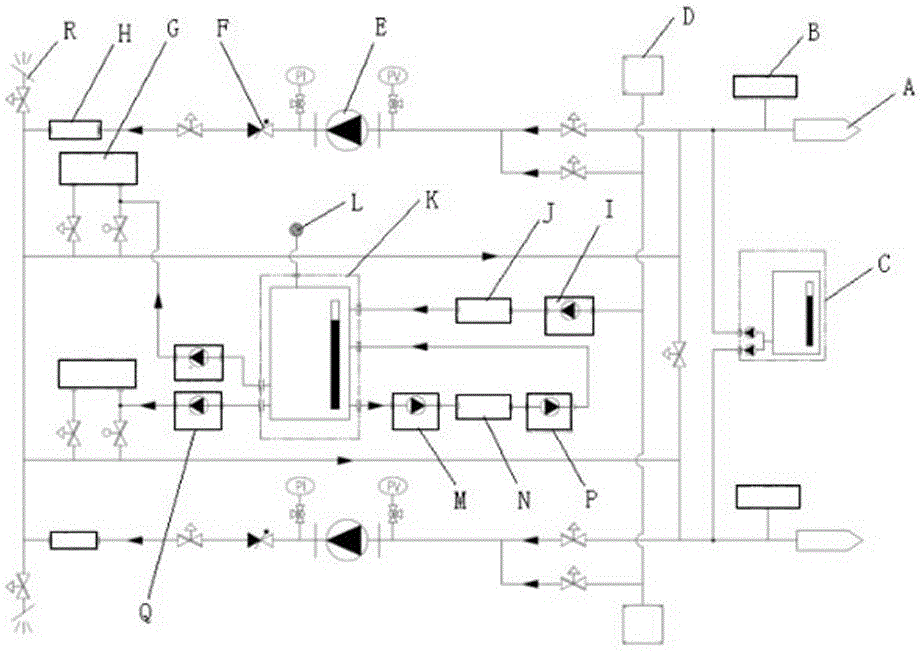

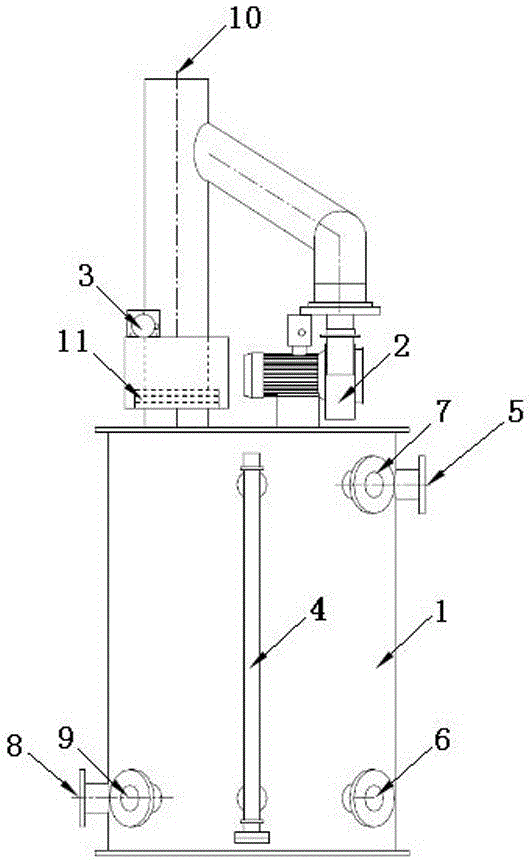

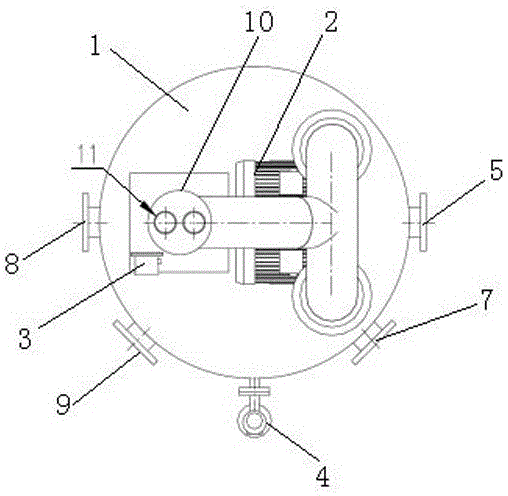

Electrolysis seawater method ship ballast water treatment system

A technology for ship ballast water and treatment system, applied in the electrolysis process, electrolysis components, etc., can solve the problems of high manufacturing cost and affect the stable operation of the system, and achieve the effect of compact equipment, stable operation and simplified electrolysis unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] For a 114,000-ton oil tanker, the ballast pump processing capacity is 2000m3 / h×2, and the ballast water is treated by the new electrolytic seawater method ship ballast water treatment system. The type of electrolysis unit is selected with a corresponding treatment capacity of 2000m3 / h. The whole system can run stably for multiple voyages and for a long time, and the ballast water treatment meets the requirements of the Convention.

Embodiment 2

[0040] For a 13500TEU bulk carrier, the treatment capacity of the ballast pump is 1500m3 / h×2, and the ballast water is treated by the electrolysis method in advance. The type of electrolysis unit is selected with a corresponding processing capacity of 1500m3 / h. The whole system can run stably for multiple voyages and for a long time, and the ballast water treatment meets the requirements of the Convention.

[0041] Factory experiments and real ship experiments have proved that electrolysis of ballast water treatment in advance is feasible. During the operation of the system, parameters such as pressure and flow are stable without large fluctuations. Compared with the original technology, the type selection of the electrolysis unit can be reduced by 30%~50%, and the layout is more flexible. The electrolyte storage tank is used as a hydrogen removal device, and the average hydrogen removal efficiency reaches 99%. The whole system can fully meet the requirements of ship ballast wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com