Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Compact equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

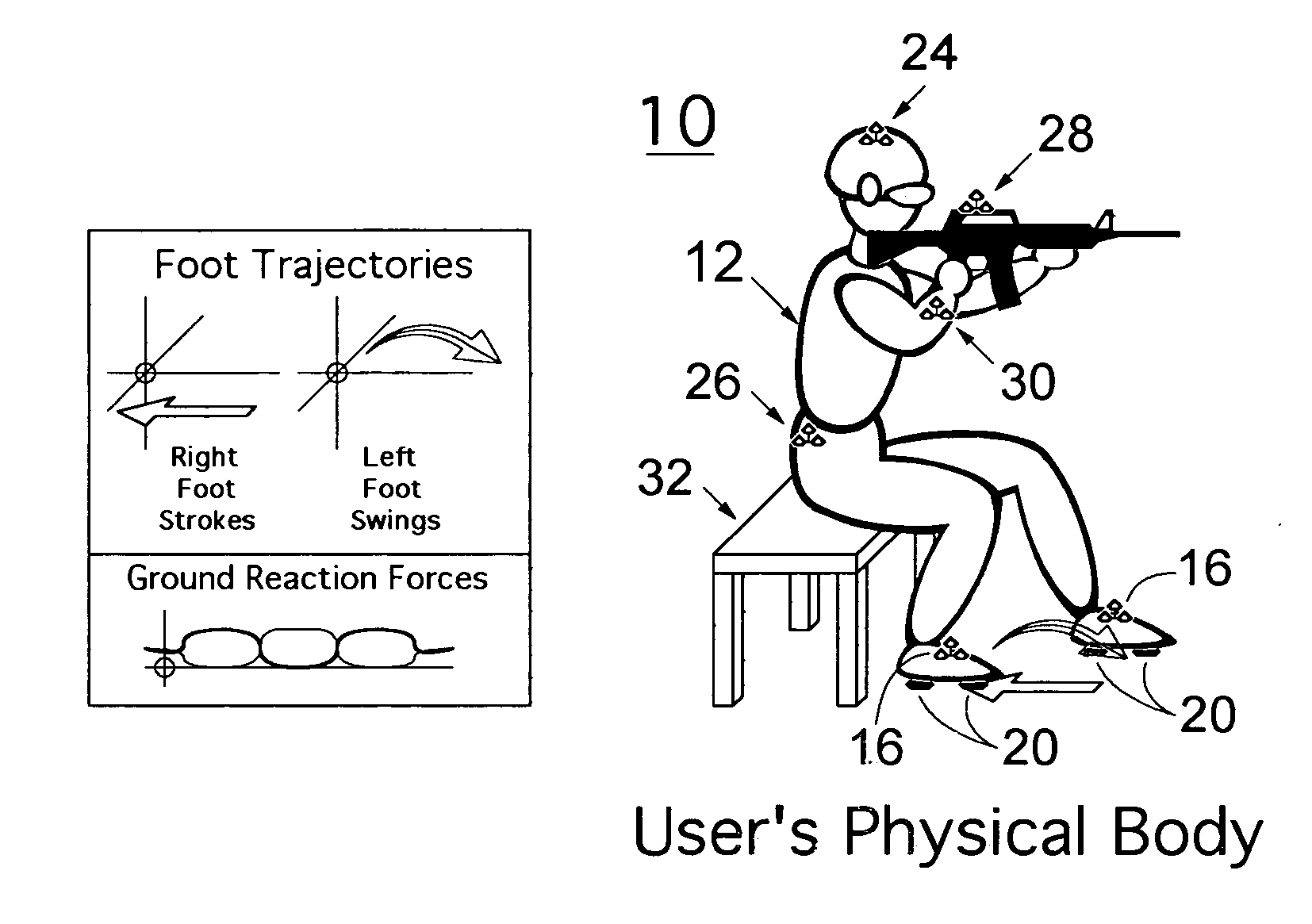

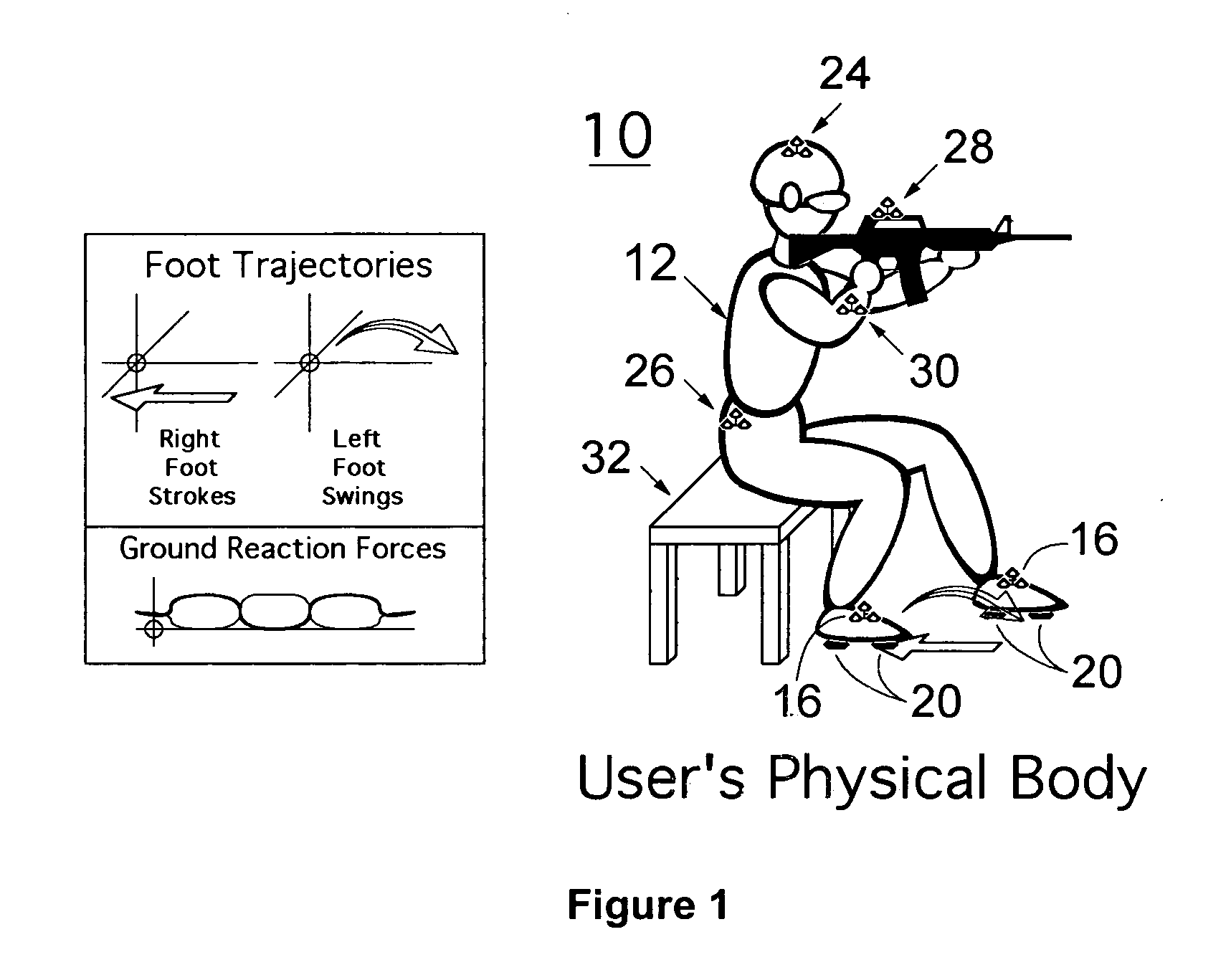

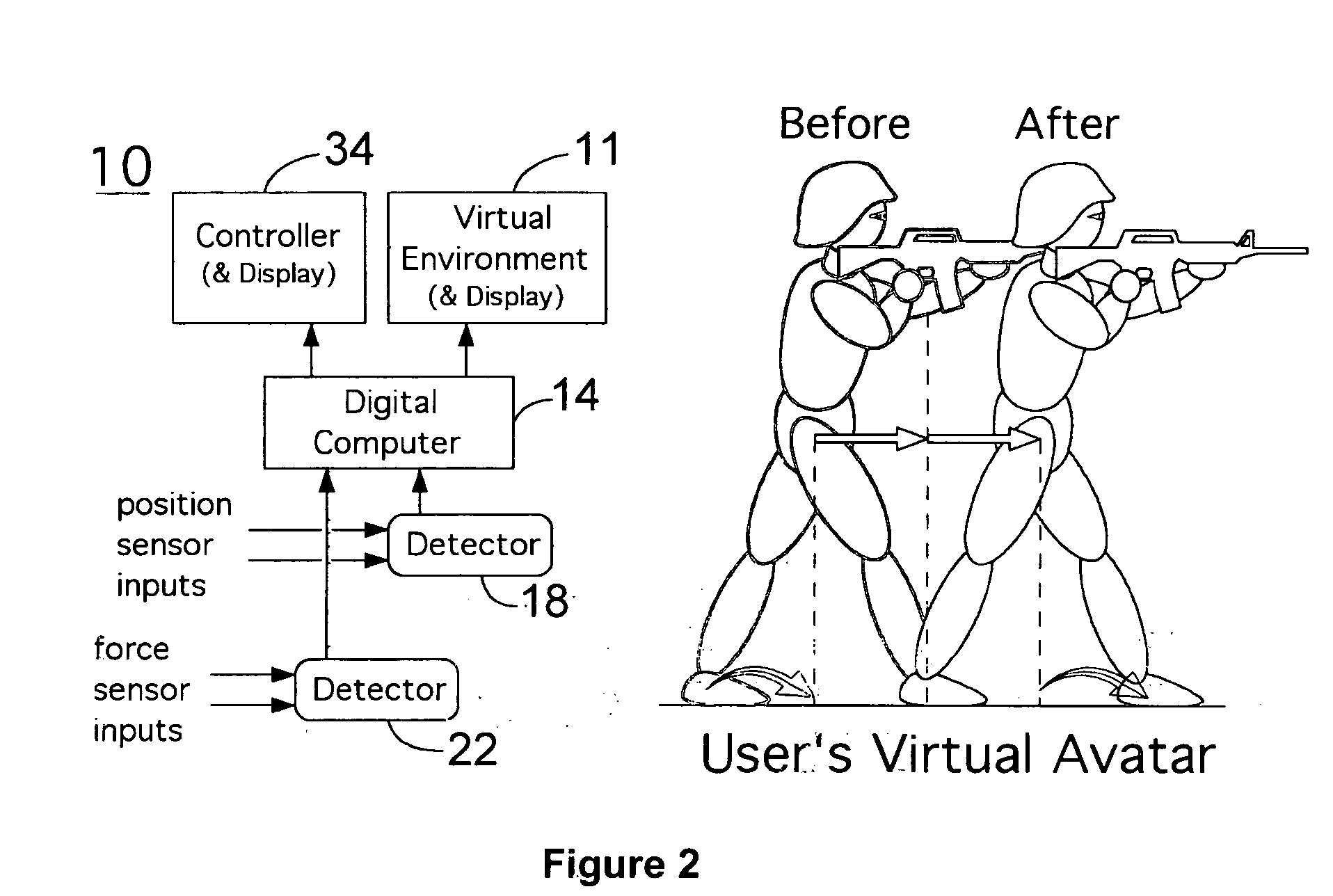

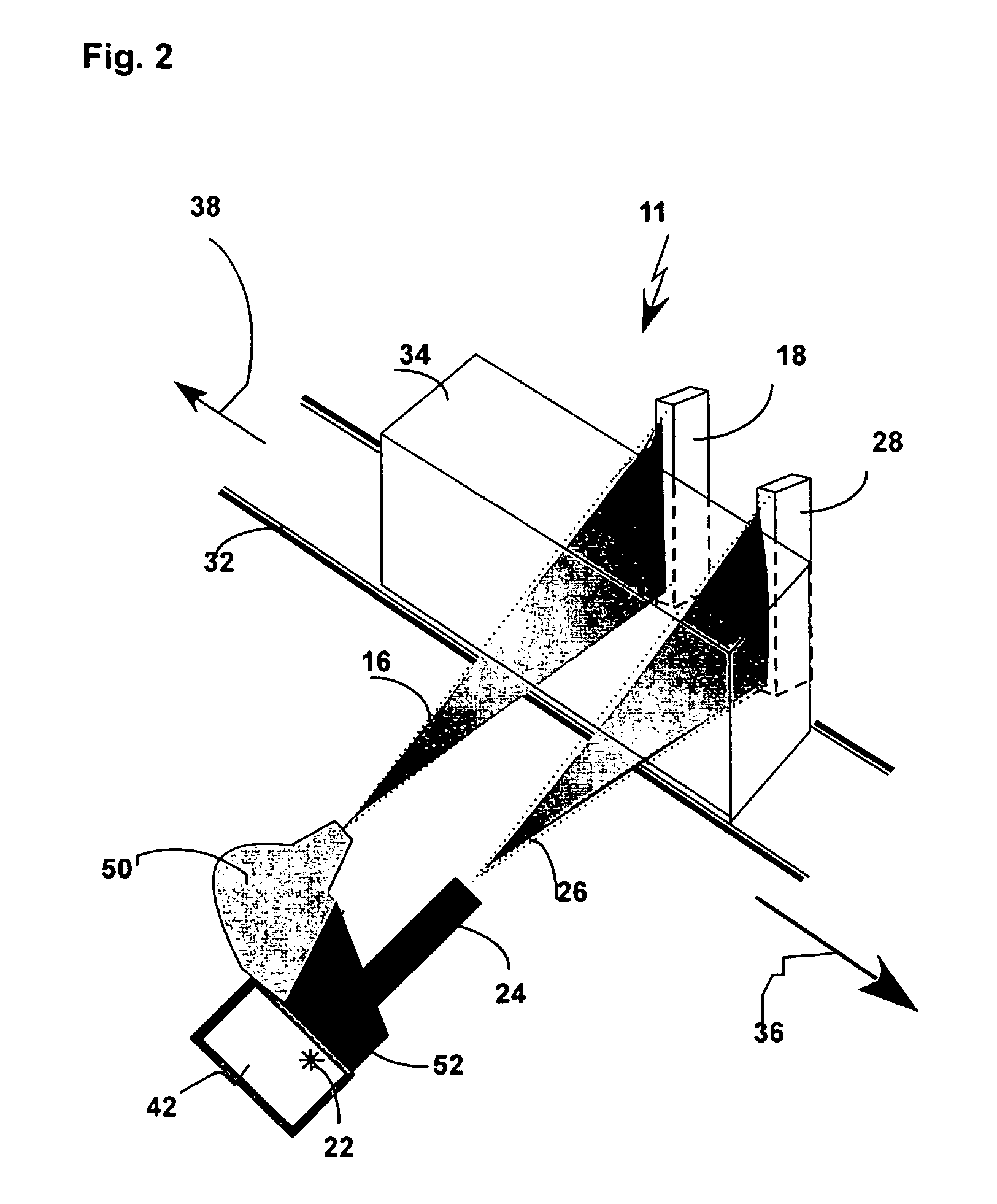

Simulated locomotion method and apparatus

InactiveUS20070003915A1Reduced footprintReduces vertical extentCosmonautic condition simulationsAnimationVirtual locomotionHuman–computer interaction

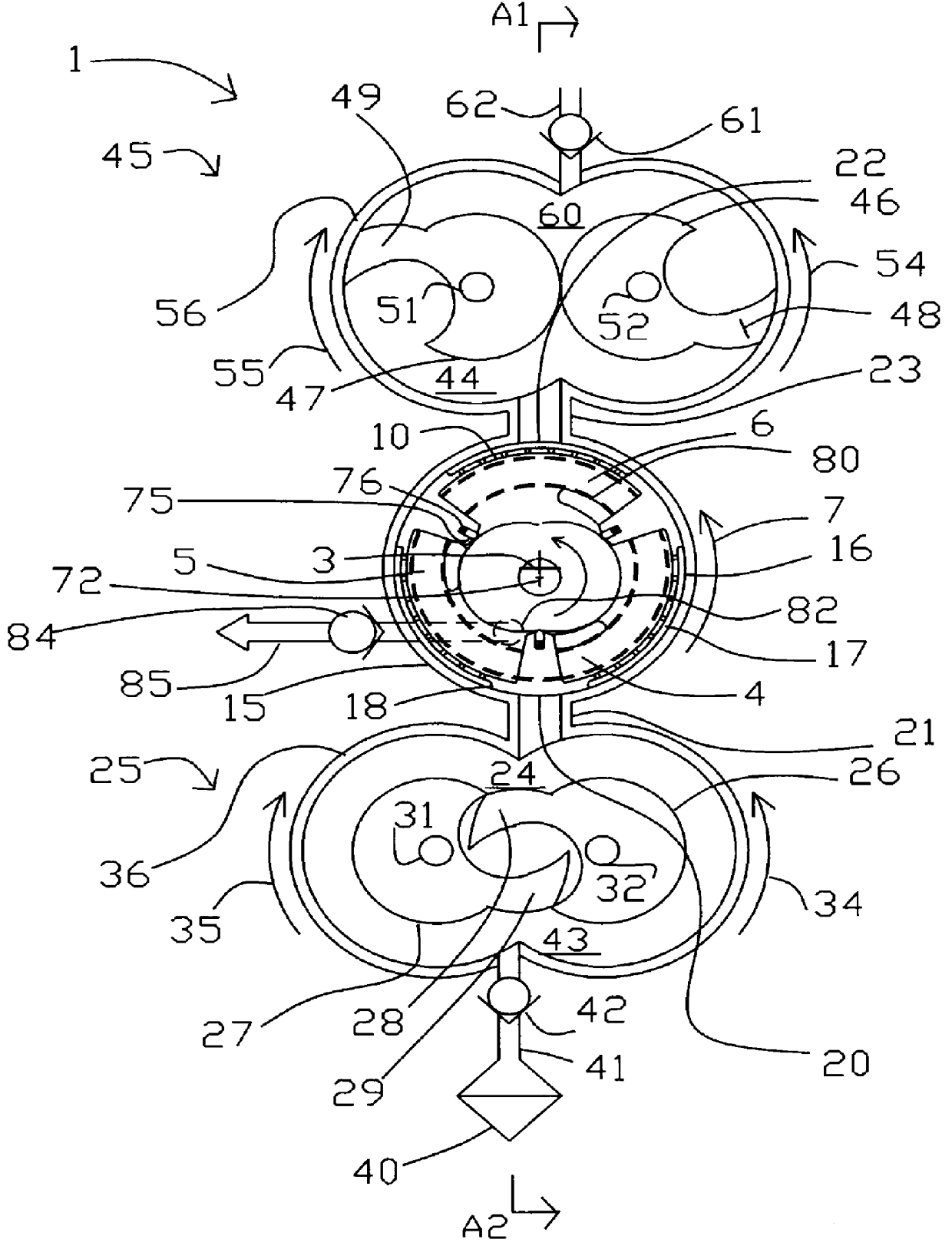

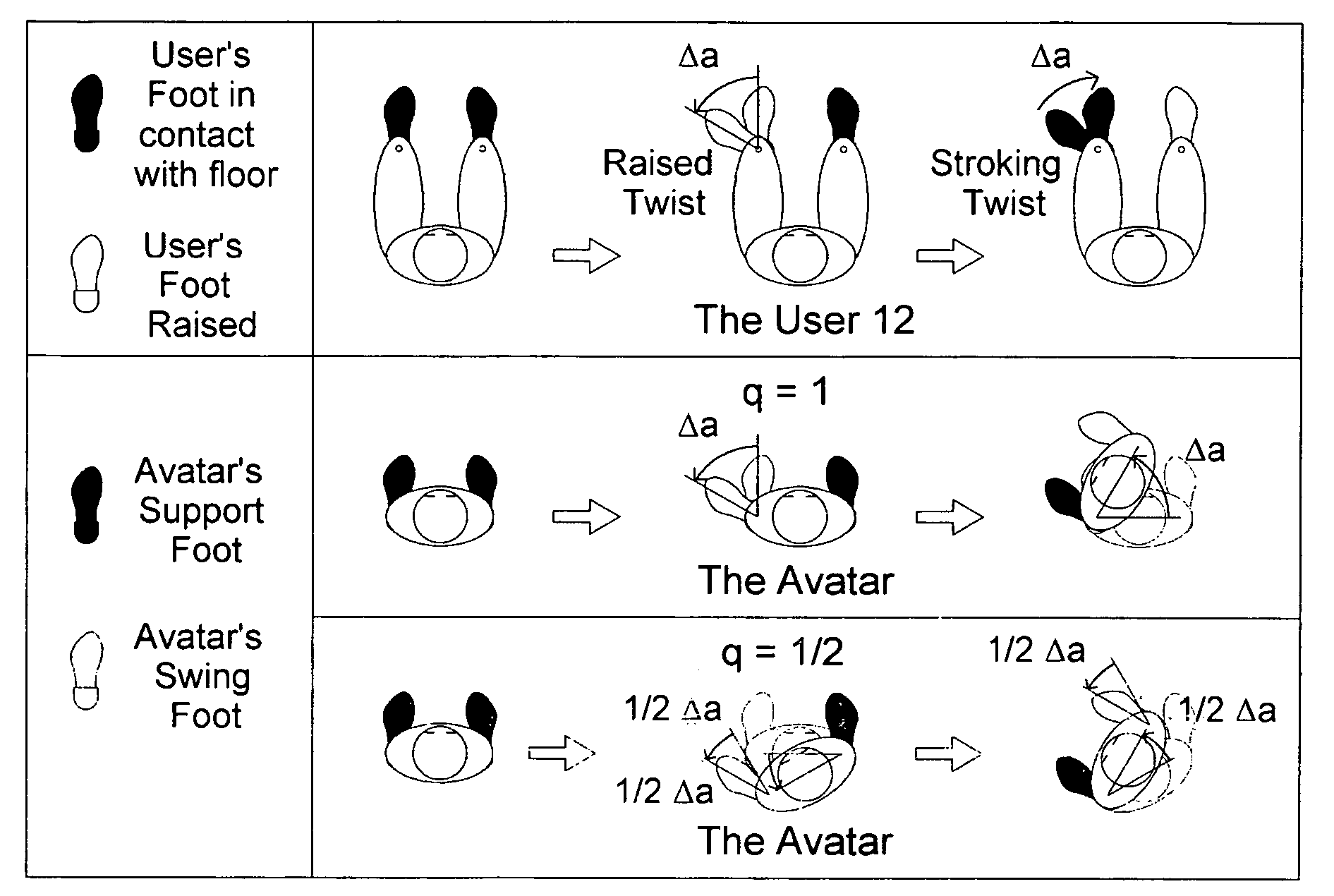

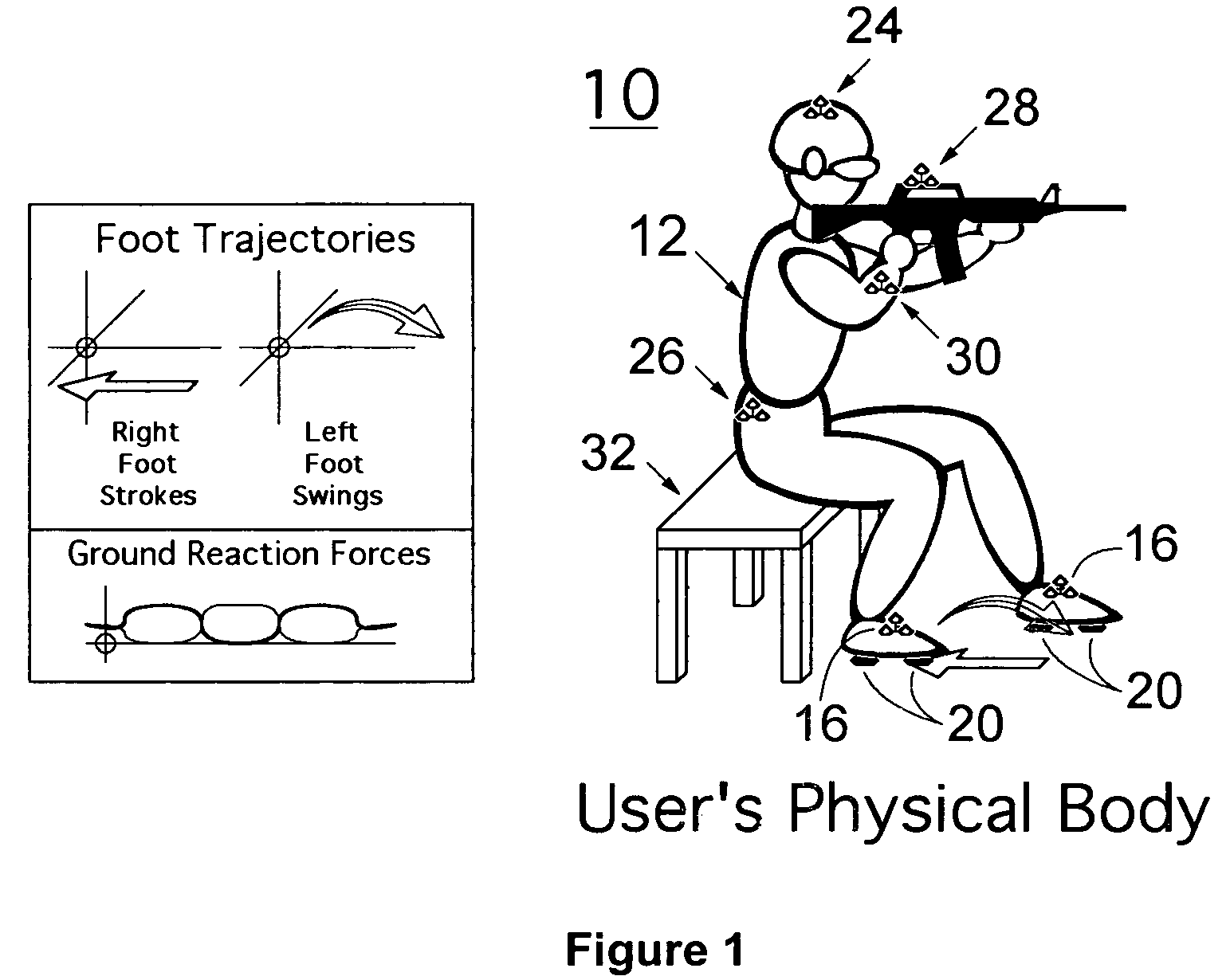

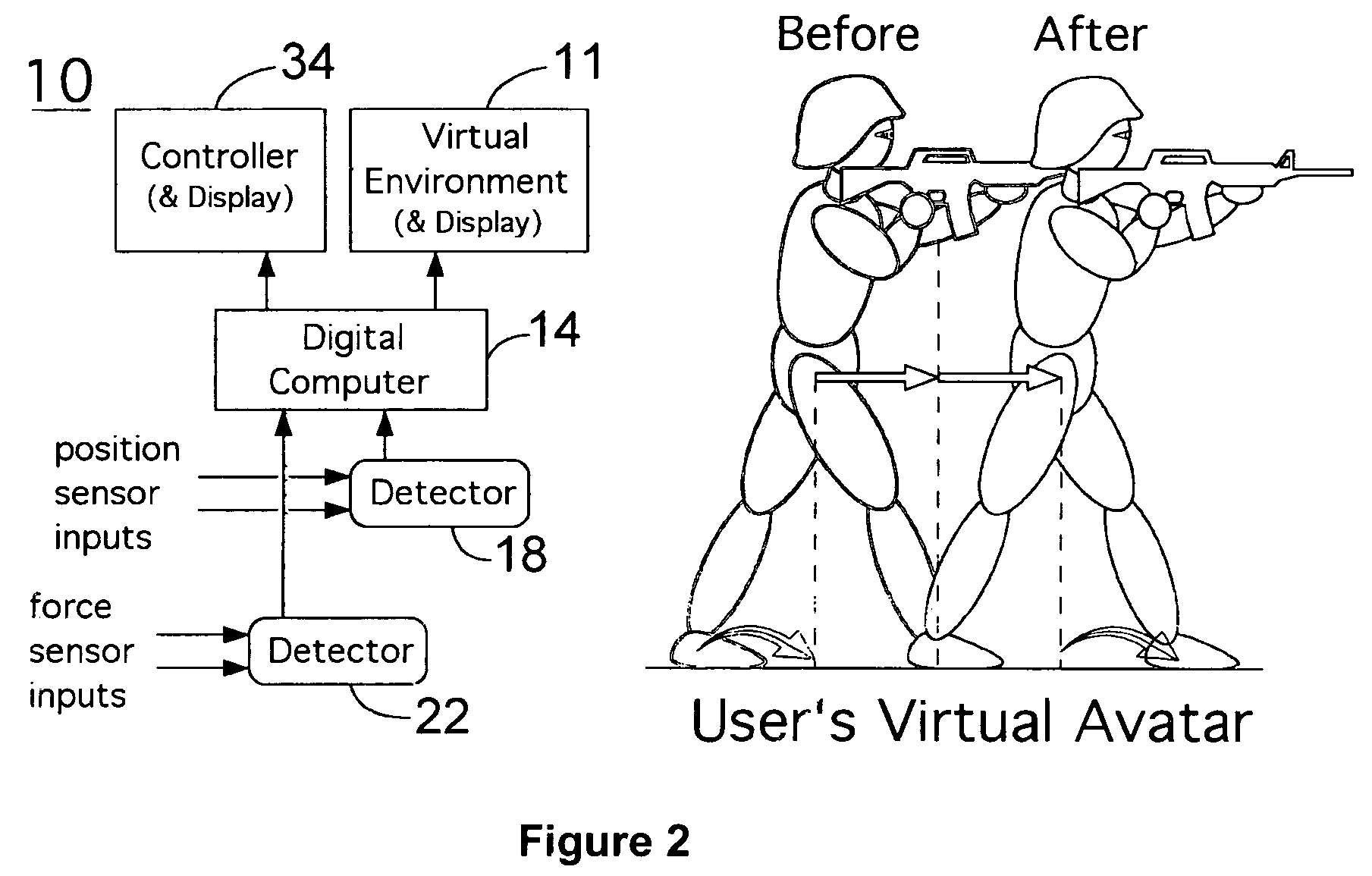

An apparatus for interfacing 3D movements of a user to control the locomotion of an avatar in a virtual environment includes a position tracker for tracking the position of a user's feet, with the foot motions including swinging and stroking; a computer programmed for (i) computing a direction and extent of motion of a reference in the virtual environment based on the foot positions and (ii) providing an avatar corresponding to the computed direction and extent of motion; and a display for displaying the avatar in the virtual environment. The apparatus accordingly uses the gestural motion of the user's feet while seated to simulate natural human locomotion. The gestural motions of stroking and swinging include translational and rotating movements, and are chosen to correspond to the actions of the feet and legs during natural human locomotion, providing natural control of virtual locomotion. The apparatus is also designed for controlling the locomotion of a remote vehicle.

