Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "No waste water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

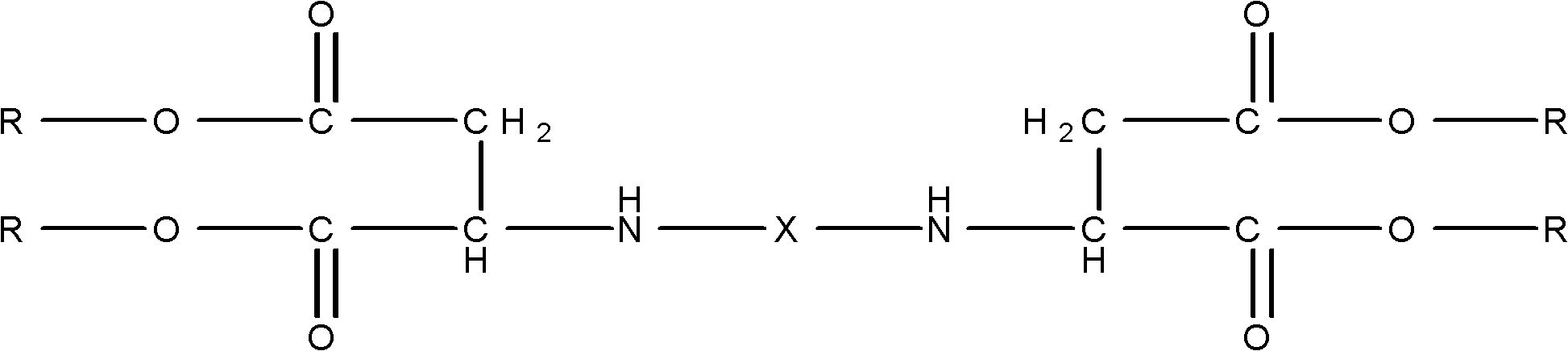

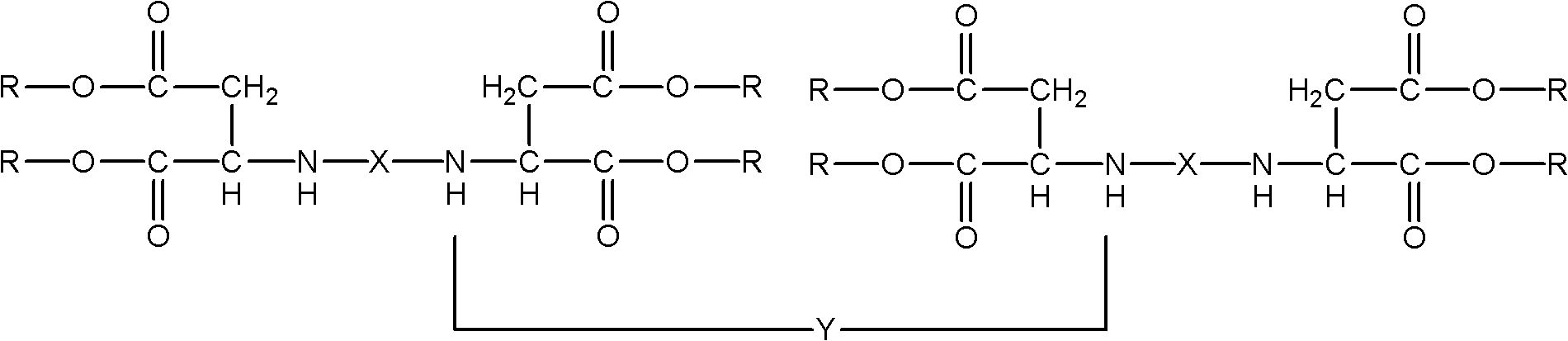

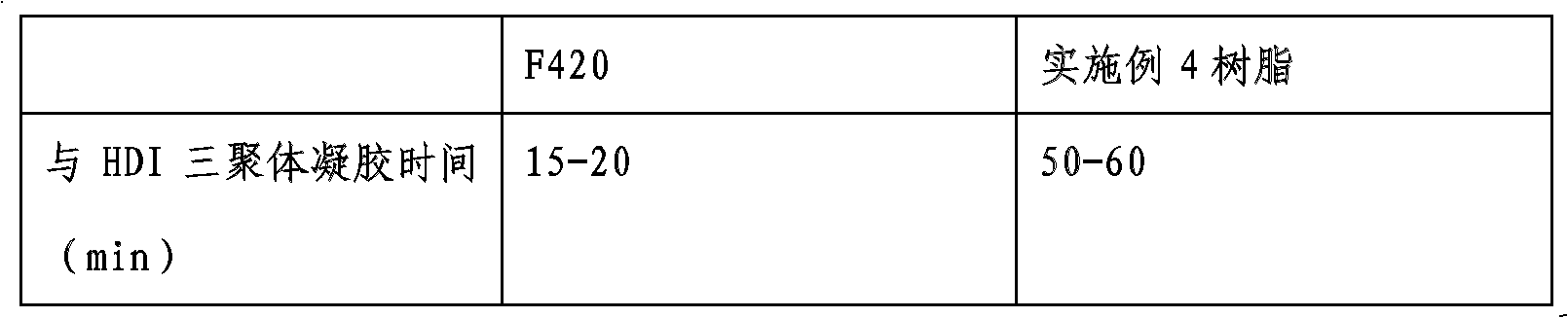

Polymerized modified polyaspartic acid ester compound and preparation method thereof

InactiveCN103030773AReduce concentrationImprove performancePolyurea/polyurethane coatingsPolyaspartic acidCarbon chain

The invention relates to a coating raw material and discloses a polymerized modified polyaspartic acid ester compound, which has the following structural general formula shown in the specification, wherein R is alkyl with at most ten carbon atoms, Y is a chain extender, and X is a straight-chain or ring-shaped carbon chain structure. The invention also discloses a preparation method of the compound. Compared with the polyurea paint prepared by the polyaspartic acid ester, the polyurea paint prepared by using the compound disclosed by the invention as the raw material has the advantages of convenience in construction, prolonged gel time, shortened surface drying time, enhanced tensile strength, enhanced elongation at break and improved elastic film coating hardness.

Owner:ZHUHAI FEIYANG NOVEL MATERIALS

L-2-reanal biological preparation method

ActiveCN102605014ALow costMild transformation conditionsChemical recyclingFermentationSeparation technologyThreonine

The invention relates to an L-2-reanal biological preparation method, which includes: utilizing L-threonine as raw materials, stirring the L-threonine in water at the temperature of 15-50 DEG C under the catalytic action of L-threonine deaminase and whole cells with a leucine dehydogenase and coenzyme regenerating function, and obtaining L-2-reanal after reaction. In the L-2-reanal biological preparation method, water is used for substituting for buffer salt solution to form a water-phase reaction system, cost of raw materials is reduced, threonine deaminase and whole cells used for catalyzing can be produced in batch by fermentation of microorganisms, are low in cost and wide in sources. Biological enzymatic catalysis reaction is water-phase reaction, transformation conditions of the enzymic method are mild, raw materials are transformed thoroughly, post-treatment is simple, products are separated by isoelectric point crystallization technology and film evaporation separation technology jointly, and the L-2-reanal biological preparation method is capable of recovering water and ammonium formate is low in cost, free of discharge of waste water and waste residues, environment-friendly in process and applicable to industrialized production of the L-2-reanal.

Owner:ENZYMEWORKS

Molding sand adhesive for casting

InactiveCN1721103AReduce residual gas concentrationReduce dosageFoundry mouldsFoundry coresSoluble glassMetallurgy

Sand sticking collapse agent for casting comprises raw material of weight per cent: soluble glass 94.5-98úÑ, dextrose powder 1.5-2.5úÑ, light calcium carbonate powder 0.2-2úÑ, suspending agent 0.2-0.5úÑ and antiseptic 0.1-0.5úÑ. It succeeds to integrate aforementioned raw material, has good high temperature collapsibility and anti-sticking ability, can fit to multiple hardening ways, cut baking time for CO2 and can increase recovery rate for used sand.

