Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Simple pulping process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

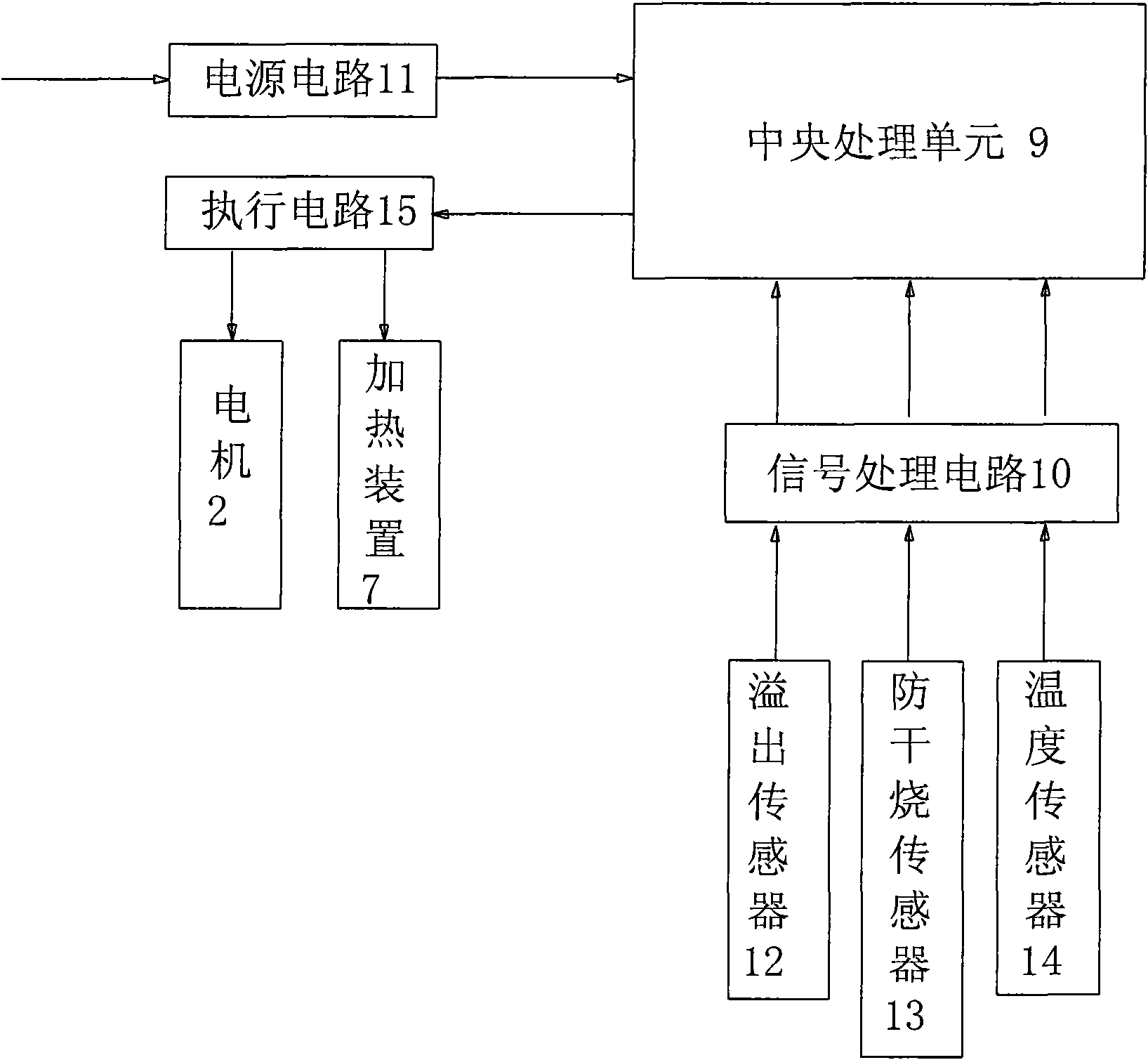

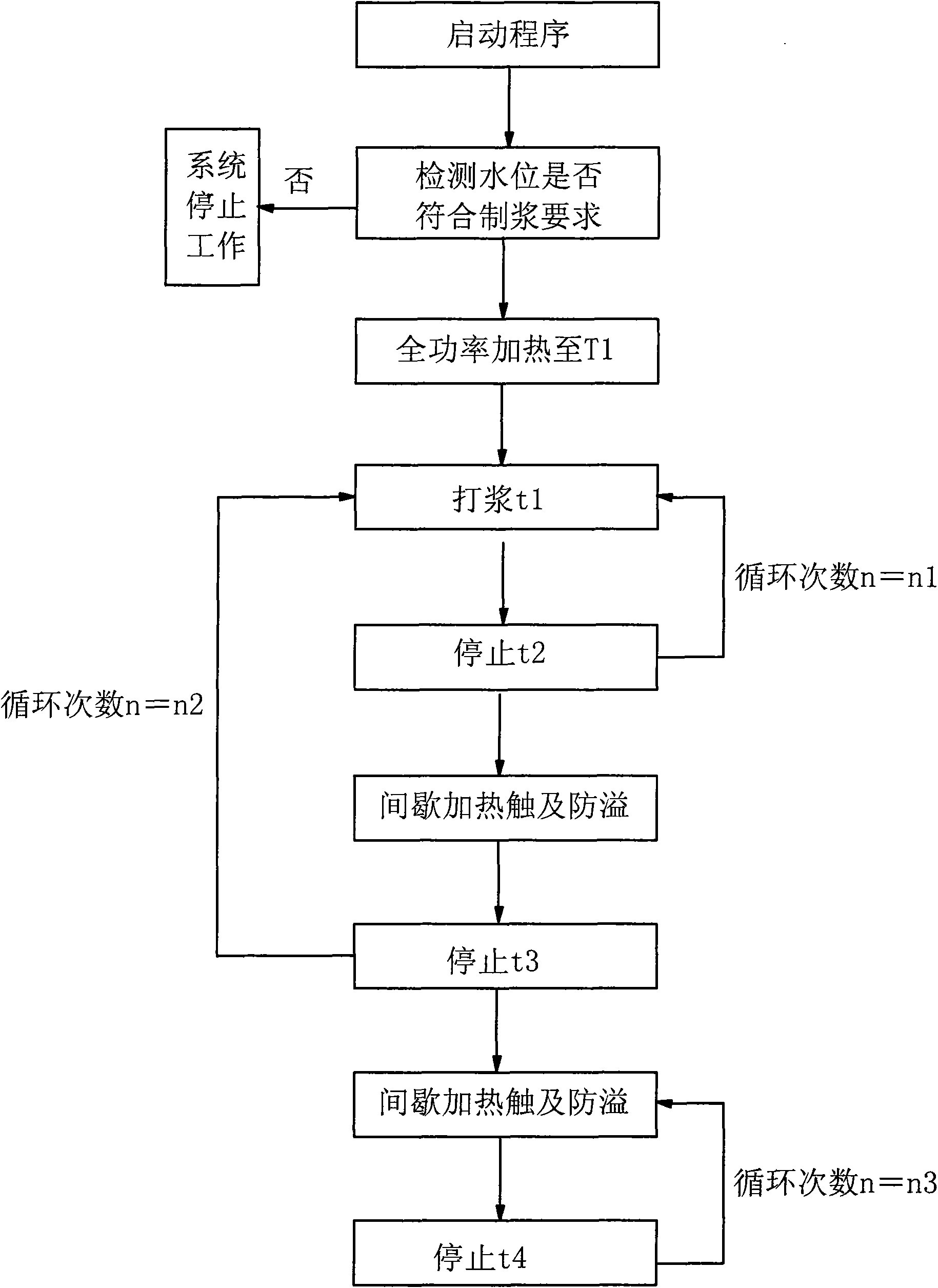