Owner:USA AS REPRESENTED BY THE SEC OF THE NAVY THE

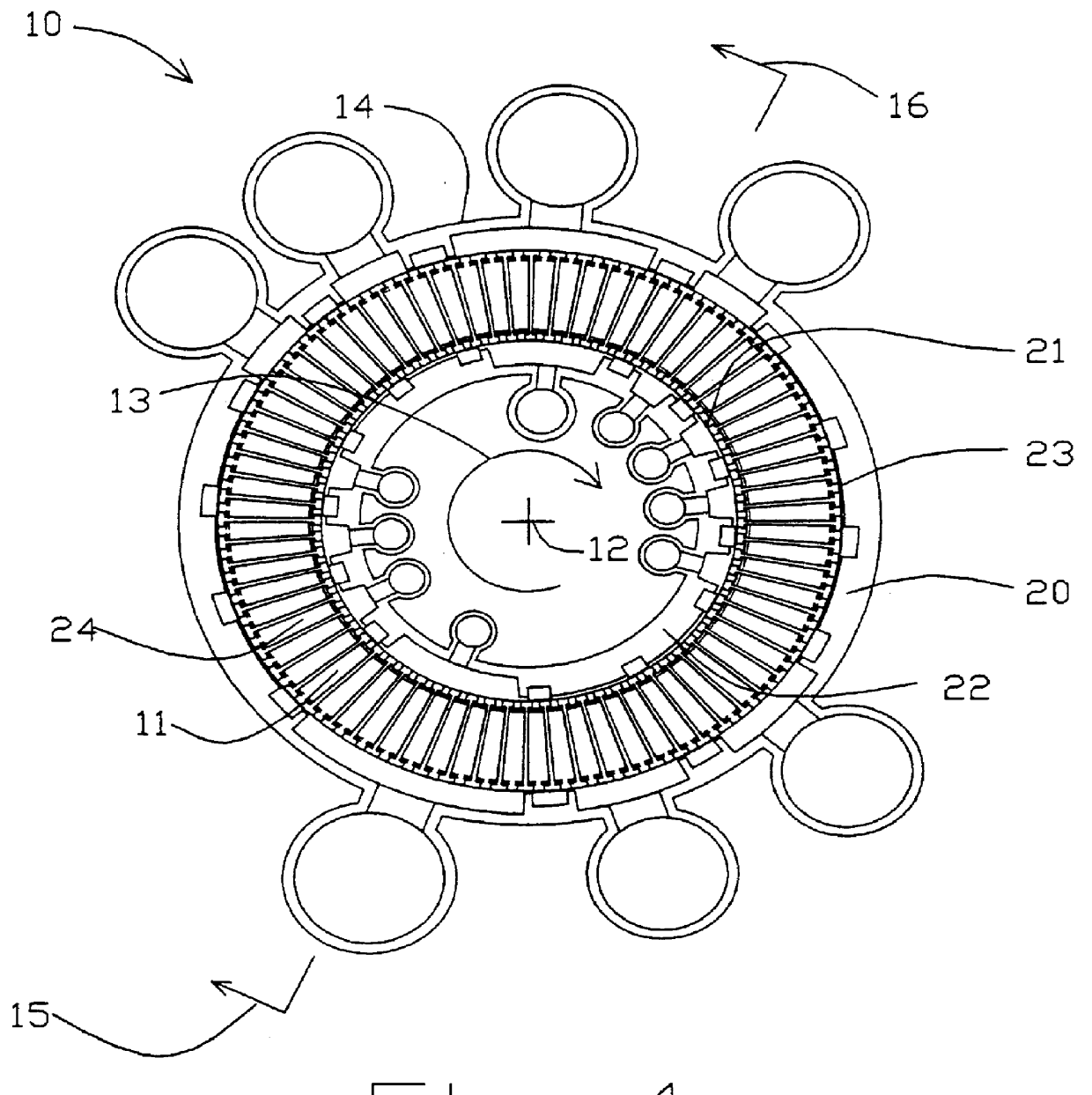

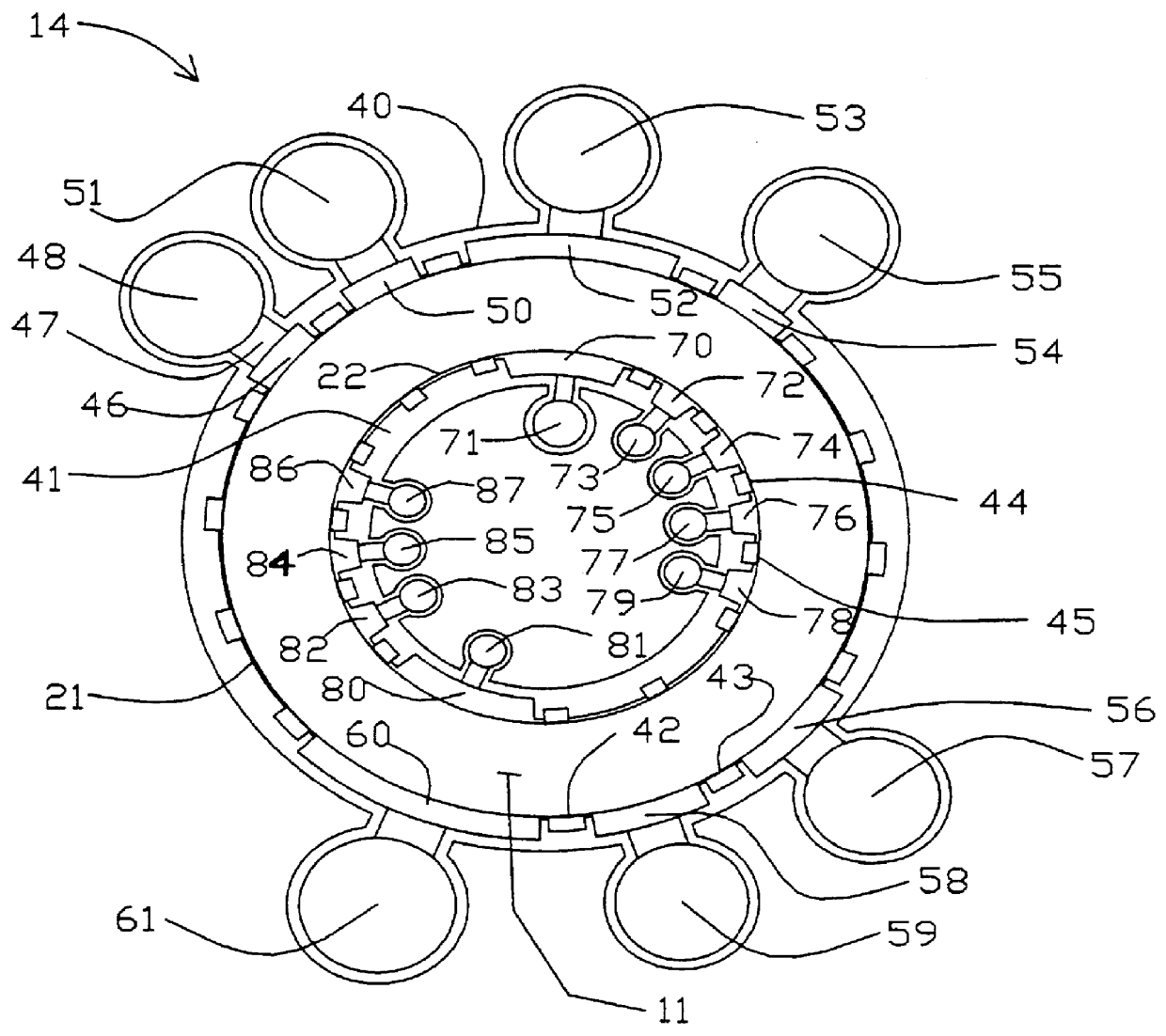

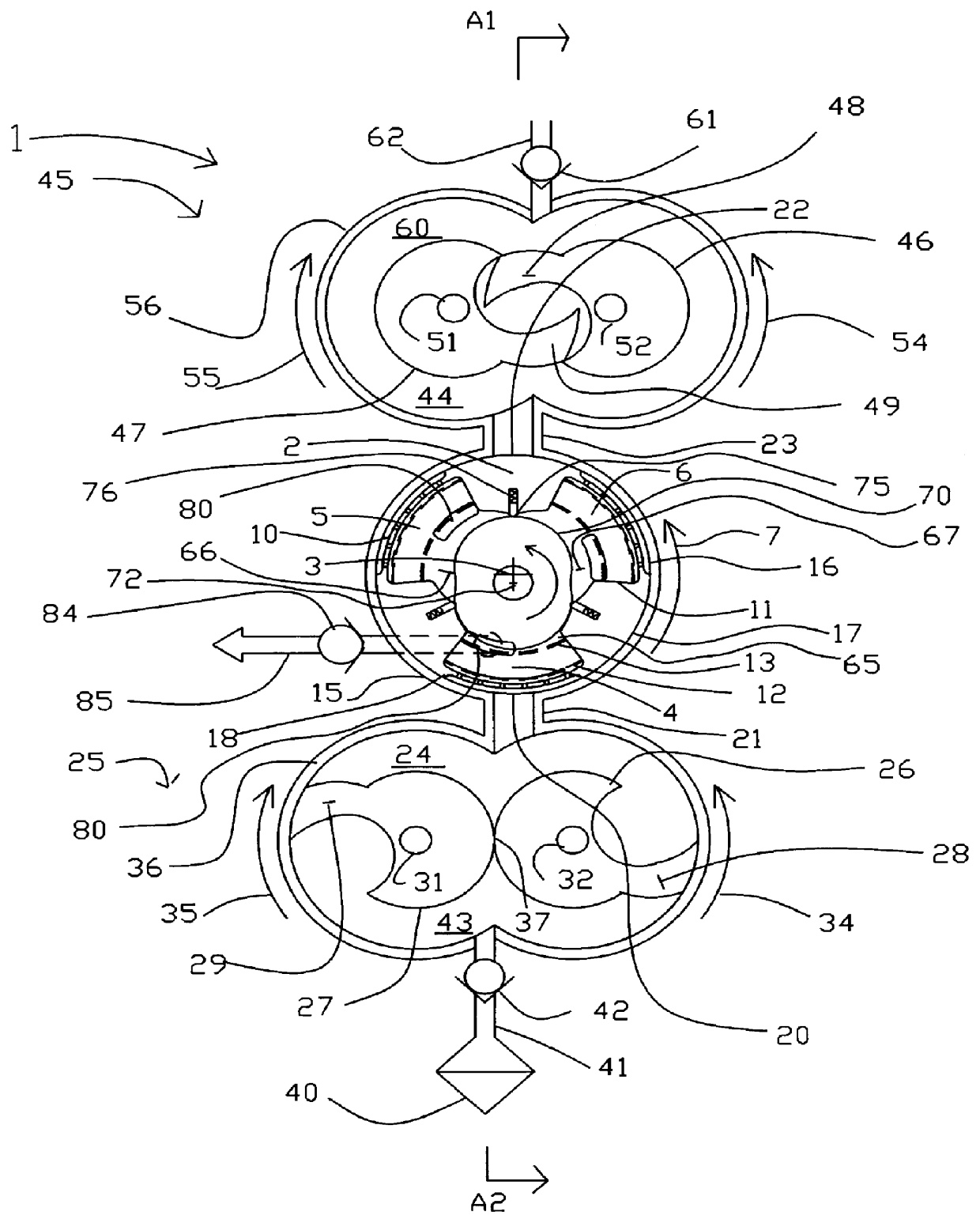

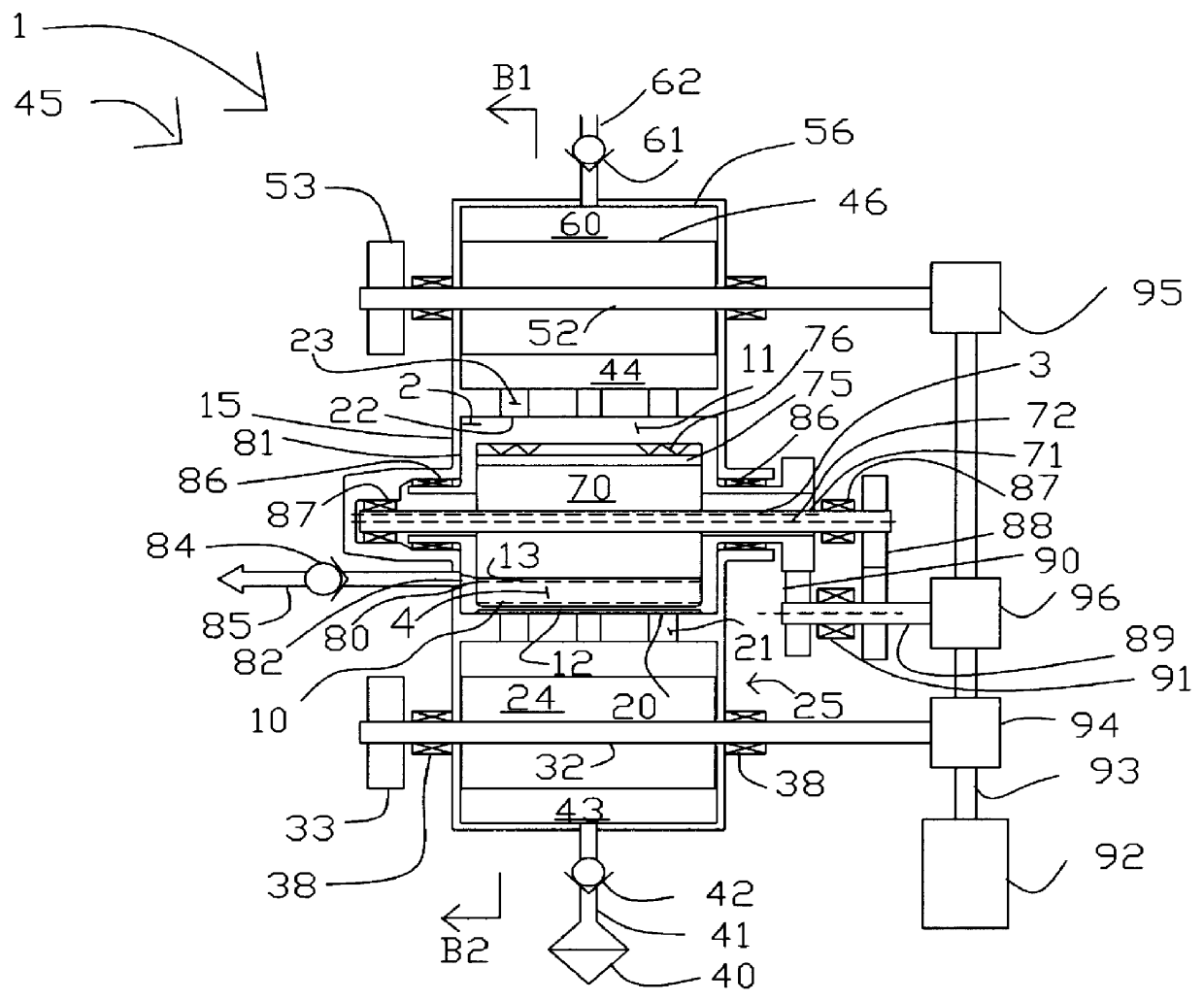

Modular pressure swing adsorption with energy recovery

InactiveUS6051050AHigh-frequency operationCompact equipmentIsotope separationRefluxProcess engineering

Pressure swing adsorption (PSA) separation of a feed gas mixture is performed within an apparatus having typically a single prime mover powering a feed compressor for one or multiple rotary PSA modules in parallel, each module including a rotor with a large number of angularly spaced adsorber elements, with valve surfaces between the rotor and a stator so that individual adsorber elements are opened to compartments for staged pressurization and blowdown, with thermally boosted energy recovery from staged expansion of countercurrent blowdown and light reflux gases, and a plurality of adsorber elements opened at any instant to each compartment so that each compressor and expander stage operates under substantially steady conditions of flow and pressure.

Owner:AIR PROD & CHEM INC

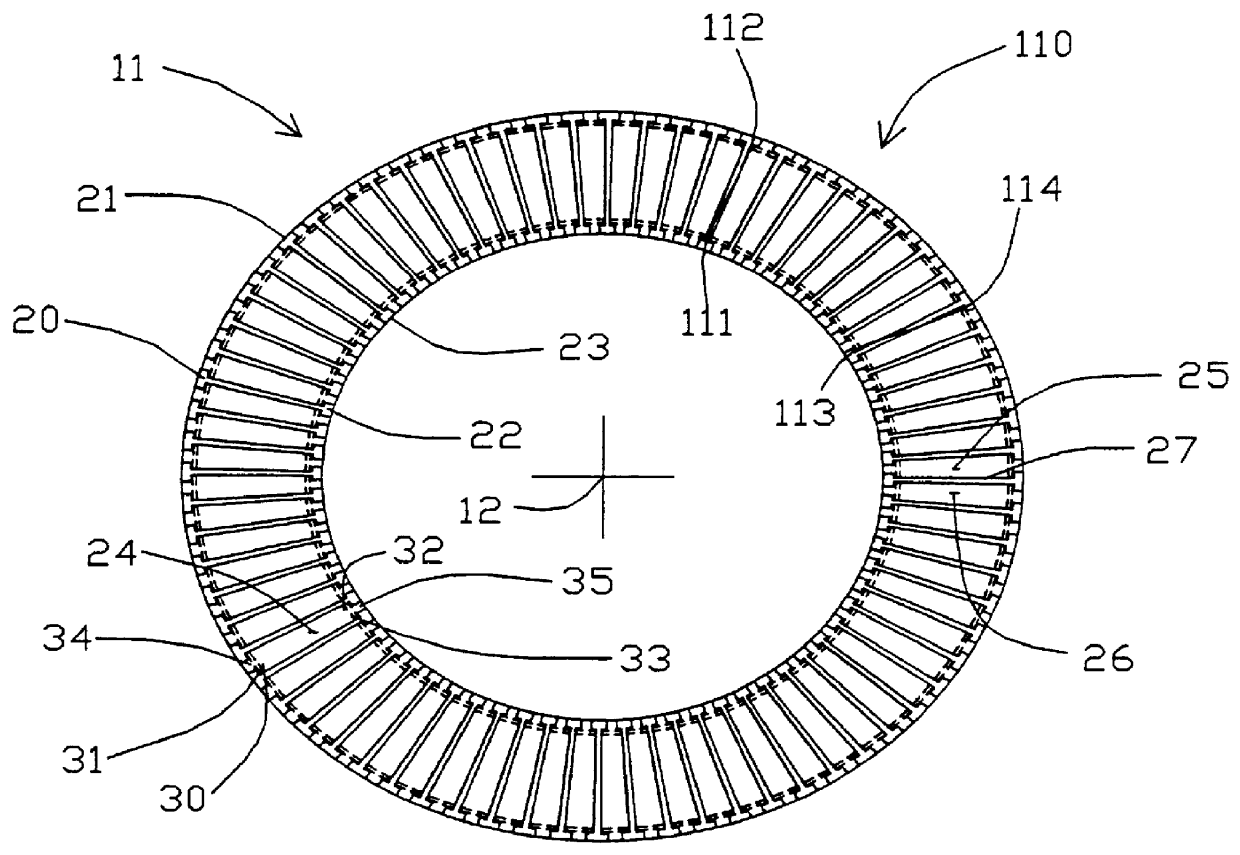

High frequency rotary pressure swing adsorption apparatus

InactiveUS6056804AHigh-frequency operationCompact equipmentGas treatmentIsotope separationProduct gasDistributor

Pressure swing adsorption separation of a feed gas mixture, to obtain a purified product gas of the less strongly adsorbed fraction of the feed gas mixture, is performed with a cooperating set of "N" adsorbers in a rotary assembly, with each adsorber communicating at its product end directly to a rotary cyclic displacement chamber, and at its feed end by rotary distributor valve ports to a rotary piston feed compressor and a rotary piston exhaust vacuum pump. The compressor and vacuum pump are integrated with the cycle, and rotate at "N" times the cycle frequency. Alternative adsorber configurations for high frequency operation are disclosed.

Owner:AIR PROD & CHEM INC +1

Simulated locomotion method and apparatus

InactiveUS7542040B2Reduced footprintReduces vertical extentCosmonautic condition simulationsAnimationVirtual locomotionLocation tracking

An apparatus for interfacing 3D movements of a user to control the locomotion of an avatar in a virtual environment includes a position tracker for tracking the position of a user's feet, with the foot motions including swinging and stroking; a computer programmed for (i) computing a direction and extent of motion of a reference in the virtual environment based on the foot positions and (ii) providing an avatar corresponding to the computed direction and extent of motion; and a display for displaying the avatar in the virtual environment. The apparatus accordingly uses the gestural motion of the user's feet while seated to simulate natural human locomotion. The gestural motions of stroking and swinging include translational and rotating movements, and are chosen to correspond to the actions of the feet and legs during natural human locomotion, providing natural control of virtual locomotion. The apparatus is also designed for controlling the locomotion of a remote vehicle.

Owner:USA AS REPRESENTED BY THE SEC OF THE NAVY THE

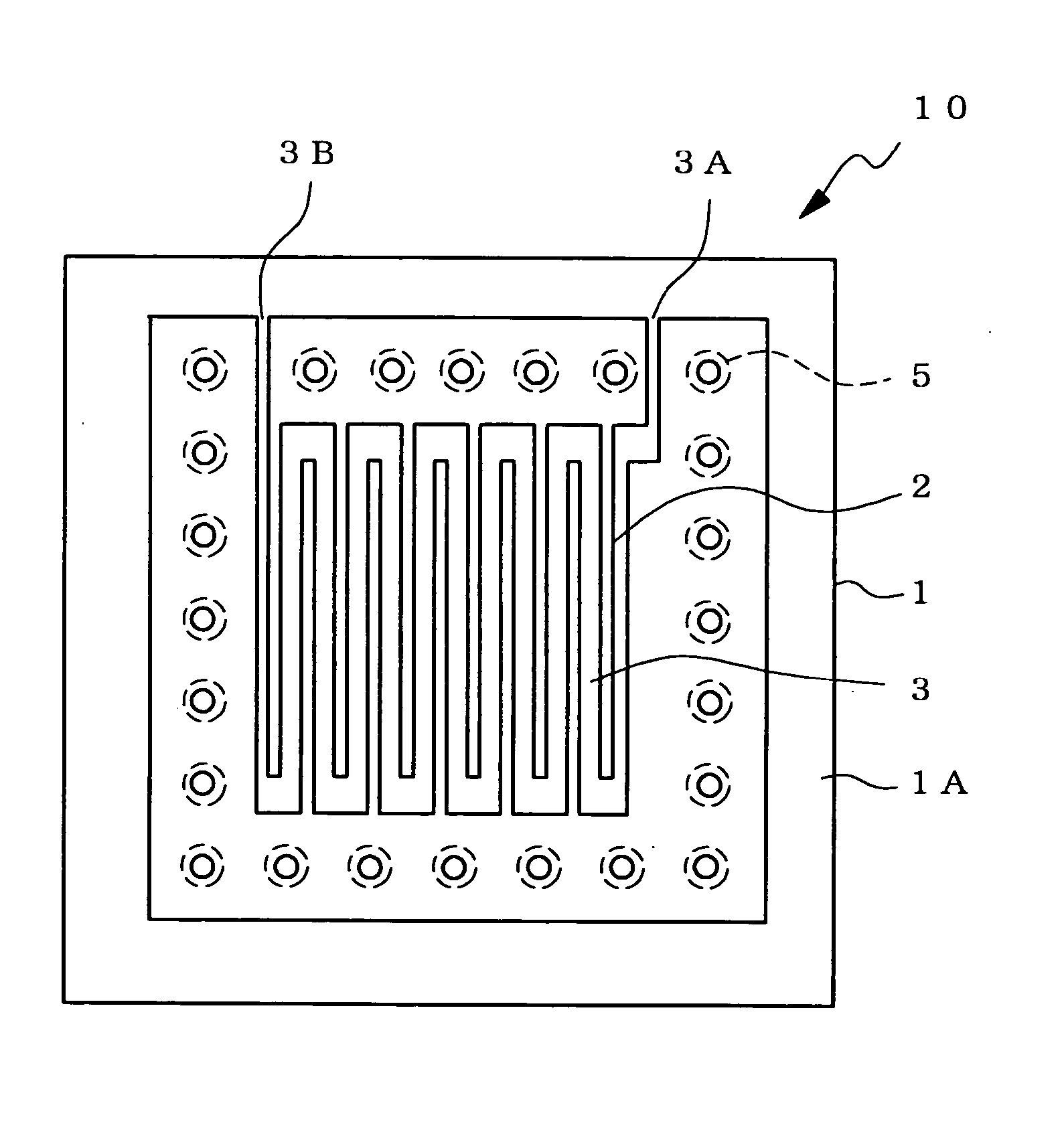

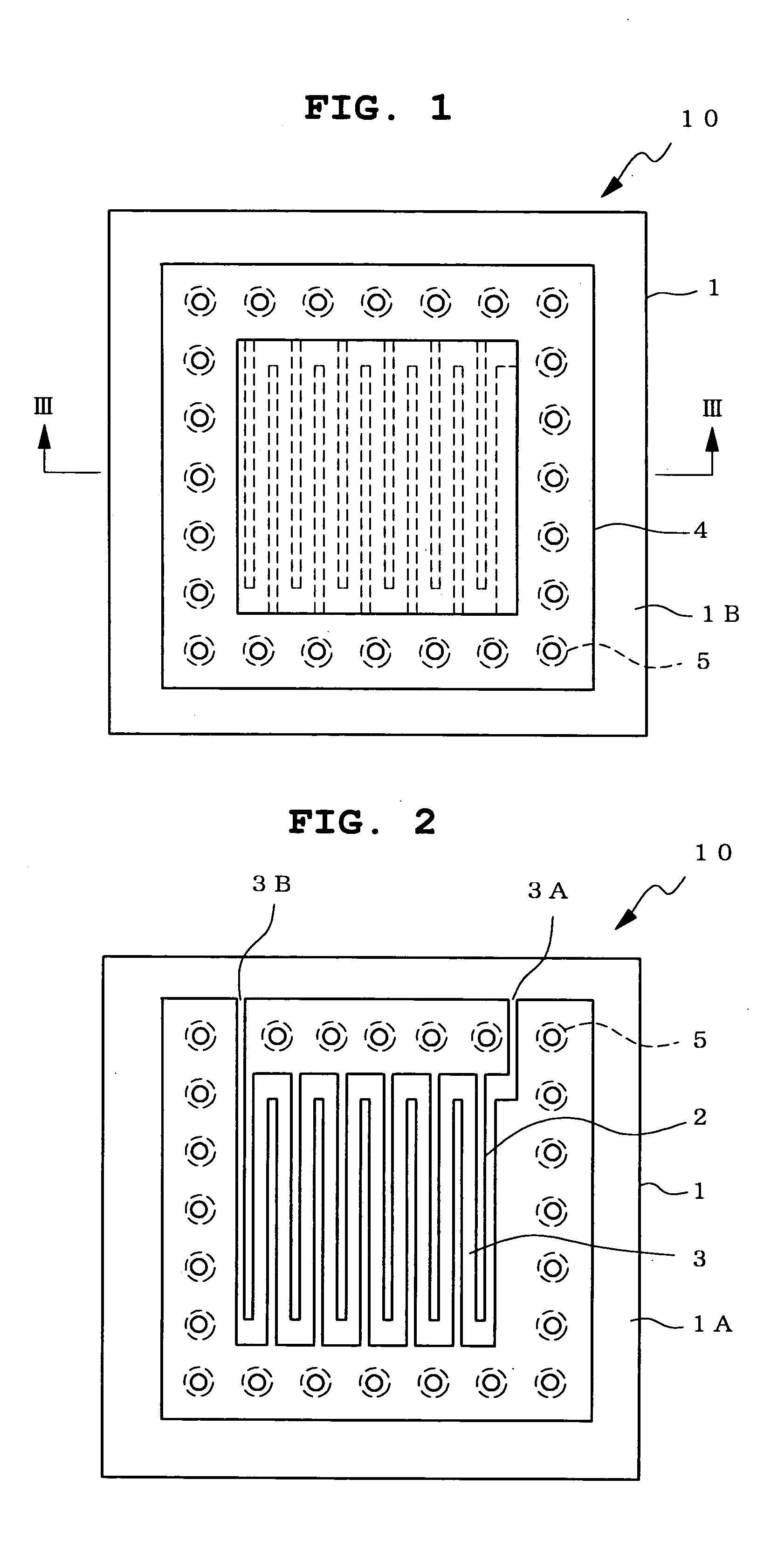

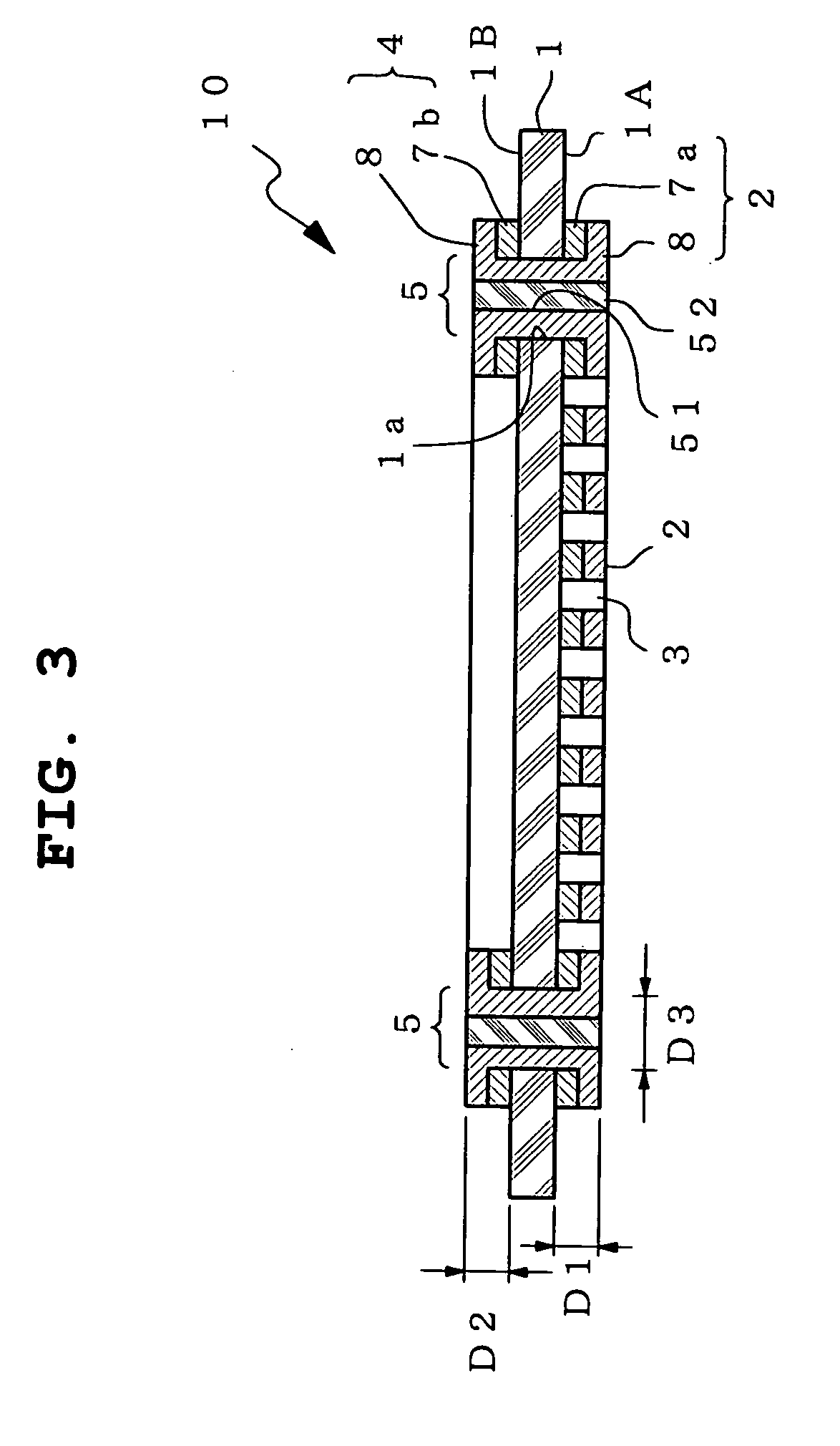

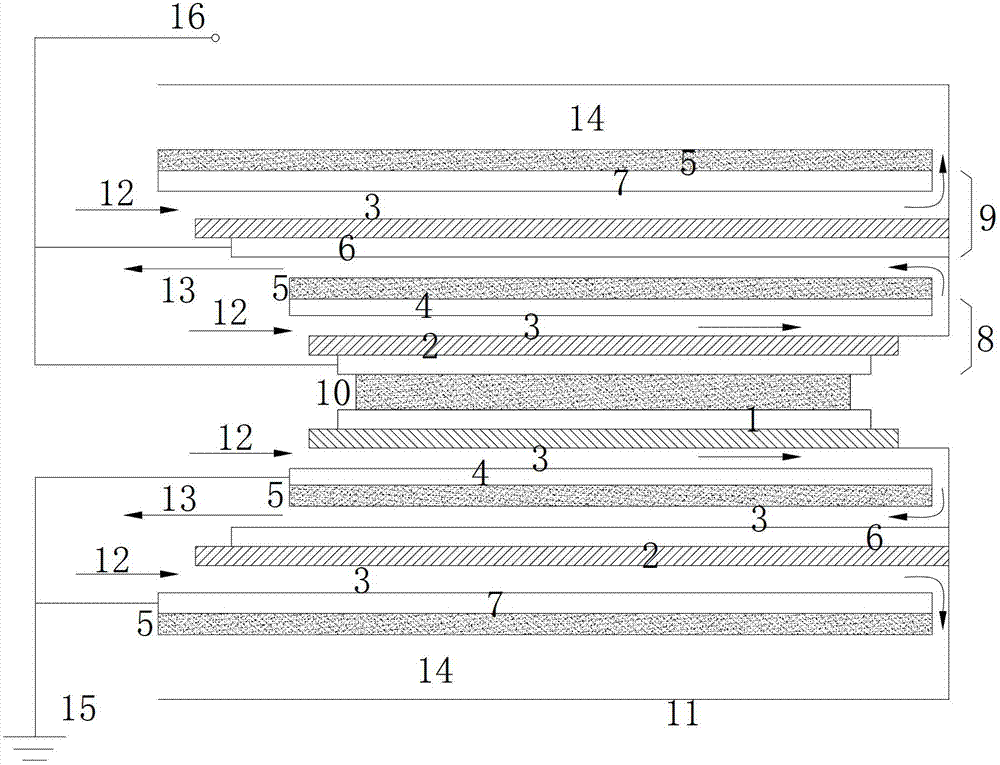

Separator for fuel cell and fuel cell using the same

InactiveUS20050026028A1Simple processMaintain strengthFuel cells groupingFuel cell auxillariesFuel cellsElectrical conductor