Owner:王继启

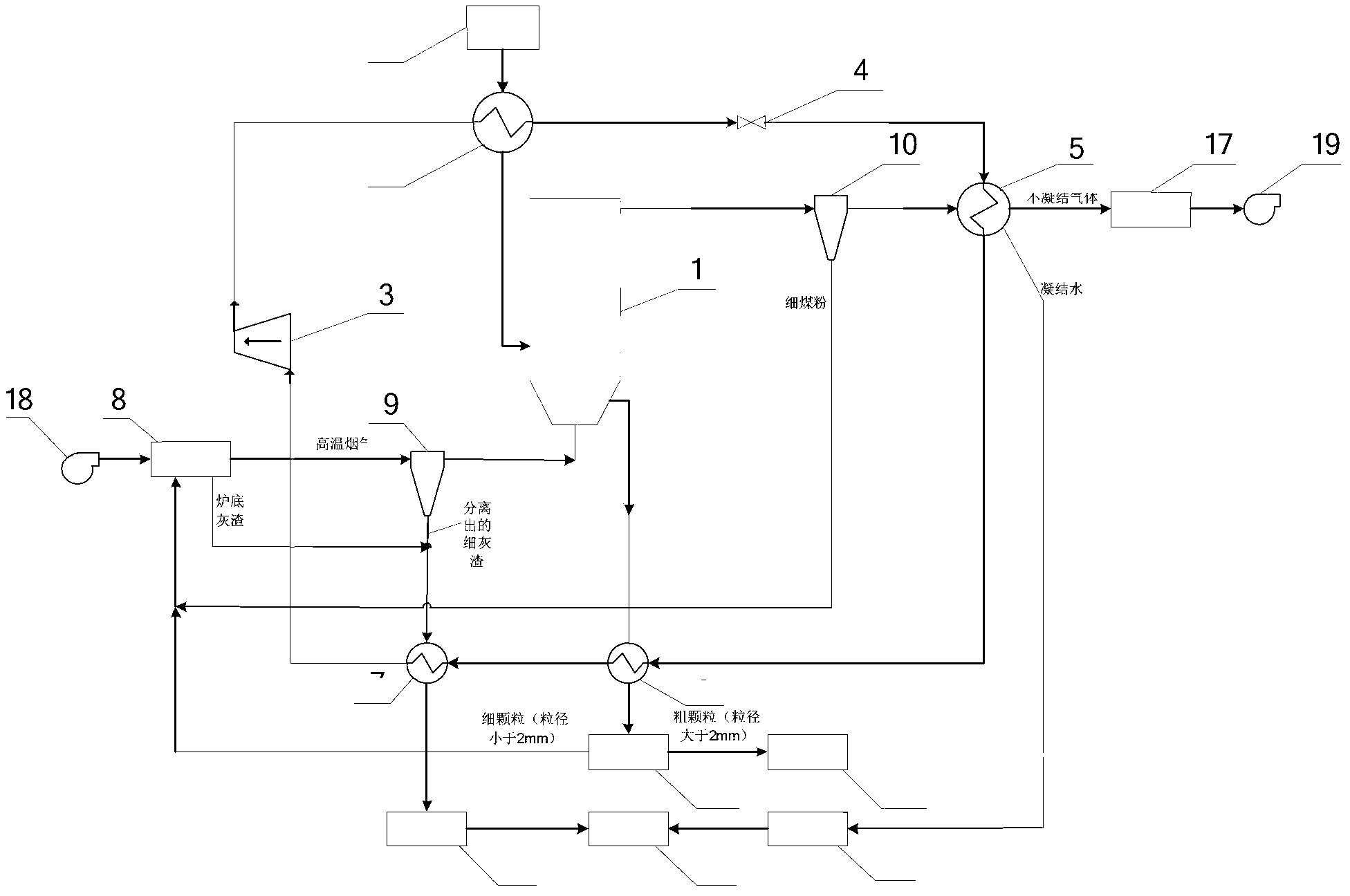

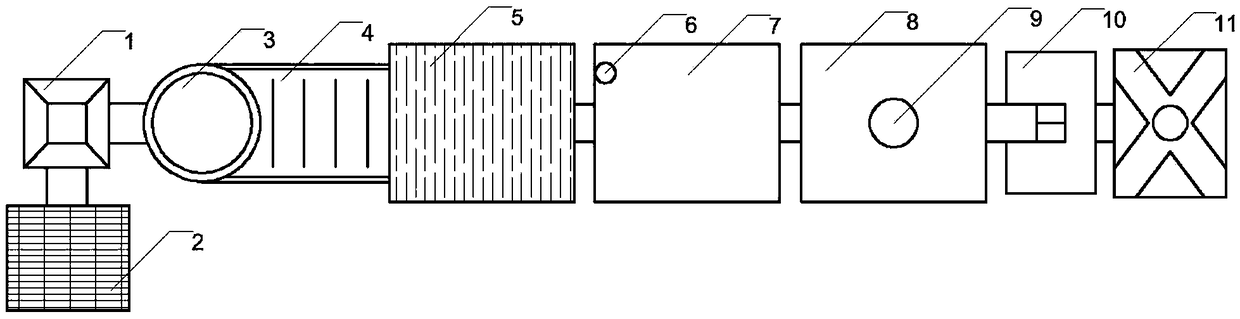

Comprehensive utilization system and method for lignite upgrading and drying energy

InactiveCN103307891AHigh calorific valueImprove combustion efficiencyDrying solid materials with heatHearth type furnacesFluidized bed dryingBrick

The invention discloses a comprehensive utilization system and method for lignite upgrading and drying energy. According to the system, a fume outlet of a hot blast stove (8) is connected with a fly ash separator (9); an ash residue outlet at the lower end of the fly ash separator (9) is connected with a high-temperature ash cooler (7); a clean fume outlet is connected with a dry wind inlet of a fluidized bed dryer (1); a fume outlet of the fluidized bed dryer (1) is connected with a cyclone separator (10); and a material outlet of the fluidized bed dryer (10) is sequentially connected with an inlet of a finished product coal temperature reduction device (6), and an inlet of a lignite screen separation device (12). The system makes the best of the heat generated during fine pulverized-coal combustion after the completion of lignite drying to dry the lignite, without an external heat; the heat pump technology is adopted to recover the exhaust heat generated by ready coal, high-temperature ash residue, exhaust steam and the like during the lignite drying process for predrying of the lignite; and meanwhile, the ash residue and solidified water are adopted to form ash residue slurry for industrial brick manufacturing raw materials, so as to achieve the purposes of energy conservation, emission reduction and waste utilization.

Owner:SOUTHEAST UNIV

Method of preparing pnenolic aldehyde foam from modified foamable phenolic resin

The invention relates to a method for preparing phenolic foam with the modified phenolic resin. In the invention, it mixes 100 weight share of cashew oil modified phenolic resin, 1~4 weight share of surfactant, 2~8 weight share of foaming agent, and then it adds 8~15 weight share of curing agent into the mixture and stirs it for 2~15 minutes, and then it cures the mixture at 65 ~ 80deg.C environment for 30 ~ 125 minutes to achieve the phenolic foam.

Owner:安徽复材科技有限公司

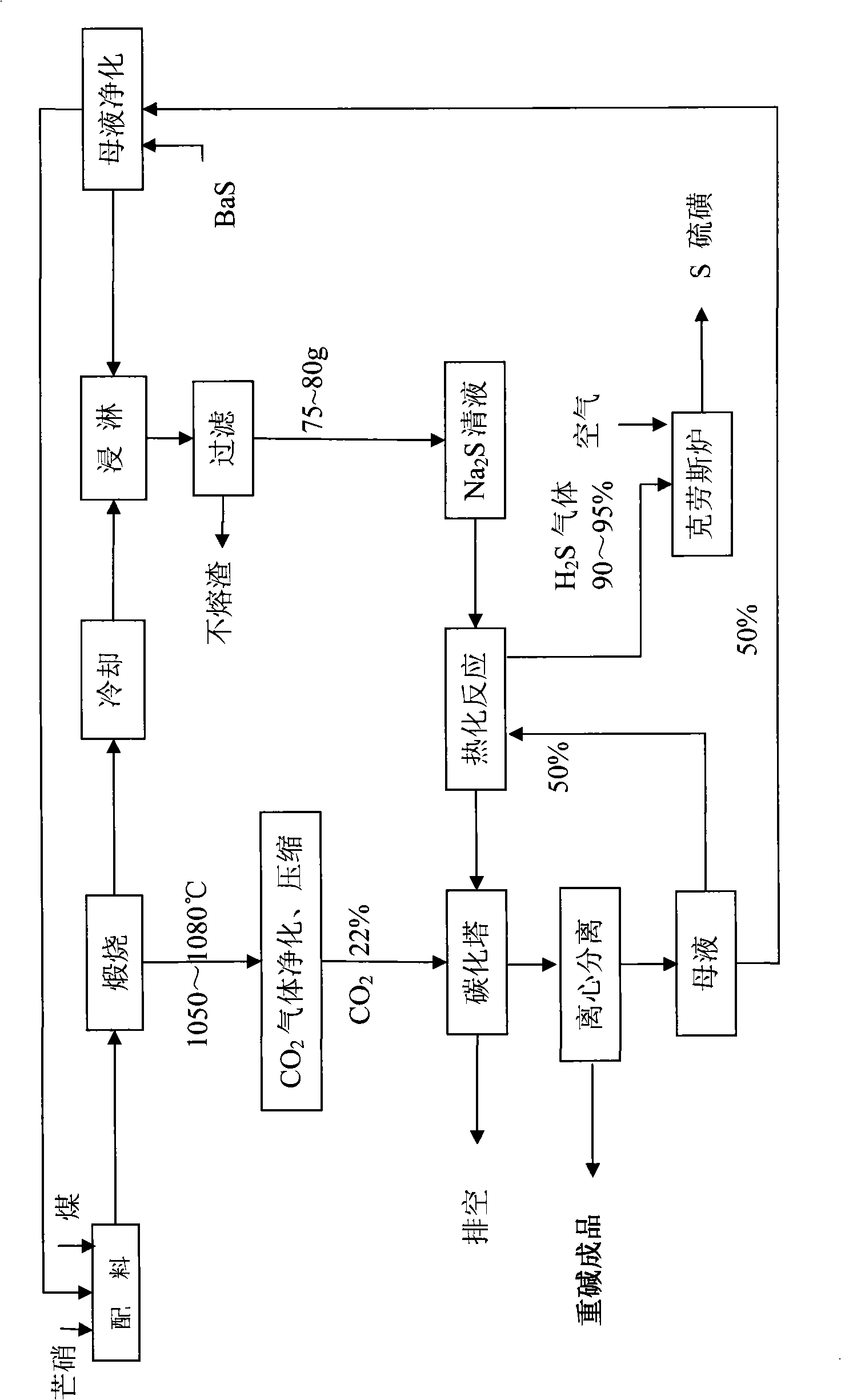

Method for producing sodium bicarbonate and sulfur from mirabilite by wet process

InactiveCN101264904AAchieving zero emissionsAchieve recyclingBicarbonate preparationSulfur preparation/purificationSodium bicarbonateCarbonization

The invention discloses a method for clean method for producing sodium bicarbonate and sulphur by means of Glauber salt wet method for reducing the emission of CO2 and avoiding the discharge of wastewater, which comprises the following steps: A, sodium sulphide preparing process, B, hot carbonatation process, C, sulphur preparing process, D, cold carbonization process, and E, mother liquor purifying. Glauber salt coal is reduced and calcined into sodium sulphide, and the sodium sulphide solution is heated and carbonized into a mixed solution with the soda as the main component by use of sodium bicarbonate, then the mixed solution is cold-carbonated by CO2 to separate out NaHCO3 crystal, which is dried to finally obtain the soda in conformity with relevant standard. The production method has the advantages of simple process, environmental friendliness, no pollution, full circulation of the mother liquor, and no wastewater discharged.

Owner:GANSU JINSHI CHEM

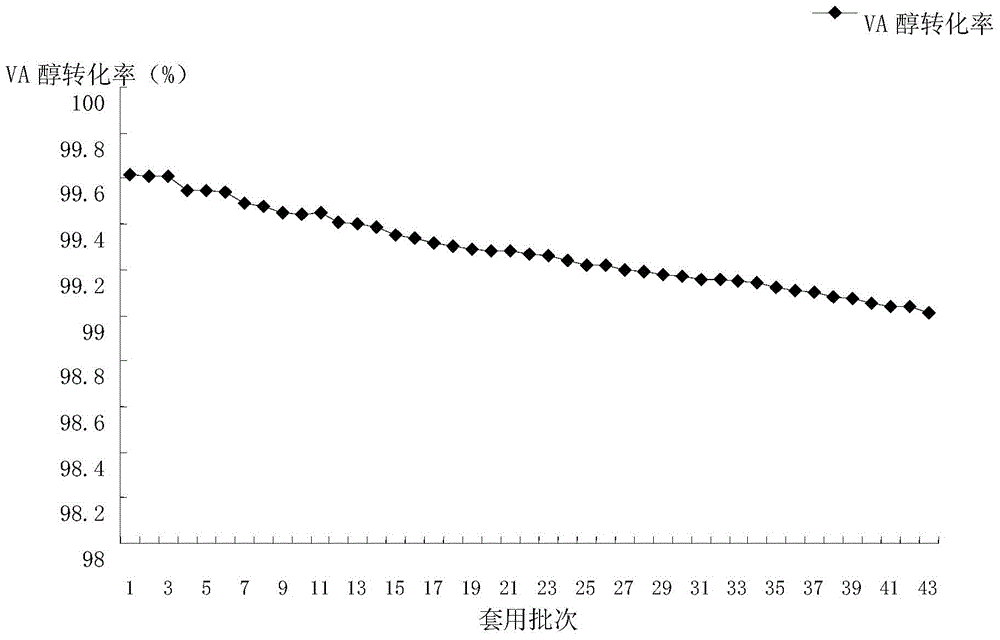

Method for synthesizing vitamin A palmitate by using immobilized esterase E.coli BioH as catalyst

The invention relates to a method for synthesizing vitamin A palmitate in a non-water-phase system by using immobilized esterase E.coli BioH as a catalyst. The method comprises the following steps: converting raw materials vitamin A acetate and lower alcohol into vitamin A alcohol by using immobilized esterase E.coli BioH as a catalyst, and carrying out esterification reaction with palmitic acid under non-water-phase conditions by using the immobilized esterase E.coli BioH as a catalyst to obtain the vitamin A palmitate. The conversion rate of the method is up to 98% above, the number of enzyme recycling times can reach more than 40, the subsequent product separation and purification process is simple, and the production cost is lower, thereby being beneficial to implementing industrialization. The vitamin A palmitate prepared by the method is light yellow grease on the appearance. The analysis by the United States Pharmacopeia USP28 process proves that the potency is 1.79-1.8 million IU / g, which the equivalent to the content of 98-99%; and the vitamin A palmitate can be widely used as a drug, feed additive, food additive or the like.