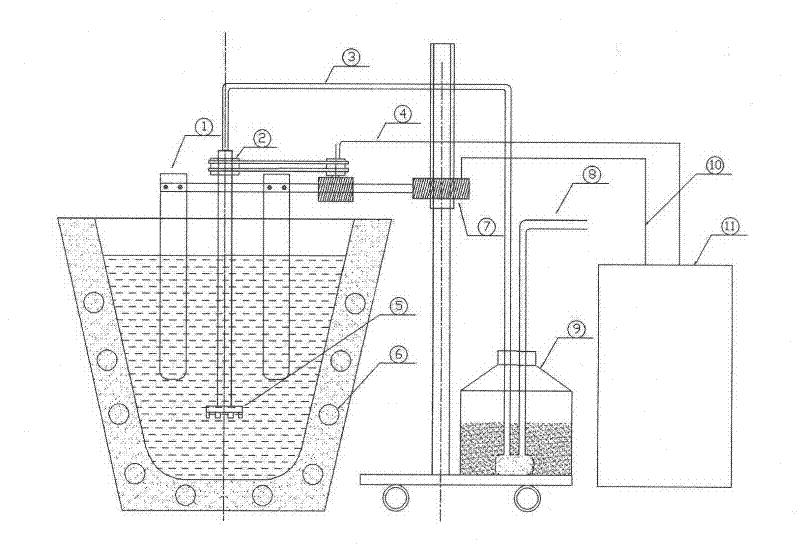

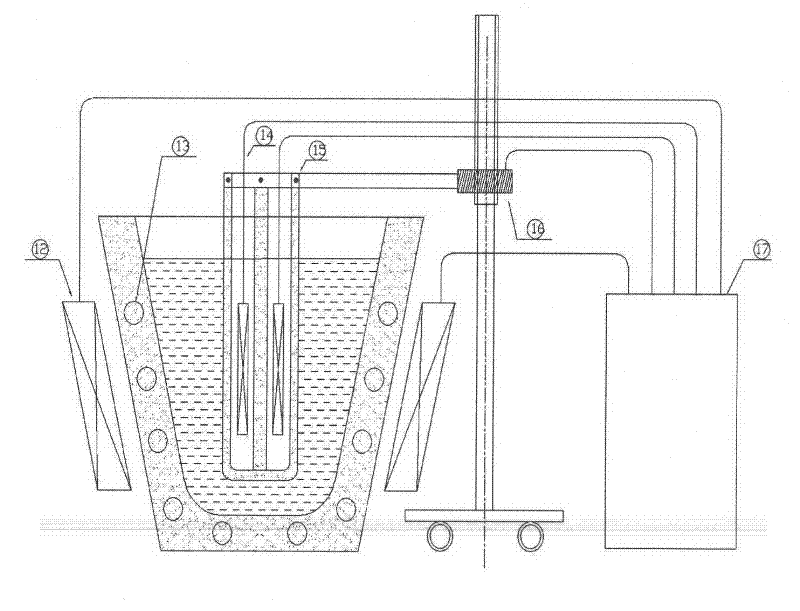

Soaking-free pulping machine and method for controlling same

InactiveCN101569501ASimple pulping processEasy to operateTemperatue controlBeverage vesselsEngineering