The present invention provides, as a separator for fuel cell which is lightweight, can be easily made thin, and which has superior corrosion resistance and shape stability, a fuel cell 100 containing a separator for fuel cell 10, wherein a conductor pattern 2 is formed on one principal plane 1A of an insulation layer 1 to form a groove for a gas flow path 3 sectioned by the conductor pattern 2 on this principal plane, a conductor terminal 4 is formed on the other principal plane 1B of the insulation layer 1, and this conductor terminal 4 and the conductor pattern 2 are electrically connected by a via hole 5 penetrating the insulation layer 1, and a membrane electrode assembly (complex having an electrolyte membrane and an electrode (fuel electrode, oxygen electrode) laminated thereon) 14 having the separator for fuel cell disposed on both surfaces.

Owner:NITTO DENKO CORP

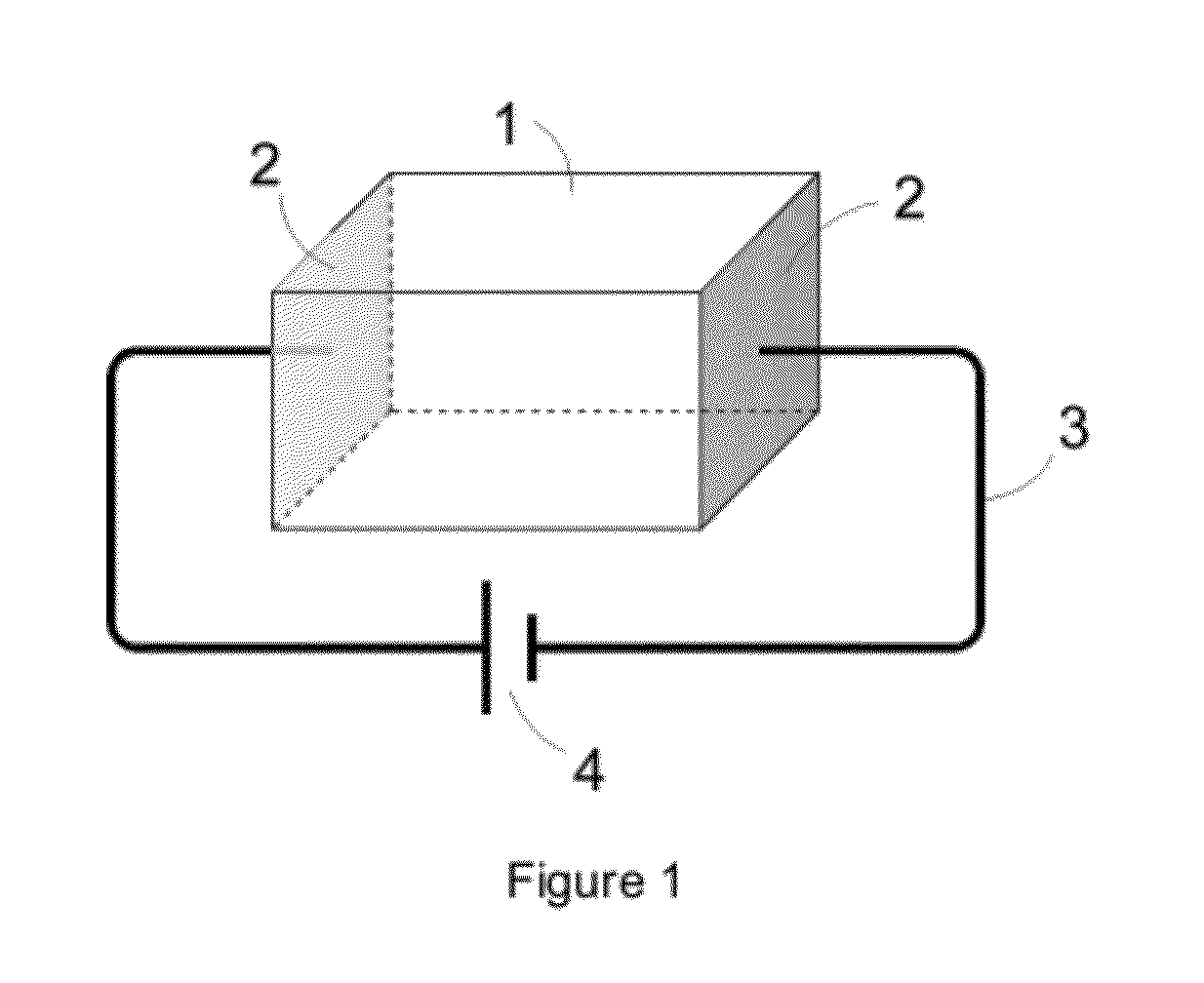

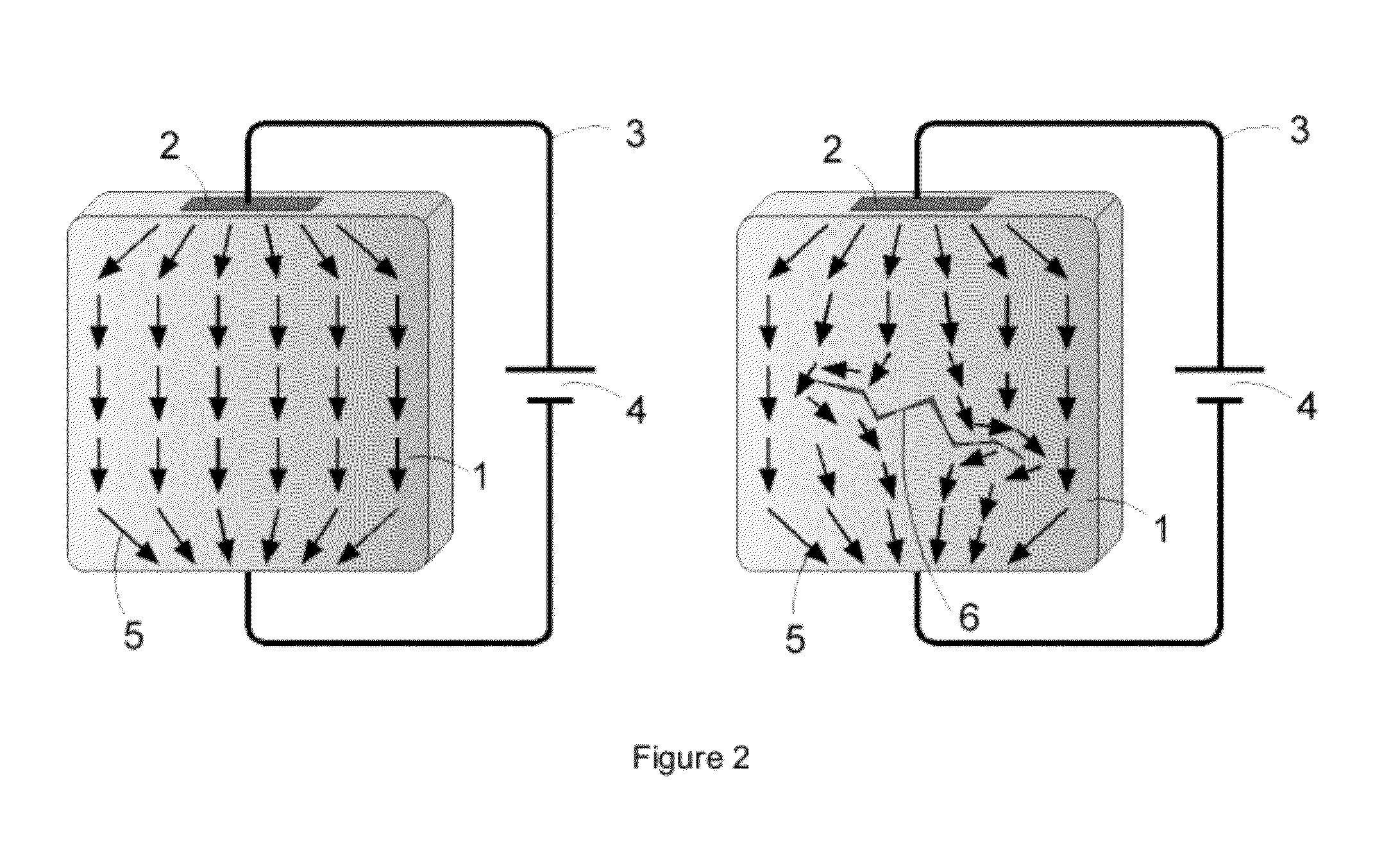

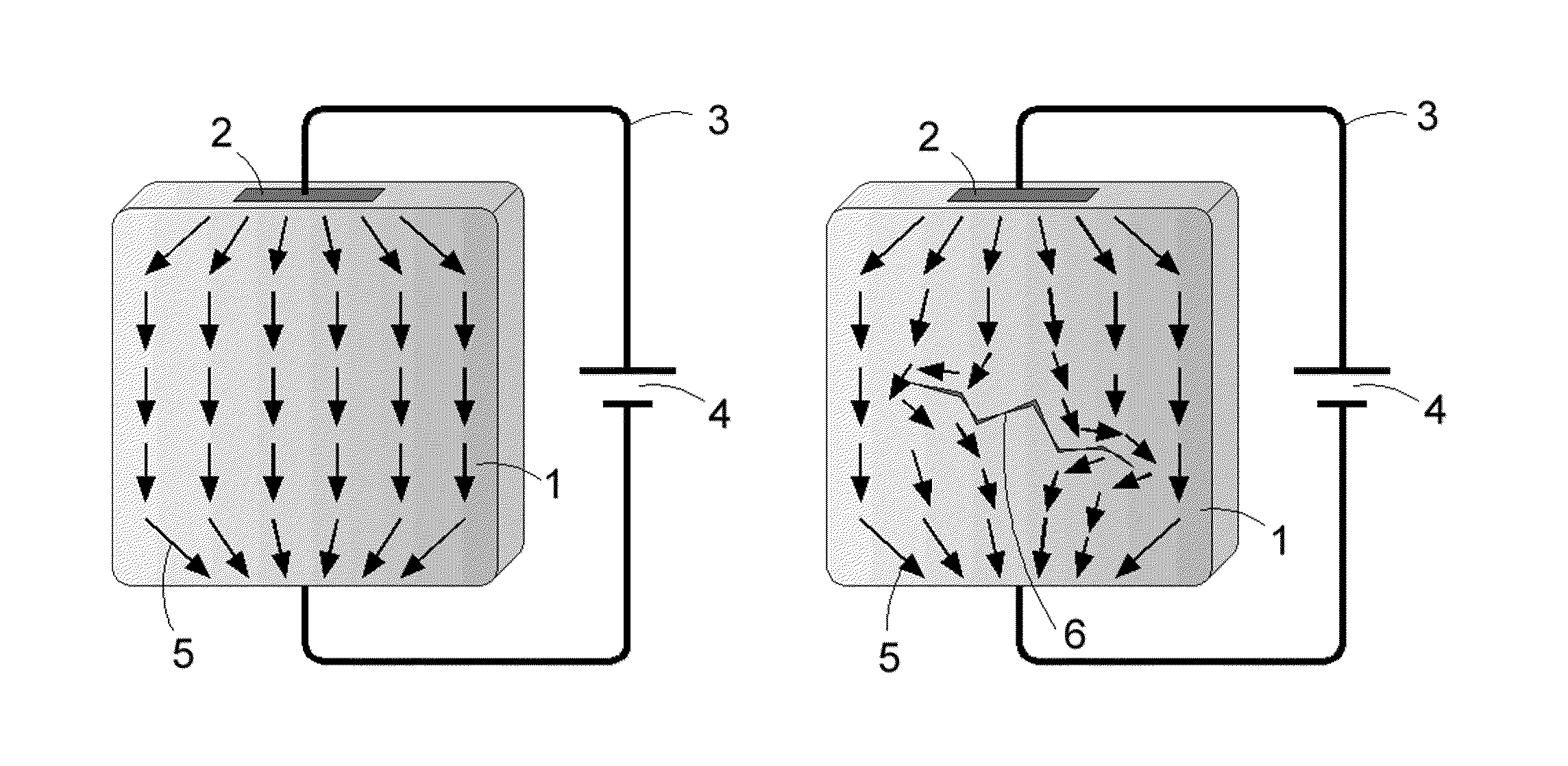

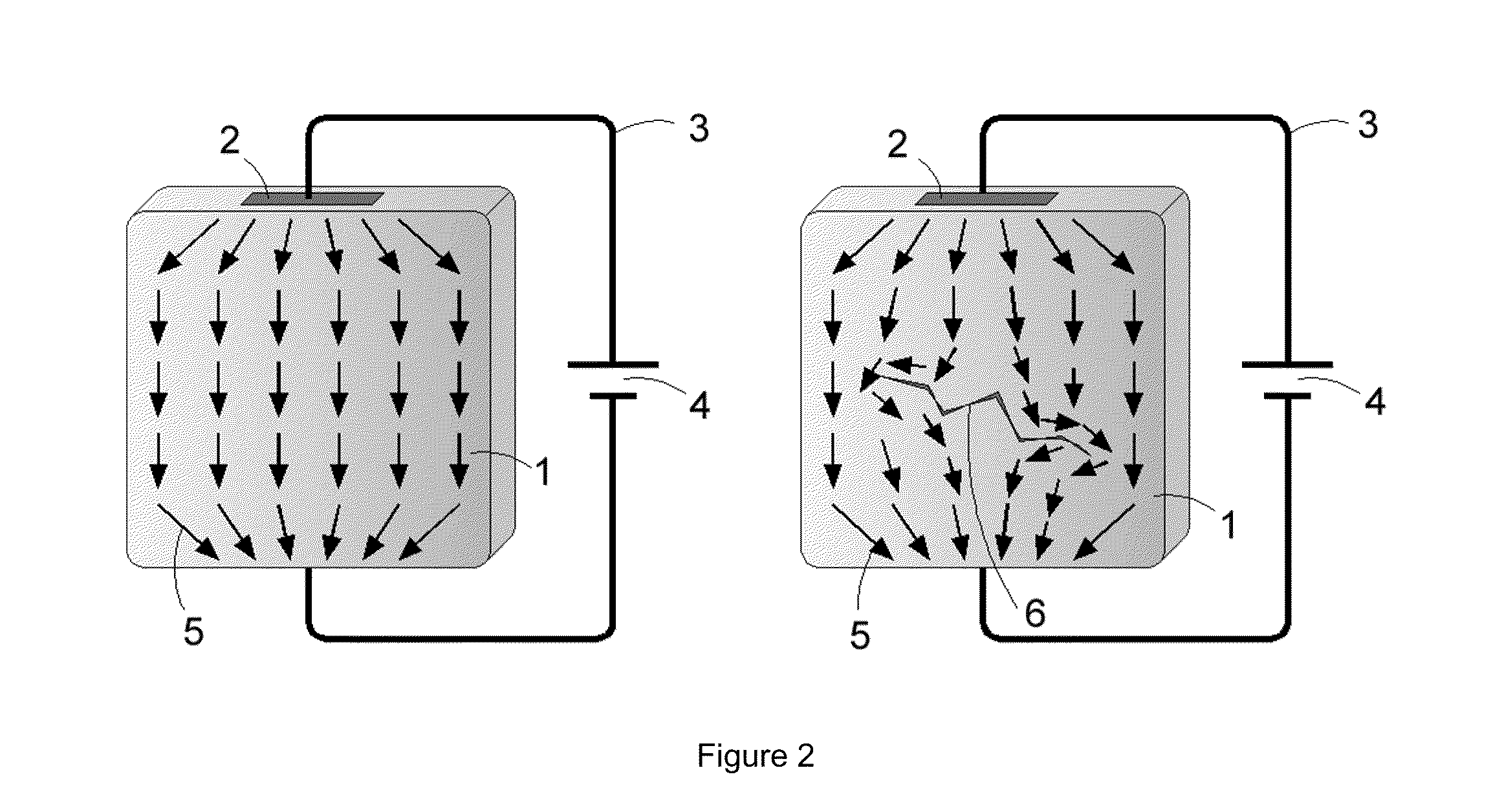

Ceramic Crack Inspection

InactiveUS20120235693A1Reliable and low-costLow operationResistance/reactance/impedenceMaterial resistanceCeramicMaterials science

A method and apparatus for non-destructive inspection including detection, quantification, and location of a surface or subsurface crack in a body made of advanced technical ceramics. The method and apparatus can detect all cracks in a ceramic body, including microscopic cracks, with a high sensitivity, accuracy and reliability, by measuring changes in electrical resistances through a plurality pairs of electrodes affixed on surfaces of the ceramic body. The extent of the cracks can be quantified and expressed as numerical data, and the location of the cracks can be identified. An automated inspection process enables a convenient, real-time, cost-effective crack inspection.

Owner:FENG HONG

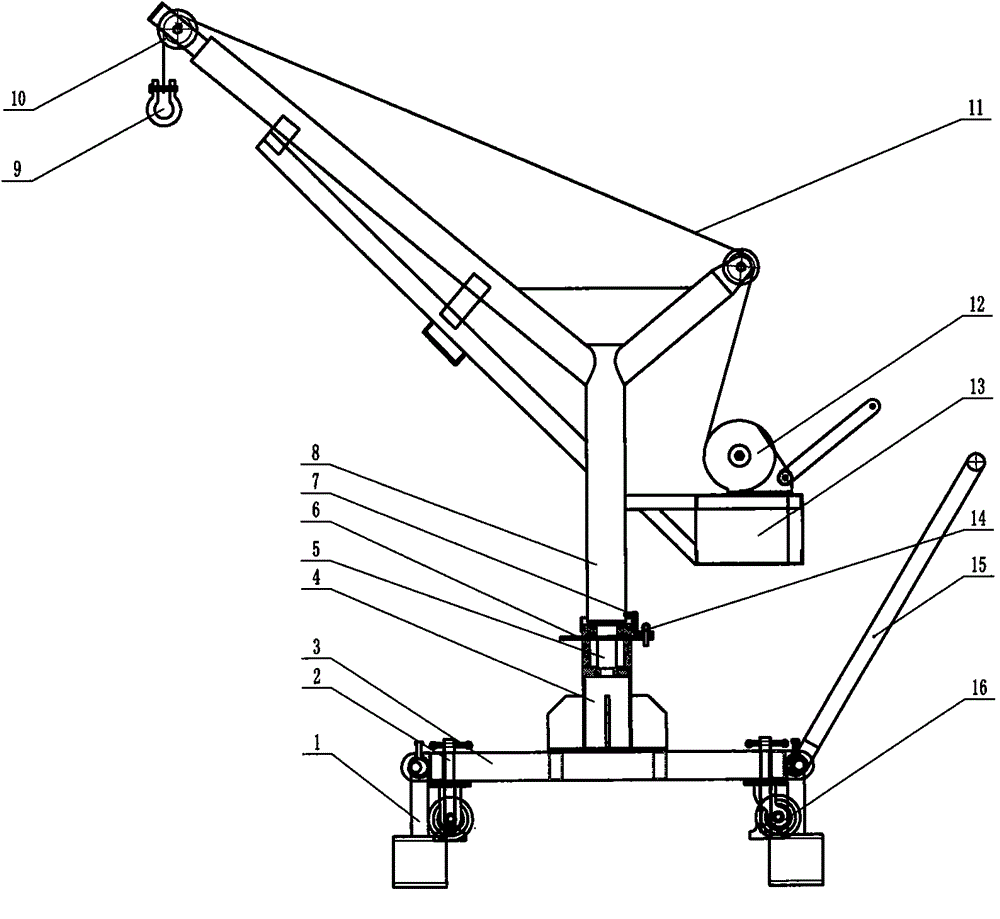

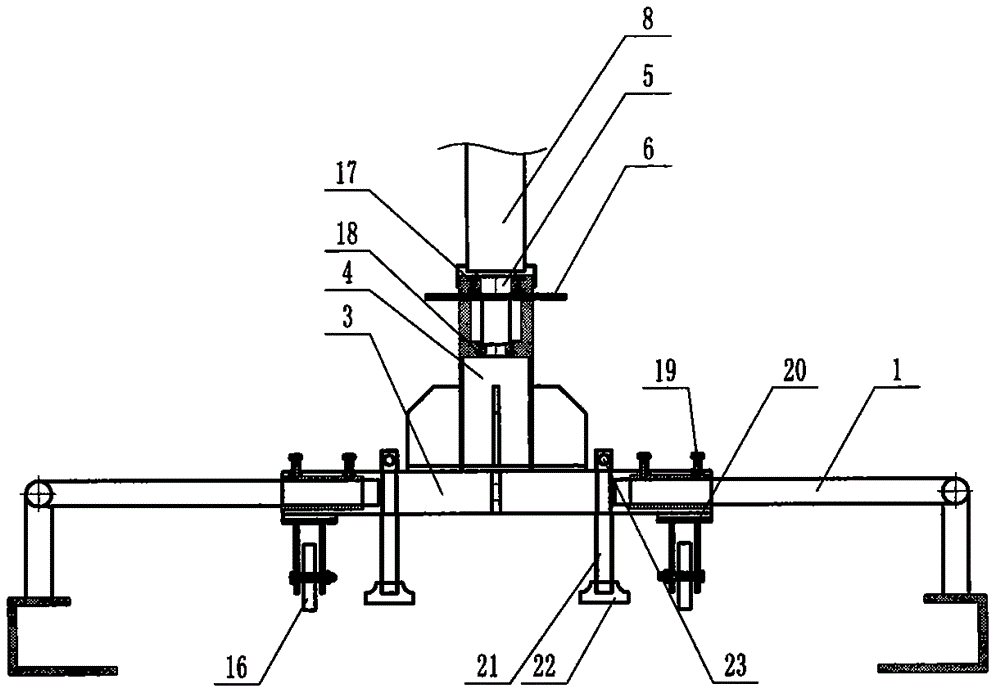

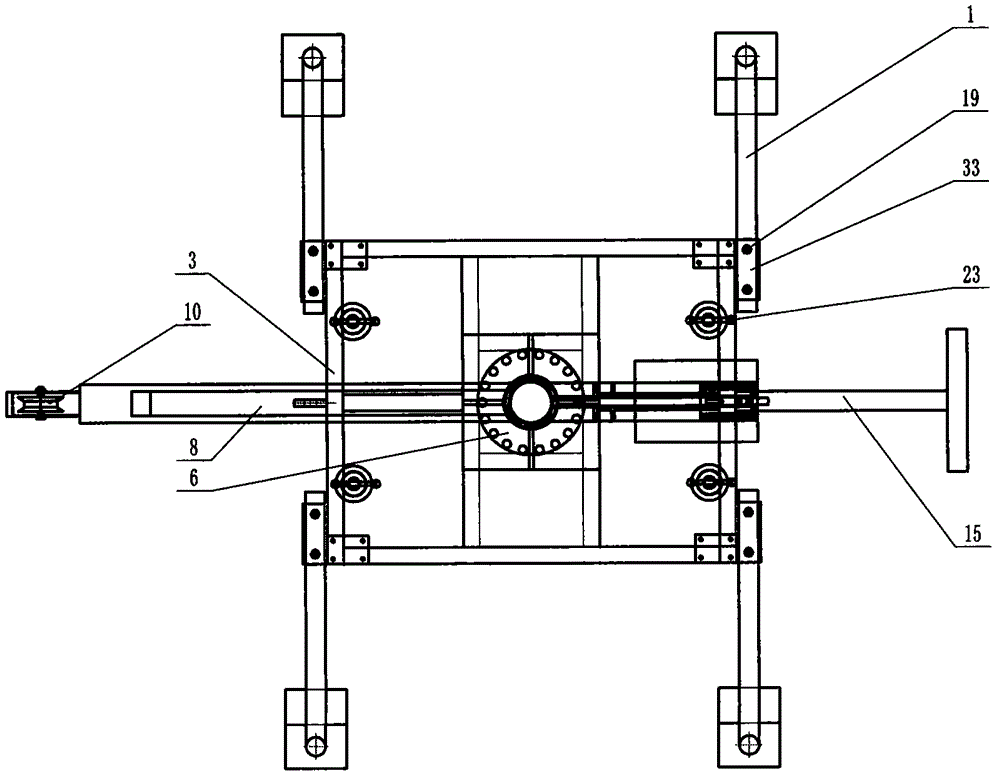

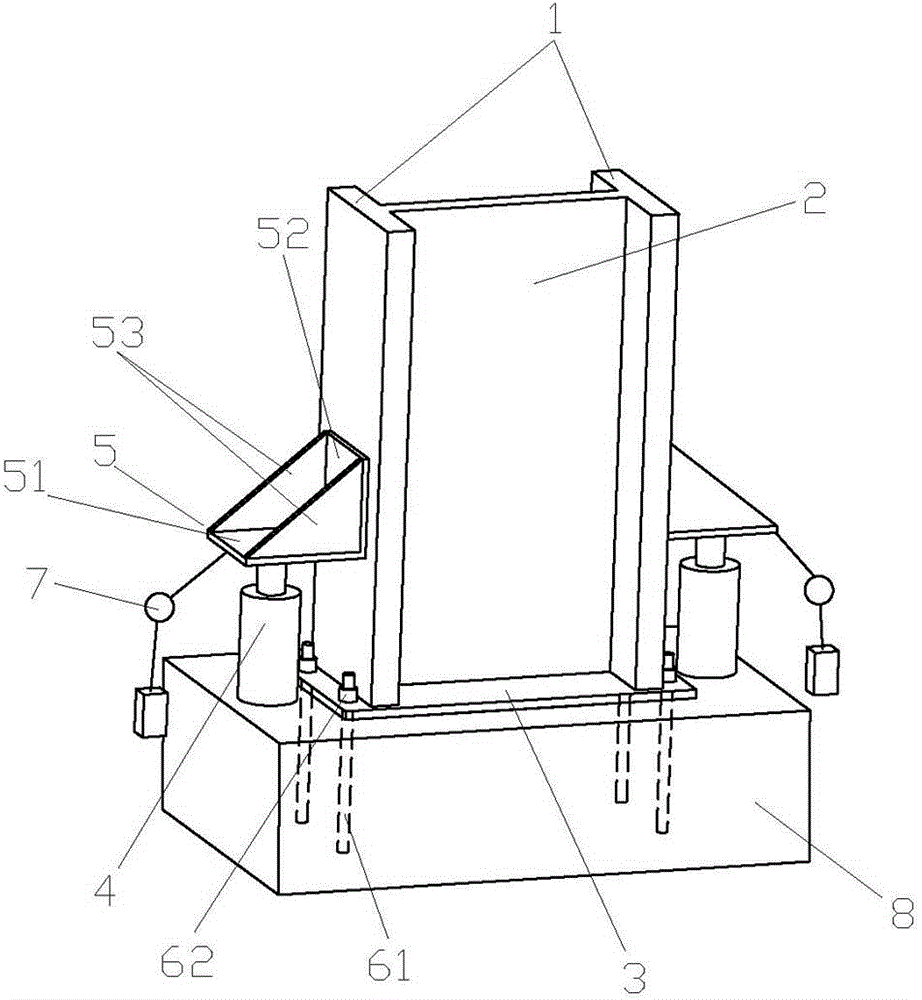

Small movable crane

The invention relates to a small movable crane, which comprises a hoisting device, a counterweight device, a movable pedestal, leading screw supports, and support assemblies. A Y-shaped hoisting hanger of the hoisting device comprises an upper support and a lower support, wherein each end of the upper support is provided with a fixed pulley; the bottom of the lower support is fixed to a rotating shaft, which is inserted into a rotating seat. The rotating seat is fixedly mounted on the center of the movable pedestal; and the counterweight device is arranged at one side of the lower support of the hoisting hanger and is provided with a hand-operated capstan. A steel wire rope is transited via two fixed pulleys, and one end of the steel wire rope is provided with a hook. Every two of the four leading screw supports are symmetrically arranged at front and rear sides of the inner sides of two frames of the movable seat; every two of the four support assemblies are symmetrically arranged at front and rear sides of the outer sides of two frames of the movable seat; and each corner of the movable seat is provided with an omni-directional wheel. The small movable crane has advantages that the crane is small, exquisite, light and convenient, is flexible to move, and is safe and reliable; a large amount of physical power is saved for a maintenance person; the maintenance speed is greatly improved; and an emergency rescuing function of a reaction pool is provided.

