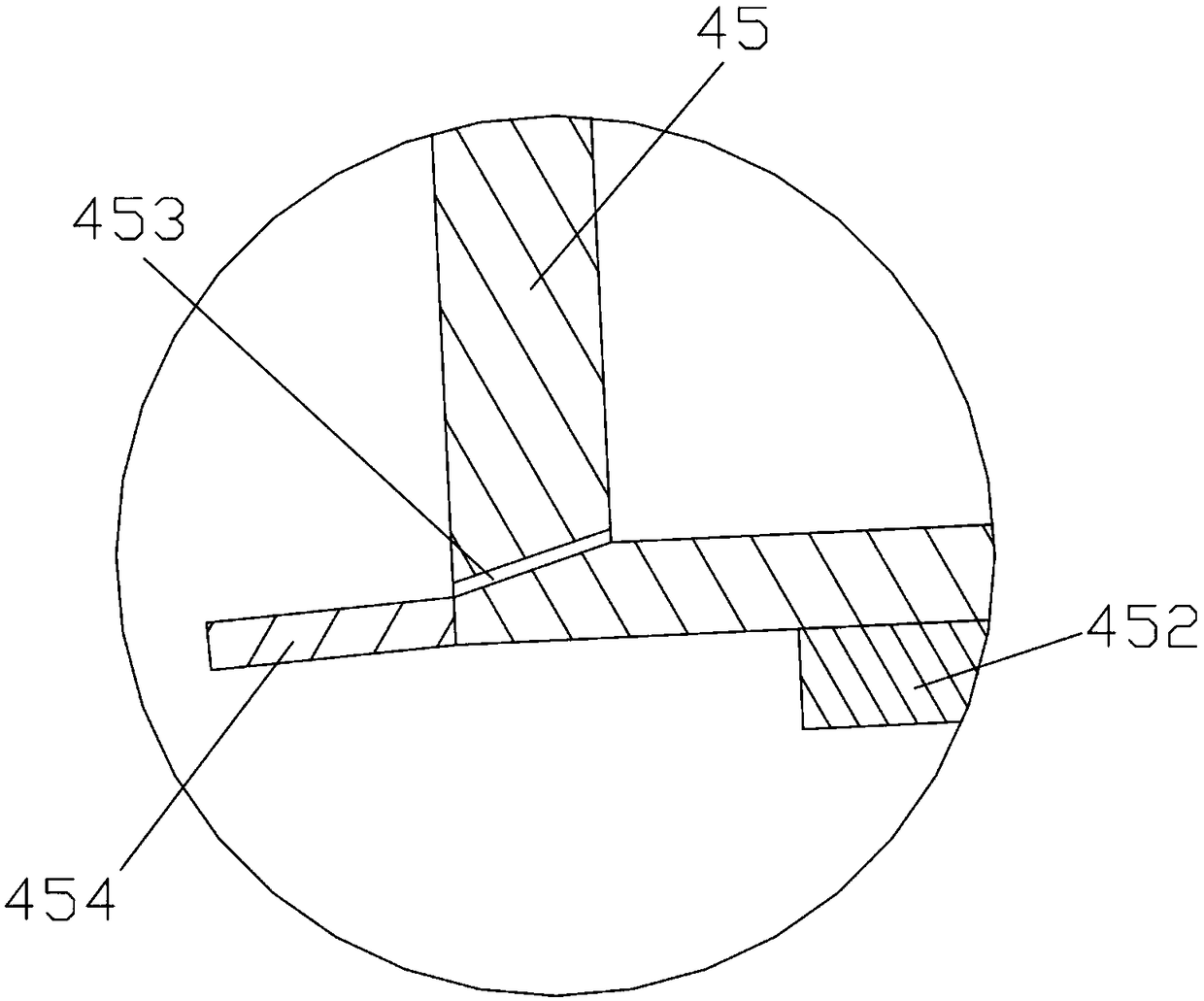

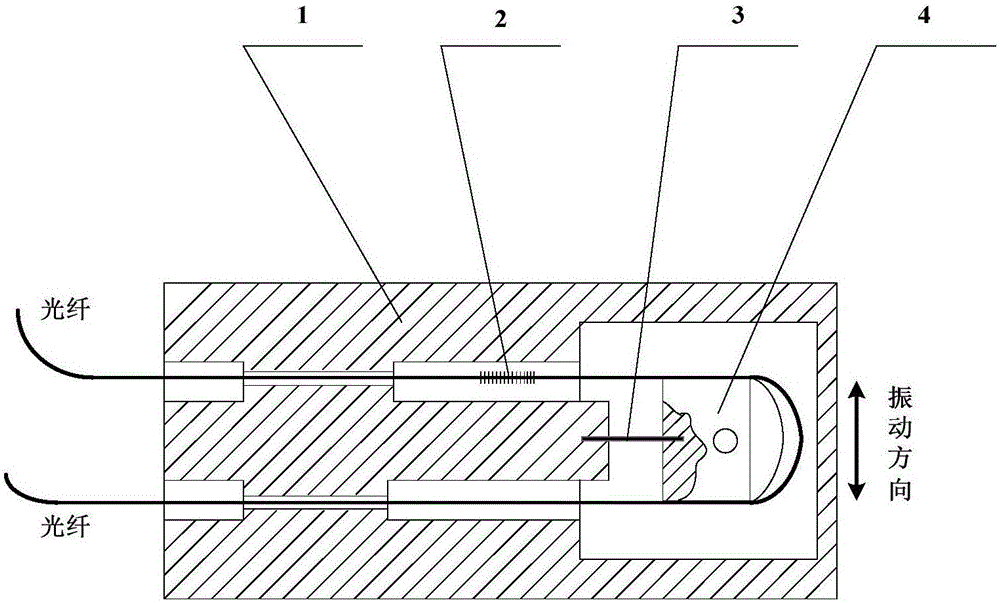

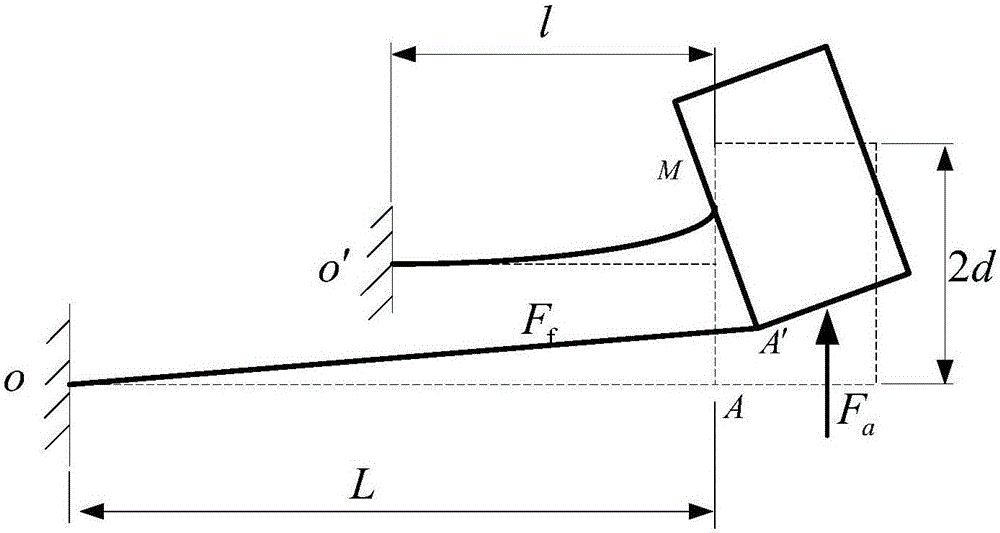

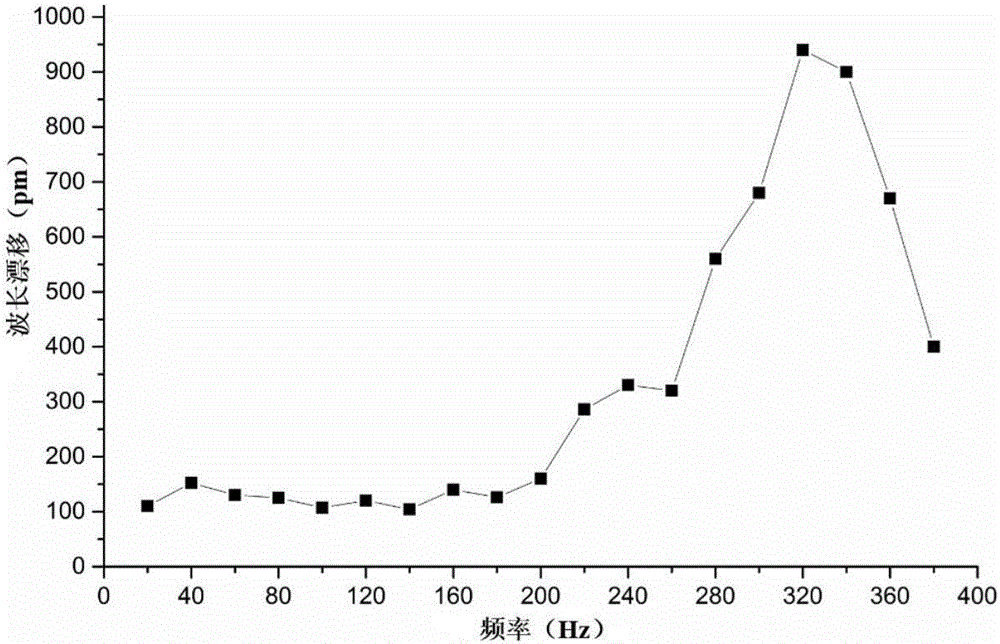

Manufacturing method of cantilever beam fiber grating accelerometer

The present invention provides a manufacturing method of a cantilever beam fiber grating accelerometer. The sensor comprises a substrate, a spring leaf, a quality block, a side cover and a fiber grating. The substrate, the spring leaf and the quality block are assembled through mechanical coordination and laser welding to form a cantilever structure. The fiber grating performs etching on the G.657 fiber, the fiber tension performance is improved through adoption of macromolecule ultrathin coating, and the epoxy resin dispensing is employed to fix the positions between the fiber grating and substrate and the quality block to assemble a fiber grating acceleration sensor. A balance weight hole is processed on the quality block in advance, the assembled sensor is calibrated, and the dispensing or machining is performed on the balance weight hole to flexibly regulate the sensitivity and the resonant frequency point of the sensor to optimize the performance index of the acceleration sensor. The manufacturing method of the cantilever beam fiber grating accelerometer simplifies the design and processing requirement of the acceleration sensor, simple in operation method and high in practicality, and the made sensor is high in sensitivity, small in insertion loss and excellent in performace.

Owner:湖北三峡物联网知识产权运营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com