The invention relates to a soaking-free pulping machine and a method for controlling the same. The pulping process at least comprises the following stages: a stage of preheating and softening a pulping material, a stage of grinding and crushing the pulping material, and a stage of boiling the pulping material. The method for controlling the pulping comprises the following steps: putting un-soaked soybeans into the pulping machine to crush and grind the soybeans at a temperature of T1 which is more than or equal to 50 DEG C and less than or equal to 90 DEG C, controlling overflow, heating continuously, and boiling the soybean milk until the soybean milk is cooked. Thus, during pulping, dry pulping material can be put into the pulping machine directly to perform pulping without presoaking the material so that the soaking-free pulping machine has the advantages of simple pulping process and convenient operation.

Owner:MIDEA GRP CO LTD

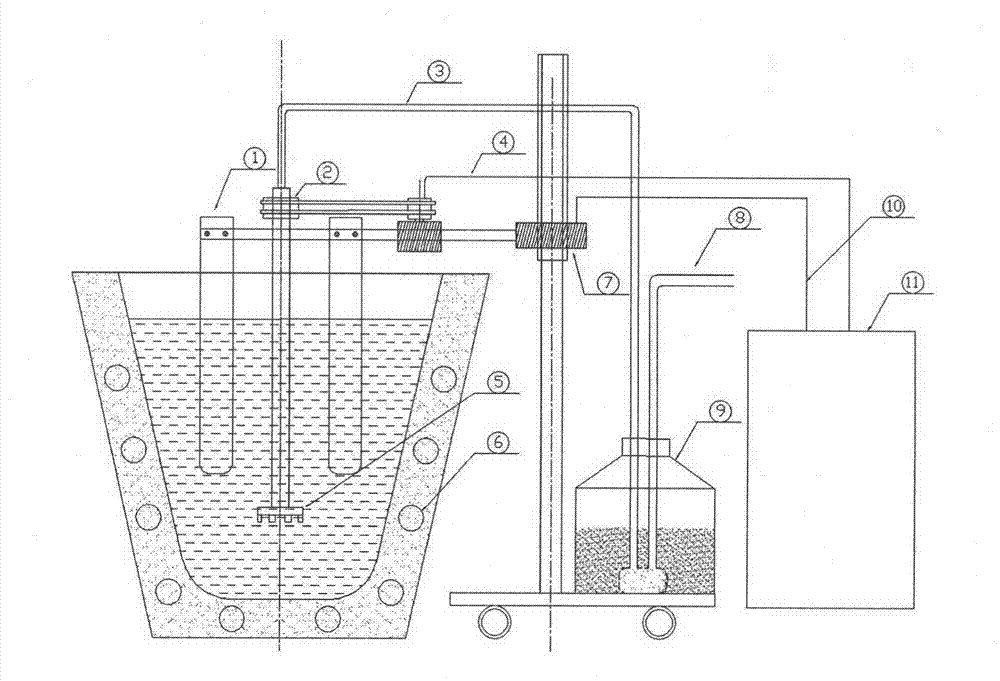

Method and apparatus for preparing semisolid slurry for automobile aluminium wheel through compound modification refinement and electromagnetic stirring

A method and an apparatus for preparing a semisolid slurry for an automobile aluminium wheel through compound modification refinement and electromagnetic stirring. The method comprises steps of: transferring alloy with degree of superheat of 100-120 DEG C into a transit bag, adding a refinement modification agent with high purity nitrogen by an injecting device, wherein the refiner is Al-Zr-B-O intermediate alloy with a granularity of 150-200 um, and the alterant is Al-Sr-RE complex alloy with a granularity of 200-2505 um; standing for 5-8 min, pouring into an electromagnetic stirring crucible when a temperature is 40-50 DEG above a liquidus, putting the crucible in an electromagnetic stirrer, and carrying out composite stirring through a crucible peripheral stirrer and central stirrer, wherein the peripheral stirrer has a frequency of 10-20 Hz, a power of 12 kw, a rate of 300-500 rmp and a time of 2-3 min, and the central stirrer has a frequency of 5-15 Hz, a power of 1-2 kw, a rate of 300-800 rmp and a time of 2-3 min; stopping stirring, when a melt temperature drops to 10-15 DEG C below the liquidus, to obtain a near sphaerocrystal structure semisolid aluminium alloy slurry. The method solves problems of nonuniform slurry and low pulping efficiency.