Owner:北京市自来水集团门城污水处理有限公司

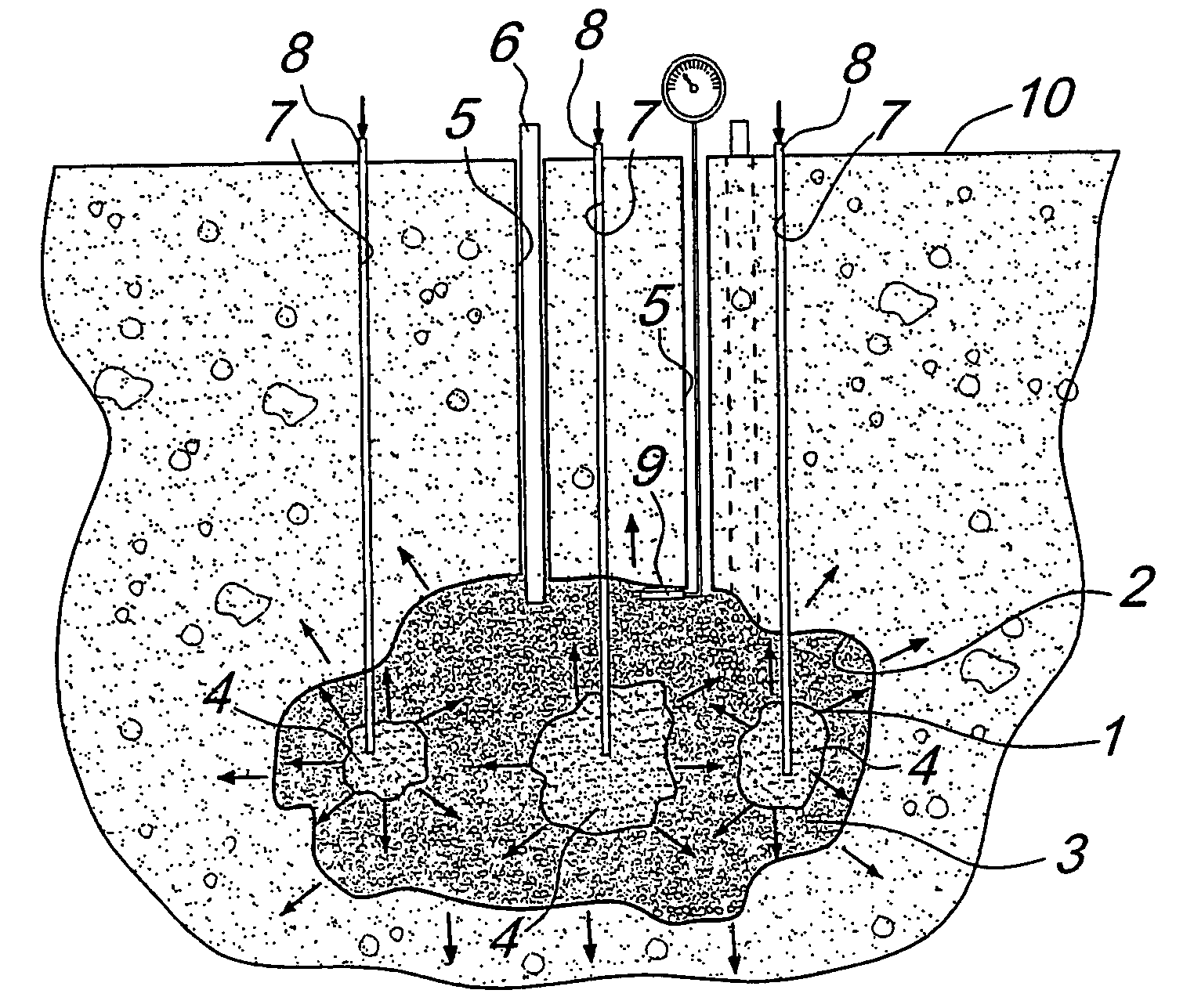

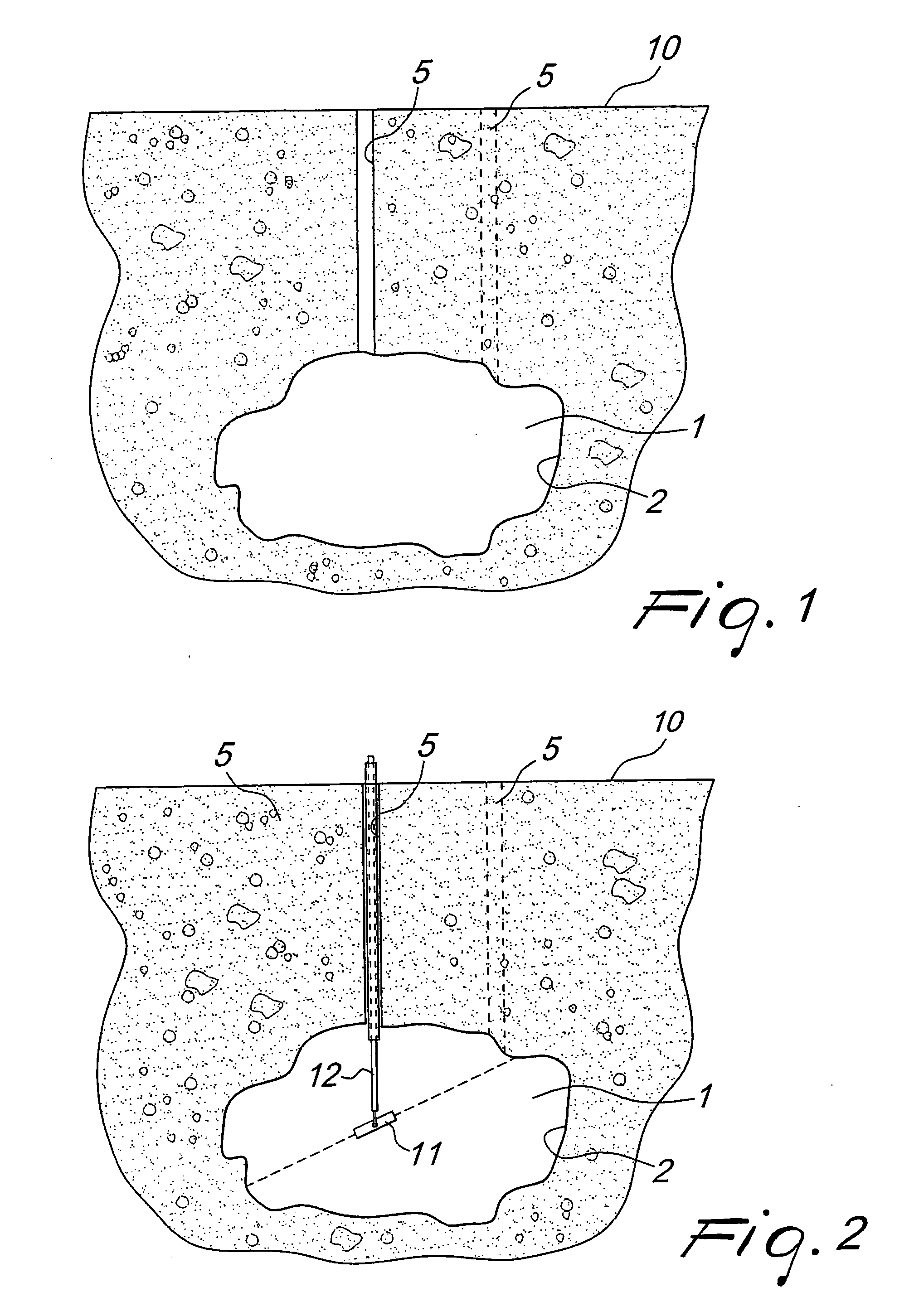

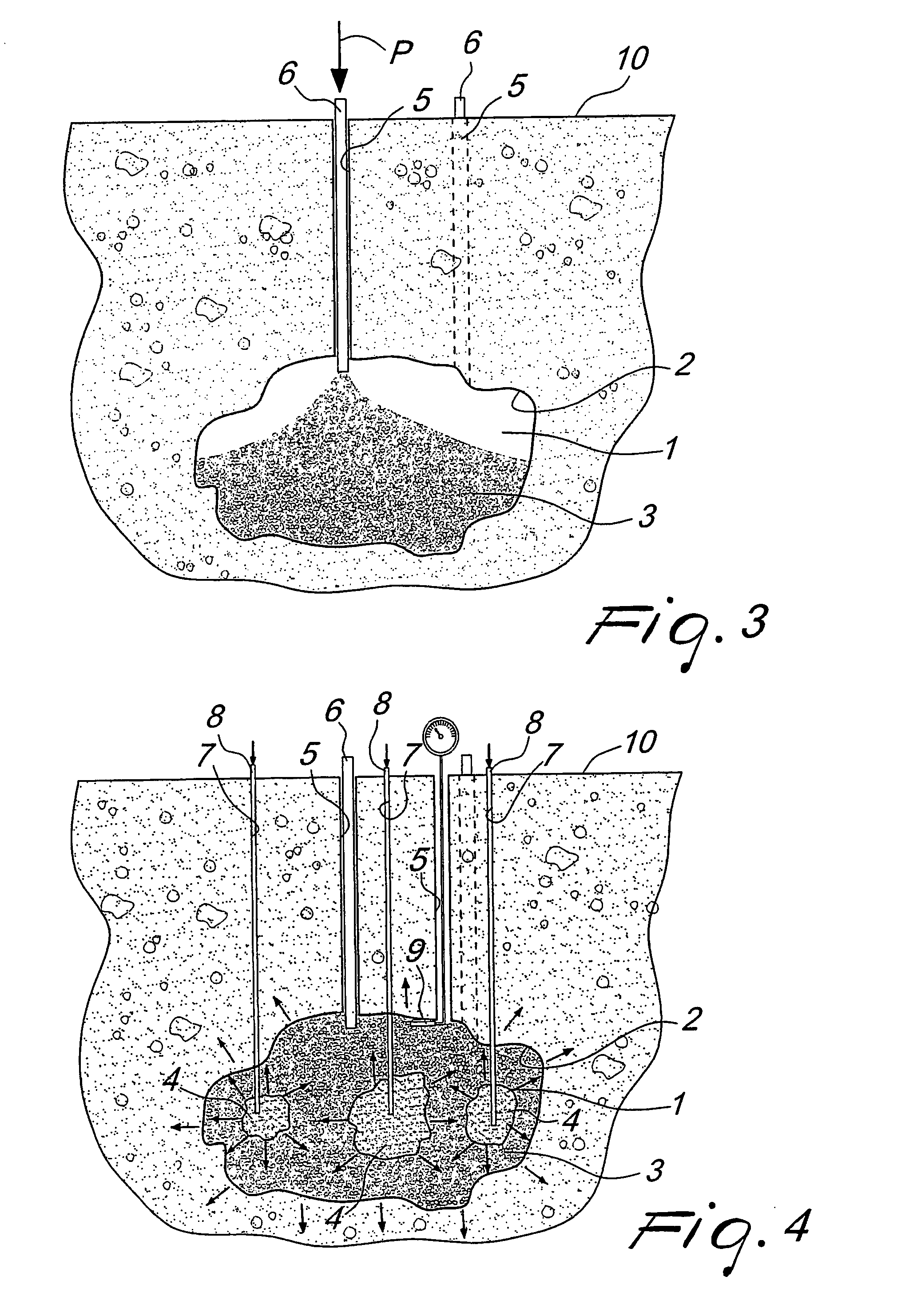

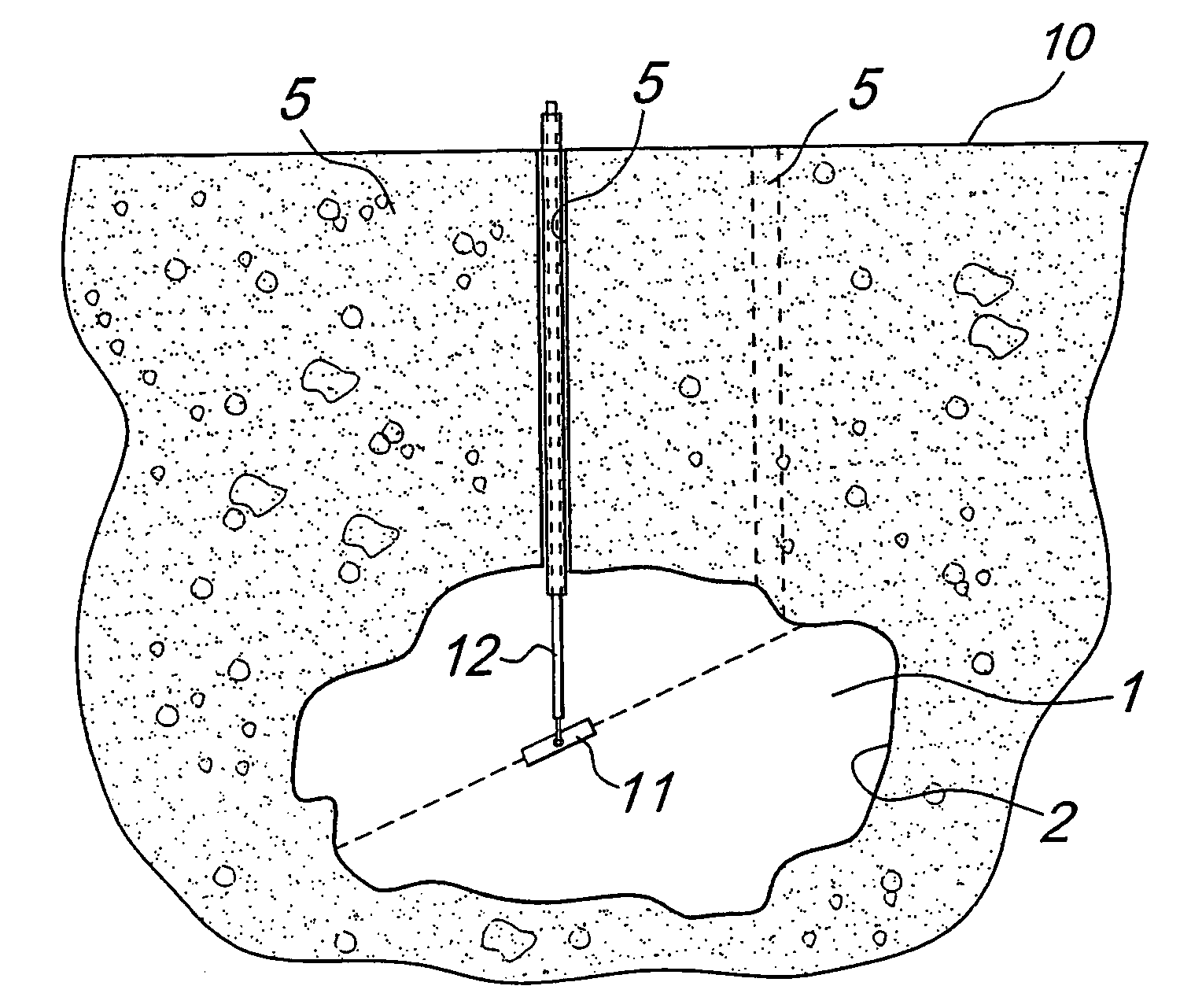

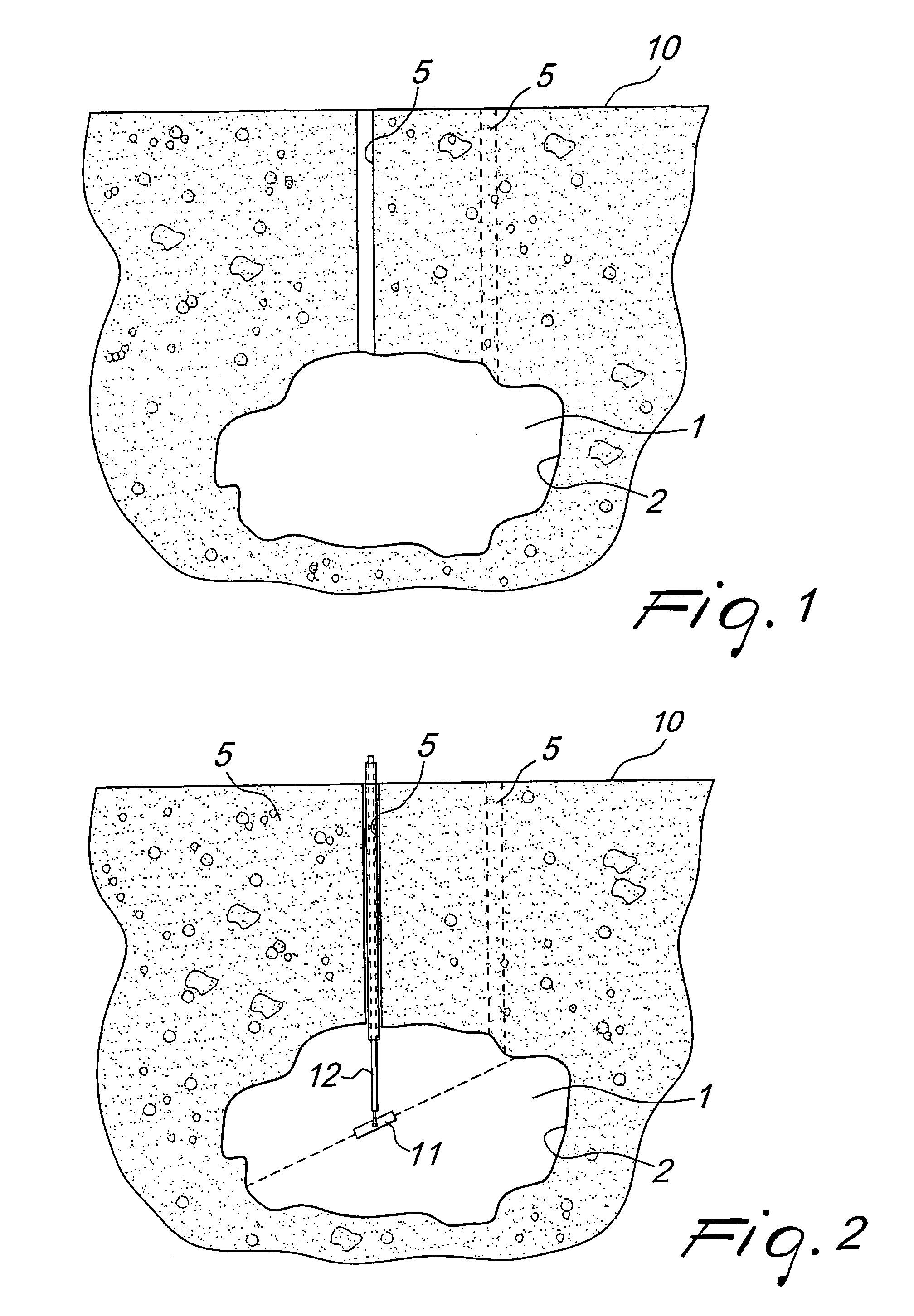

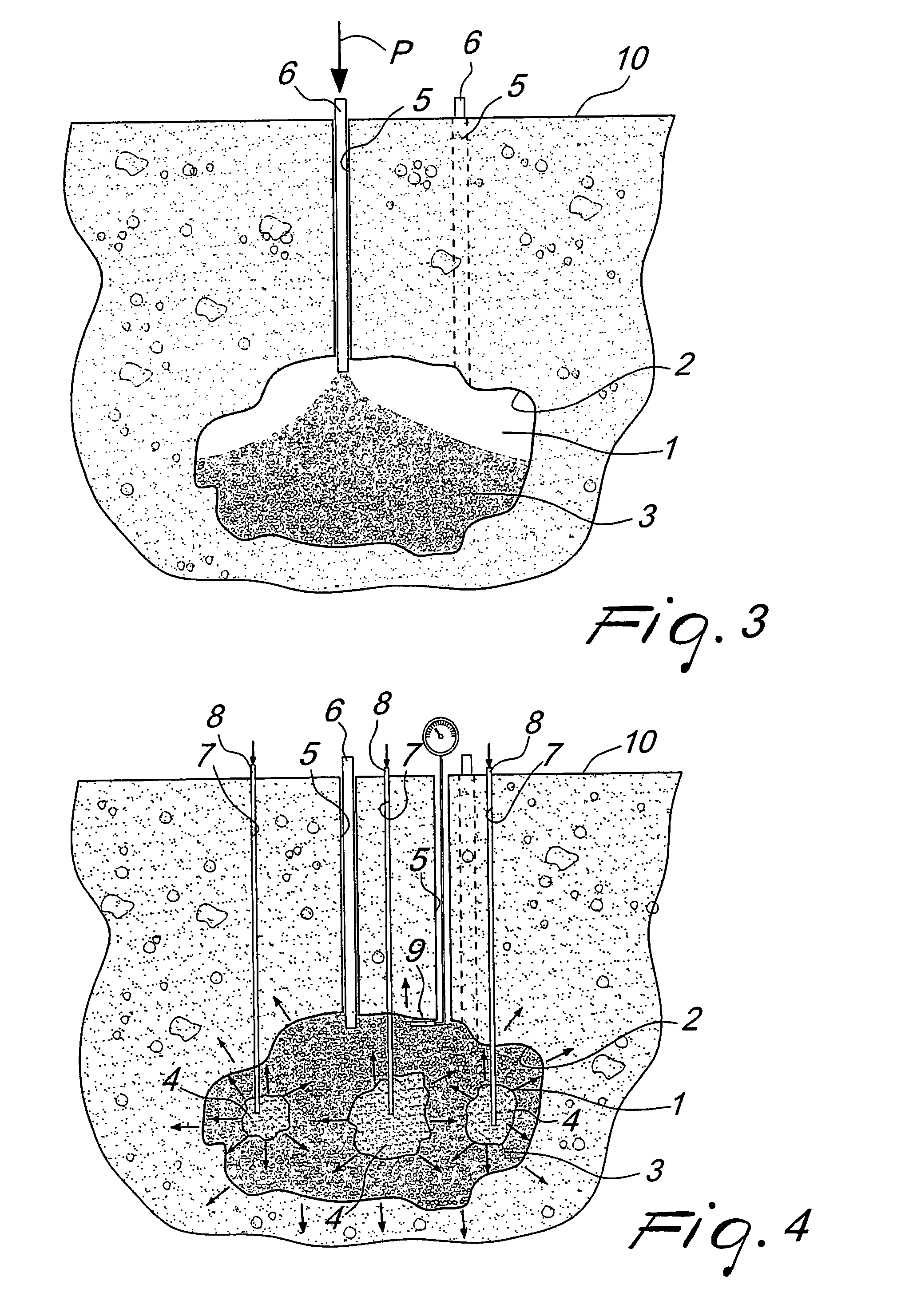

Method For Saturating Cavities Present in a Mass of Soil or In a Body in General

ActiveUS20080205995A1Short timeSpace be limitedArtificial islandsMaterial fill-upFilling materialsSolid-state

A method for saturating cavities present in a mass of soil or in a body in general, comprising at least one step for at least partial filling of the cavity by introducing into the cavity a filler material in the solid state or in the fluid state and capable of setting. At least one step of saturating the cavity is then performed by introducing into the cavity a fluid synthetic substance which expands and sets by chemical reaction. The synthetic substance is adapted to generate, as a consequence of its expansion, at least the saturation of the cavity and a compaction and / or loading of the filler material introduced into the cavity in the filling step, creating an optional state of permanent tension on the walls that delimit the cavity, to the point of producing, if necessary, a deformation of the walls.

Owner:THUR

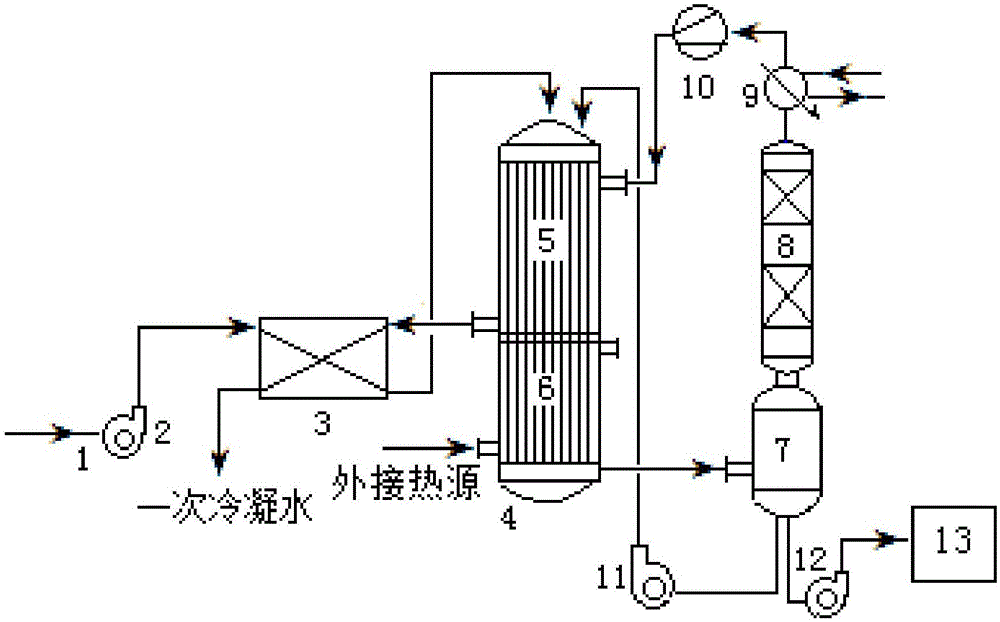

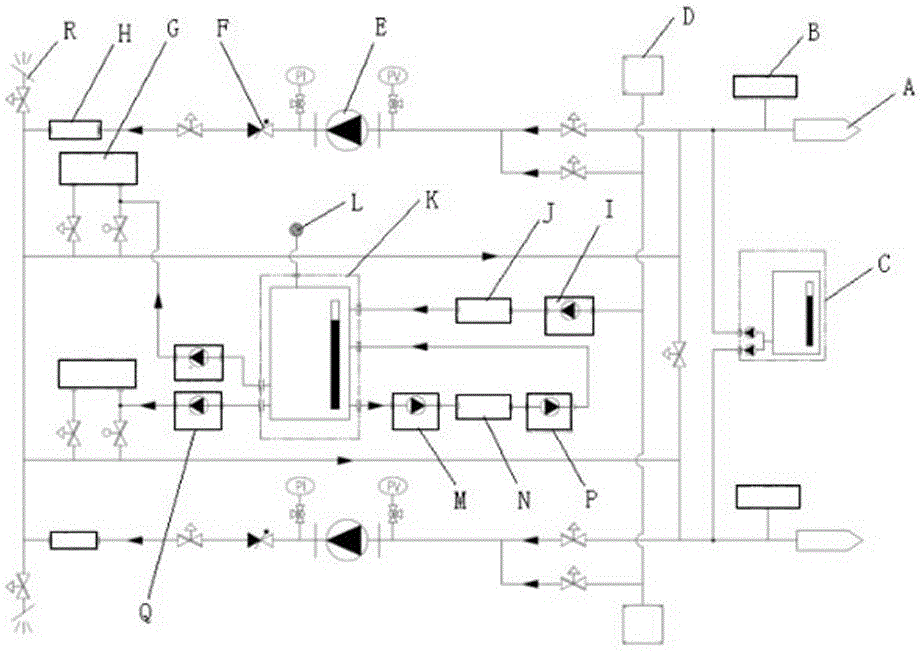

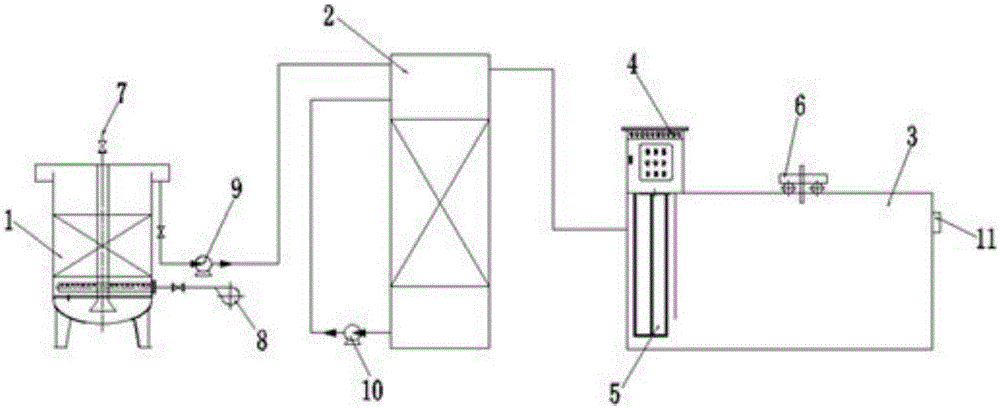

Mechanical vapor recompression system of concentrated organic waste water and method

ActiveCN105000612ACompact equipmentSmall footprintWater/sewage treatment by heatingChemistryEvaporator

The invention discloses a mechanical vapor recompression system of concentrated organic waste water and an application method of the mechanical vapor recompression system, and relates to the technical field of energy conservation and emission reduction. A second-stage evaporating unit is added outside a heat exchange pipe of an existing MVR evaporator, secondary heat exchange is conducted on the evaporator through an outer heating source, and therefore the ethanol concentration of a concentrated solution concentrated through MVR is further improved, the energy utilization efficiency is improved, and the waste water volume and energy consumption in the reconcentration process are lowered. Due to an added rectifying tower and an added condensation device, the utilization efficiency of the outer heating source is fully improved, the ethanol concentration in vapor can be reduced, and convenience is provided for making the waste water meet the emission requirements. The procedures are simple, operation is convenient, and a cooling water system can be omitted.

