Waste plastic film recovery processing system and method

A treatment system and treatment method technology, applied in the field of waste plastic film recycling and treatment system, can solve the problems of environmental pollution, high energy consumption, low efficiency, etc., and achieve the effect of less process steps, low energy consumption and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

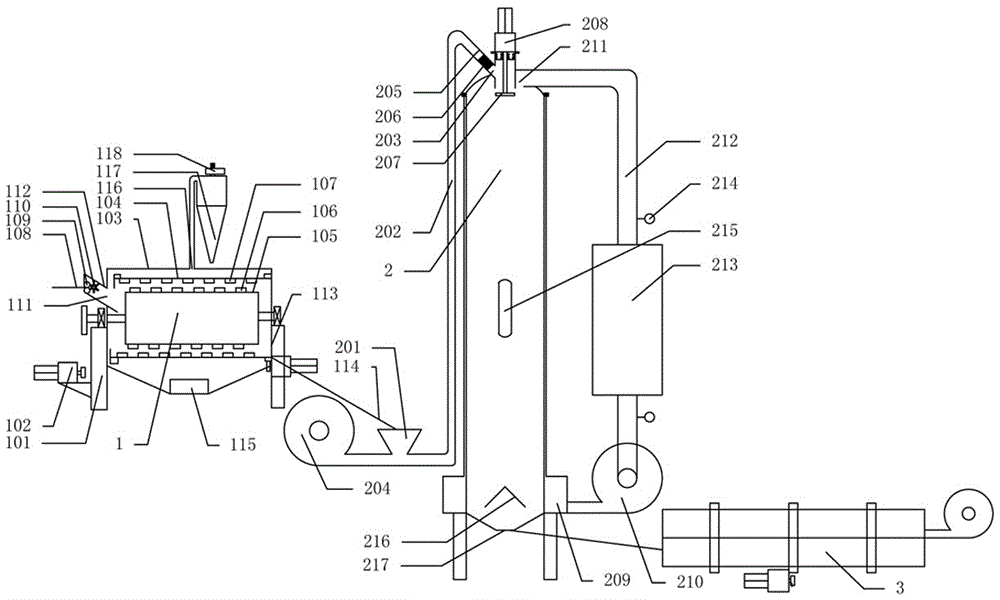

[0025] Such as figure 1 As shown, the waste plastic film recycling system of the present invention mainly includes a crushing and dry cleaning machine 1, a granulation system and a cooling device.

[0026] The crushing and dry-cleaning machine 1 includes a base 101, a driving mechanism 102, a feeding crushing mechanism, a double-layer drum, a screen, a casing 103, and a discharging mechanism. The driving mechanism 102 and the double-layer drum are arranged on the base 101, the screen is arranged on the bottom of the double-layer drum, the casing 103 is wrapped around the periphery of the double-layer drum, and the casing 103 is provided with a feeding crushing mechanism and an outlet. material organization. The discharge mechanism includes a dry-cleaning material outlet 113, an impurity outlet 115 and a suction hole 116, wherein the dry-cleaning material outlet 113 is located at one end of the casing 103, the impurity outlet 115 is positioned at the bottom of the casing 103, ...

Embodiment 2

[0034] Waste plastic film recovery processing method of the present invention comprises the following steps:

[0035] 1. Crushing and impurity removal: The recycled waste plastic film is broken into plastic film fragments through the crushing and dry cleaning machine 1, and the crushed plastic film fragments are rubbed and separated by the crushing and dry cleaning machine 1 to make the and / or adhering to the plastic film fragments Or the dust and impurities mixed in the plastic film fragments are separated from the plastic film fragments, and are discharged from the crushing dry cleaning machine 1 to realize the removal of impurities from the plastic film fragments.

[0036] 2. Granulation: the plastic film fragments after removal of impurities are sent to the feed port 203 at the top of the prilling tower 2 by wind in the feeding pipe 202, and fall freely in the prilling tower 2; The hot air port 209 blows hot blast, and the inlet temperature of the hot blast entering the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com