Owner:JIANGSU KAITE AUTO PARTS

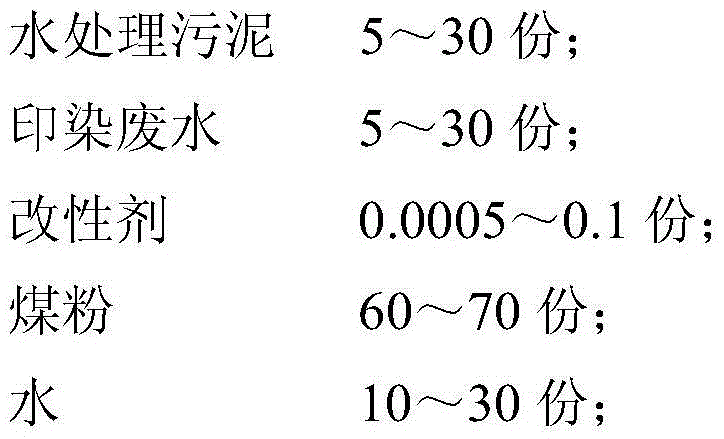

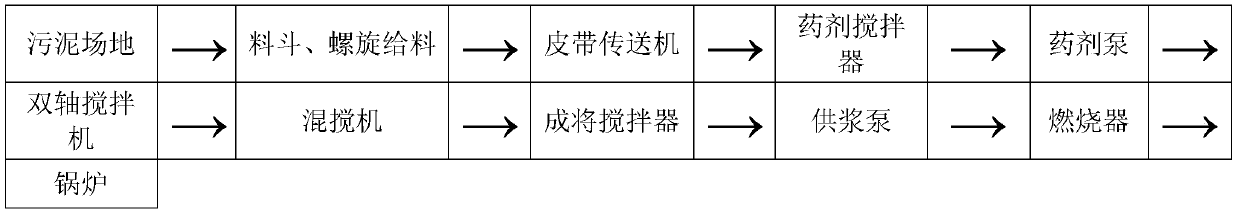

Sludge coal-water slurry and preparation method thereof

The invention discloses sludge coal-water slurry and a preparation method thereof. The sludge coal-water slurry comprises the following components in parts by weight: 5-30 parts of water-treatment sludge, 5-30 parts of printing and dyeing wastewater, 0.0005-0.1 part of modifier, 60-70 parts of coal powder and 10-30 parts of water. The preparation method provided by the invention has the advantages that the slurrying process is simple, and energy and the slurrying cost are saved; the added amount of the water-treatment sludge is high, and the fluidity of the modified sludge is good, so that the sludge is easy to mix with the coal powder uniformly; the slurrying concentration of the sludge coal slurry is higher than 60%, and the fluidity, the stability and the rheological property are relatively good; additives can be saved by more than 40%, water for slurrying can be partially or wholly saved, and a stabilizer can be saved by 100%; and while the heat value of the sludge is fully utilized, an effective technical path is provided for reclamation, reduction and harmlessness of the sludge.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Chemical treatment and hot pulping process of wood pulp and dreg pulp with mechanical mill and stone mill

InactiveCN1388287ASimple pulping processLow investment costFibrous raw materialsMultistage pulping processMaterials scienceChemical treatment

The present invention features that after chemical treatment with alkali, the wood pulp is ground mechanically. Thus produced wood pulp has whiteness of 57-60 % (ISO), beating degree of 70-78 deg SR, breaking length greater than 2200 m, splitting index greater than 2.8 mN.sq.m square / g and wet weight of 4.0g. The present invention, as one optimized pulp grinding process, has simple process, low cost and high pulp grinidng effect.

Owner:YUEYANG FOREST & PAPER CO LTD

Method for producing corrugated base paper pulp by utilizing scrap materials of fibre board

InactiveCN102677498ASimple pulping processCompact equipmentPaper recyclingWaste paper working-upScrapPulp fibre

The invention discloses a method for producing corrugated base paper pulp by utilizing scrap materials of a fibre board. The method comprises the main steps of: preparing, soaking, steaming, spirally extruding, chemically processing, grinding, eliminating, washing and purifying materials. A majority of free formaldehyde in the raw material is removed and recycled possibly in a pulping process; a little of chemical solution is added from the rear part of a twin screw extruder, and the liquid medicine is uniformly mixed with the fibre and then subjected to mild chemical reaction by utilizing high-concentration mixing action of an extruder and heat energy generated in extruding and mixing processes, so that the high pulping yield is kept, the damage to the fibre in a grinding process is alleviated, the excellent physical strength of the pulp fibre is ensured, and the pollution load in the pulping process is reduced at the same time.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Semi-solid flow variable rheolytic pressure casting forming method for flame-retardant magnesium alloy

InactiveCN108315621AImprove mechanical propertiesImprove flame retardant performanceCombustionPressure casting

The invention provides a semi-solid flow variable rheolytic pressure casting forming method for a flame-retardant magnesium alloy. The alloy comprises the following components of , by mass, 6.5- 9.5 wt% of Al, 0.5-2.5 wt% of Zn, 0.5-2.5 wt% of Y, 0.2-2 wt% of Ca, 0.5-1.5 wt% of Ce and the balance Mg. The method comprises the following steps of preparation of flame-retardant magnesium alloy semi-solid slurry and semi-solid rheological pressure casting. According to the semi-solid flow variable rheolytic pressure casting forming method, three elements of Y, Ca and Ce are simultaneously added into Mg-Al-Zn, oxidation and combustion of the magnesium alloy can be further prevented, so that the strength and the heat treatment strengthening effect of the magnesium alloy are improved; filling andsolidification are carried out under a low-pressure high-speed condition through a pressure casting process, the semi-solid slurry flows in a laminar flow mode during the filling process, so that theoverall structure of the casting is compact, the surface quality is high, and the room temperature mechanical property of the obtained flame-retardant magnesium alloy is excellent.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing chemical-mechanical pulp for fluting medium by using fresh empty fruit bunches

ActiveCN103103864ASimple pulping processLess investmentPretreatment with water/steamPulp beating/refining methodsPalm fruitPalm fiber