Owner:SHANGYU NHU BIOCHEM IND +3

Solanesol extracting and preparing process

InactiveCN1810747ALow costGood economic and social benefitsHydroxy compound separation/purificationSolventKetone

The process of extracting and preparing high purity solanesol from tobacco extractum includes: dissolving crude tobacco extractum in alkane solvent, saponifying under alkali alcoholate condition for 3 hr, filtering the reaction product, adsorbing the filtrate with macroporous resin, eluting with low toxicity mixed lower ketone and lower alcohol solvent, rotary evaporating the eluted solution to recover solvent, and decompression vacuum drying to obtain solanesol in the purity of 90-95 %. The said process has simple operation, reusable solvent, low cost and no pollution, and may be used in industrial production of solanesol in the purity over 90 %.

Owner:EAST CHINA UNIV OF SCI & TECH +1

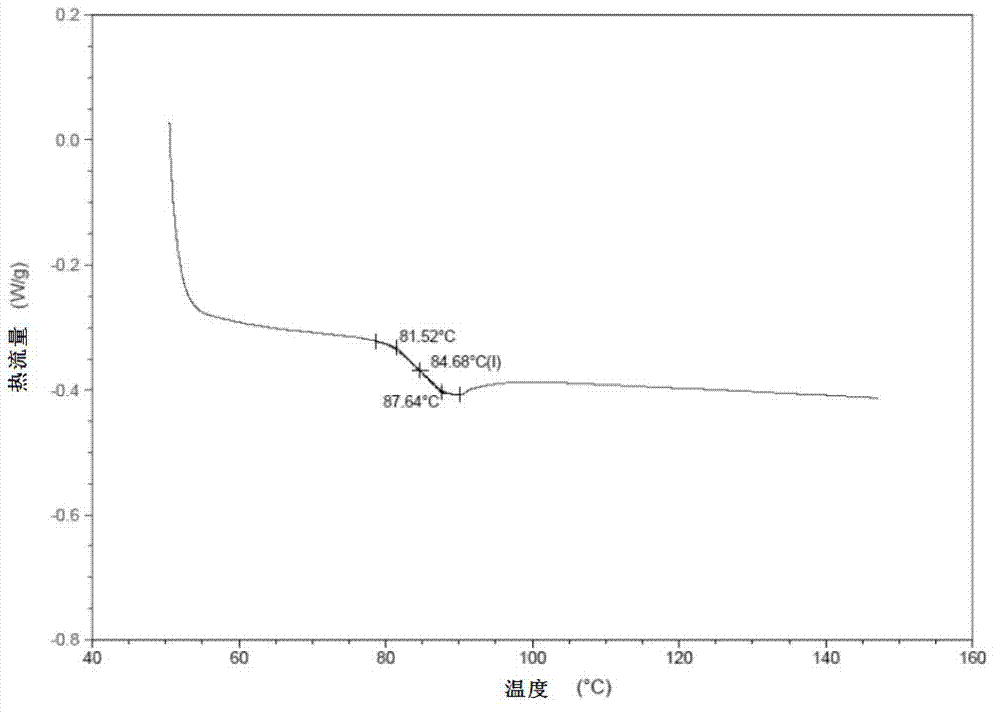

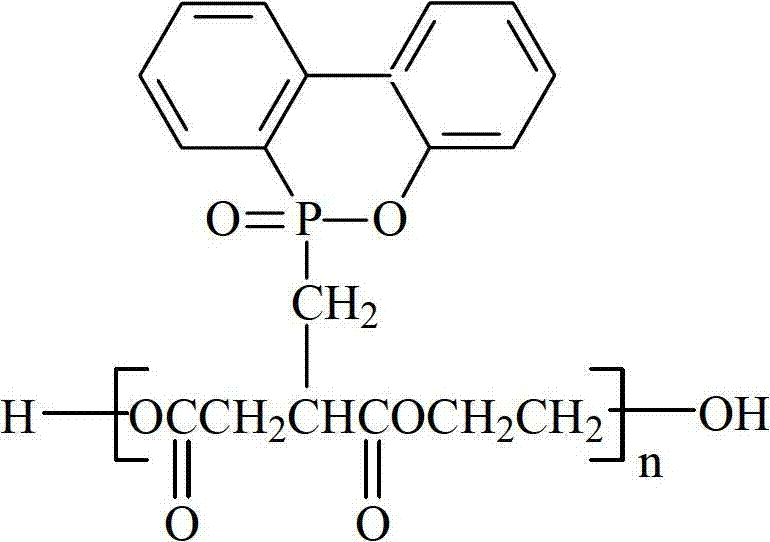

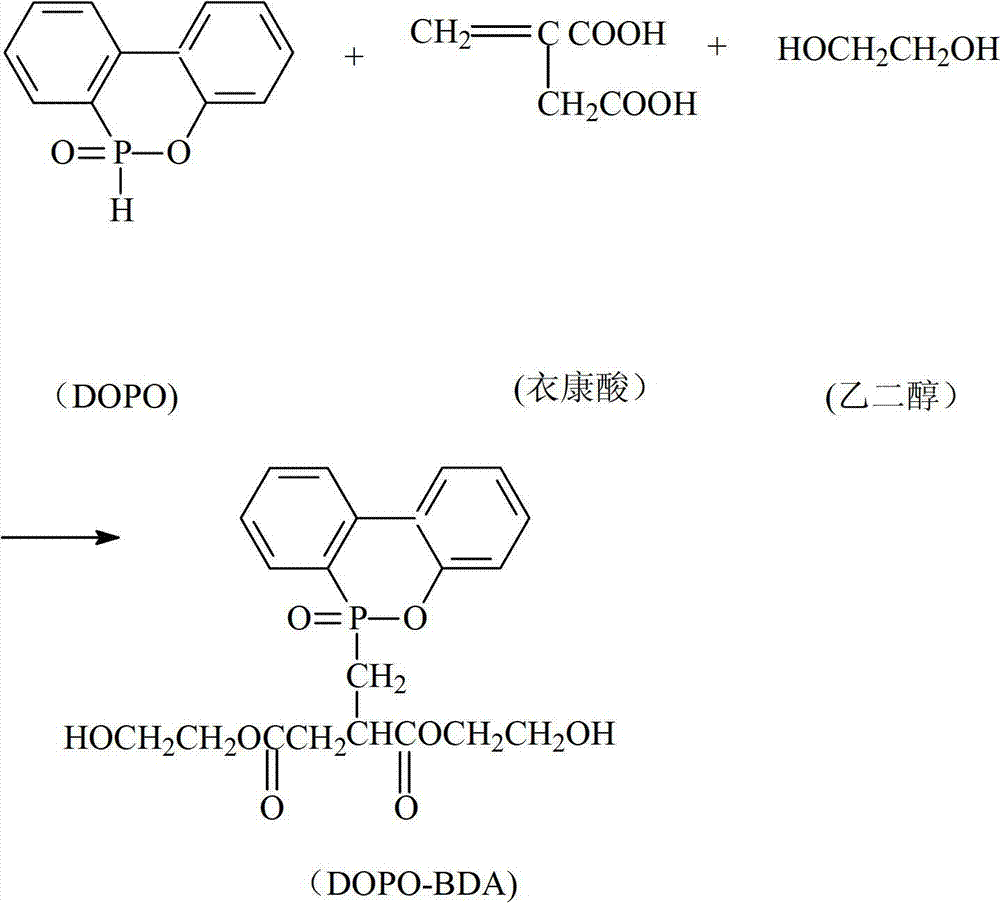

Additive type phosphorus phenanthrene oxa-flame retardant and preparation method thereof

InactiveCN102888085ARaise the processing temperatureImprove flame retardant performanceGroup 5/15 element organic compoundsFiberPolyester

The invention discloses an additive type phosphorus phenanthrene oxa-flame retardant and a preparation method thereof. The chemical name of the additive type phosphorus phenanthrene oxa-flame retardant is poly-(10-taconic acid gylcol ester-9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide). The preparation method comprises the following steps of: firstly carrying out a reaction on DOPO, itaconic acid and ethylene glycol to generate a monomer midbody 10-taconic acid gylcol ester-9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide; and polymerizing the reacting midbody at high temperature under the function of catalyst to obtain a target product. The additive type phosphorus phenanthrene oxa-flame retardant provided by the invention is applicable to various high molecular materials with higher processing temperature such as linear polyester, fiber, polyamide, polyurethane and the like; and the preparation method is free from halogen, environment-friendly, simple in operation process, easy to control, high in yield, good in product repeatability, and less in impurity, wherein the product yield can be 98.5%-99.9%, and the production cost can be reduced.

Owner:SHOUGUANG WEIDONG CHEM

Cement-free calcination-free shale pressing bearing brick and preparation thereof

InactiveCN101209909AImprove performance indicatorsLow costSolid waste managementEngineeringCalcination

The invention relates to a cement-free and baking-free shale suppression bearing brick and a manufacturing method thereof, which relates to a construction-used bearing brick and a manufacturing method thereof. Ordinary shale is used as main raw material and various 'wastes' are used as ingredients in the method; no open fire, waste gas, ash or waste water is produced in the manufacturing process which ensures low water and electricity consumption; various primary technical performances of a product are excellent. The method comprises steps that: (1) the materials are prepared according to following weight ratio: 40 to 50 percent of shale rock, 20 to 21 percent of auxiliary material, 4 to 6 percent of taillings powder, 7 to 9 percent of heavy calcium carbonate, 4 to 6 percent of gravel soil, 3 to 4 percent of alkali residue, 4 to 7 percent of construction waste, 5 to 6 percent of MSH polymerization condensate material especially used for shale and proper amount of water; (2) raw material treatment; the primary material and the auxiliary material are grinded; (3) ingredient stirring; (4) well-proportioned mixing and ageing; (5) mulling and plasticizing; (6) suppressing and forming; (7) steaming, pressing and solidification into finished product. The practice of the invention is environment friendly, and the quality of manufactured products is excellent, which reaches the standard of the bearing brick but has low cost and can be taken as the bearing brick for replacing a clay brick.