Owner:成都民航六维航化有限责任公司

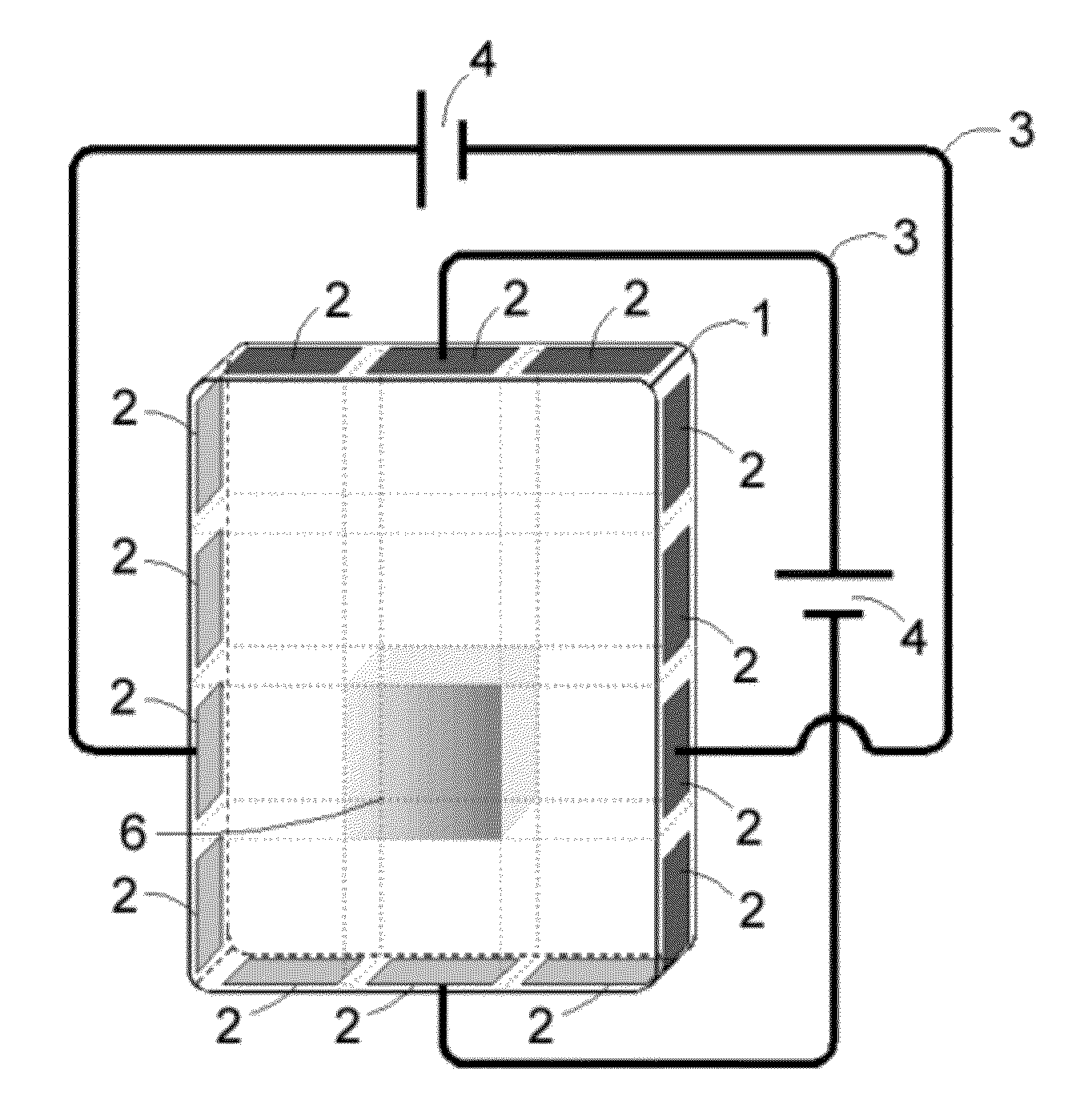

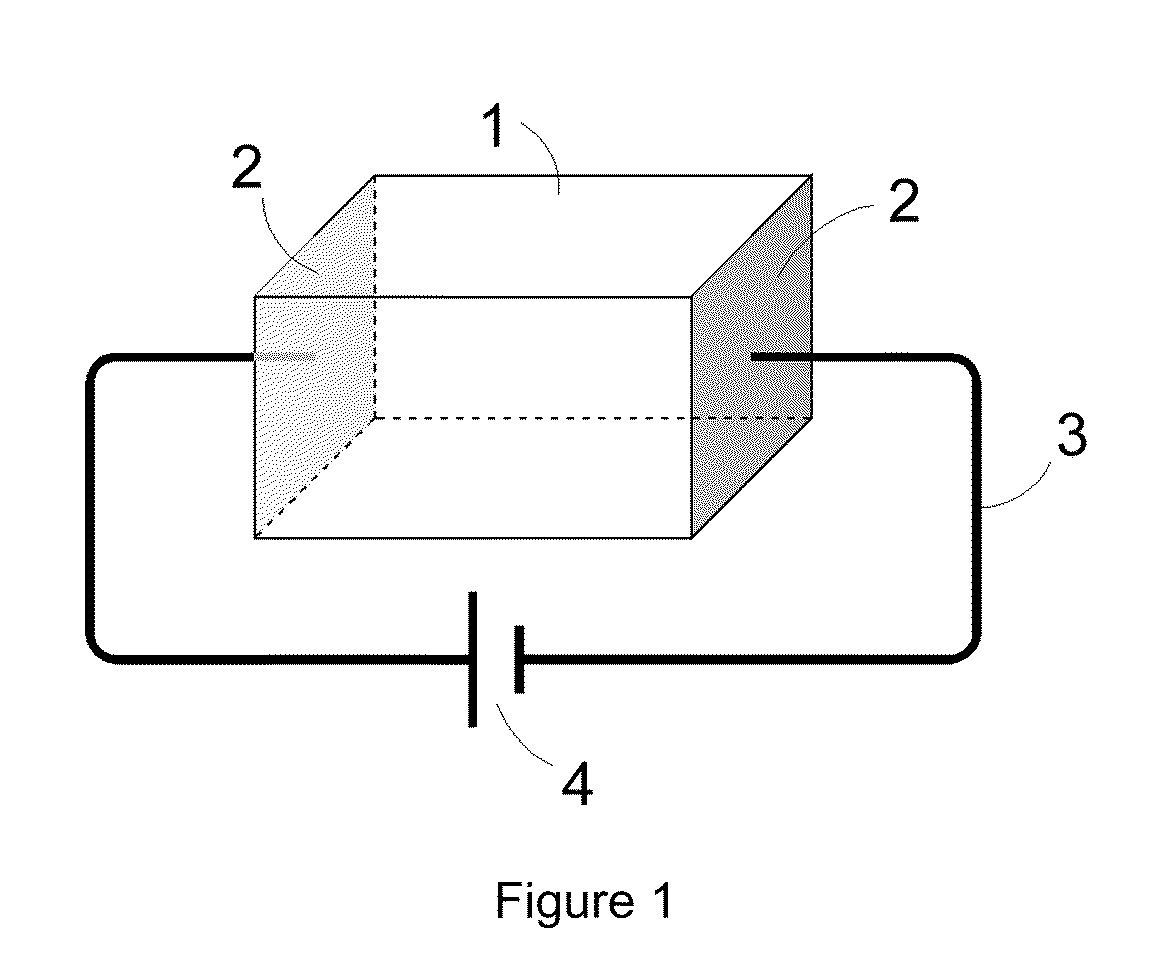

Method and Apparatus for Inspecting Crack in Ceramic Body

InactiveUS20110060536A1Reliable and low-costCompact equipmentResistance/reactance/impedenceMaterial analysis by electric/magnetic meansElectrical resistance and conductanceNon destructive

The invention is defined as a method and apparatus for non-destructive inspection including detection, quantification, and location of a surface or subsurface crack in a body made of advanced technical ceramics. The method and apparatus can detect all cracks in a ceramic body, including microscopic cracks, with a high sensitivity, accuracy and reliability, by measuring changes in electrical resistances through a plurality pairs of electrodes affixed on surfaces of the ceramic body. The extent of the cracks can be quantified and expressed as numerical data, and the location of the cracks can be identified. An automated inspection process enables a convenient, real-time, cost-effective crack inspection.

Owner:FENG MARIA QING

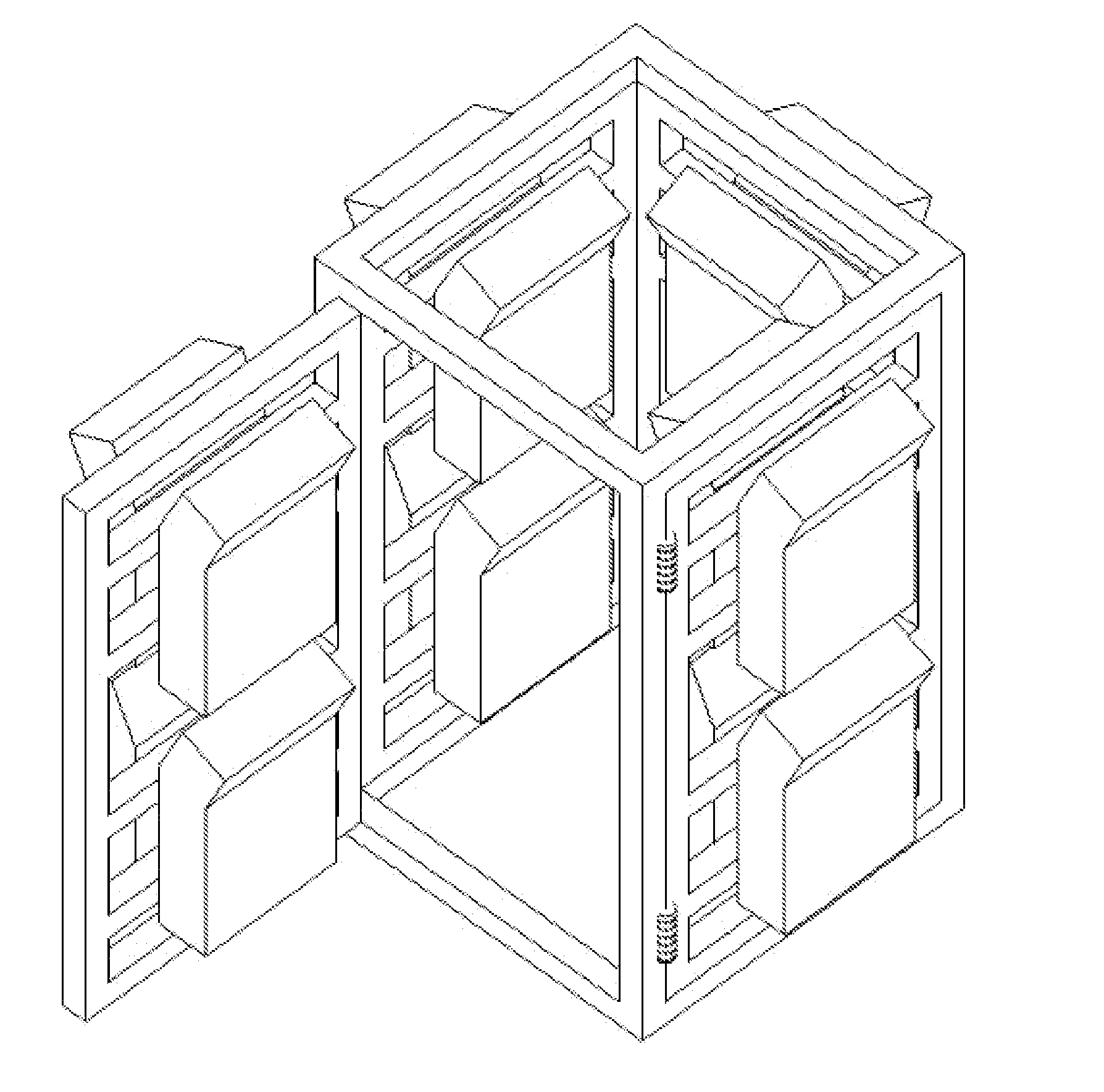

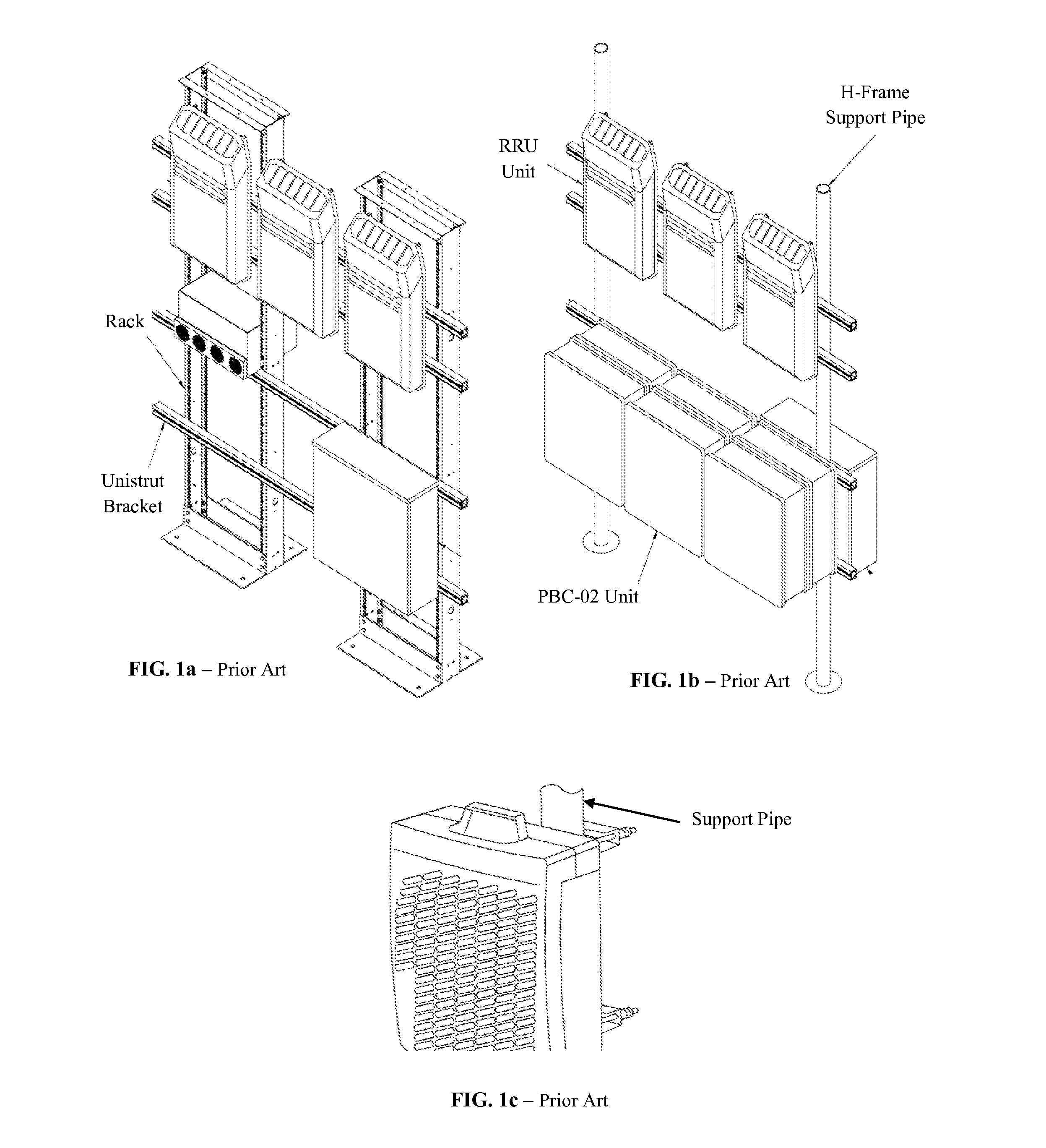

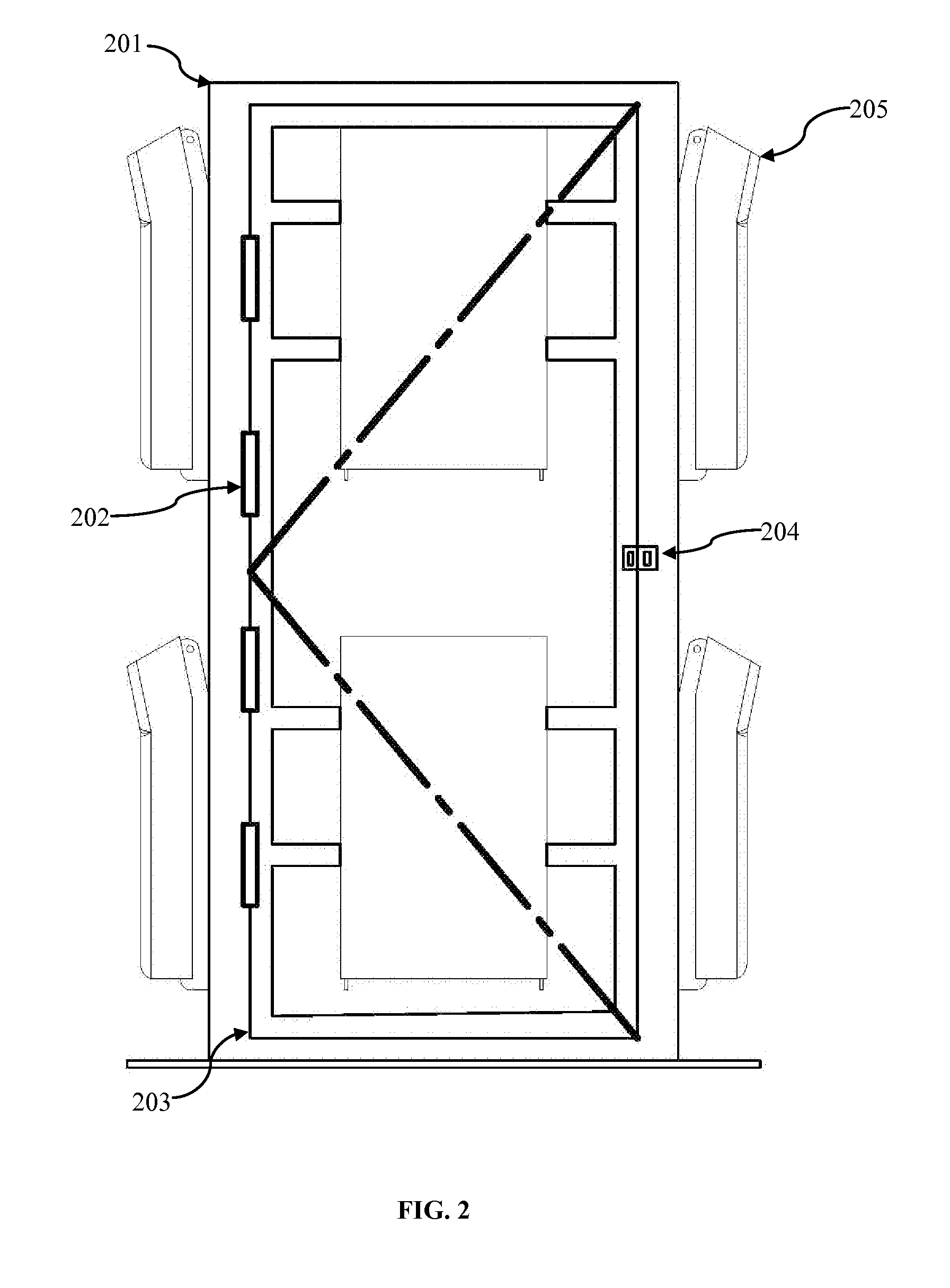

Adaptable remote radio unit mounting frame

InactiveUS20130214652A1Compact and versatile mountingCondenses footprintCabinetsSuspended tablesPrismEngineering

A prism-like frame for mounting telecom equipment made of a prism-like skeleton, which in turn is made of at least three vertical members coupled with at least six horizontal members, and at least one open panel connected to at least one lateral side of the skeleton, wherein the panel includes at least two horizontal members arranged apart from each other and away from the bottom and top of the skeleton.

Owner:MATHEWSON RICHARD

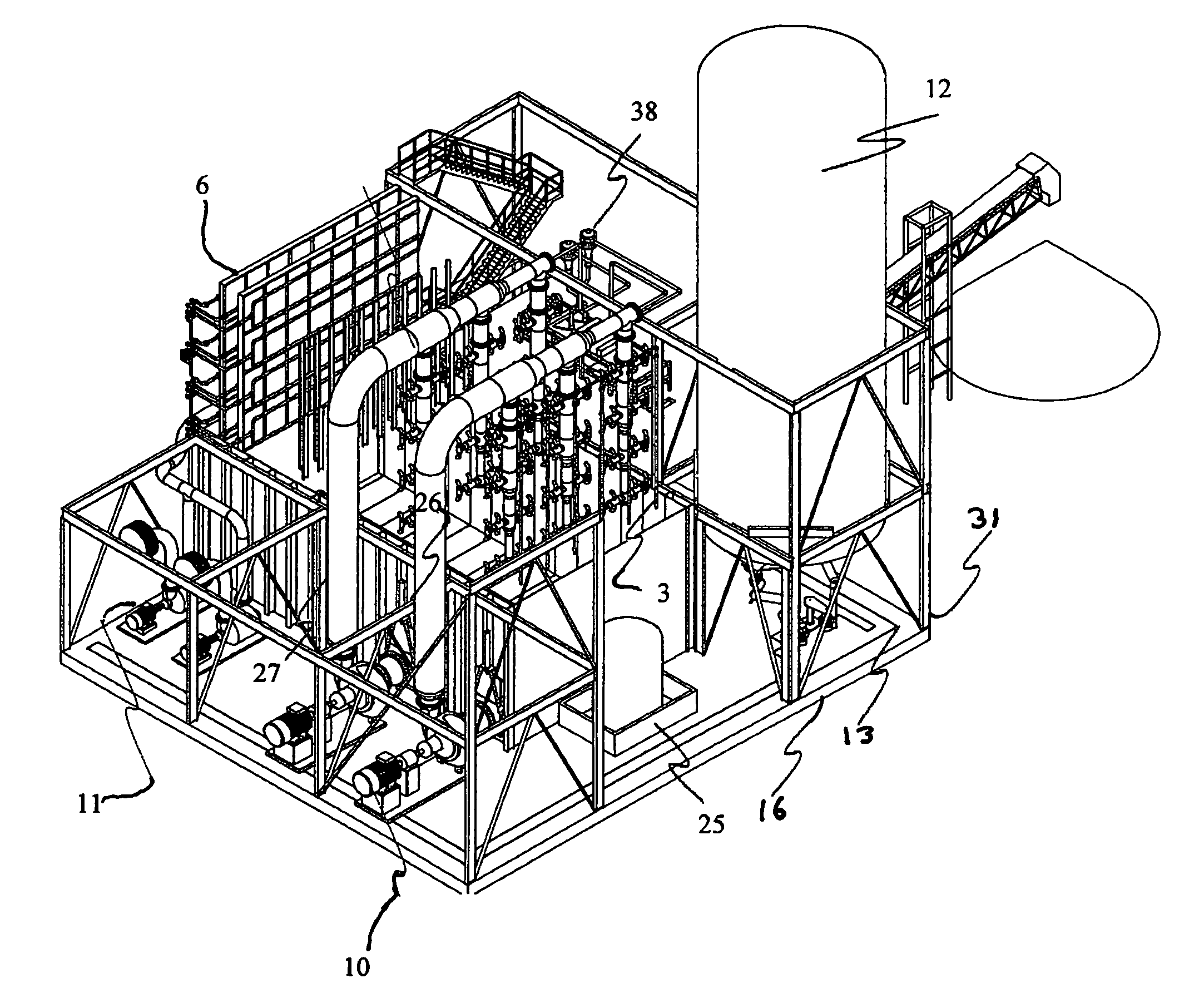

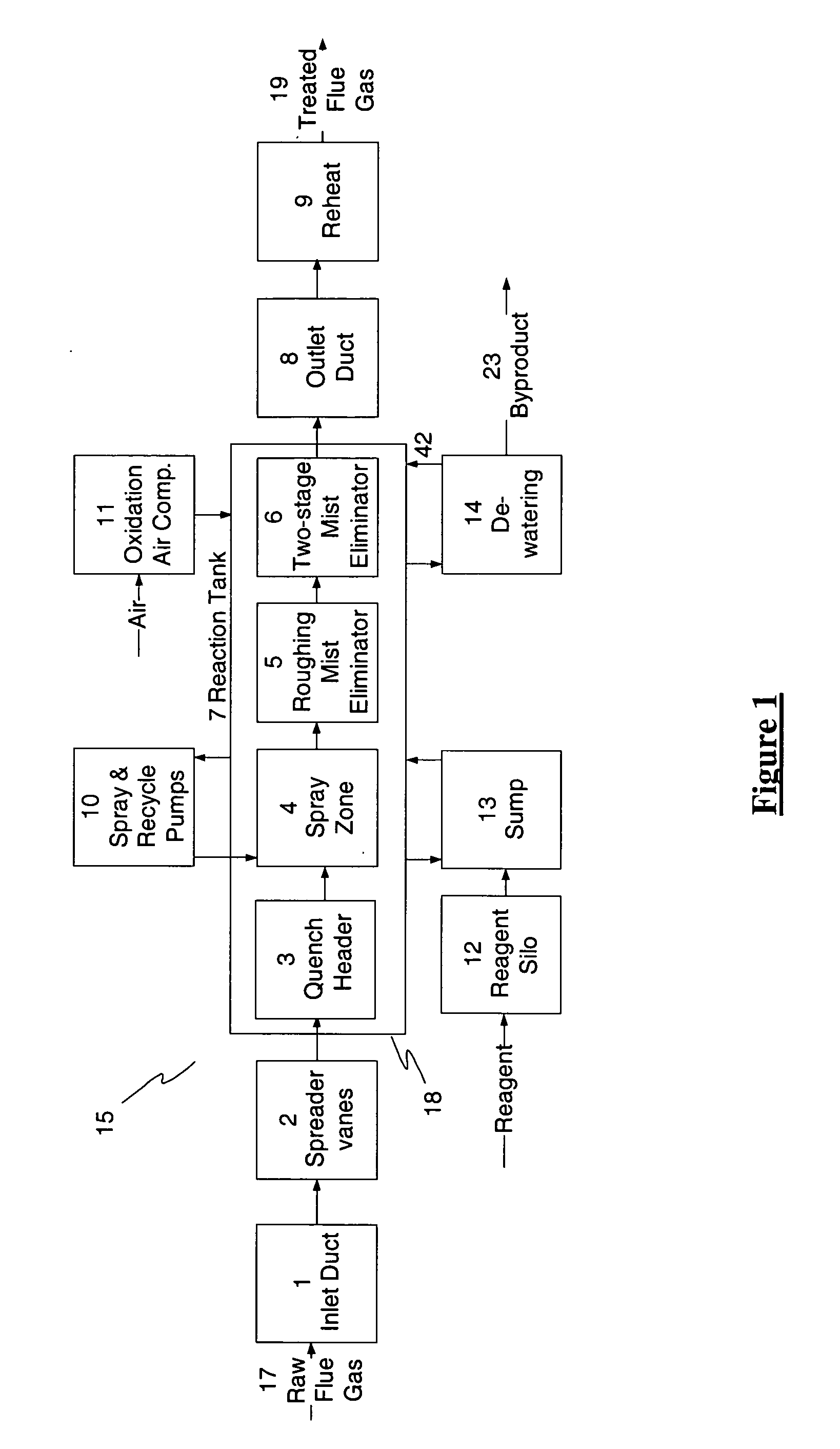

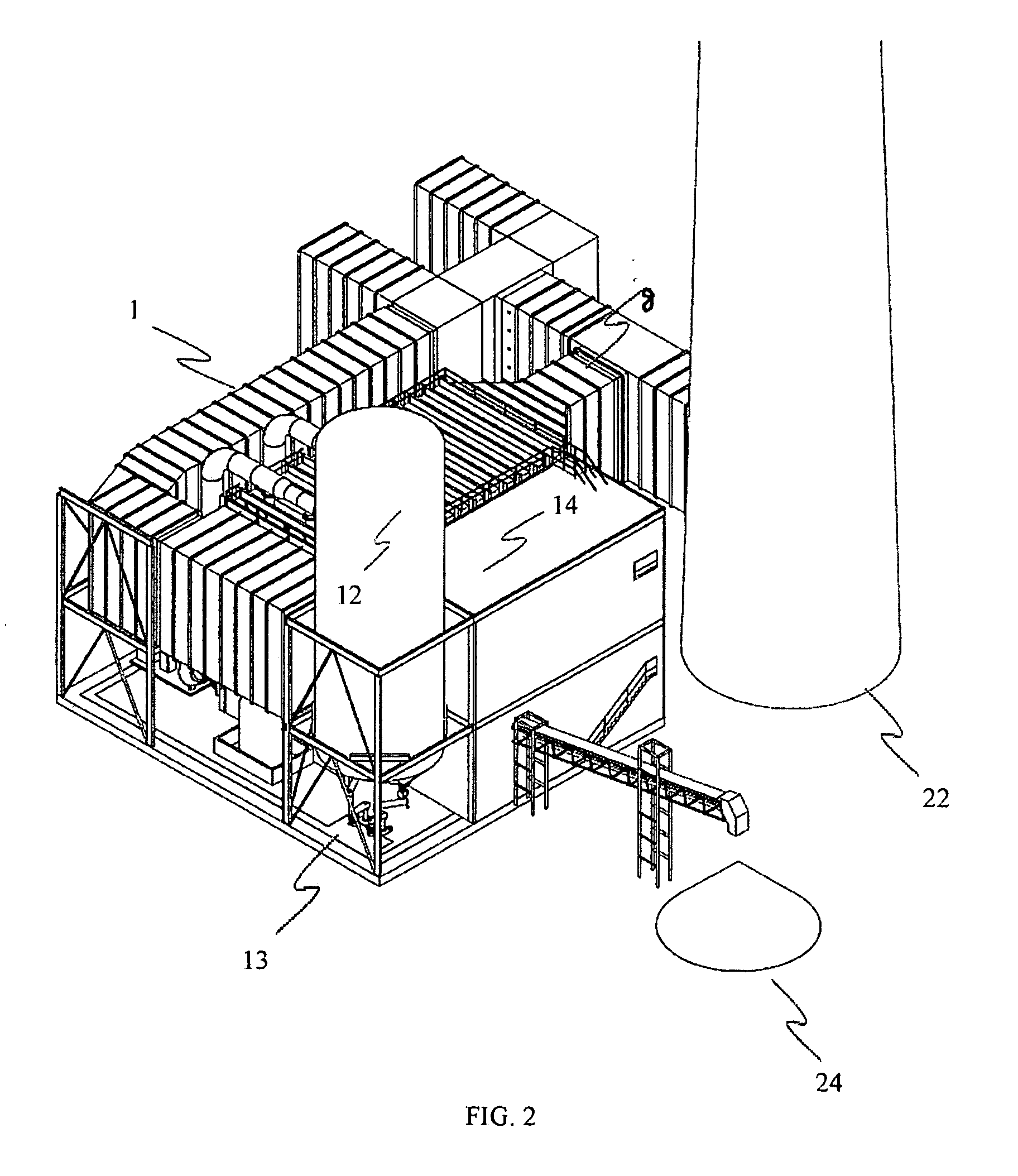

Low cost wet lime/limestone/sodium FGD system

InactiveUS20100111777A1Quick and easy applicationMinimizes byproduct conveyorCombination devicesGas treatmentPressure riseEngineering

An FGD system is provided which can be retrofitted on existing utility coal-fired boilers. The design is based on a horizontal co-current scrubber capable of generating a pressure rise across the absorber. Modifications to existing plant equipment are minimized by the co-current horizontal scrubber design. The system includes features, which eliminate much equipment typically associated with other FGD designs, and reduces the use of support equipment such as tanks, agitators, and pumps. It also minimizes or eliminates the need for new buildings.