The method discloses a method for preparing chemical-mechanical pulp for fluting medium by using fresh empty fruit bunches, mainly aiming at the characteristics that the water content of the fresh empty fruit bunches is high, hard impurities such as residual palm fruit granules, sands and the like are carried in the fruit bunches and the palm silk surfaces of the empty fruit bunches contain more non-fiber surfaces; and on the basis of the technology process and the equipment configuration, the processing steps of granule removing, slicing, extruding, washing with water, pre-steaming, chemical soaking, pulping, washing and the like are performed gradually to materials. Before the pulp is formed, the non-fiber parts such as non-fiber surfaces with higher content on the fiber surface and the carried palm fruit granules in the EFP (empty fruit bunches) fiber raw materials are effectively removed as much as possible in the whole process and are used. The dosage of chemical product needed in the pulping process and the pollution load generated by pulping are effectively reduced, the paper pulp prepared by refining the palm fibers has the advantages of less dust, high strength and the like and is suitable for blending of the fluting medium; and by adopting the method, the clean and high-efficiency comprehensive utilization of the EFP raw materials in pulping and paper making is achieved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Fiber for cement concrete

The invention discloses a fiber for cement concrete, which comprises the following constituents that the water cement ratio is 0.35-0.45; the glue sand ratio is 1:0.5-1:1.2; the content of high-efficiency expansive agent is 8-10 percent of the dosage of cement; the content of the high-efficiency water reducing agent is 0.5-1 percent of the dosage of the cement; and the content of polypropylene fibers is 1 m, and 0.8-1.2kg of the polypropylene fibers are doped in sand pulp. The invention also discloses a production method of the fiber. The fiber is a high-strength prestressed anchor grouting material having high rupture strength, compressive strength and tensile strength, small brittleness, good cracking resistance and impermeability and high bonding shearing strength and bondability strength.

Owner:赵文平

Antibacterial paper towel and preparation method thereof

InactiveCN109914138AHigh whitenessEfficient degradationAntibacterial agentsCosmetic preparationsFiberMicrowave radiometry

The invention relates to an antibacterial paper towel and a preparation method thereof, and discloses a process for papermaking by using Qianjinfang medicine residue, wherein the process comprises: microwave pretreatment, fermentation, washing, paper making, extracting of medicinal ingredients from waste liquid, paper modification and the like. According to the present invention, the short fiber is prepared by using the Qianjinfang medicine residue, and the long fiber property of the cotton fiber is combined, such that the prepared antibacterial paper towel has good tensile property; the prepared antibacterial paper towel has remarkable wet strength through internal sizing and surface application; by using the microwave radiation method and the biological method, harmful chemicals are notintroduced during the whole process, such that the hygienic characteristics of the paper are ensured; and the medicinal ingredients are extracted from the pulping waste liquid, and are mixed with thebase medicine liquid component comprising Cortex Ailanthi, Sophora flavescens Ait, Cortex Moutan, frankincense and borneol, and the obtained mixture is applied on the paper, such that the obtained antibacterial paper towel has good anti-inflammatory and antibacterial effects, can prevent microbial infection, does not have irritation and side effects on the skin and vaginal mucosa, and is suitablefor women.

Owner:ZHUZHOU QIANJIN PHARMA

Clean pulping catalyst and its application process

InactiveCN1611673ARealize cleaner productionEasy to operateNon-fibrous pulp additionPaper/cardboardFiberPtru catalyst

The present invention relates to a catalyzer for clean pulping and process for using the same. The composition of the catalyzer for clean pulping according to the present invention includes sodium salicylate, anion silicic acid softener, cooking aids, liquid(gaseous) chlorine and water. The process for using the catalyzer for clean pulping according to the present invention includes the following steps: 1, cutting and impurities removing for the raw material, 2, feed preparation and impurities removing, 3, dividing into fibers by refining, 4, catalysis copolymerization, 5, refining, 6, concentration and separation 7, pulp bleaching, 8, pulp washing and 9, finished pulp. All kinds of the herbs can be used for the raw material. The advantages of the present invention is shown as the following: it realizes the clean production; it does not need to digest and does not produce black liquor; the process is simple and is performed at normal temperature; the resource of crops is fully used; the effect of water conservation is remarkable; it can easily realize continuous production, modularization production and automatization production, and can realize industrialization.

Owner:程相武

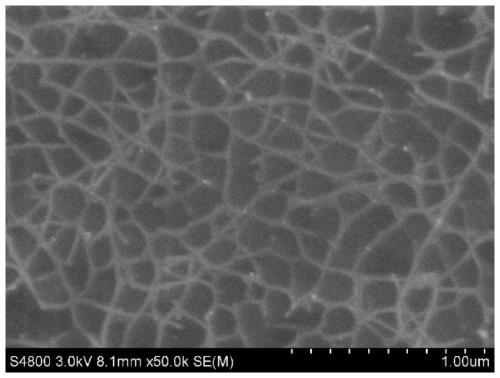

Water-based conductive adhesive for lithium battery and preparation method thereof

InactiveCN111129499AGood dispersionImprove cycle performanceMaterial nanotechnologyCell electrodesAdhesiveInternal resistance

The invention provides a water-based conductive adhesive for a lithium battery, and the adhesive comprises 0.01-0.8 part of single-walled carbon nanotube, 1-10 parts of multi-walled carbon nanotube and 10-50 parts of water-based adhesive, wherein the outer diameter of the single-walled carbon nanotube is 0.4-40nm, and the thickness of the tube wall of the single-walled carbon nanotube is greater than or equal to 1[mu]m; the outer diameter of the multi-walled carbon nanotube is 2-20nm, and the thickness of the tube wall of the multi-walled carbon nanotube is 500nm-10cm; and the length-diameterratio of the single-walled carbon nanotube to the multi-walled carbon nanotube is greater than or equal to 1,000nm. The water-based conductive adhesive for the lithium battery, which is prepared by adopting a simple process of one-step synthesis and one-step dispersion, has the properties of electric conduction, adhesion and dispersion, is low in dosage, and can reduce the internal resistance of the battery, improve the adhesion force of a pole piece and improve the cycle performance of the battery; in addition, the preparation cost of the water-based conductive adhesive is low, water is usedas a solvent in the whole process, and the water-based conductive adhesive conforms to the trend of environmental protection.