Owner:天津国威科技有限公司

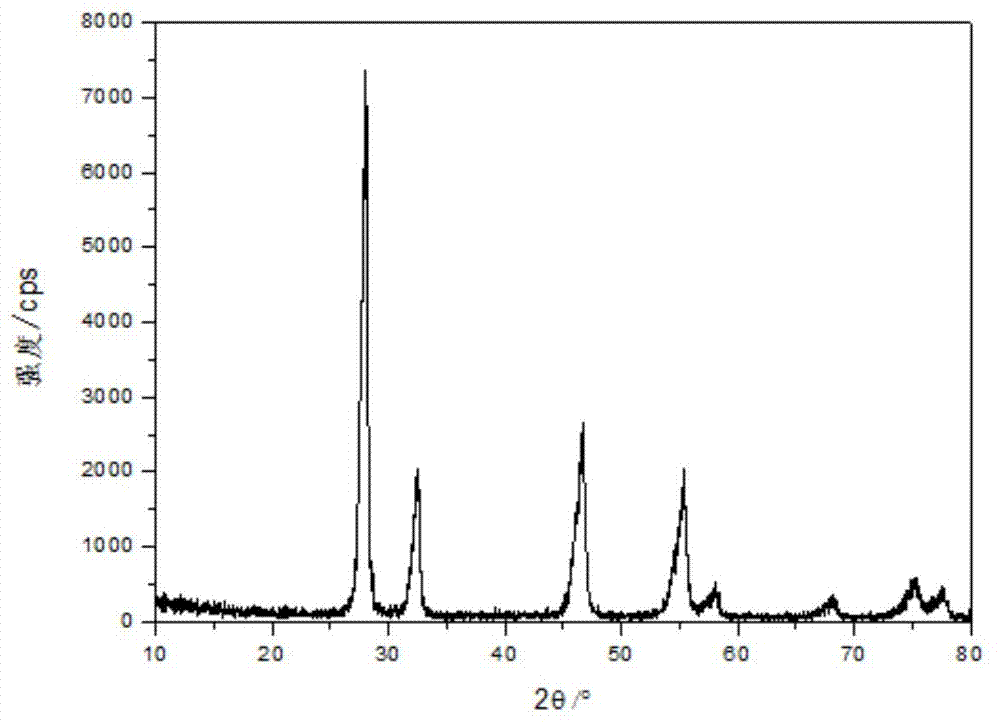

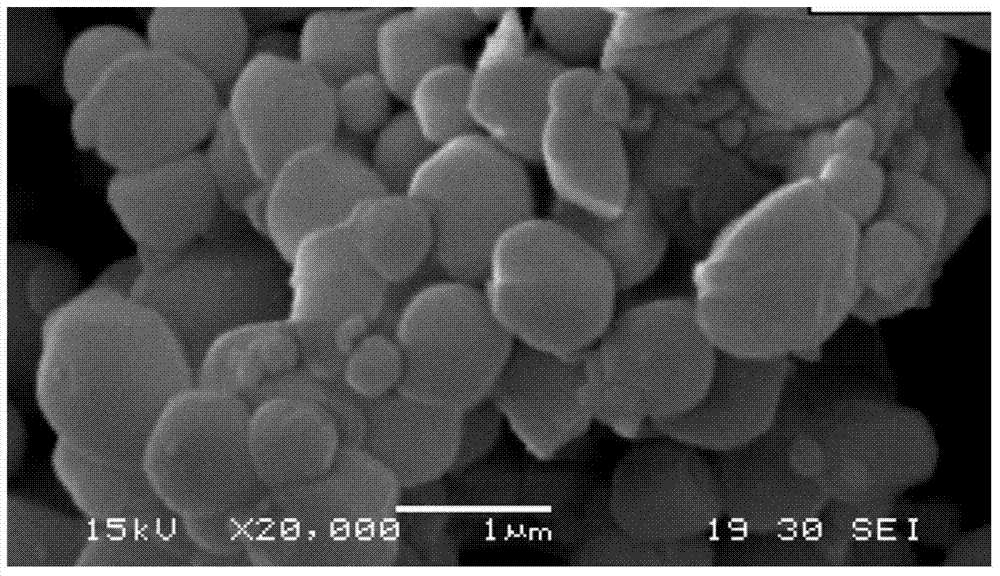

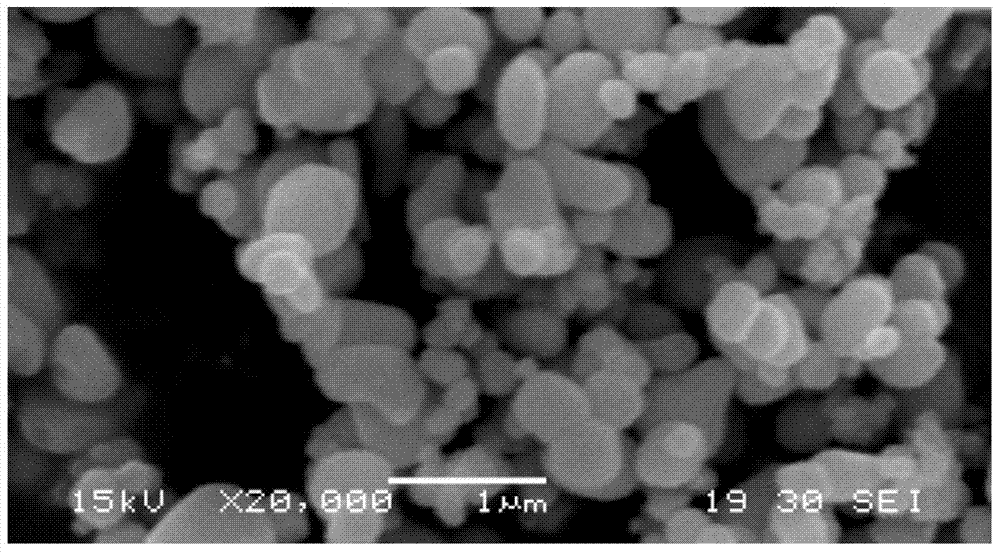

Cerium oxide polishing powder and preparation method thereof

ActiveCN103571334ASimple processLow costOther chemical processesRare earth metal compoundsCubic crystal systemWastewater

The invention discloses cerium oxide polishing powder. The purity TREO of cerium oxide CeO2 is more than or equal to 99.95%; cerium oxide is CeO2 powder with crystal form being a uniphase cubic crystal system; cerium oxide is shaped like a round cake with the average particle size of 1mum. The invention further discloses a preparation method for the cerium oxide polishing powder. The preparation method comprises the steps of preparation of cerium chloride, precipitation, dehydration, roasting, smashing and the like. Compared with the existing preparation method, the polishing powder prepared by adopting the method is cerium oxide powder, F is not required for introduction in the preparation process, and the preparation method has the advantages of being simple in process, low in cost, and free from waste water; the cerium oxide polishing powder has the advantages of having no scratch in the polishing process of products, being high in polishing precision and the like.

Owner:方复(上海)新材料科技有限公司

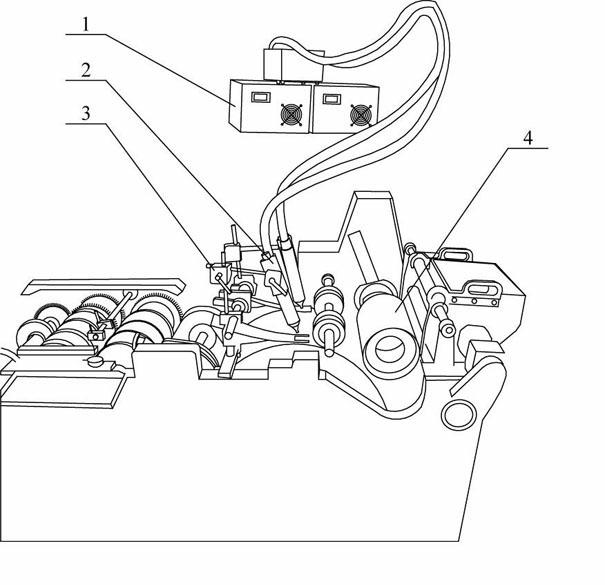

Industrial automatic method and device for producing sludge dry powder by sludge dehydration

InactiveCN101265010ARealize fully closed productionNo waste waterSludge treatment by de-watering/drying/thickeningGrain treatmentsWater contentSludge dewatering

The invention relates to an industrial automatic production method of sludge dry powder by sludge dewatering and equipment thereof. The method realizes industrial automatic production in industrial automatic production equipment of sludge dry powder by sludge dewatering, particularly sludge dewatering machine as main equipment. The sludge of water content below 85 wt% is dewatered to obtain sludge of water content below 5 wt%. The inventive method and equipment realize harmlessness, stabilization and reclamation of sludge dewatering; and can be widely used for dewatering domestic sludge or sediments, industrial sludge or sediments, lake and river course sludge or sediments.

Owner:何治国 +1

Processing method for laminated paper bag

InactiveCN102320409ADurable and stable surface propertiesKeep for a long timePaper-makingBox making operationsPack materialPlastic film

The invention discloses a processing method for a laminated paper bag which relates to the technical field of packaging materials and aims at the problems that the strength of the Dyne value of the surface of an existing corona-processed laminated paper bag is low; the timeliness is short; and the stored film cannot achieve the required surface tensile for adhesive bonding. The method disclosed by the invention comprises the following steps of: (1) paper printing: printing a design pattern on the paper to prepare a printed matter; (2) laminating after printing: covering a layer of transparent plastic film on the surface of the printed matter to prepare a laminated printed matter; (3) die cutting processing: performing die cutting and creasing processing for the laminated printed matter; (4) plasma processing technology: performing plasma treatment for the area to be bonded of the laminated printed matter subjected to the die cutting; and (5) case bonding technology: coating a binder on the area to be bonded subjected to the plasma treatment, jointing the area to be bonded; and solidifying the binder to prepare the laminated paper bag. The method disclosed by the invention is used for processing and manufacturing the laminated paper bag to enhance the binding strength of the joint of the paper bag.