Owner:URS

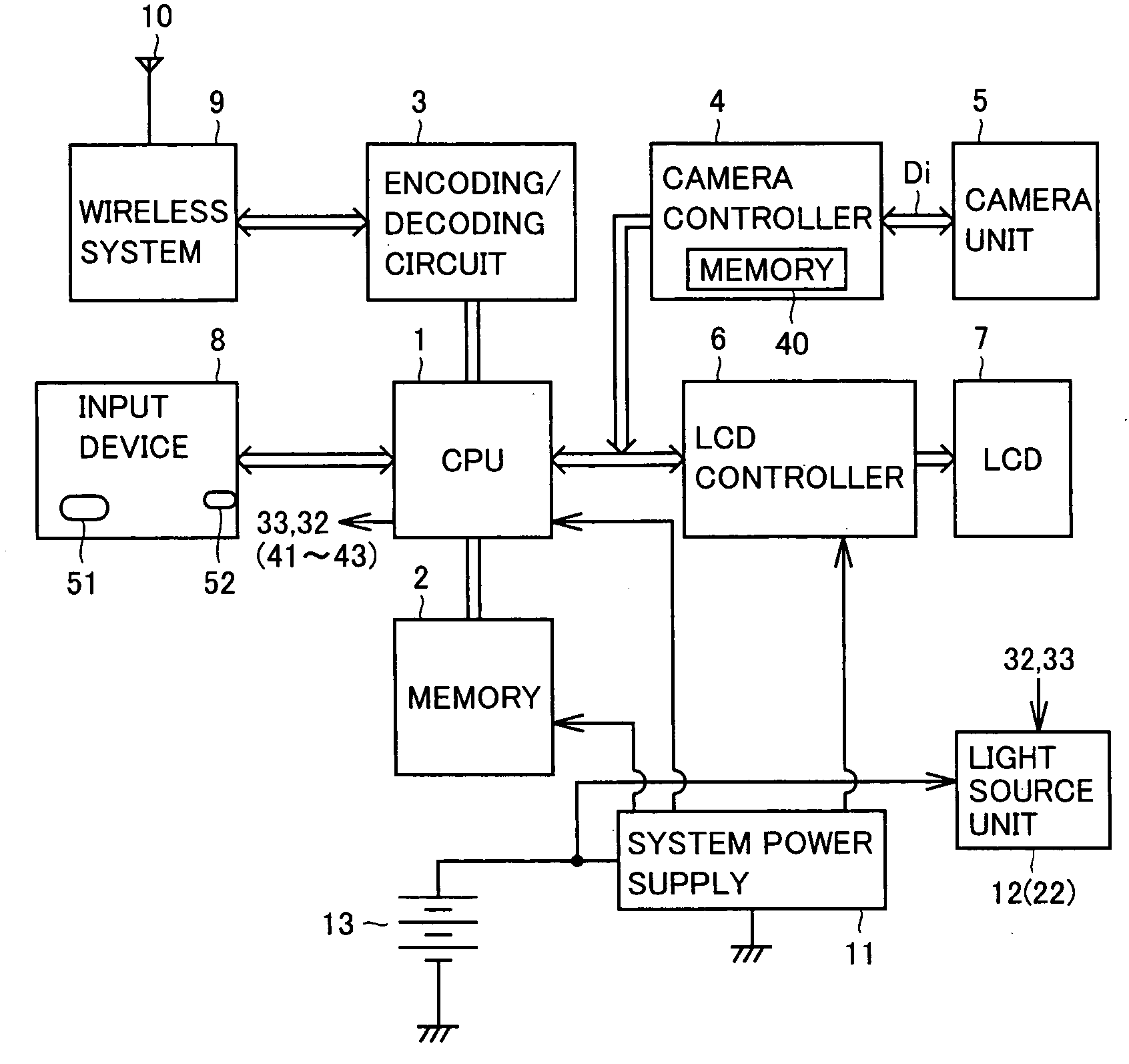

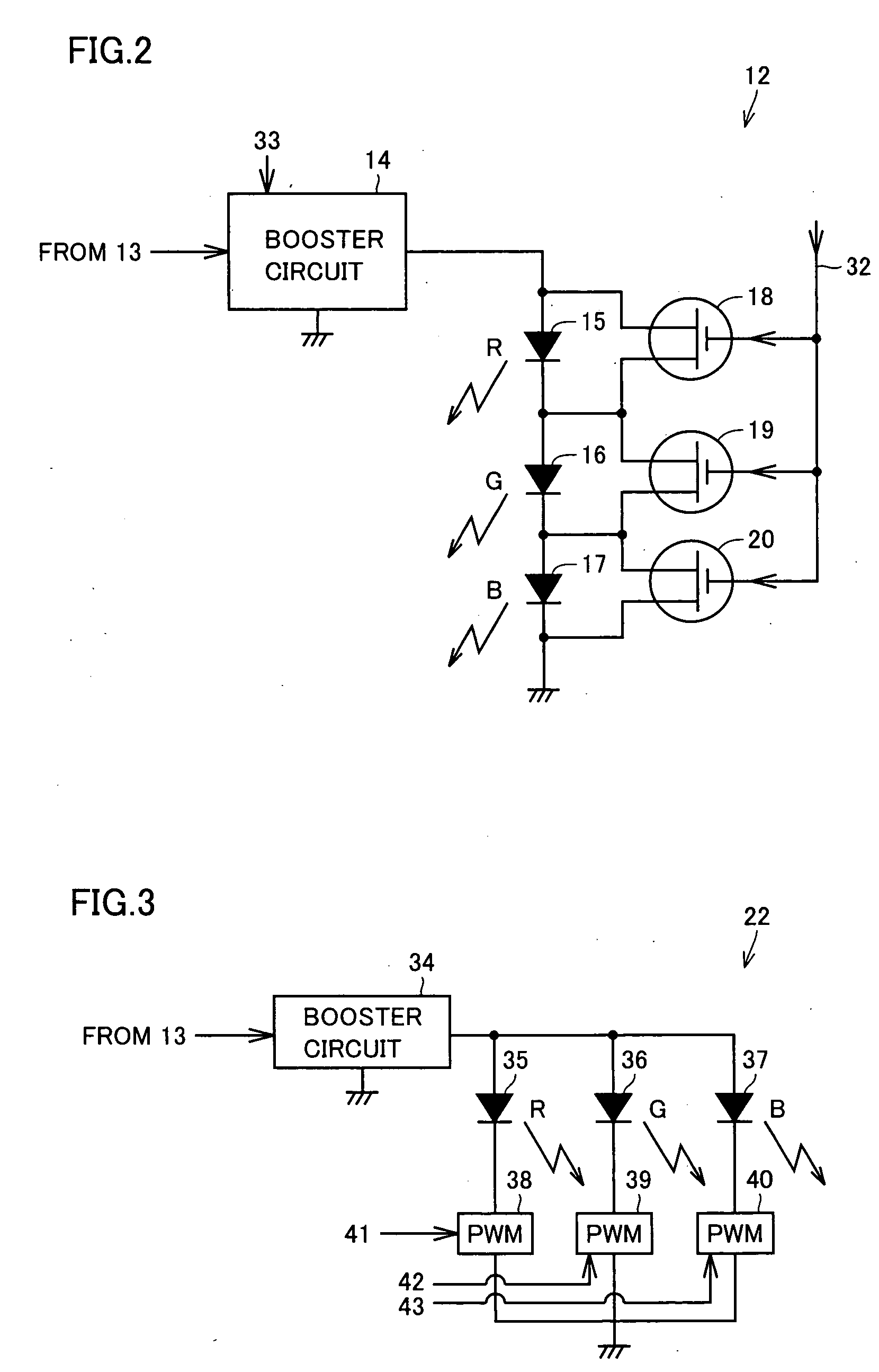

Mobile device and mobile telephone device having imaging function

InactiveUS20050148364A1Make fastUser discouragementTelevision system detailsPrintersLight spotEngineering

Mobile equipment includes LEDs supplied with a current to emit red light, green light and blue light, FETs and a booster circuit for controlling the current supplied. The current supplied is controlled to supply all of the LED with a current of a low level to illuminate an object in a shooting mode with light for illumination. Thus in the shooting mode a white spot light illuminates the object, and the object can clearly be confirmed. At the moment of shooting, a current supplied can be increased at a burst to emit white flashlight to illuminate the object. A satisfactory image can thus be obtained. The source of light for illumination can be formed of miniature, light-weight LED, and does not impair in mobility mobile equipment having the source of light incorporated therein.

Owner:SHARP KK

Method for producing corrugated base paper pulp by utilizing scrap materials of fibre board

InactiveCN102677498ASimple pulping processCompact equipmentPaper recyclingWaste paper working-upScrapPulp fibre

The invention discloses a method for producing corrugated base paper pulp by utilizing scrap materials of a fibre board. The method comprises the main steps of: preparing, soaking, steaming, spirally extruding, chemically processing, grinding, eliminating, washing and purifying materials. A majority of free formaldehyde in the raw material is removed and recycled possibly in a pulping process; a little of chemical solution is added from the rear part of a twin screw extruder, and the liquid medicine is uniformly mixed with the fibre and then subjected to mild chemical reaction by utilizing high-concentration mixing action of an extruder and heat energy generated in extruding and mixing processes, so that the high pulping yield is kept, the damage to the fibre in a grinding process is alleviated, the excellent physical strength of the pulp fibre is ensured, and the pollution load in the pulping process is reduced at the same time.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method and equipment for discriminating materials by employing fast neutron and continuous spectral x-ray

ActiveUS7399976B2Improve permeabilitySimple materialMaterial analysis by optical meansNeutron radiation measurementImaging qualityX-ray

Disclosed is a method of discriminating materials by employing fast neutron and continuous spectral X-ray and an equipment for the same. The method comprising the steps of: (a) transmitting a fast neutron beam produced by a fast neutron source and a continuous spectral X-ray beam produced by a continuous spectral X-ray source through inspected objects; (b) directly measuring the intensity of the transmitted X-rays and the intensity of the transmitted neutrons by a X-ray detector array and a neutron detector array respectively; and (c) identifying the materials of the inspected object by Z-dependency curves formed by the attenuation differences between the neutron beam and X-ray beam transmitted through different materials of the inspected object. This direct measurement of transmitted dual-ray technique has much more efficient than secondary radiations measurement such as neutron activation analysis, has much more material discrimination sensitivity than dual-energy x-ray technique. The respective measurements of neutrons and x-rays make the usages of high detect efficiency neutron detectors and x-ray detectors possible. The using continuous spectral x-ray produced by Linac adds more advantages such as: high penetration ability, high spatial resolution, and high image quality over monoenergetic dual-ray technique.

Owner:TSINGHUA UNIV +1

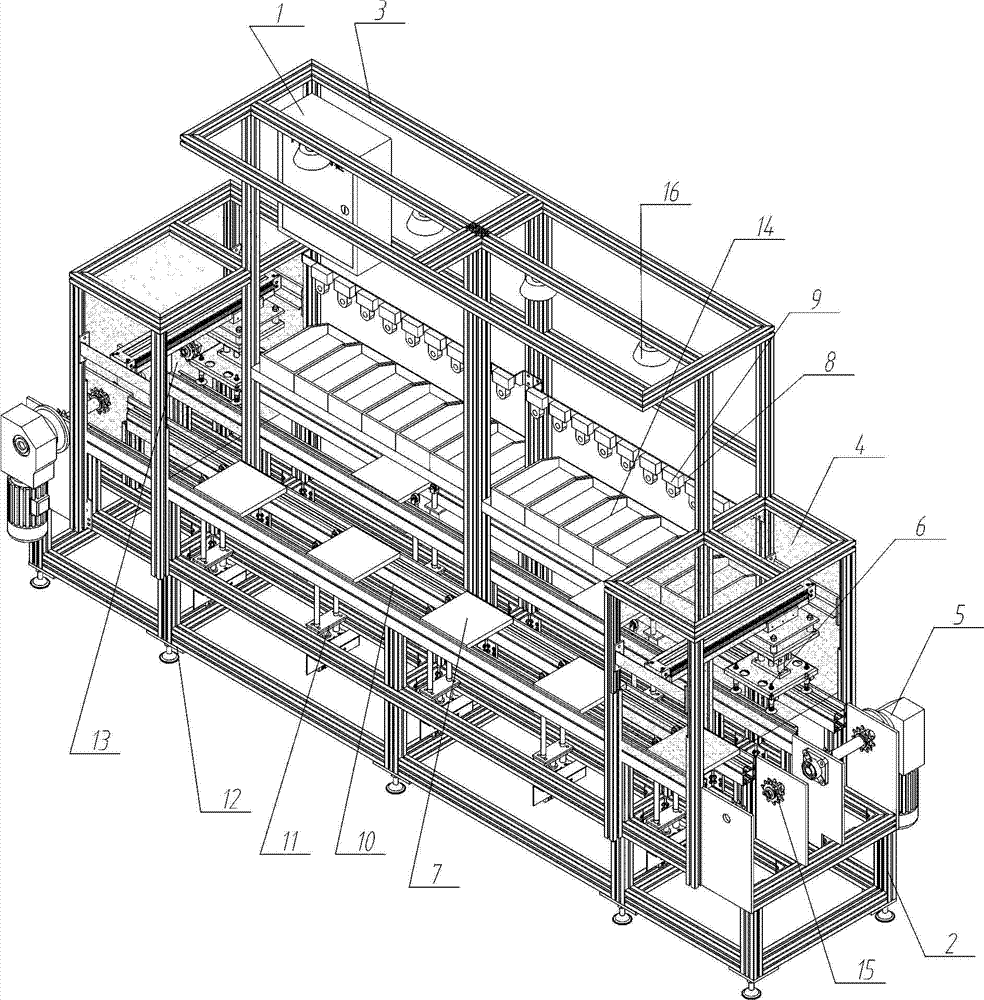

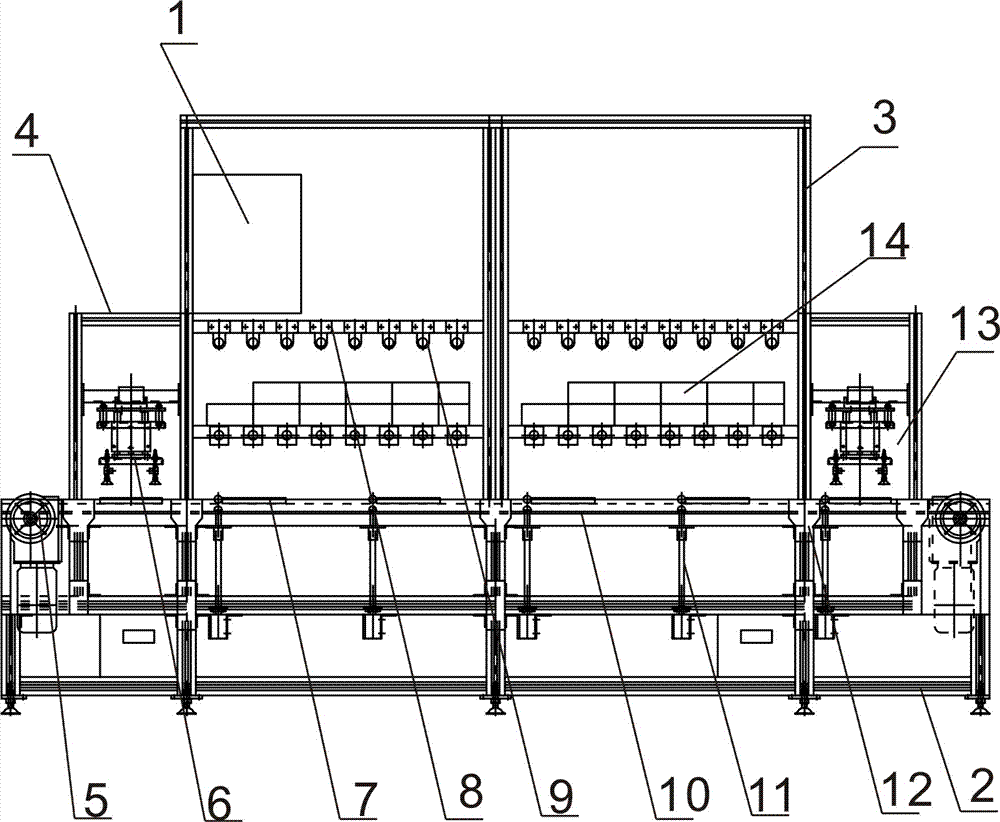

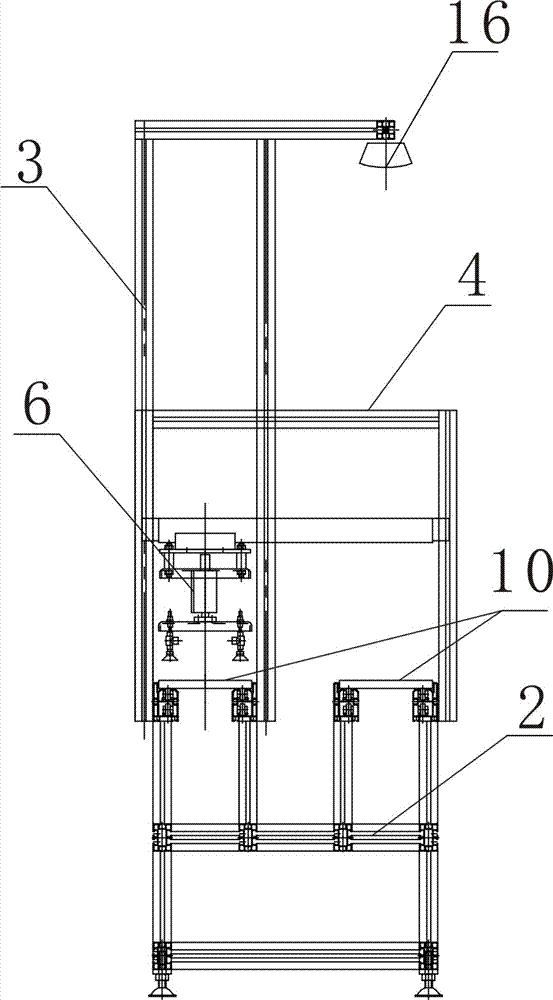

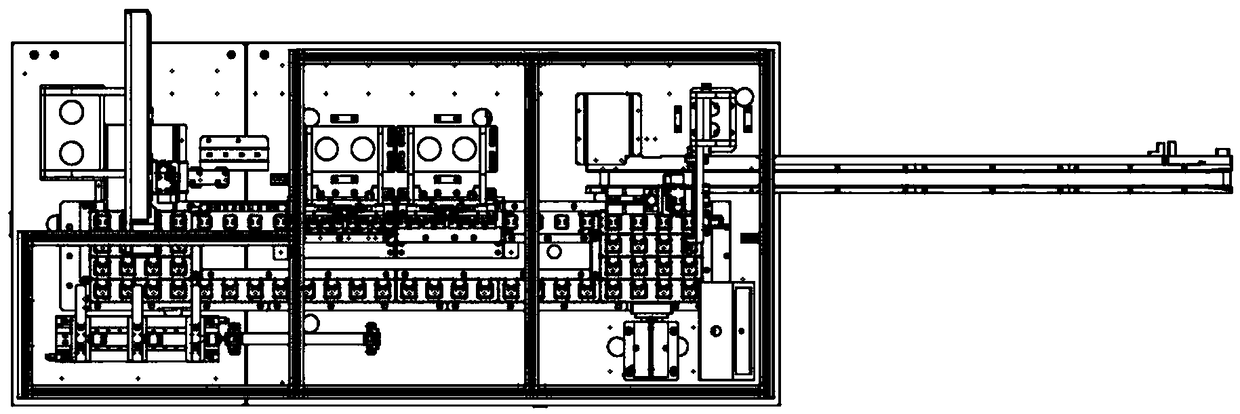

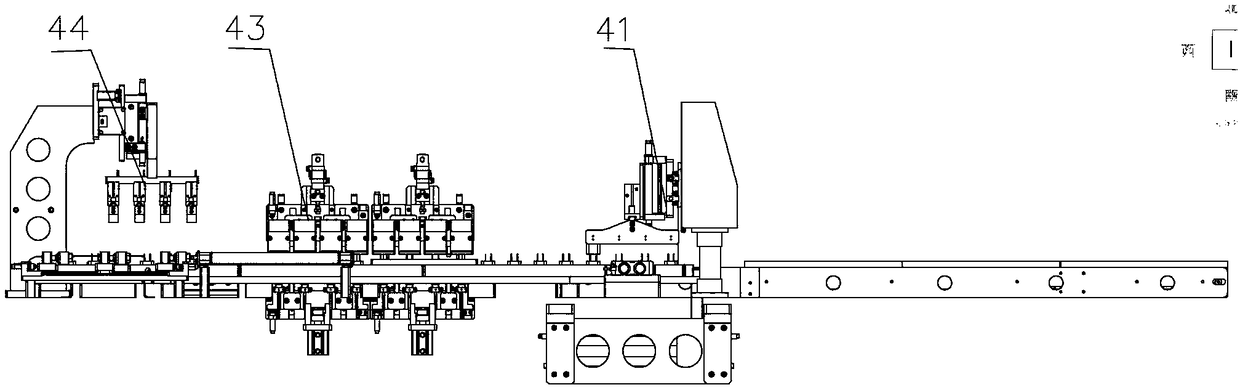

Bottom valve and piston valve assembly line as well as bottom valve and piston valve assembly error identification method

ActiveCN102756273AThe appearance of the equipment is beautiful and generousCompact equipmentAssembly machinesPistonProgrammable logic controller

The invention mainly relates to a bottom valve and piston valve assembly line, comprising a PLC (Programmable Logic Controller) control cabinet, a rack, a shadowless lamp frame, a dustproof cover, two columns of conveying lines which have opposite transmission directions and are mounted on the rack in parallel, a tool board, a transferring device for transferring the tool board, and a driving part. The transferring device is provided with two groups of double-ended heads which are respectively mounted on the conveying lines; the tool board is located on the conveying line; the dustproof cover and the shadowless lamp frame are mounted on the rack; the shadowless lamp frame is higher than the dustproof cover; and a shadowless lamp is mounted at the top of the shadowless lamp frame. The bottom valve and piston valve assembly line provided by the invention has the advantages of beautiful and elegant appearance, small equipment size, and small occupied area, and can be used for effectively saving space and field for a user. With the adoption of the assembly line, the automatic conveying is realized, so that the labor productivity is greatly improved, and the labor is saved. Meanwhile, a photoelectric error-prevention system is arranged, so that the problem of assembly error caused by personal factors can be effectively solved, and the product quality is greatly improved.

Owner:GUANGYUAN XINYUAN EQUIP MFG

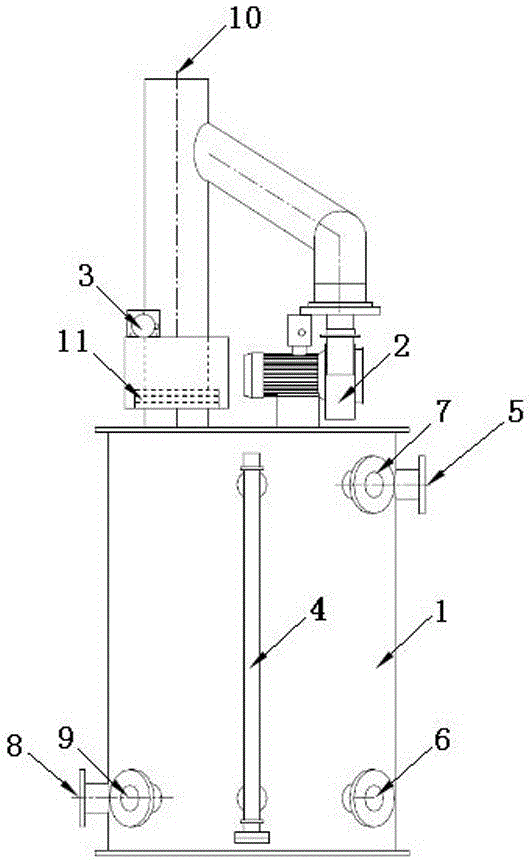

Electrolysis seawater method ship ballast water treatment system

InactiveCN106222689ASimplified electrolysis unitCompact equipmentElectrolysis componentsSeawaterWater treatment system

The invention discloses an electrolysis seawater method ship ballast water treatment system. The system comprises an electrolysis hydrogen removing unit; the electrolysis hydrogen removing unit includes an electrolyte storage tank, an electrolysis unit and an electrolyte circulating pump; an inlet and an outlet of the electrolyte storage tank are respectively connected with an outlet of a prefilter and an inlet of a medicine charging pump; two circulating joints of the electrolyte storage tank are serially connected with the electrolysis unit and the electrolyte circulating pump to form a circulating loop; and a hydrogen removing device is mounted at the top end of the electrolyte storage tank. The electrolysis seawater method ship ballast water treatment system has the following advantages: the electrolyte storage tank is provided, and the electrolysis unit is used for circularly electrolyzing seawater, so that the ballasting after electrolysis is realized, the equipment selection limit from ballasting during electrolyzing is overcome, the electrolysis unit with a small model number can be selected, and the multi-way medicine charging complex process of one set of electrolysis units can be realized; the electrolyte storage tank is fully used for realizing the liquid storage function, and meanwhile, an air blowing device is added for realizing the hydrogen removing function; and the electrolysis unit is simplified, and a hydrogen removing part is canceled, so that the equipment is more compact, the operation is more stable, and the cost can be reduced.