Owner:YANYI NEW ENERGY TECH CO LTD

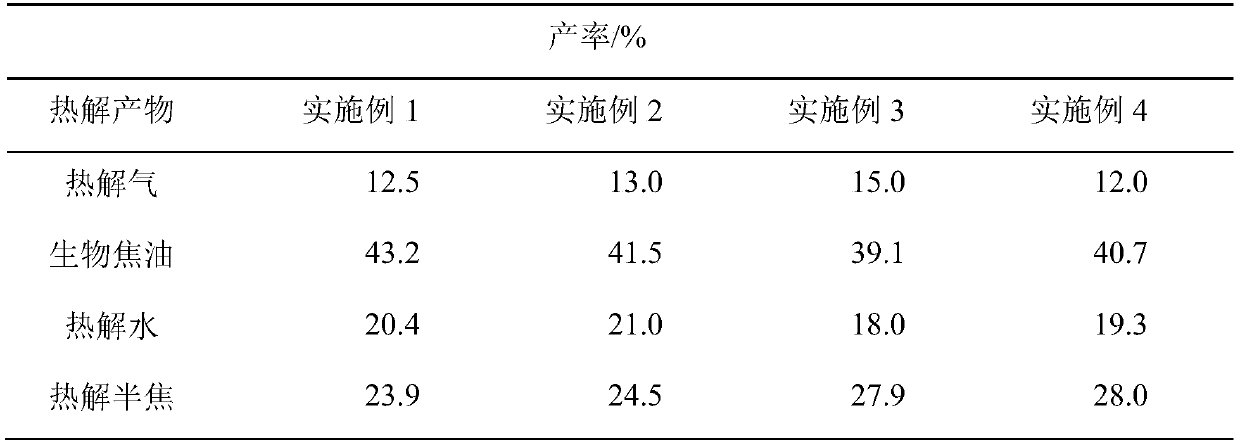

Method for preparing chemical raw material and liquid fuel from biomass

ActiveCN110540857AEasy to operateSimple pulping processLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesDistillationHydrogenation reaction

The invention discloses a method for preparing a chemical raw material and a liquid fuel from biomass. The method comprises the following steps: 1, subjecting a biomass raw material to a pyrolysis reaction so as to obtain pyrolysis products including pyrolysis gas, biological tar, pyrolyzed water and pyrolyzed semicoke; 2, preparing a first hydrogenation catalyst with the obtained pyrolyzed semicoke as a carrier and putting the prepared first hydrogenation catalyst aside for subsequent usage; 3, preparing slurry from the obtained biological tar, the first hydrogenation catalyst and hydrocarbonoil, allowing the obtained slurry to enter a slurry bed hydrogenation reactor for a hydrogenation reaction so as to obtain hydrogenated bio-oil, subjecting the obtained hydrogenated bio-oil to distillation separation to obtain light bio-oil, water and tail oil, and circulating a part of the obtained tail oil to replace the hydrocarbon oil for preparation of the slurry; and 4, carrying out catalytic cracking on the obtained light bio-oil to obtain the chemical raw material and the liquid fuel. The biomass conversion method provided by the invention is simple in slurry preparation and can be continuously operated.

Owner:黑龙江省龙油石油化工股份有限公司

Clean pulping catalyst and its application process

InactiveCN1216203CRealize cleaner productionEasy to operateNon-fibrous pulp additionPaper/cardboardFiberBlack liquor

The invention relates to a clean pulping catalyst and its application process. The clean pulping catalyst of the present invention is composed of the following raw materials: sodium salicylate, anionic silicic acid softener, cooking aid, chlorine (gas) and water. The application process of the clean pulping catalyst of the present invention includes the following steps: 1. Crushing and removing impurities from raw materials; 2. Prepare materials and remove impurities; 3. Combing and splitting; , pulp bleaching; 8, pulp washing; 9, finished pulp. Various herbaceous fiber plants can be used as raw materials. The advantages of the present invention are: the present invention realizes clean production, it does not need cooking, does not produce black liquor; its process is simple; it can be carried out under normal temperature and pressure; fully utilizes crop resources; water saving is obvious: it is easy to realize continuous production, Modular production and automatic production, and can realize industrialization.

Owner:程相武

Process for pulping by biochemical solvent

InactiveCN1657696AChange performanceImprove integrityMachine wet endCellulose material pulpingFiberSolvent

The invention relates to a technology for pulping with biochemical solvent, with the technical course: use the nonwood fiber plant as the raw material, scatter it and clear the mixture away, through pulping, disc mill, potching and pulp washing to be the product brei. It has the characteristics that the pulping course is immersing the scattered material into biochemical solvent for 2-2.5h under the general temperature and pressure, it has simple technique convenient operation, low cost, and no pollution.