Owner:SHANGHAI WANHONG PRINTING

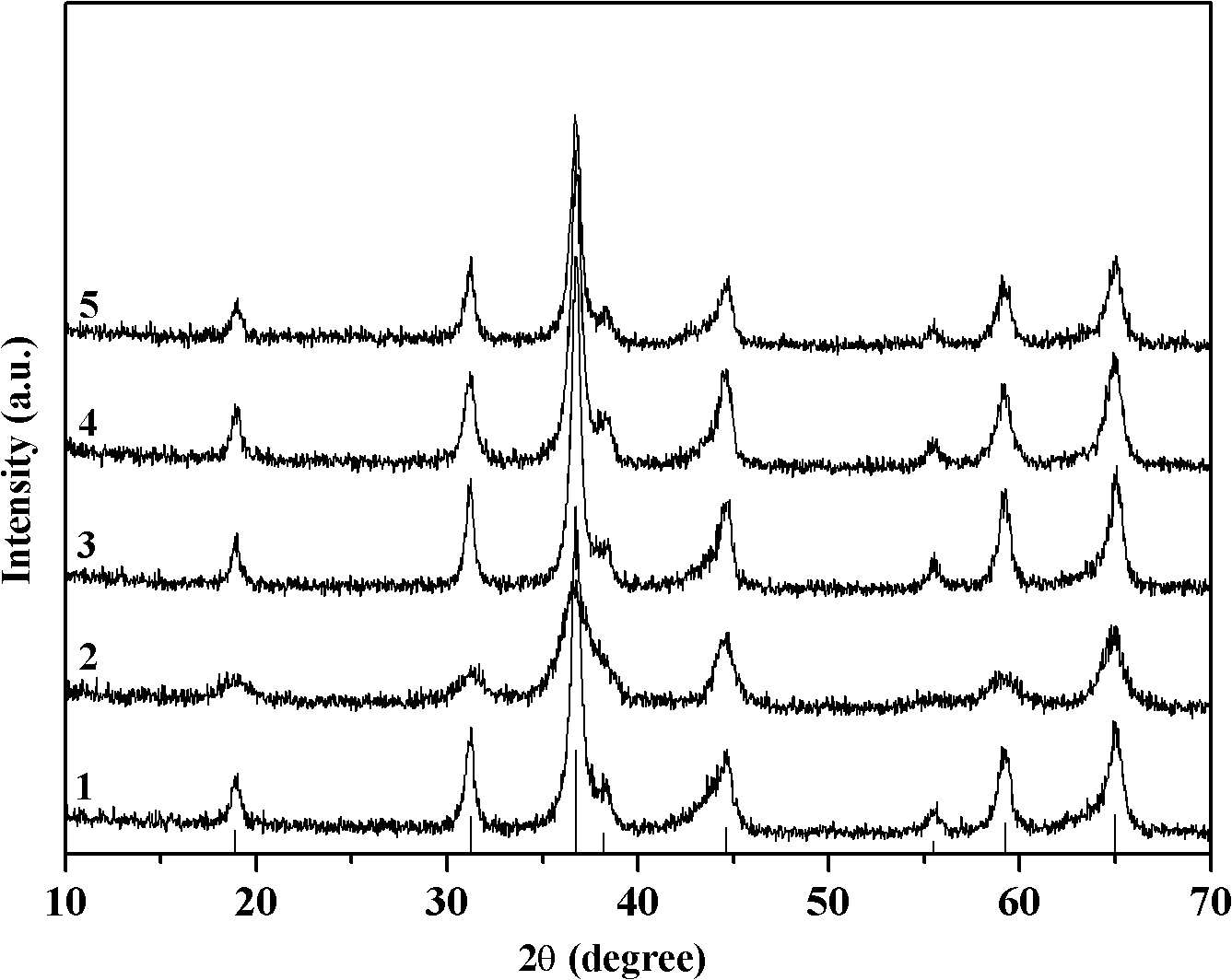

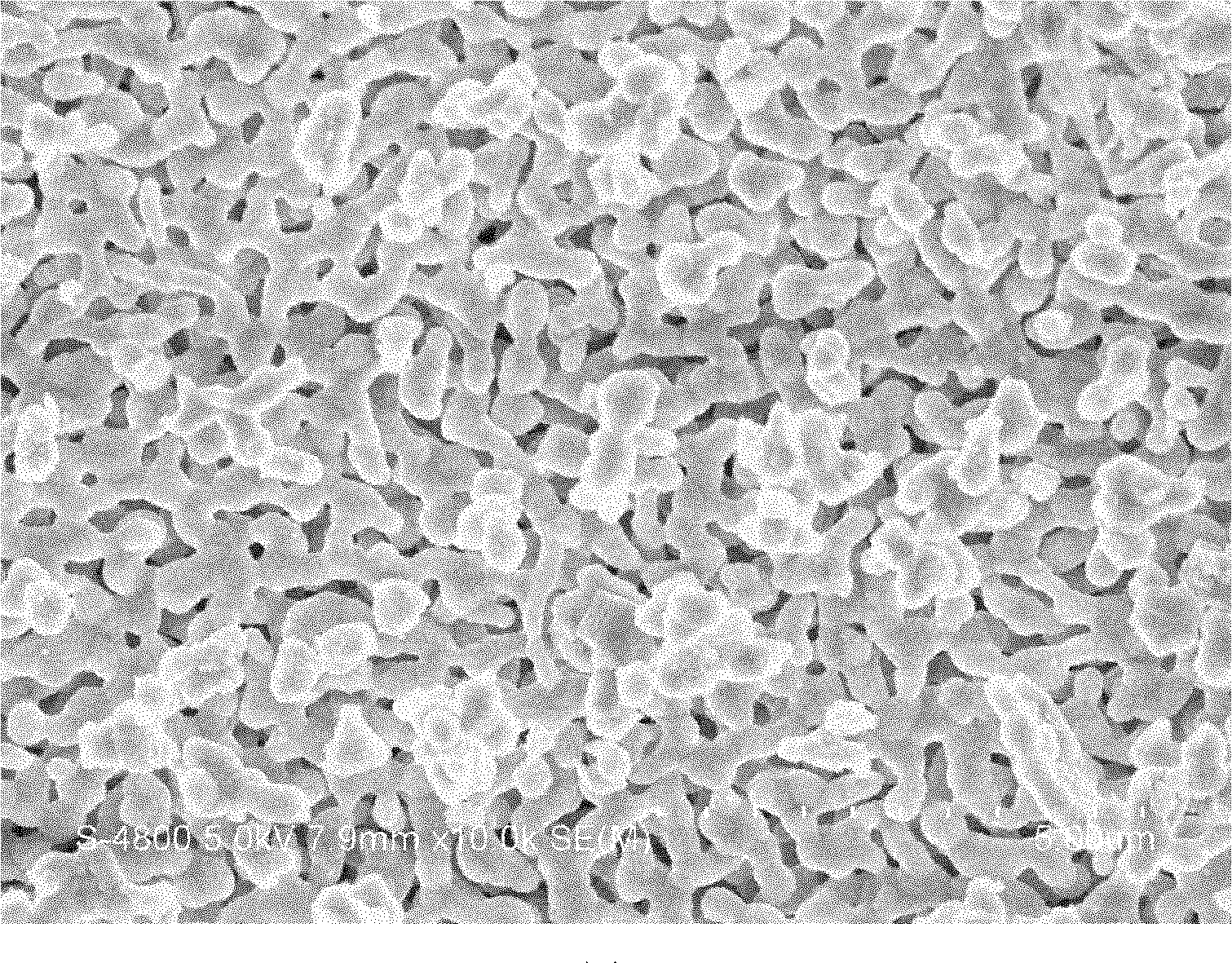

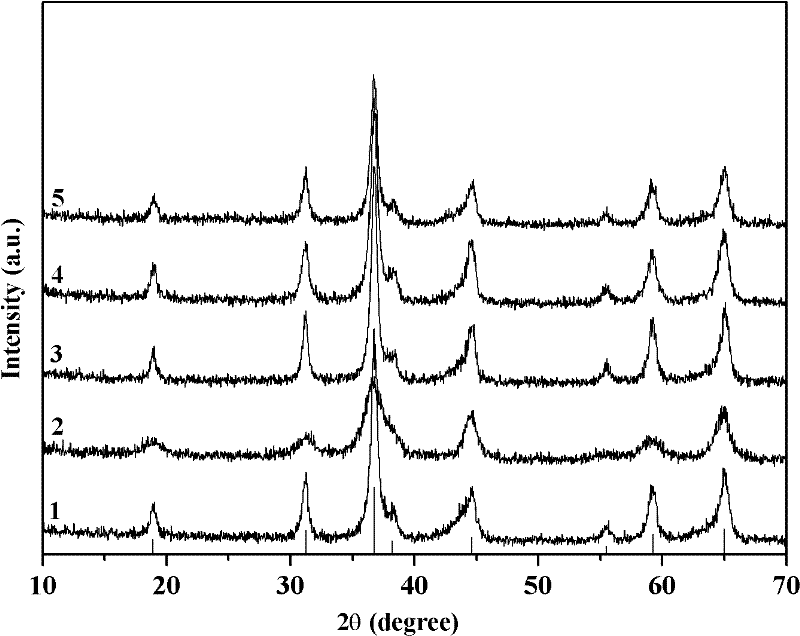

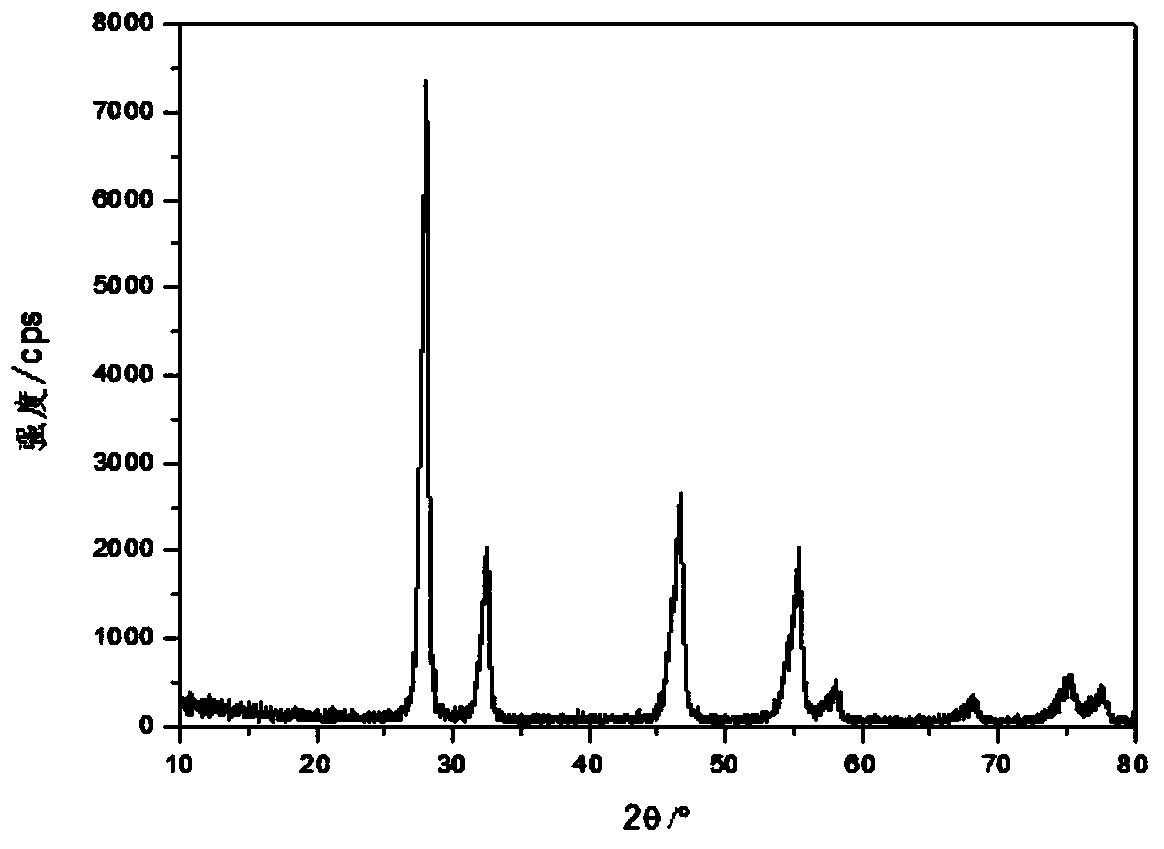

Sol-gel preparation method of porous nickel cobaltate material

The invention discloses a sol-gel preparation method of a porous nickel cobaltate material. The method comprises the following steps of: dissolving cobalt acetate and nickel acetate in distilled water to obtain acetate aqueous solution, adding citric acid aqueous solution, uniformly mixing, adding distilled water for diluting until the concentration of the cobalt acetate is between 0.016 and 0.05 mol / L to obtain diluted solution, and drying to obtain a precursor; and grinding and calcining the precursor to obtain the porous nickel cobaltate material. The method has a simple preparation process and is environmentally-friendly; and the obtained nickel cobaltate has a spinel cubic phase, high purity, high degree of crystallinity, uniform pore diameter distribution and the pore diameter size of less than 200 nanometers, and is porous.

Owner:HEFEI UNIV OF TECH

Sol-gel preparation method of porous nickel cobaltate material

The invention discloses a sol-gel preparation method of a porous nickel cobaltate material. The method comprises the following steps of: dissolving cobalt acetate and nickel acetate in distilled water to obtain acetate aqueous solution, adding citric acid aqueous solution, uniformly mixing, adding distilled water for diluting until the concentration of the cobalt acetate is between 0.016 and 0.05mol / L to obtain diluted solution, and drying to obtain a precursor; and grinding and calcining the precursor to obtain the porous nickel cobaltate material. The method has a simple preparation process and is environmentally-friendly; and the obtained nickel cobaltate has a spinel cubic phase, high purity, high degree of crystallinity, uniform pore diameter distribution and the pore diameter size of less than 200 nanometers, and is porous.