Owner:SUNRUI MARINE ENVIRONMENT ENG

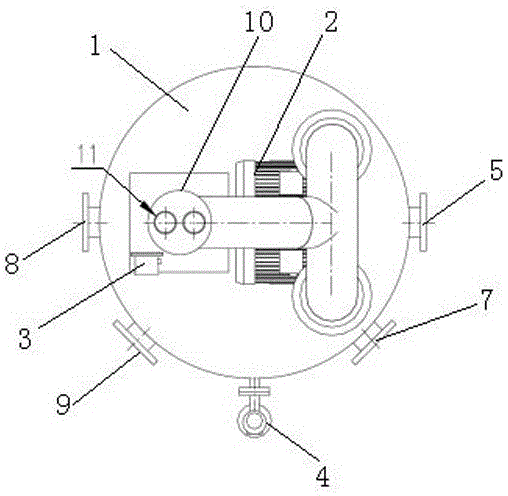

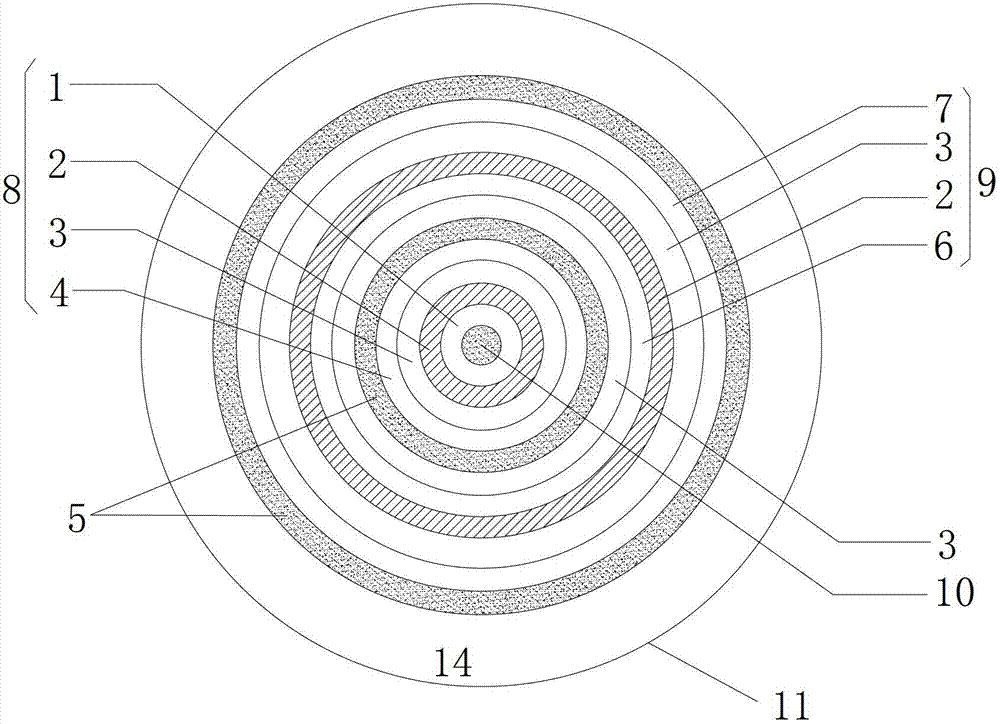

Multiple ozone generating device

InactiveCN103159185AIncrease profitHigh ozone concentrationOzone preparationCorona dischargeDielectric

The invention discloses a multiple ozone generating device which is formed by a plurality of electrode couples, and the electrode couples are distributed from inside to outside in a concentric-circle mode in sequence. Each electrode couple is composed of an inner electrode and an outer electrode, the inner electrode is connected with a high-voltage terminal, the outer electrode is grounded, the inner electrode of each electrode couple is coated with dielectrics, a discharging gap is arranged between the inner electrode and the outer electrode, and a discharging gap is arranged between two adjacent electrode couples. Double cooling liquid is used in the multiple ozone generating device, a cooling oil layer is arranged on the outer side of each outer electrode, and the innermost layer of the device is filled with cooling water. The discharging gap of each electrode couple and the discharging gap between the electrode couple and the adjacent electrode couple on the outer layer are in a communicating state, and a stainless steel jacket is arranged on the outermost layer of the whole device. The technical problems that the efficiency of existing high-voltage corona discharge type ozone generating is low, an ozone generating device is high in running cost and the like are solved, the use ratio of raw material gas is improved, ozone concentration is increased, and discharging tube consumption and electric-discharge energy consumption are reduced, so that cost is lowered.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

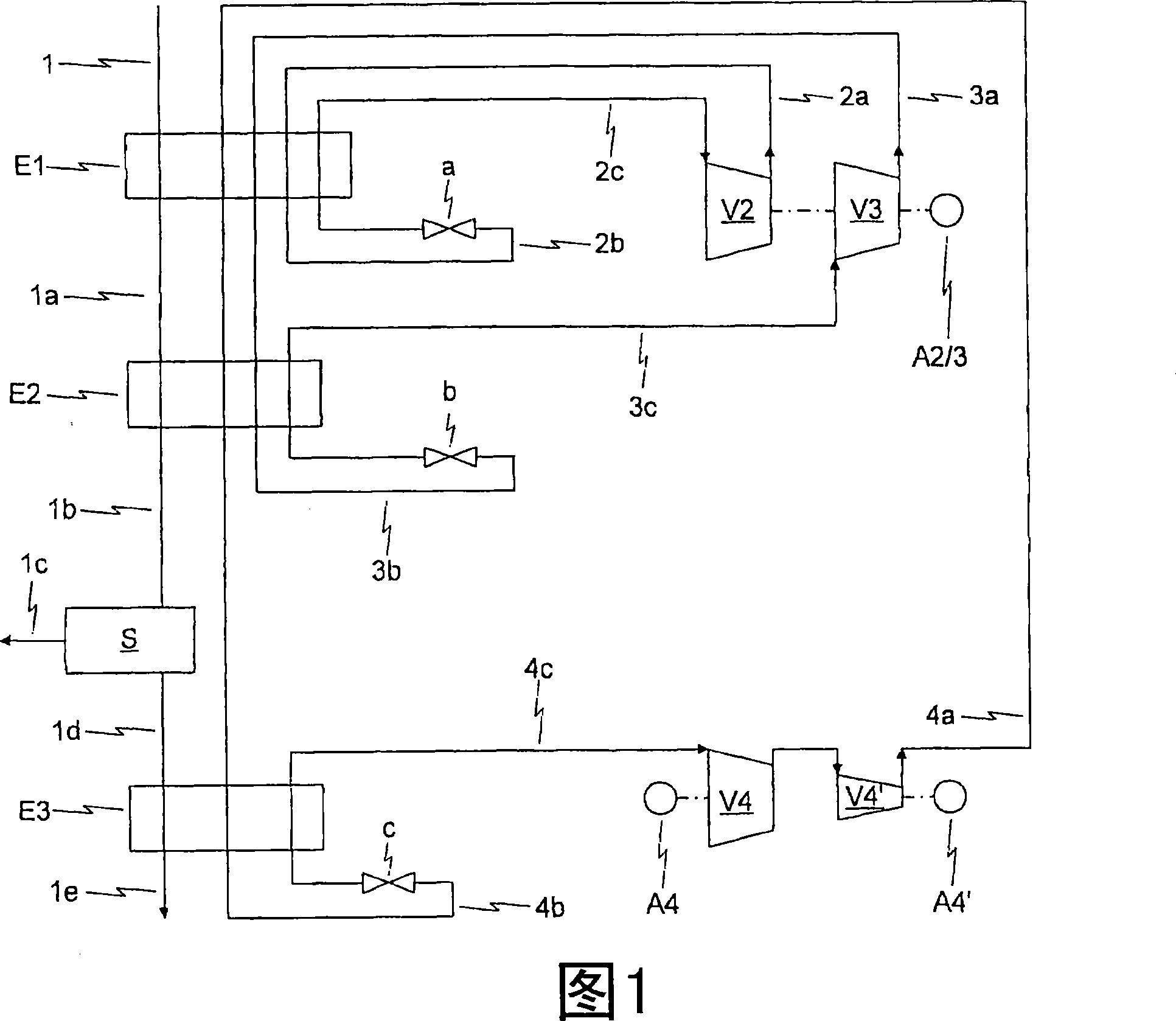

Method for liquefying a hydrocarbon-rich flow

InactiveCN101223410AIncrease gas densityCompact equipmentSolidificationLiquefactionSubcoolingNatural gas

The invention relates to a method for liquefying a hydrocarbon-rich stream, in particular a natural gas stream, wherein the liquefaction of the hydrocarbon-rich stream is carried out against a mixed refrigerant cycle cascade consisting of three mixed refrigerant cycles. According to the invention, the first and second mixed refrigerant cycles (2a-2b, 3a-3b) are used for precooling, and the third mixed refrigerant cycle (4a-4b) is used for liquefaction and subcooling of the hydrocarbon-rich stream. Here, the first and / or second mixed refrigerant cycle (2a-2b, 3a-3b) is preferably designed as a single-stage mixed refrigerant cycle, while the third mixed refrigerant cycle (4a-4b) is preferably designed as It is a two-stage mixed refrigerant cycle.

Owner:LINDE AG

Integrated disposal technology for waste emulsion liquid, electroplating wastewater and landfill leachate

ActiveCN103819060ACompact equipmentLess investmentMultistage water/sewage treatmentEmulsionPre treatment

The invention discloses an integrated disposal technology for waste emulsion liquid, electroplating wastewater and landfill leachate. The integrated disposal of the waste emulsion liquid, electroplating wastewater and landfill leachate can be implemented by utilizing demulsification, oxidation pre-treatment and biological treatment. According to the integrated disposal technology for waste emulsion liquid, electroplating wastewater and landfill leachate, provided by the invention, the demulsification of various waste emulsion liquid with high COD can be implemented, the waste emulsion liquid, the electroplating wastewater and the landfill leachate can be disposed in the same disposal facility to reach the emission standard, the equipment is compact, and the investment is low.

Owner:QINGDAO NEW WORLD ENVIRONMENT PROTECTION CO LTD

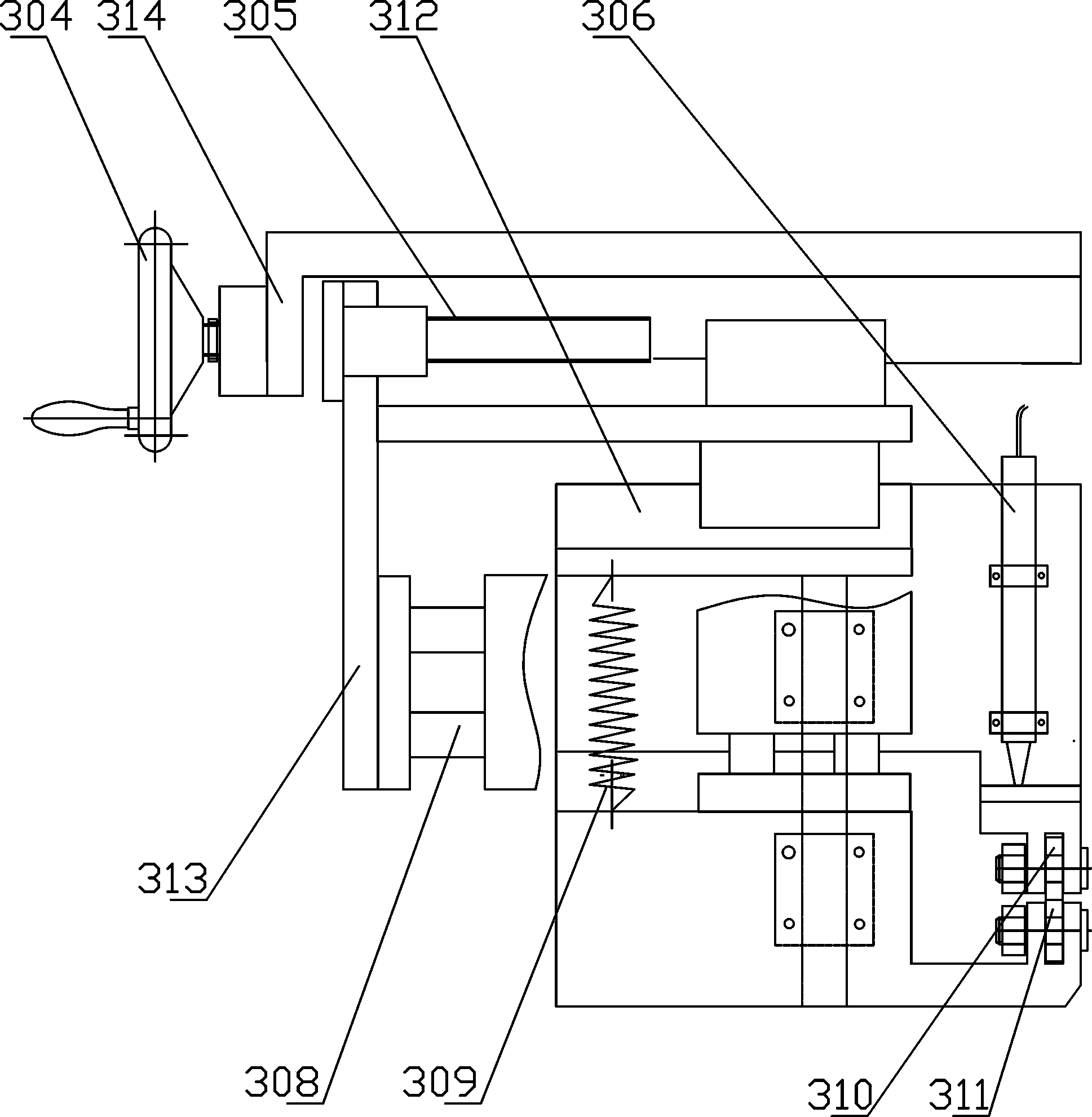

Intelligent thickness gauge

ActiveCN104162840ACompact equipmentEasy to avoid unloadingGrinding feed controlUsing optical meansEngineeringAccuracy and precision

The invention discloses an intelligent thickness gauge. An upper detection rolling wheel and a lower detection rolling wheel can both be installed on a detection lifting guide rail in a sliding mode through bases, and the base of the upper detection rolling wheel and the base of the lower detection rolling wheel are installed on a rack through springs so that a detection point between the upper detection rolling wheel and the lower detection rolling wheel can float. The intelligent thickness gauge is further provided with a detection head used for detecting a gap between the upper detection rolling wheel and the lower detection rolling wheel or a gap between the base of the upper detection rolling wheel and the base of the lower detection rolling wheel. A control device connected with the detection head is used for correcting a measurement zero point at any time when the upper detection rolling wheel and the lower detection rolling wheel do not carry out detection. According to the intelligent thickness gauge, because a floating detection point structure is adopted, on-line thickness detection is achieved, in other words, the thickness of a workpiece is directly detected in real time in the production process, and then parameters of grinding machining can be determined according to a detected thickness value. Because the floating detection point structure is adopted, the intelligent thickness gauge can further adapt to changes of thicknesses of workpieces. Because the measurement zero point is corrected at any time, influences caused by sensor zero wander on measurement accuracy are avoided.

Owner:HEIXUANFENG SAW IND

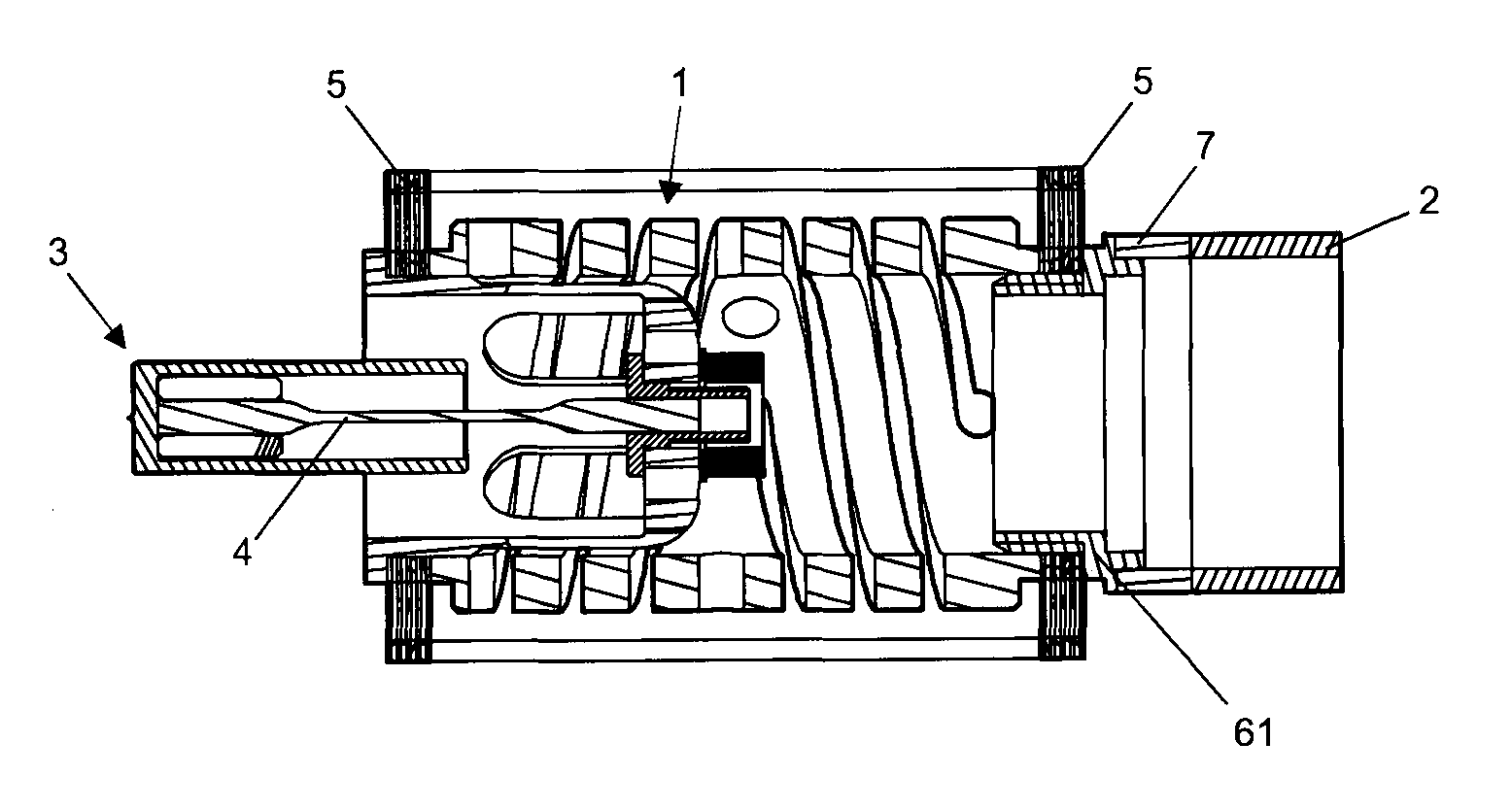

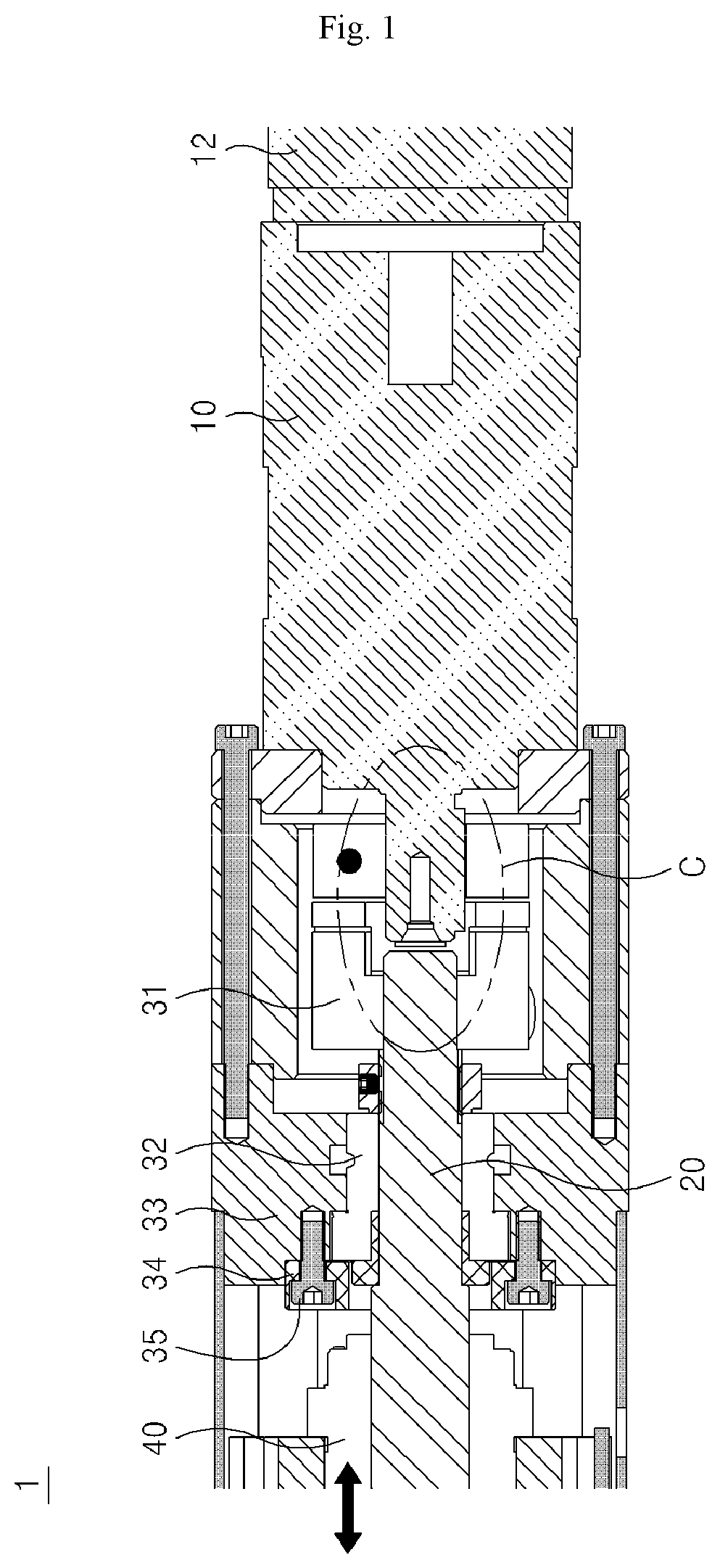

Adapting device for linear compressor, and compressor provided with such device

InactiveUS20140193278A1Compact equipmentExcessive equipmentPositive displacement pump componentsPump parameterLinear compressorActuator

The present invention relates to an adapter for connecting a resilient member 1 to a magnetic actuator 2 of a linear compressor, comprised of at least one support member 6 cooperating with a resilient element 1, said support member 6 comprising a substantially cylindrical part equipped with intermediate perimeter salient portion 61; at least one fastening element 7 cooperating with the support member 8 and the magnetic actuator 2, and means for enabling interconnection between a magnetic actuator 2 and a resilient member 1 of a detachable and electrically insulated linear compressor, the fastening element 7 being made in electrically insulating and non-magnetic material, for example, ceramic.

Owner:EMBRACO IND DE COMPRESSORES E SOLUCOES EM REFRIGERACAO LTDA

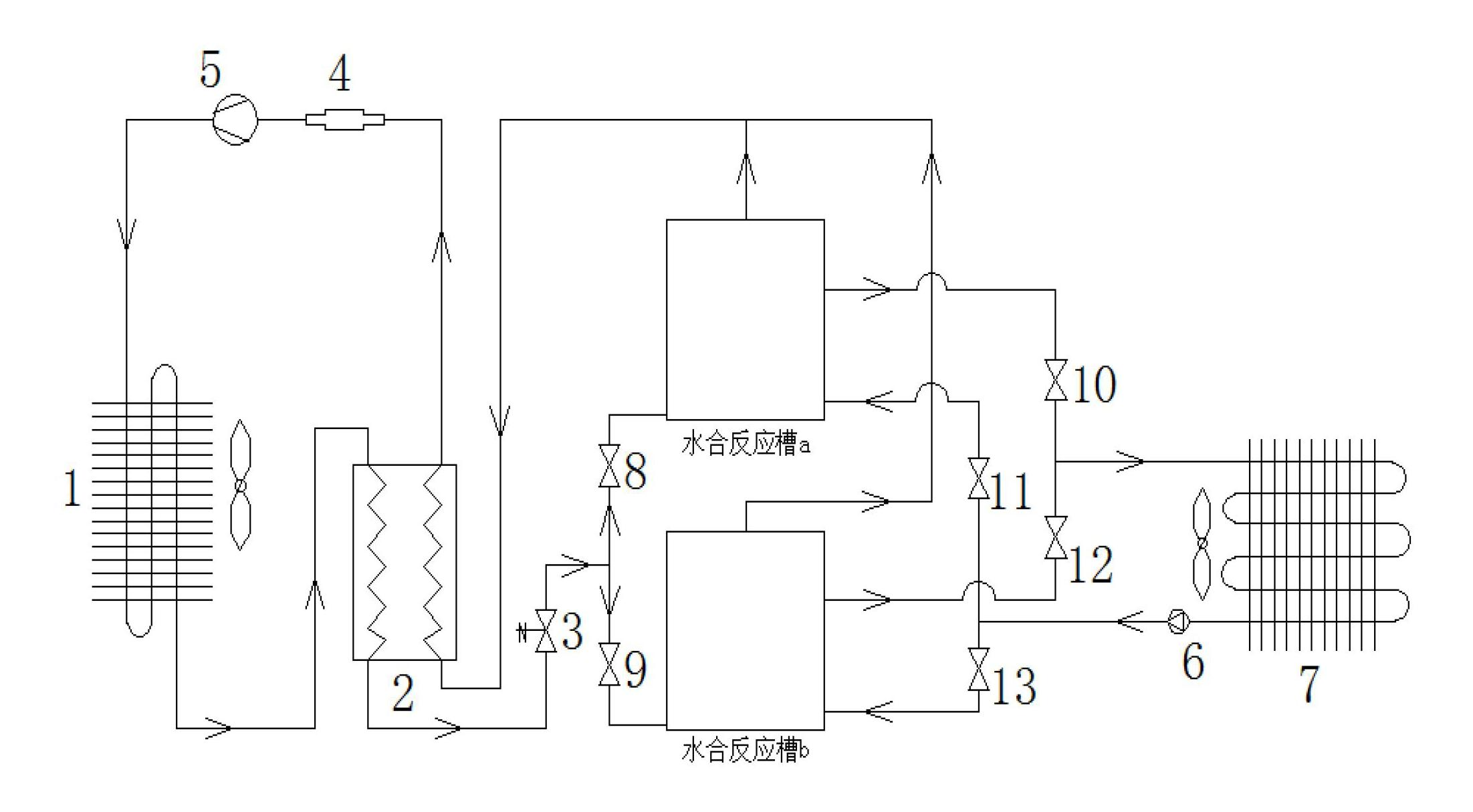

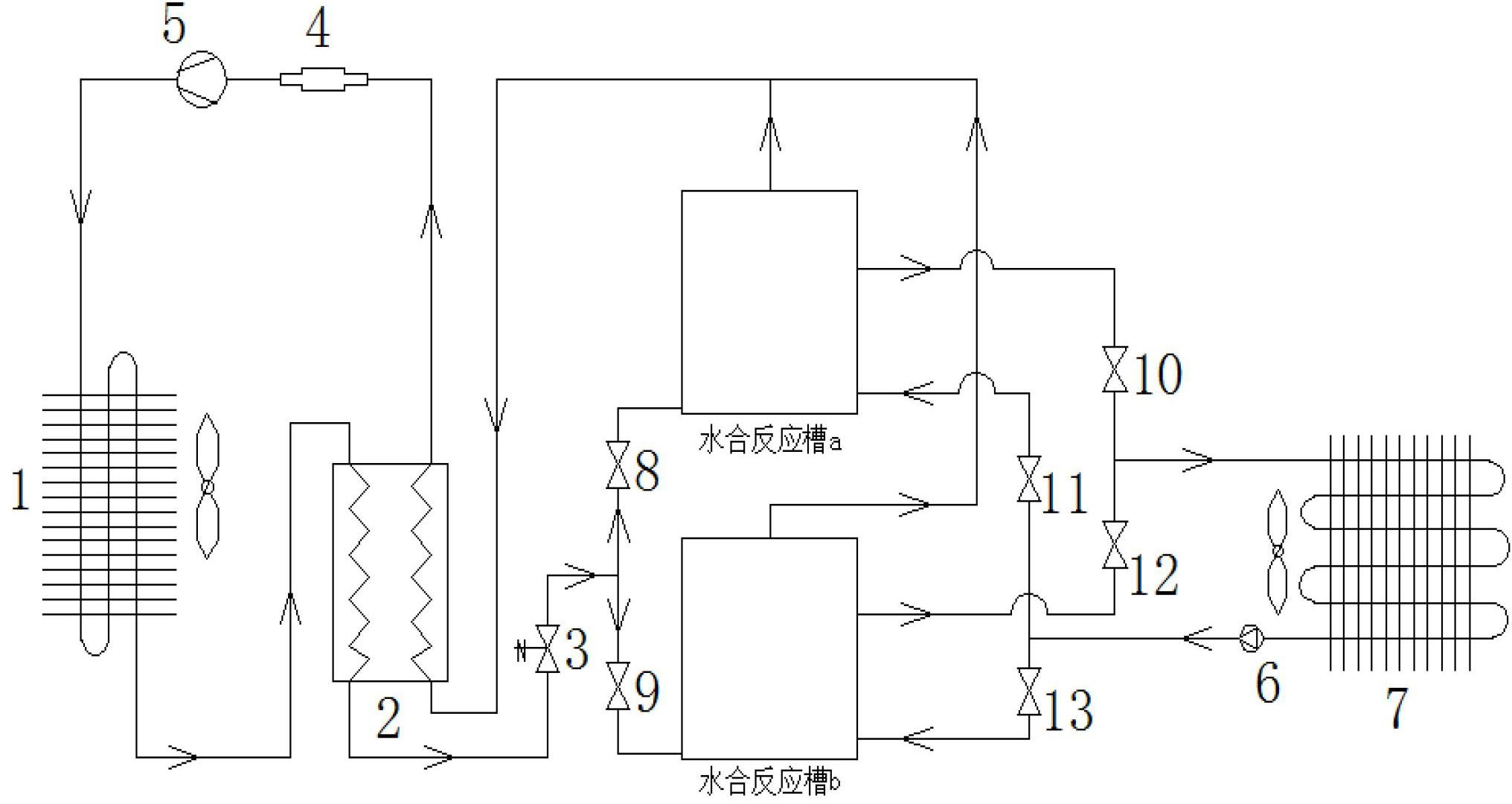

CO2 hydrate slurry circulating cold accumulation and discharge type automobile air conditioning device

InactiveCN102644980ACompact equipmentStructure miniaturizationSpace heating and ventilation safety systemsLighting and heating apparatusEvaporatorControl valves

The invention relates to an automobile air conditioning device, in particular to a CO2 hydrate slurry circulating cold accumulation and discharge type automobile air conditioning device, belonging to the technical fields of refrigeration engineering and chemical engineering. In the invention, the traditional evaporator is replaced by a reaction tank a, a reaction tank b and a fan coil, the cold accumulation is performed by use of the chemical reaction between CO2 and the water in the reaction tank a, and the reaction tank b finishing cold accumulation performs cold discharge through the fan coil under the drive of a circulating pump so as to realize a refrigeration effect in the automobile; and through the effect of a control valve, the reaction tank a and the reaction tank b alternately perform refrigeration and cold discharge so as to realize a continuous operation effect of a refrigeration circulation system. The automobile air conditioning device provided by the invention has the advantages that: the volume efficiency of the CO2 serving as a refrigerant can be kept at a relatively high level, thus a small structure of the refrigeration system is realized; and since the phase-transition temperature of the gas hydrate is 5-14 DEG C, and the temperature range is close to the operation conditions of the air conditioner, the shortcoming of low freezing temperature of the traditional ice cold accumulation unit can be overcome.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