Owner:YINCHUAN MINHE PAPER IND INST

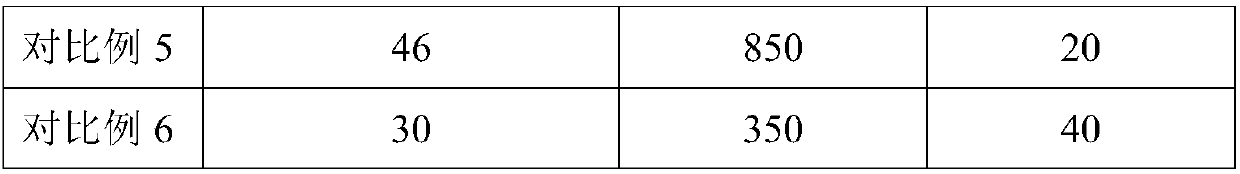

Method for preparing water coal semicoke grout by coal dust filling modification and grading technology

PendingCN107353953AImprove performanceSimple pulping processLiquid carbonaceous fuelsCoal dustCrusher

The invention discloses a method for preparing water coal semicoke grout by coal dust filling modification and a grading technology. The method comprises a step 1) of preparing coarse coal powder and fine coal grout, wherein the coarse coal powder is obtained by causing coal to be smashed through a crusher and then sieved through a 14-mesh sieve; the fine coal grout is obtained by the coal to be smashed through the crusher and undergo ball milling, the fine coal grout comprises fine coal dust, the concentration of the fine coal grout is 40%-60%, and the average grain diameter of the fine coal dust is smaller than or equal to 35 [mu]m; a step 2) of weighing the coarse coal powder, the fine coal grout and the semicoke according to a dry basis proportion of (2-5):(2-5):(2-3), adding water and dispersing agent in the fine coal grout obtained in the step 1), adding the coarse coal dust and the semicoke with stirring and finishing the operaitn in 5 min, and finally performing stirring for 5-10 min to obtain water coal semicoke grout with the viscosity of 500-1500 mPa.S. The method for preparing water coal semicoke grout by coal dust filling modification and the grading technology is simple in pulping process, improves water coal / semicoke grout performances including concentration and stability, the problem that plenty of semicoke is generated in a coal low-temperature dry distillation utilization technology and cannot be subjected to efficient clean utilization is solved, and the method has good industrial application prospect.