Owner:HEFEI UNIV OF TECH

Iron-based catalyst as well as preparation method and application thereof

ActiveCN108970614AImprove direct liquefaction catalytic activityPrevent compactionLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSlurryNitrogen gas

The invention provides an iron-based catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: 1) enabling iron-containing soluble salt solution to be mixed with alkaline aqueous solution and reacting, to obtain a slurry-state head product; 2) in an aerobic atmosphere, enabling the head product to be loaded on a solid carrier in a spraymode, performing crystal phase transition, to obtain a secondary product loaded with FeOOH on the surface of the solid carrier; and 3) in a nitrogen atmosphere, drying the secondary product, to obtain the iron-based catalyst. The provided preparation method for the iron-based catalyst is short in technological process, low in production cost, low in water consumption, and wastewater-free. The catalyst prepared by the preparation method is high in direct coal liquefaction catalytic activity.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

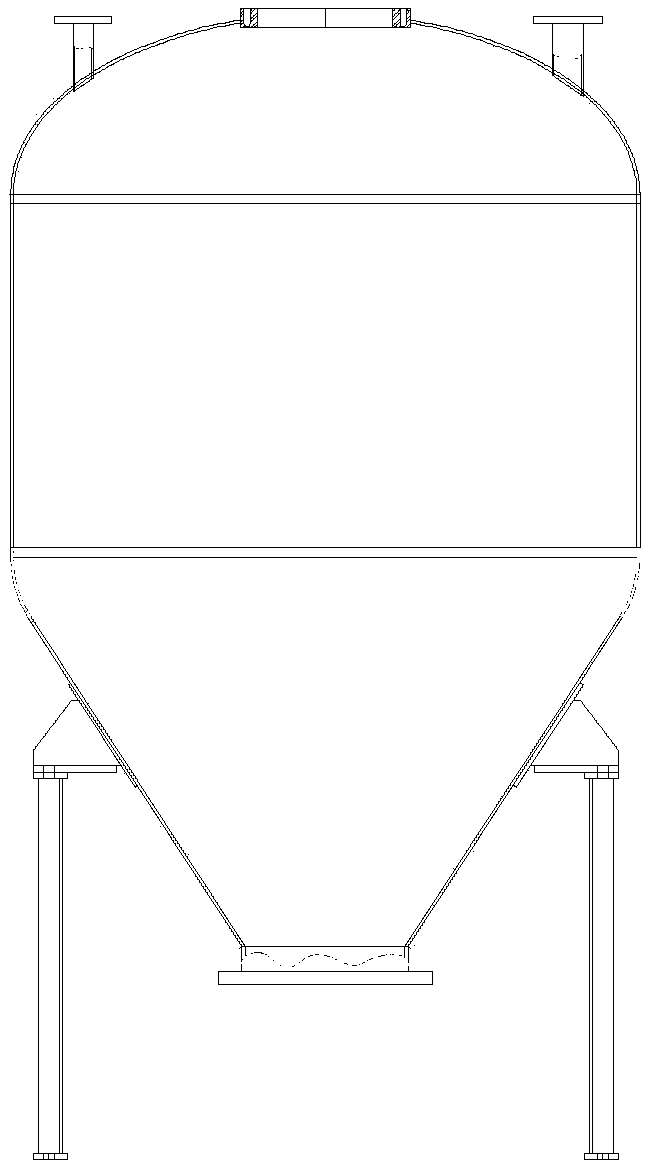

System for desulfurizing limestone in circulating fluidized bed boiler on basis of flow state reconstruction

InactiveCN103672874AExtend reaction residence timeImprove sulfur fixation effectFluidized bed combustionApparatus for fluidised bed combustionFluidized bedInlet valve

A system for desulfurizing limestone in a circulating fluidized bed boiler on the basis of flow state reconstruction comprises a hearth, a conveying mechanism, a storage bin mechanism and a pipeline, wherein the conveying mechanism comprises a temporary storage bin, a mixer and a fan; a temporary storage feed port and an exhaust port are formed in the upper part of the temporary storage bin; the storage bin mechanism comprises a storage bin, a warehouse top dust collector, a through pipeline, an electric heater and a fan; the system further comprises an air separator communicated with an exhaust gas outlet of the hearth, a return feeder, an air chamber arranged at the bottom of the hearth and led into the hearth from a primary air duct, secondary air pipes distributed on the front wall and the rear wall of the hearth, an inlet valve set communicated with the secondary air pipes and used for desulfurizing limestone in the boiler, a tail flue arranged at the top of the separator, as well as a return feeder leg integrated with the separator; the inlet valve set is connected with the mixer through the pipeline; and the return feeder is connected with the bottom of the return feeder leg. The system has the advantages that the structure is simple, the separation efficiency is high, discharging is facilitated and the like.

Owner:TAIYUAN BOILER GROUP +1

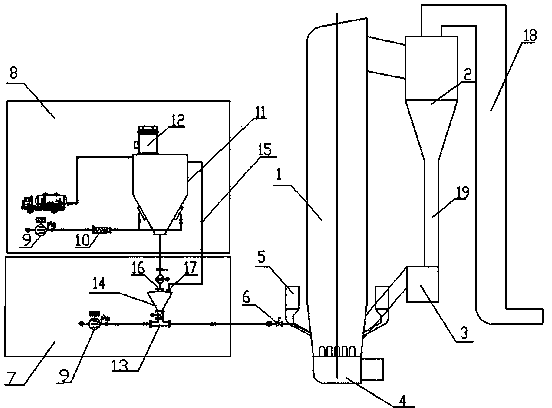

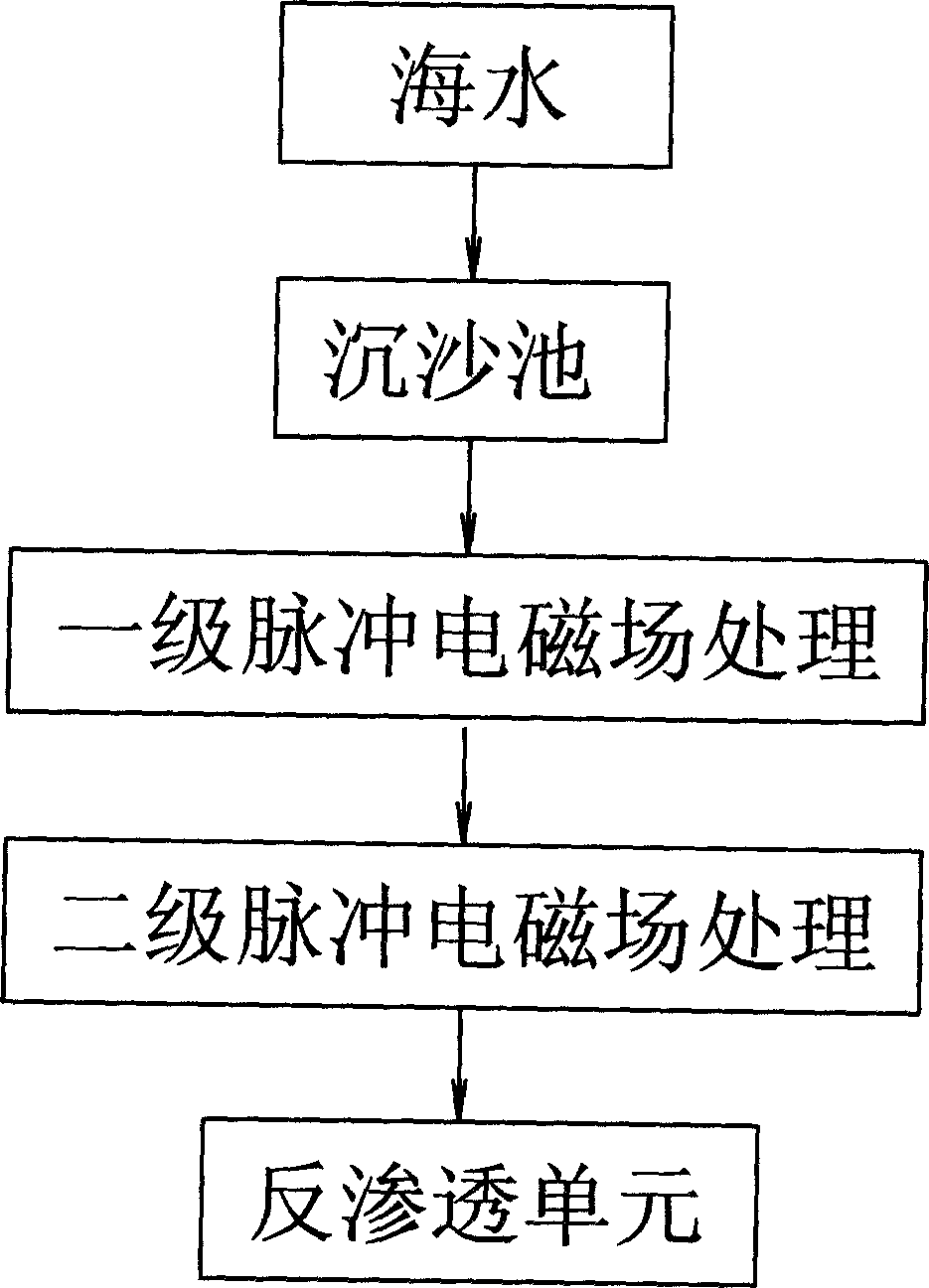

Pretreating method for reversing asmose seawater desalinating pulsing electromagnetic field

InactiveCN1613786AExtended service lifeShorten the preprocessing processGeneral water supply conservationWater/sewage treatment by magnetic/electric fieldsPretreatment methodReverse osmosis

A reverse osmosis seawater desalting pulsing electromagnetic field pretreatment is carried out by: passing seawater into the first and the second stage pulsing electromagnetic field treating apparatus by grit chamber, treating it there, and entering reverse osmosis unit at pulsing voltage 1-1000V and pulsing frequency 0.1-500Hz. Its advantages include low cost, no pollution, to improve water quality and decrease pretreatment process.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

