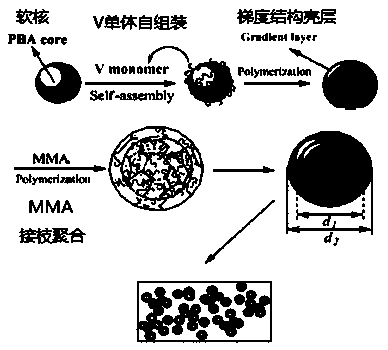

Preparation method of acrylic ester type processing aid with multilayer gradient core-shell structure

An acrylate-based, core-shell structure technology, applied in the field of preparation and modification of functional polymer materials, can solve the problems of single space structure, high cost, complicated process, etc., and achieves reasonable process parameters, low price, and excellent weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

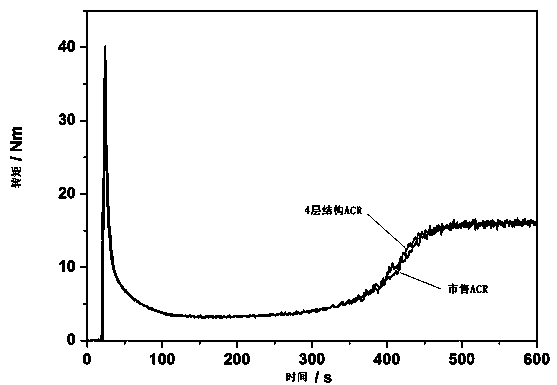

Examples

Embodiment 1

[0030] Add 100 g deionized water, 1 g potassium persulfate, 6 g Tween, 1 g sodium dodecylbenzenesulfonate emulsifier, 4 g n-butanol, 0.1 g polyvinyl alcohol, 100 g soybean oil and 5 g divinylbenzene. Stir at 30°C for 15 minutes to obtain a soybean oil pre-emulsion; then, raise the temperature of the reaction system to 75°C, keep it warm for 2 hours, then cool to room temperature to obtain the emulsion of the inner core (core layer) of the processing aid.

[0031] 1.5 g of potassium persulfate, 6 g of styrene and 20 g of methyl methacrylate were sequentially added to the above 100 g of processing aid inner core emulsion. After stirring evenly, gradually raise the temperature of the system to 75°C, and continue to add 1.5 g of potassium persulfate, 4 g of styrene and 30 g of methyl methacrylate to the system after the heat preservation reaction for 30 minutes, and add the 1.5 g of potassium persulfate and 50 g of methyl methacrylate were added into the reaction kettle, and the ...

Embodiment 2

[0033]Add 120 g deionized water, 1 g ammonium persulfate, 1.5 g alkylphenol polyoxyethylene ether emulsifier OP, 1 g sodium lauryl sulfate, 0.1 g Carboxycellulose, 100 g butyl acrylate and 8 g diene acrylate. Stir at 30° C. for 15 minutes to obtain a butyl acrylate pre-emulsion. Then, raise the temperature of the reaction system to 70° C., keep it warm for 2 hours, and then cool it down to normal temperature to obtain the emulsion of the inner core (that is, the core layer) of the processing aid.

[0034] 1 g of ammonium persulfate, 4 g of styrene and 10 g of methyl methacrylate were sequentially added to the above 20 g of processing aid inner core emulsion. After stirring evenly, gradually raise the temperature of the system to 70°C, add 1 g of ammonium persulfate, 3 g of styrene and 20 g of methyl methacrylate to the system after the heat preservation reaction for 30 minutes, Add 1 g ammonium persulfate, 2 g styrene and 30 g methyl methacrylate in the still, and add 1 g am...

Embodiment 3

[0036] Add 1000 g deionized water, 10 g ammonium persulfate, 25 g alkylphenol polyoxyethylene ether emulsifier NP, 10 g sodium lauryl sulfate, 5 g hydroxypropyl cellulose, 5 g polyvinyl alcohol, 1000 g isoctyl acrylate and 50 g divinylbenzene. Stir at 30° C. for 15 minutes to obtain isooctyl acrylate pre-emulsion. Then, raise the temperature of the reaction system to 50° C., keep the temperature for 2 hours, and then cool to normal temperature to obtain the inner core emulsion of the processing aid.

[0037] Add 100 g of peroxydicarbonate, 2000 g of acrylonitrile, and 3000 g of vinyl chloride to the above-mentioned 20,000 g of processing aid core emulsion in sequence. After stirring evenly, gradually raise the temperature of the system to 50° C., and keep the temperature and pressure for 30 minutes. The mixed solution of 200 g peroxydicarbonate, 1000 g acrylonitrile and 6000 g vinyl chloride is quickly injected into the reactor with a peristaltic metering pump, and all the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com