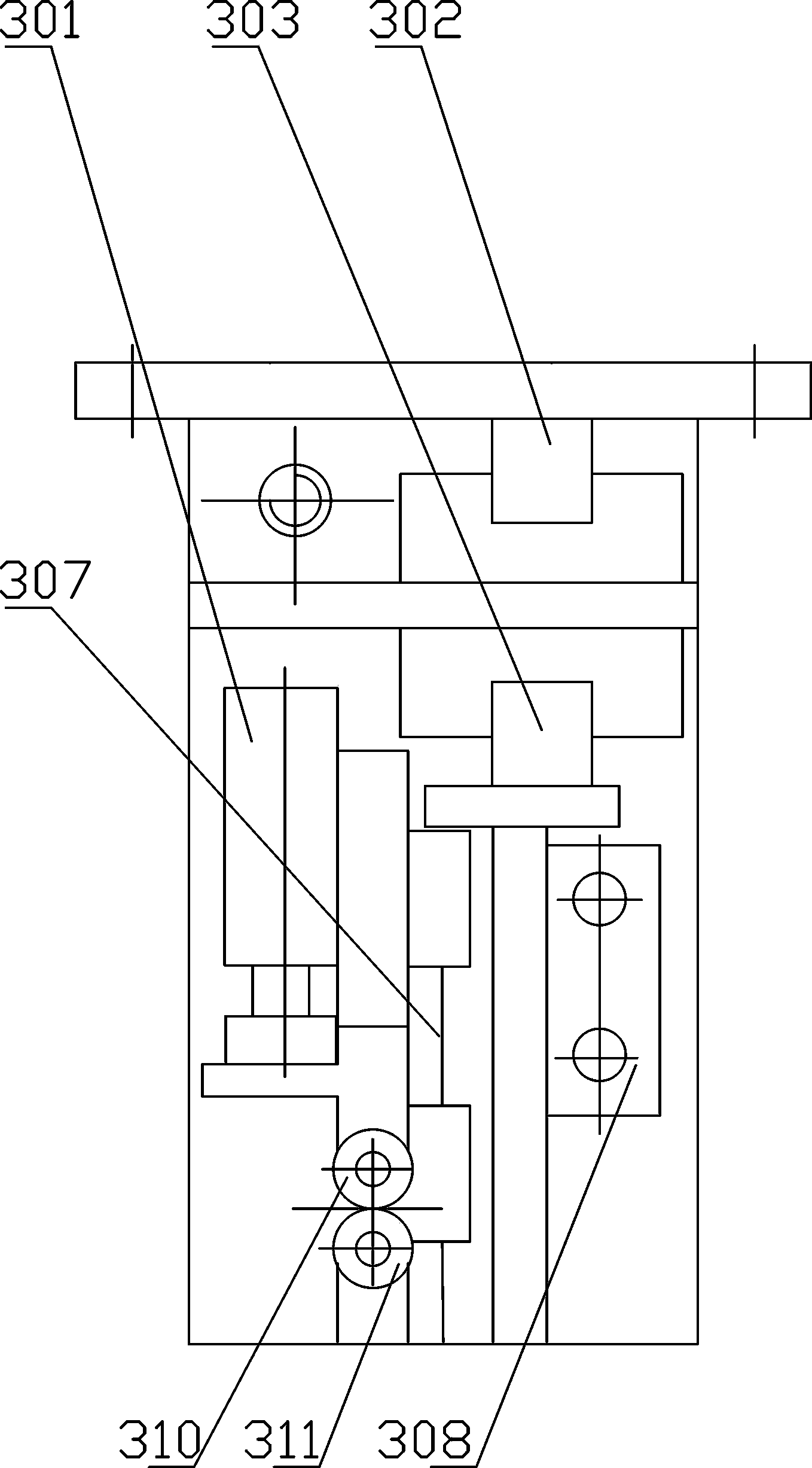

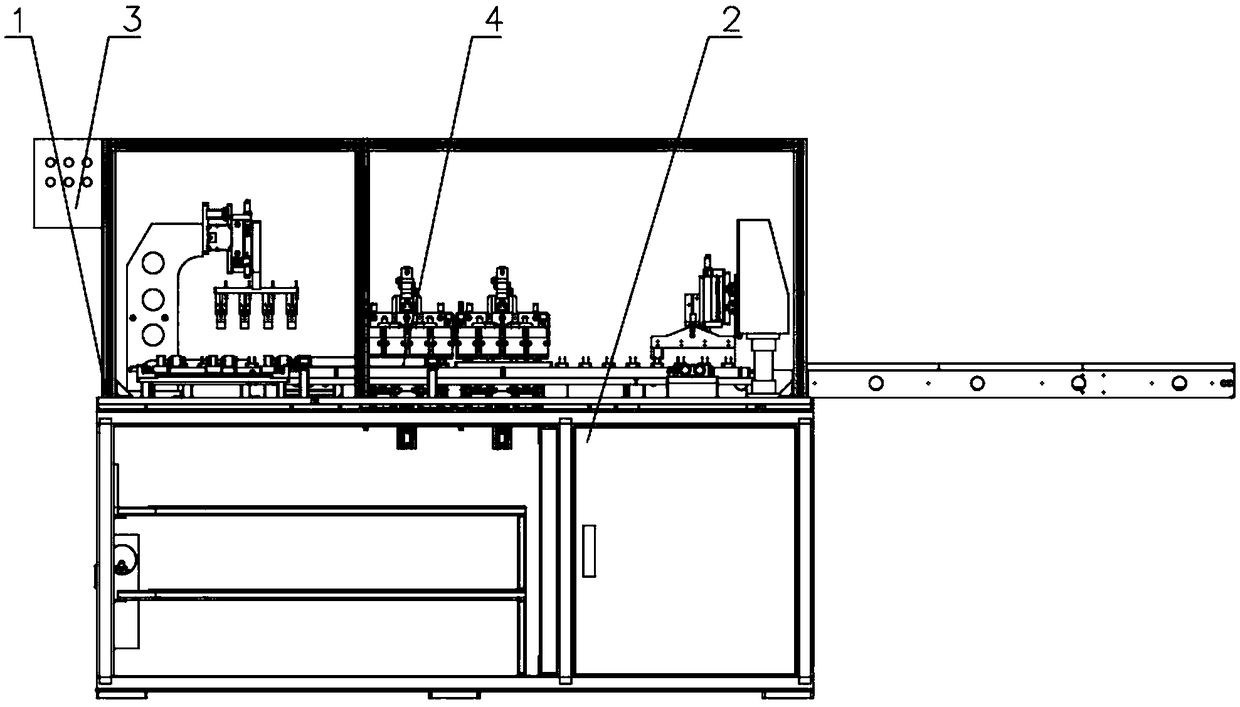

Charger charging head testing equipment

InactiveCN108646123AHigh degree of automationCompact equipmentElectrical testingTesting equipmentEngineering

The invention discloses charger charging head testing equipment,and mainly solves the problem that charger charging head testing equipment has low testing automation and low efficiency in the prior art. The charger charging head testing equipment comprises a rack,an electric control cabinet,a control panel and a characteristic mechanism,wherein the characteristic mechanism comprises a charging mechanism,a rotary conveying line,a testing mechanism and a discharging mechanism; the two ends of the rotary conveying line are provided with the charging mechanism and the discharging mechanism respectively,and the rotary conveying line is shaped like a Chinese character 'hui'. The above problem is solved better,and the method is suitable for the test of a charging head of a charger.

Owner:润桐(苏州)技术服务有限公司

Method for saturating cavities present in a mass of soil or in a body in general

ActiveUS7645097B2Short timeCompact equipmentArtificial islandsMaterial fill-upChemical reactionSolid mass

A method for saturating cavities present in a mass of soil or in a body in general, comprising at least one step for at least partial filling of the cavity by introducing into the cavity a filler material in the solid state or in the fluid state and capable of setting. At least one step of saturating the cavity is then performed by introducing into the cavity a fluid synthetic substance which expands and sets by chemical reaction. The synthetic substance is adapted to generate, as a consequence of its expansion, at least the saturation of the cavity and a compaction and / or loading of the filler material introduced into the cavity in the filling step, creating an optional state of permanent tension on the walls that delimit the cavity, to the point of producing, if necessary, a deformation of the walls.

Owner:THUR

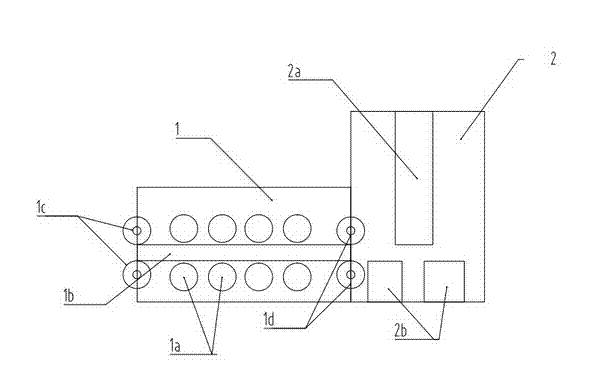

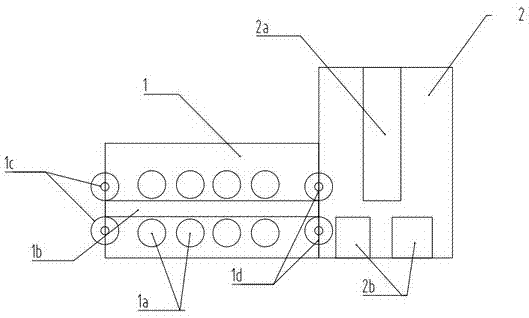

Equipment for producing two-sided stainless steel composite thin strips by explosive composite rolling

InactiveCN102248401ACompact equipmentIncrease productivityOther manufacturing equipments/toolsCarbon steelSteel quality

The invention relates to equipment for producing two-sided stainless steel composite thin strips by explosive composite rolling, and belongs to the field of production equipment for strips. The production equipment comprises a polishing unit and a straightening unit, wherein the polishing unit is a closed steel cuboid; a roller for conveying a steel plate by up-and-down clamping is arranged at one end of the polishing unit; the roller is connected with more than one pair of polishing rollers in the horizontal forwarding direction and is connected with a second roller for clamping the steel plate by up-and-down clamping, so that the steel plate is conveyed to the straightening unit; the straightening unit is provided with an upper vertex and two lower vertexes; and stainless steel is compounded on two sides of a substrate of carbon steel, so that straightening operation and polishing operation are combined. The equipment is compact and high in production efficiency and machining accuracy. Therefore, the two-sided stainless steel composite plate strips with any thicknesses are obtained by rolling.

Owner:大连沈特电缆有限公司

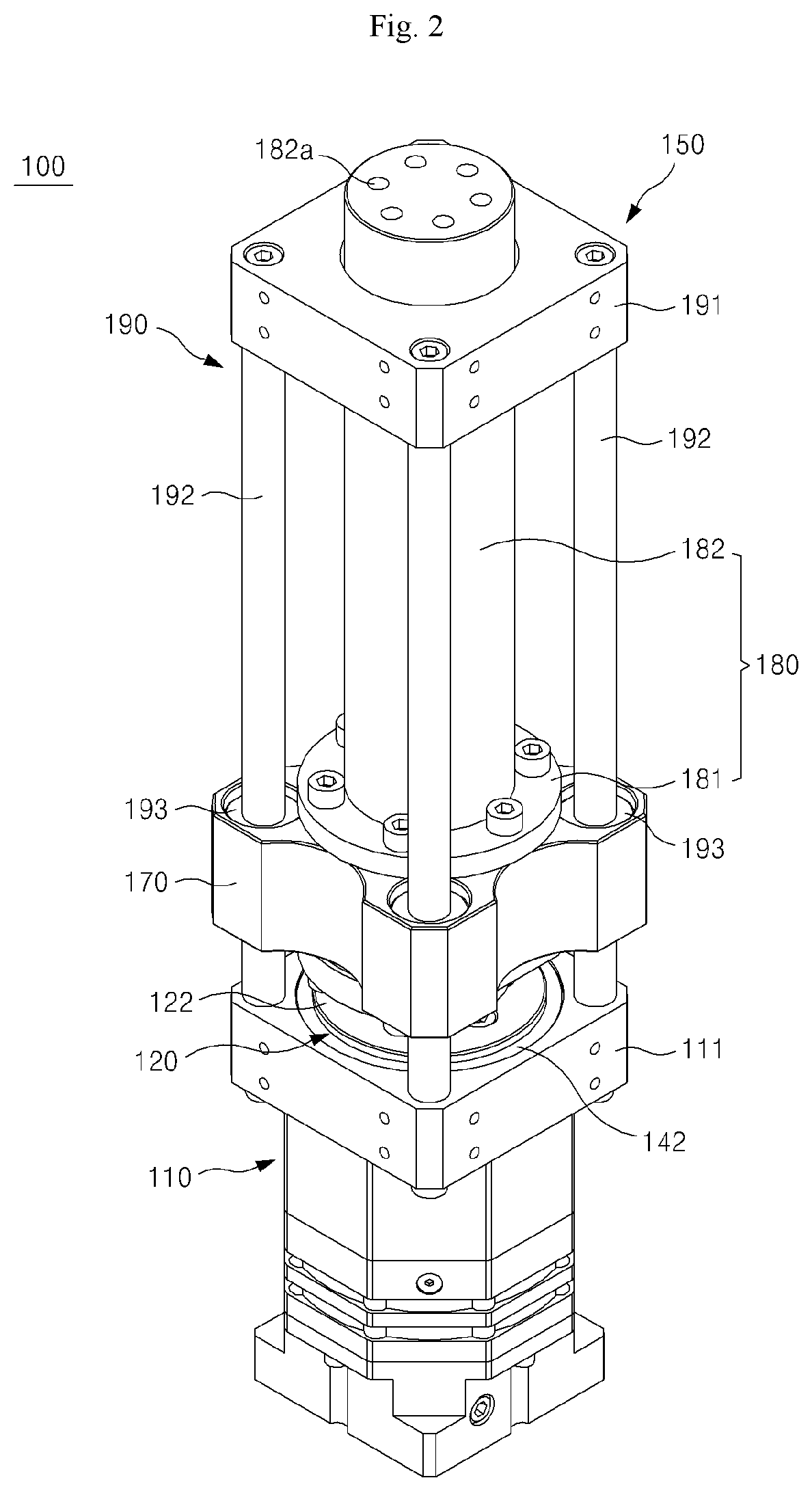

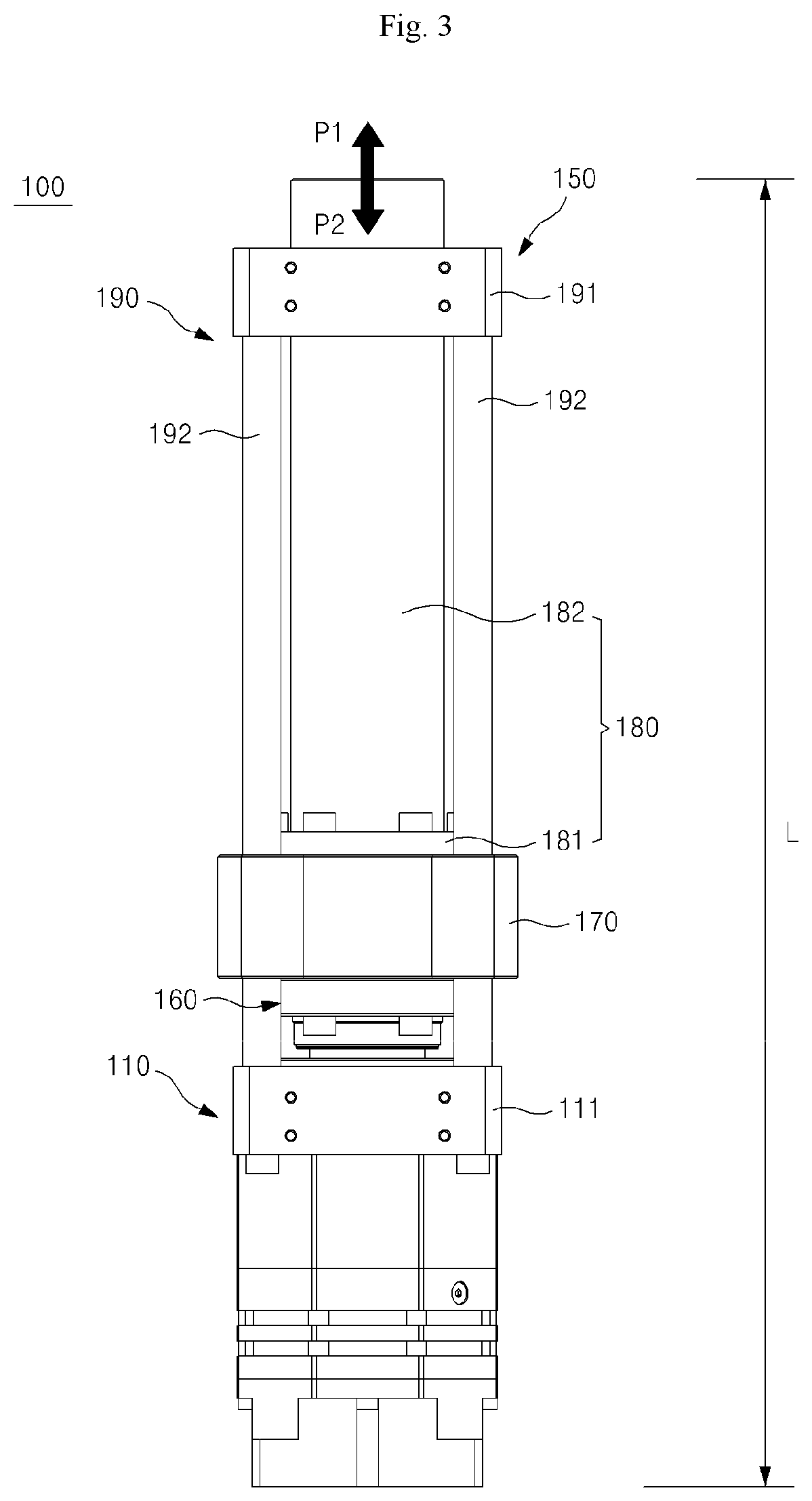

Servo cylinder

Provided is a servo cylinder. The servo cylinder includes a reducer comprising a reducer main body connected to a motor and a speed reduction output part provided in the reducer main body, the speed reduction output part outputting power from the motor by reducing a rotation speed and increasing torque; a ball screw coupled to the speed reduction output part inside the reducer when one end portion region of the ball screw is inserted into the reducer, the ball screw performing a rotational motion by the speed reduction output part; and a motion conversion output part connected to the ball screw and converting the rotational motion of the ball screw to a linear motion and outputting a converted motion.

Owner:SEJIN IGB

Sinking restoration structure for steel structure room and restoration method thereof

ActiveCN104563172ASimple construction processCompact equipmentFoundation engineeringSteel columnsArchitectural engineering

The invention relates to the technical field of steel structure rooms, and in particular relates to a sinking restoration structure for a steel structure room and a restoration method thereof. The sinking restoration structure for the steel structure room includes a steel column as the support body of the steel structure room, the steel column includes cross columns and a longitudinal column, the steel column is fixed on the column bottom plate which is rectangular in shape, the column bottom plate is arranged on the column base, the column base includes a central area positioned right below the column bottom plate and an extending area positioned at the periphery of the center area, a restoration jacking device is arranged above the extending area, a jacking traction leg is arranged at the upper end of the restoration jacking device, the jacking traction leg is also fixedly connected with the steel column, foundation bolts are arranged on the column bottom plate, plumb bobs are arranged at intervals at the middle parts of the cross and longitudinal columns in vertical direction, and a dial indicator is connected with the jacking reaction leg. According to the sinking restoration structure, the restoration method that the restoration jacking device is used for driving the steel column by the jacking traction leg to move upwards, thus being firm and stable in structure, conductive to restoring after the steel structure room sunk, low in cost, simple in technology and good in restoration effect.

Owner:ZHEJIANG HUZHOU CONSTR ENG GRP CO LTD

Treatment method of distillation extraction waste liquid in fine chemical engineering production

ActiveCN105152421ASmall footprintCompact equipmentWater/sewage treatment by electrochemical methodsDispersed particle separationScrapSmall footprint

The invention discloses a treatment method of a distillation extraction waste liquid in fine chemical engineering production, which comprises the following steps: 1) microelectrolysis treatment: when scrap iron and carbon particles are immersed in acidic wastewater, uncountable micro primary cells can be formed in the wastewater due to the polarization potential difference between the iron and carbon, wherein the lower-potential iron becomes the anode, and the higher-potential carbon becomes the cathode; 2) advanced oxidation treatment: chemical oxidation is performed many times with hydrogen peroxide under the action of a circulating pump by using Fe<2+> as a catalyst; and 3) electric flotation treatment: the wastewater enters electric flotation equipment, the electric flotation equipment generates hydrogen by adopting a three-dimensional-like electrode subjected to special treatment and a cathode connected with the negative pole of a direct current power supply, and the bubbles take the suspended substance in the sewage onto the water surface to form a scum layer. The method integrates the microelectrolysis, chemical oxidation and electric flotation treatment, has the advantages of lower chemical consumption, simple after-treatment, small occupied area and high treatment capacity, and is convenient for management.

Owner:广东绿巨人环境科技有限公司

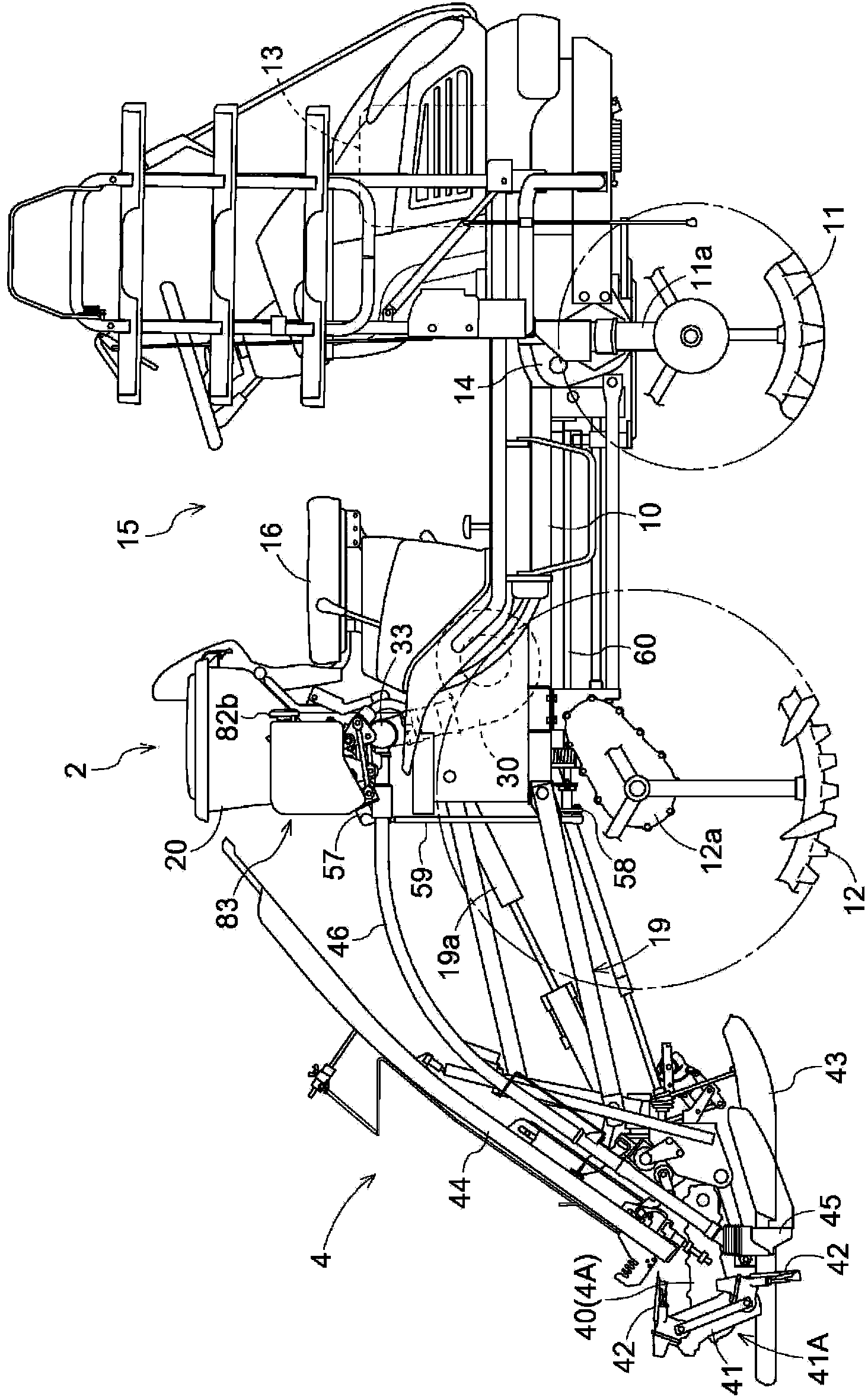

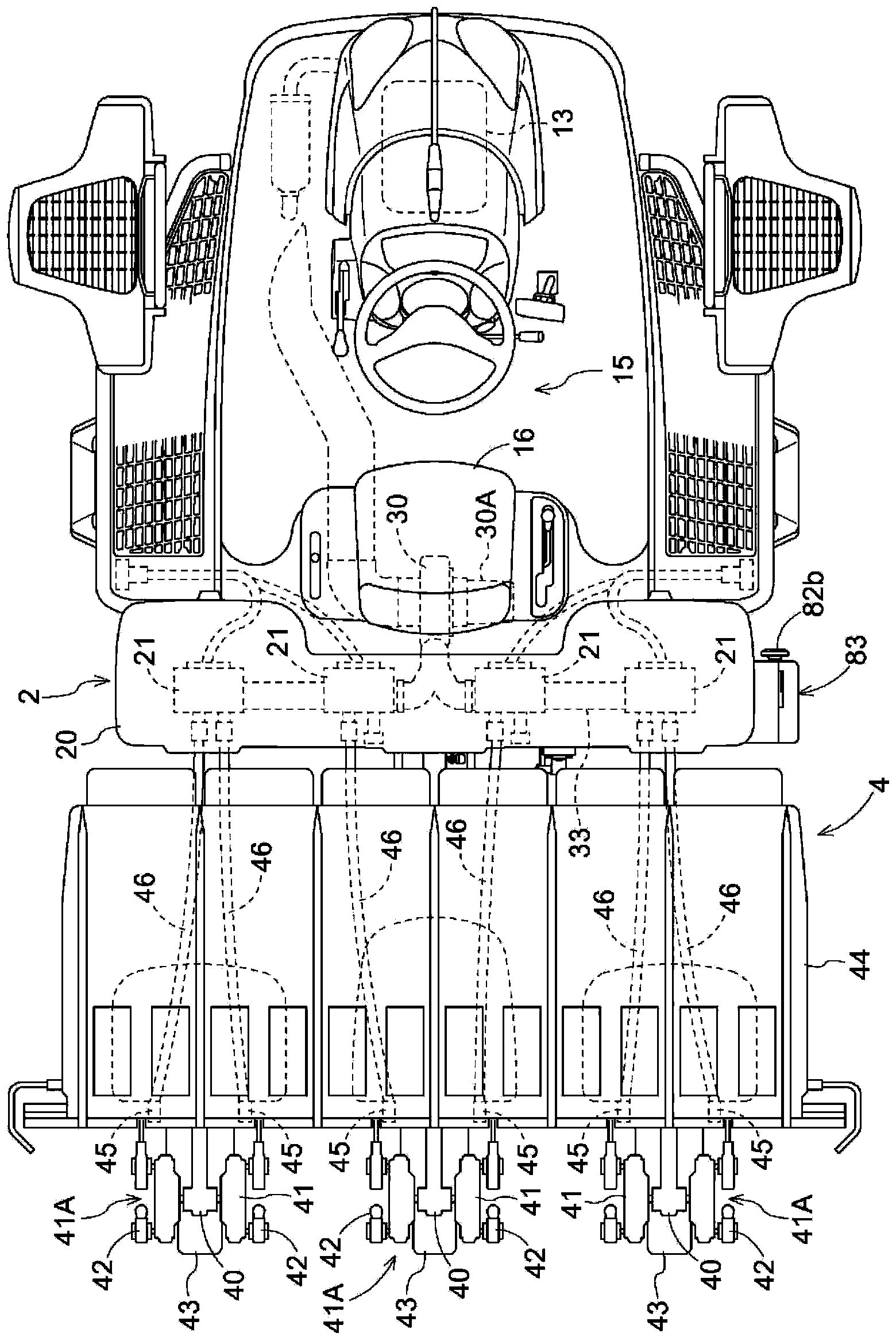

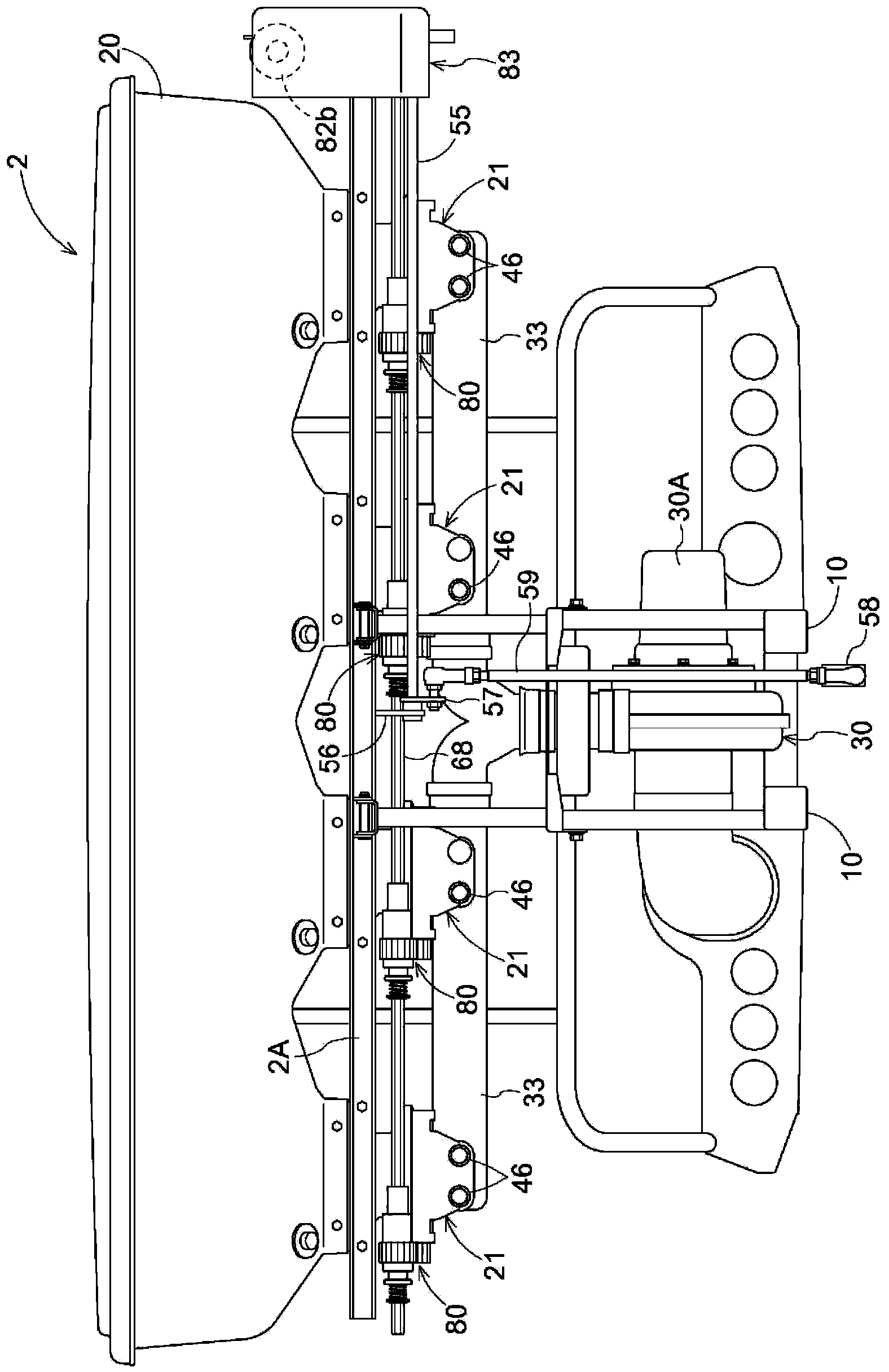

Agricultural material supply device

ActiveCN103563531AIncrease or decrease to adjust the delivery volumeCompact equipmentFertiliser distributersTransplantingPush–pull outputPush pull

The object of the invention is to provide an agricultural material supply device comprising a rotating body on one side and an agricultural material supply device on the other side. The output rotating body can be used to transmit the driving force of a swinging diving body to a swinging operation body by a push-pull input rod, a relay swinging body, and a push-pull output rod. The agricultural material supply device can be used to adjust the output amount quickly. An output amount adjusting unit (83) is capable of moving and adjusting the swinging fulcrum (62) of the relay swinging body (52), and can be used to maintain the fulcrum on the adjusting position. The output amount adjusting unit (83) can be used to change the relay swinging body (52) to swing along the swinging direction of the push-pull output rod (66) and along the direction vertical to the push-pull output rod (66),and therefore the output amount generated by the output rotating body can be changed.

Owner:KUBOTA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com