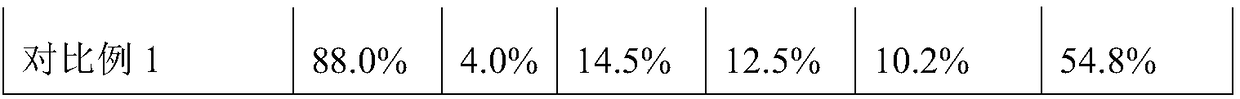

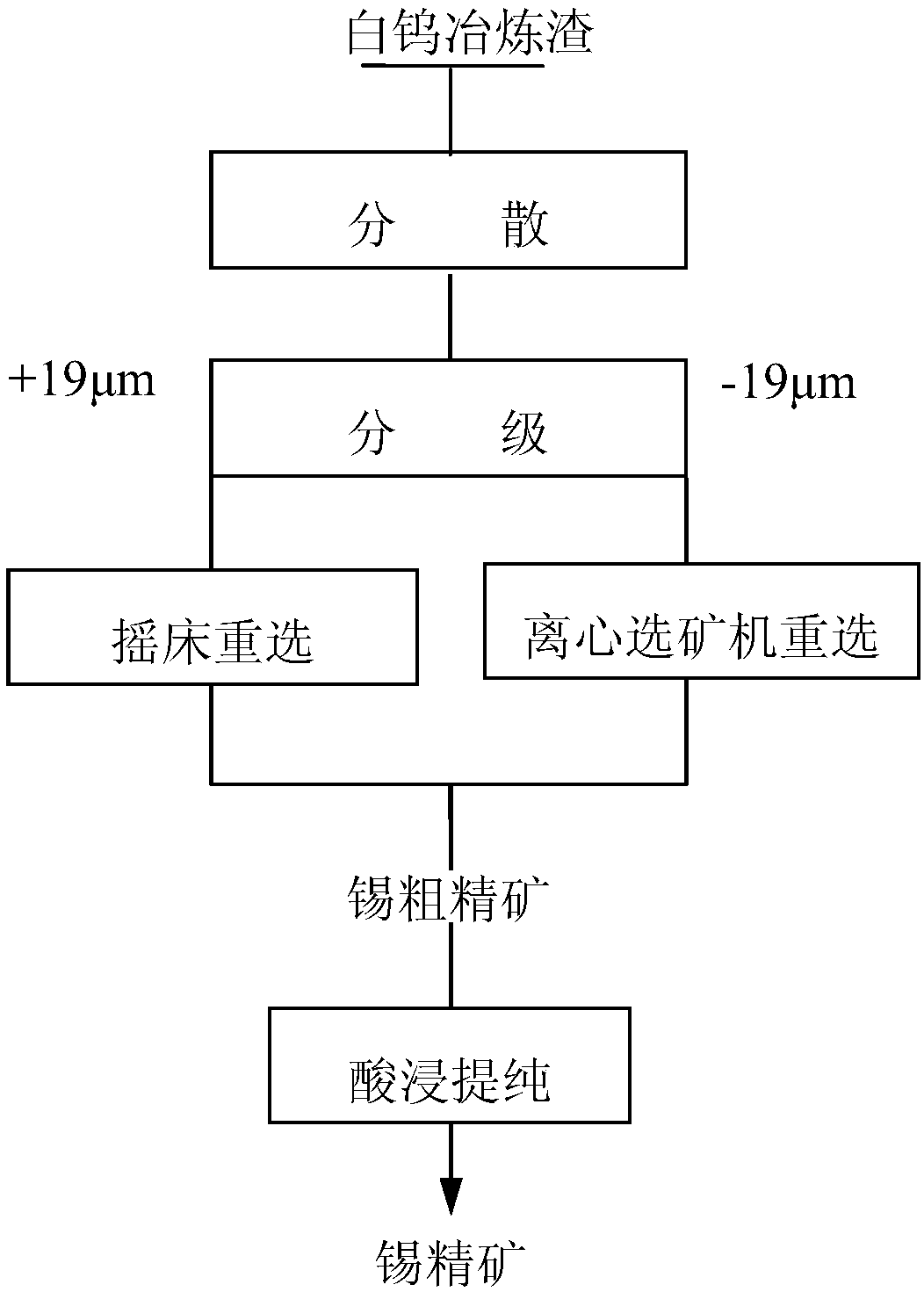

Method for recovering cassiterite from scheelite smelting slag

InactiveCN107858522ARaise the gradeHigh recovery rateProcess efficiency improvementWet separationSlagGravity separation

The invention belongs to the technical field of mineral recovery and particularly relates to a method for recovering cassiterite from scheelite smelting slag. According to the method, sodium polyacrylate is used as a micro-fine-grained cassiterite mineral dispersant, then micro-fine-grained cassiterite minerals are classified, then the classified micro-fine-grained cassiterite minerals are subjected to gravity separation and recovery through a micro-fine mud shaking table and a centrifugal separator, two kinds of coarse-grained cassiterite concentrates different in size fraction are obtained,finally the coarse-grained cassiterite concentrates are subjected to acid leaching purification, and tin concentrates are obtained. By the adoption of the method, the cassiterite can be recovered fromthe scheelite smelting slag, and the method is especially suitable for recovery of the micro-fined-grained cassiterite of negative 19 micrometers in the cassiterite smelting slag; the method is efficient, environmentally-friendly and free of waste water, and liquid in the gravity separation and acid leaching processes is used in a circulating manner; and the technological process is short, the number of equipment is small, the cassiterite recovery rate is high, and the industrial application investment cost is low.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Liquid soap

InactiveCN103834511AEasy to operateLow costSurface-active non-soap compounds and soap mixture detergentsBenzoic acidStearic acid

The invention relates to the field of articles for daily use and particularly relates to liquid soap. The liquid soap is prepared by the following steps of: mixing sodium hydroxide and water, adding the mixture into a reactor, stirring and heating to 68 DEG C, adding lauric acid and oleic acid while stirring, gradually adding mixture of ethylene-glycol monoester stearate and lauroyl diethanolamide after stirring uniformly, after fully stirring and complete reaction, adding ethylenediamine tetraacetic acid and methyl parahydroxybenzoats when the temperature is reduced to 50 DEG C, and finally adding a proper amount of glycerinum and a proper amount of essence. The mass ratio of the materials such as sodium hydroxide, lauric acid, oleic acid, ethylene-glycol monoester stearate, lauroyl diethanolamide, ethylenediamine tetraacetic acid and methyl parahydroxybenzoats is 1:8:1.5:6:1.5:5:0.5.

Owner:马俊杰

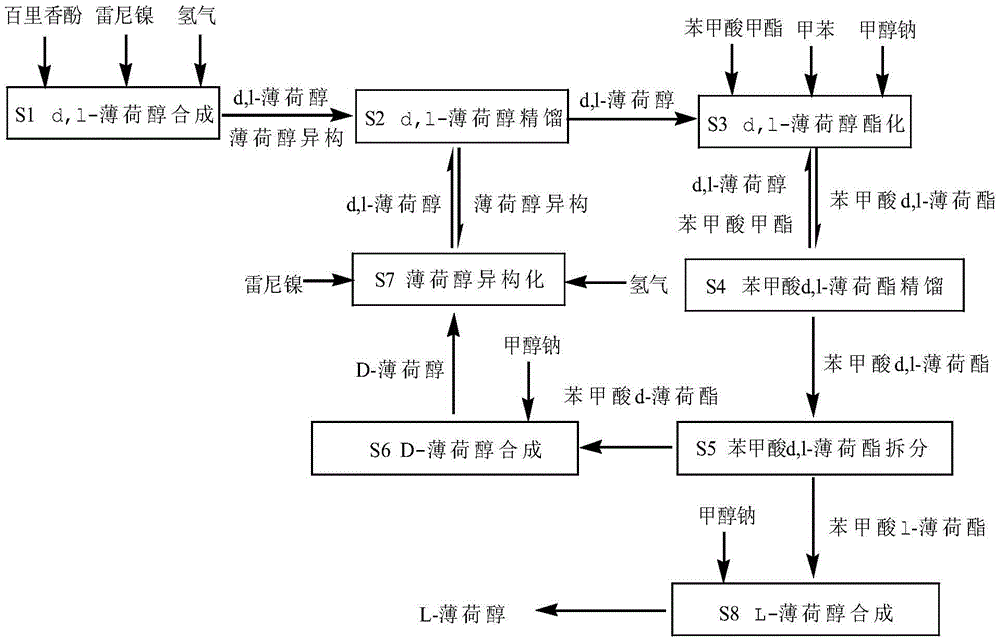

A synthetic process of L-menthol

ActiveCN105461516AHigh yieldLow costOrganic compound preparationPreparation by hydrogenationBenzoic acidIsomerization

The invention relates to the field of spice synthesis and particularly relates to a synthetic process of L-menthol. The process includes steps of d,l-menthol synthesizing, d,l-menthol rectification, d,l-menthol esterification, d,l-menthyl benzoate rectification, d,l-menthyl benzoate resolution, D-menthol synthesizing, menthol isomerization and L-menthol synthesizing. The process adopts thymol that is a simple, easily available and cheap chemical product as a raw material. Esterification conditions are optimized and the esterification and rectification are performed at the same time so as to allow the esterification to be converted into a way beneficial to d,l-menthyl benzoate production, thus increasing the esterification yield. Crystallization and resolution are optimized by utilization of the d,l-menthyl benzoate. Preparation of the L-menthol by the process is characterized by being high in yield, low in cost, simple and convenient in operation, suitable for continuous and large-scale production, and the like. According to the process, operation of the process is cyclic with a whole system being sealed, and the process is free of waste water, energy-saving and environmental friendly.

Owner:ANHUI HAIHUA CHEM

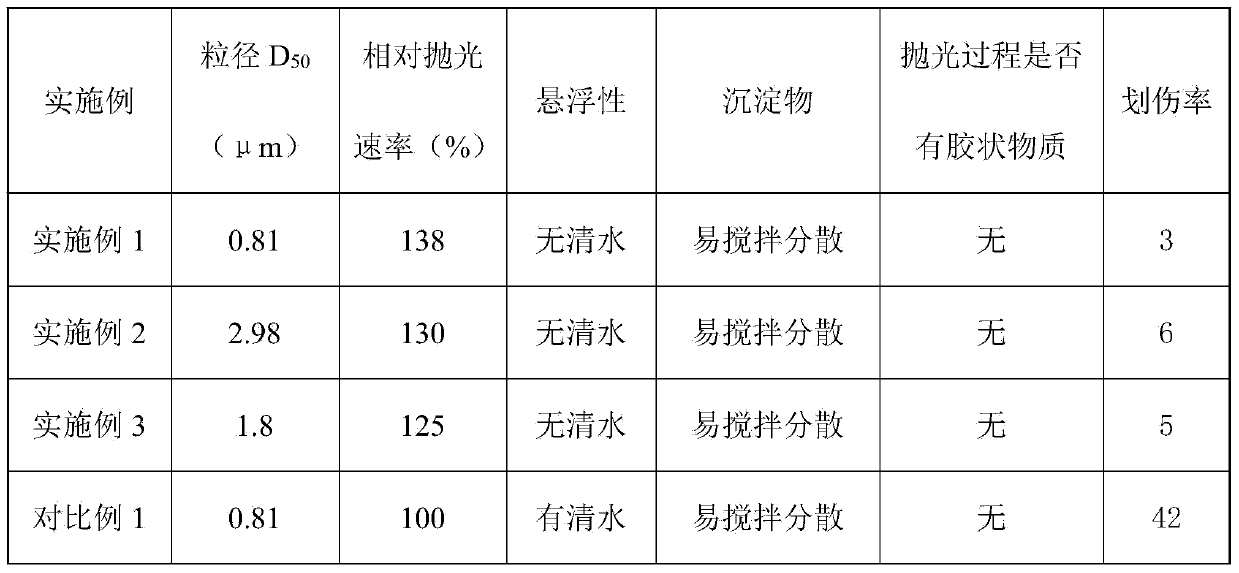

Cerium oxide polishing powder and preparation method thereof

ActiveCN103740329AControl pH changesGood suspensionOther chemical processesPolishing compositions with abrasivesPhosphateWastewater

The invention discloses cerium oxide polishing powder and a preparation method thereof. The cerium oxide polishing powder is characterized by consisting of cerium oxide and phosphate, wherein the weight content of phosphate is 3-15% of the amount of cerium oxide. Compared with the conventional preparation method, the preparation disclosed by the invention has the advantages of simple process, low cost and no generation of wastewater as the polishing powder is cerium oxide polishing powder and no F is introduced in the preparation process; and the cerium oxide polishing powder has the advantages that a product is not scratched in the polishing process of the product, the polishing precision is high and the like.

Owner:方复(上海)新材料科技有限公司

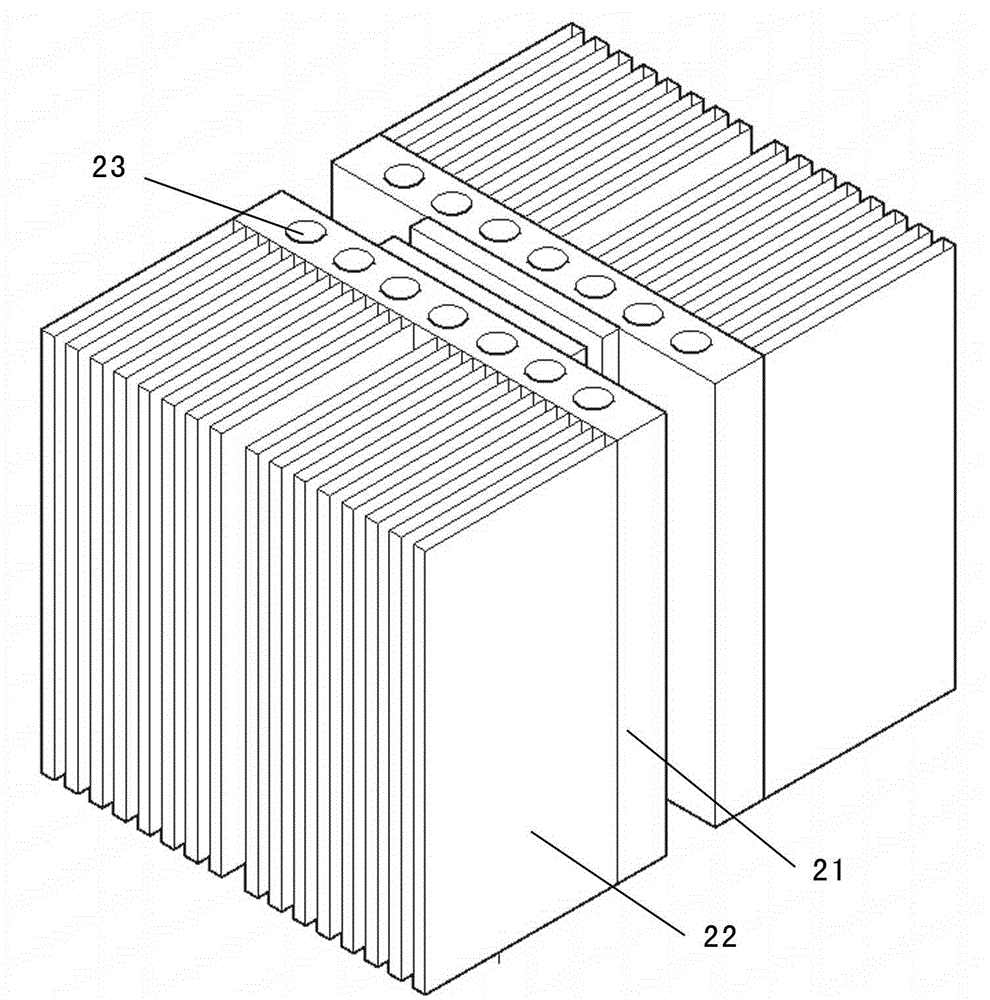

Sealed rack environment controller

ActiveCN104881069AThe principle of the device is simpleCompact equipmentSimultaneous control of multiple variablesAir cleaningEnvironment controlled

The invention relates to a sealed rack environment controller including an air cleaning device, a temperature adjusting device, a humidifying device, an automatic opening-closing device, a base and a control panel. The air cleaning device performs purifying processing on the air in a sealed rack, the temperature adjusting device regulates and controls the temperature in the sealed rack, the humidifying device generates water steam to humidify the air in the sealed rack, the automatic opening-closing device controls the opening and closing of the sealed rack, the humidifying device is arranged on the base, and the control panel integrally detects, regulates, and controls the work conditions of the air cleaning device, the temperature adjusting device, the humidifying device, and the automatic opening-closing device. The sealed rack environment controller accurately controls the temperature, humidity, and dust granularity of the inside environment of the sealed rack and makes the inside environment be the ideal environment for various precision apparatuses and electric appliances.

Owner:兖矿中科清洁能源科技有限公司

Method for extracting corn straw modified fine fibers by machinery-chemistry combined method

InactiveCN109162131AEfficient extractionRealize energy saving and environmental protectionRaw material divisionCombined methodSugar

The invention relates to the technical field of crop processing devices, in particular to a method for extracting corn straw modified fine fibers by a machinery-chemistry combined method. The method comprises the following steps: increasing the water content of corn straw crude fibers to at least 70% by a water soaking mode; draining off water, then carrying out fiber separation through a stacked-screw fiber rolling and separating machine, and separating the crude fibers into fine fibers through a mechanical method; placing the fine fibers in a biological purification machine, and removing saccharide small molecules which are located among the fine fibers and are attached to the surfaces of the fine fibers through sugar-loving microorganisms to obtain biologically modified fibers; inactivating the biologically modified fibers through a steam heating mode; then carrying out dehydration through a rolling dehydrator to obtain the corn straw modified fine fibers; and packing and transporting the corn straw modified fine fibers. The quality of the straw modified fine fibers is guaranteed, the separation efficiency is improved, and energy conservation and environmental protection are achieved. The invention further provides complete equipment which is used for extracting the corn straw modified fine fibers and has occupies a small area.

Owner:JILIN UNIV

Method for synthesizing carbamazepine

Provided is a method for synthesizing carbamazepine. The method comprises the steps that 1 part by weight of iminostilbene and 10 parts by weight of benzene are put into a glass lining reaction vessel of 1,000 L to be dissolved, and the materials react with 0.7 part of triphosgene for 5 h to 6 h at 70 DEG C to 80 DEG C after being dissolved to enable all the materials to react completely; 2 / 3 of benzene is distilled off through reduced pressure distillation, suction filtration is conducted after cooling is conducted, the materials are put into a drying oven or a drying room to be dried for 3 h to 4 h at 60 DEG C after being filtered, iminostilbene carbonyl chloride is obtained and put into a glass lining reaction vessel of 1,000 L, 15 parts of 95% ethyl alcohol is added, the materials are dissolved in the glass lining reaction vessel, 0.8 part of liquid ammonia is dropwise added, reacting is conducted for 8 h at 50 DEG C to 60 DEG C, heat preservation is conducted for 30 min, all the materials are cooled to room temperature, 1%-3% by weight of activated carbon is added, the temperature is increased to 78 DEG C, decoloration is conducted for 2 h, a mother solution is subjected to hot filtration, residues are discarded, and the mother solution is sent back to the glass lining reaction vessel; 1 / 2 of ethyl alcohol is distilled off, after cooling is conducted, natural crystallization and suction filtration are conducted, a crystal substance obtained after filtration is conducted is put into the drying oven or drying room to be dried for 3 h to 4 h at 60 DEG C, and the finished carbamazepine product is obtained. The yield ranges from 82% to 90%, and the content ranges from 91.5% to 99.1%.

Owner:陈建国

Preparation method of environment-friendly wall surface sealing glue for building

ActiveCN104178061AImprove interface adhesionHigh bonding strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesBasementLayer interface

The invention discloses a preparation method of environment-friendly wall surface sealing glue for a building, relating to the technical field of building appliances. The preparation method comprises the steps of in a stirring tank A, dissolving PVA into water according to a proportion that 850kg of water is added in150kg of PVA, heating to 90 DEG C within about 1.5 hours while stirring, preserving the heat for half an hour, and then, cooling to 50 DEG C; in the stirring tank B, simultaneously and sufficiently dissolving boric acid and sodium benzoate in water; and in the stirring tank C, (1) adding 75-85% of water, (2) simultaneously pouring 10-15% of products in the stirring tank A and VAE into water, mixing and dissolving the products in the stirring tank A, VAE and water, and stirring for 30 minutes; and (3) pouring 0.025% of defoaming agents, 0.025% of emulsifiers and 0.2% of thickening agents at one step to dissolve, and uniformly stirring. By using the preparation method, the adhesive force of a smooth basement layer interface can be increased, the bonding strength is high, the cement galling process is firm and reliable, hollowing is avoided, and no waste gas, waste water and waste power consumption are generated in the production process.

Owner:山东韩师傅新材料有限公司

Production process of acetamiprid

InactiveCN107501172ALess by-productsCondensation reaction is simpleOrganic chemistrySolventAcetamiprid

The invention discloses a production process of acetamiprid. The production process comprises the following steps: (1) amination: adding a solvent into an amination reaction kettle, reducing the temperature, introducing a certain quantity of monomethylamine gas into the solvent, controlling under certain temperature conditions, adding 2-chloro-5-chloromethylpyridine into the reaction kettle, reacting, increasing the temperature for amine discharge, then reducing the temperature, filtering, filtering out methylamine hydrochloride, removing the solvent from a filtrate and transferring to the next step; and (2) condensation: controlling a material obtained from the above step under certain temperature conditions, dropwise adding ethyl N-cyanoethanimideate, reacting, reducing the temperature, filtering, obtaining the acetamiprid, drying, distilling a filtrate and recovering ethanol. The production process disclosed by the invention is high in amination reaction yield, simple in post-treatment, incapable of producing wastewater, simple in condensation reaction, high in yield and free from wastewater production.

Owner:JIANGSU CHANGQING AGROCHEMICAL CO LTD

Method for vanadium extraction through leaching and extracting

InactiveCN107619954ANo high temperature sectionMild conditionsProcess efficiency improvementThree stageWastewater

The invention relates to the technical field of wet metallurgy, in particular to a method for vanadium extraction through leaching and extracting. A leaching work section and an extracting work section are included, and a vanadium-containing product is obtained through evaporation concentration after three-stage reverse flow leaching and extracting. The method for vanadium extraction through leaching and extracting has the beneficial effects that high-temperature ore burning is not needed, poisonous gas such as hydrogen chloride and chlorine is not generated, a high-temperature section is omitted, the condition is mild, and energy is saved; water is recycled, and waste water is avoided; ozone oxidation is used, the oxidation effect is good, and oxidation products do not generate pollution;and an inductive agent is used, and the leaching efficiency is improved.

Owner:ZHONGFANLIAN TECH DEV CO LTD

Packaging box sticky folded surface processing method

InactiveCN101224644AExcellent adhesionHigh quality sticky effectContainer making machineryAdhesiveEngineering

The invention provides a bonding surface disposal method of a packing box. The surface of the bonding position of the packing box is disposed by a low-temperature plasma before the bonding is achieved by an adhesive. The method can effectively reinforce the bonding of the packing box, gains the bonding effect with high quality, and is safe and protects the environment.

Owner:SHENZHEN NINE STARS PRINTING & PACKAGING GRP

Magnesium sulfate and manufacturing method thereof

The invention discloses a magnesium sulfate and a manufacturing method thereof, and the magnesium sulfate has the chemical molecular formula of MgSO4. nH2O, wherein n is arbitrary value in 0.0-5.0. The magnesium sulfate is manufactured by the steps of: 1. gradually and evenly adding chemical by-product sulfuric acid, industrial concentrated sulfuric acid, water and magnesium oxide powder into a reaction mixer to be fully stirred and mixed together for chemical reaction, preparing into slurry, and determining the adding quantity of the industrial concentrated sulfuric acid and the water according to the concentration of the chemical by-product sulfuric acid; and controlling the dry degree of the reaction slurry and the temperature at an outlet; 2. further reacting and curing the prepared slurry obtained by the reaction, drying and solidifying the slurry by the self reaction heat, and maintaining the solidifying time within 20-180min; and 3. shaping, cooling and packaging the cured material, and obtaining the magnesium sulfate. The invention is manufactured by comprehensively utilizing the chemical by-product sulfuric acid as raw materials, has high production efficiency and no pollution, and is economical, energy-saving and environment-friendly, and the manufactured magnesium sulfate has high cost performance.

Owner:陈玉芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com