Owner:NANJING UNIV +1

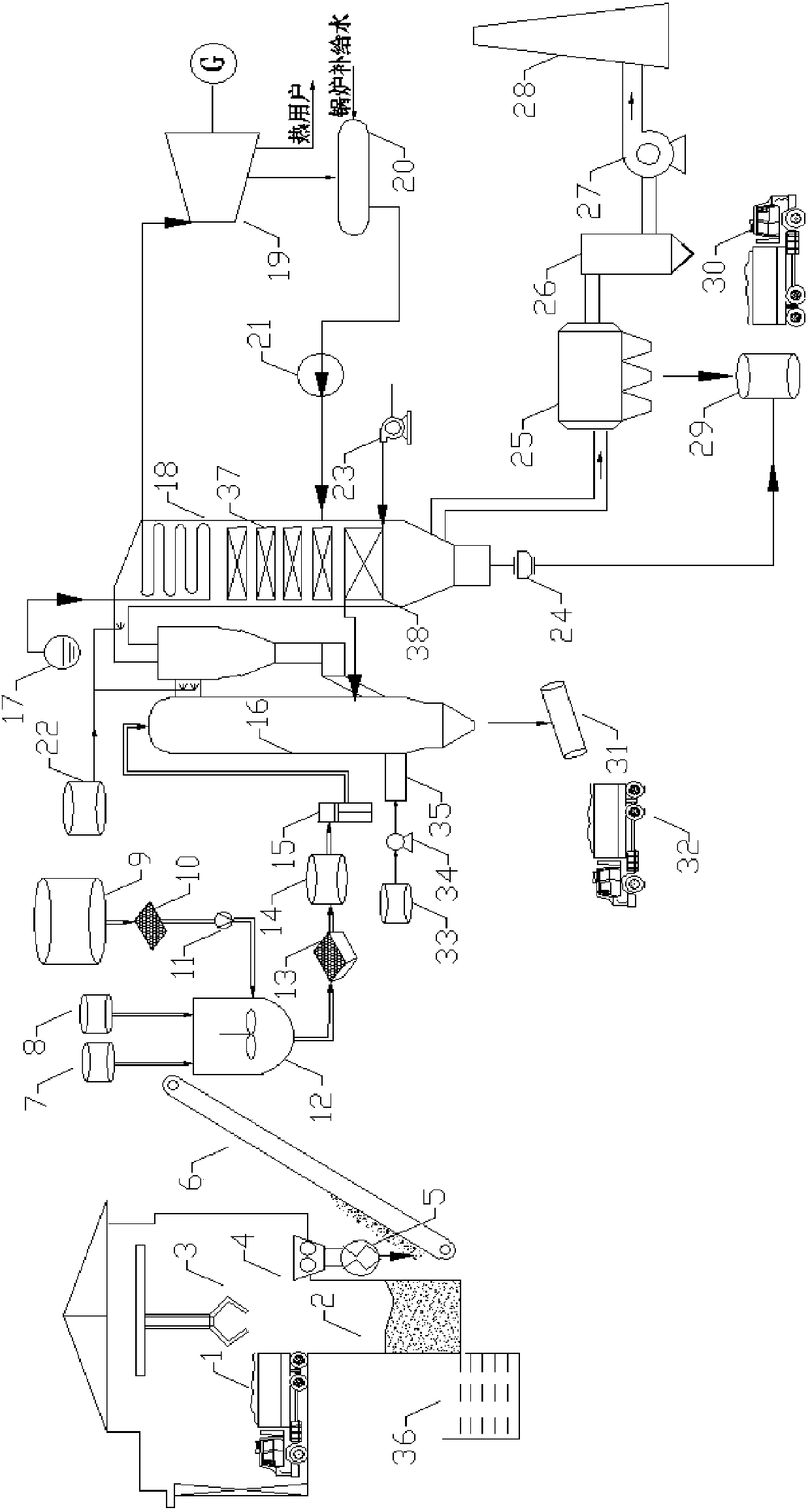

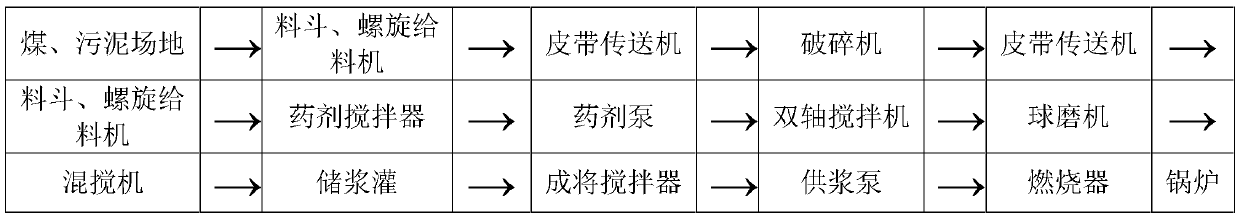

High-concentration organic waste innocent treatment system and process

InactiveCN103776037ASimple pulping processLess investmentIncinerator apparatusLump/pulverulent fuel feeder/distributionFluidized bedEnvironmental engineering

The invention provides a high-concentration organic waste innocent treatment system and process. High-concentration organic waste discharged from industrial production is mixed with coal slime or fine particle clean coal to proportionally produce coal water slurries, the water content of the coal water slurries is controlled through a slurry ability experiment, and a coal water slurry plunger pump is used to continuously and stably convey the coal water slurries to a circulating fluidized bed boiler for burning to produce superheated steam for comprehensive utilization of enterprises, so that effects of energy conservation and environmental protection are achieved. Combustion tail gases are subjected to desulfurization, denitrification and dedusting through a flue gas cleaning system and discharged until the combustion tail gases meet the requirement of environment protection, and ashes left in the production process can be used as building materials or brick-making raw materials. According to the high-concentration organic waste innocent treatment system and process, the high-concentration organic waste discharged from industrial production and coal slime or fine particle clean coal is used as raw materials of the coal water slurries, and by means of a water coal slurry clean combustion technology, the high-concentration organic waste is used as production water for the water coal slurries, so that treatment costs of high-concentration organic waste and waste water are saved, industrial production waste is absorbed, and production costs of enterprises are reduced.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

Process for preparing semisolid non-dendritic zinc base alloy

The process of preparing semisolid non-dendrite zinc base alloy includes preparing green body, heating treatment at solid solution temperature for certain time, and re-melting at semisolid temperature. During preparing semisolid ZA27 alloy slurry, ZA27 alloy rod is first solid solution treated at 370 deg.c for 3-5 hr and then heated at 460 deg.c inside one heater for 30 min.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Low energy consumption clean paper pulp extracting method and papermaking process thereof

InactiveCN101694075BAchieve recyclingGood flexibilityPretreatment with alkaline reacting compoundsPulp de-wateringFiberChemical solution

The invention relates to a low energy consumption clean paper pulp extracting method and a papermaking process thereof, solving the problems that fibrous raw materials need to be boiled at high temperature and pressure in the pulp preparing and papermaking processes and chemical solutions produce a large quantity of black or red liquid in the pulp preparing and papermaking processes to cause great waste to resources and great pollution to the environment in the prior art. The invention adopts the following technical scheme: the low energy consumption clean paper pulp extracting method is realized by removing impurities from biomass raw materials rich of fiber, crushing, softening and soaking, separating organic matters, grinding and pulping, wherein a softening and soaking solution contains the following components in percent by weight: 10-20 sodium oxide, 3-5 sodium carbonate, 0.5-2.5 penetrating agent T, 0.5 magnesium oxide and 0.05-0.15 chelating agent EDTA. The papermaking processmatched with the method comprises the following steps: getting materials ready, rubbing to devillicate, soaking to react, separating liquid medicine, spirally squeezing pulp, refining with high consistency, removing slag, coarsely screening and making paper. The pulp preparing process has simple course, no high requirements on environment and equipment condition, easily popularized technology, norequirement on the scale of production, low costs for building production lines and purchasing equipment and less running expense.

Owner:林宣禧

Sludge coal-water slurry and preparation method thereof

The invention discloses sludge coal-water slurry and a preparation method thereof. The sludge coal-water slurry comprises the following components in parts by weight: 5-30 parts of water-treatment sludge, 5-30 parts of printing and dyeing wastewater, 0.0005-0.1 part of modifier, 60-70 parts of coal powder and 10-30 parts of water. The preparation method provided by the invention has the advantages that the slurrying process is simple, and energy and the slurrying cost are saved; the added amount of the water-treatment sludge is high, and the fluidity of the modified sludge is good, so that the sludge is easy to mix with the coal powder uniformly; the slurrying concentration of the sludge coal slurry is higher than 60%, and the fluidity, the stability and the rheological property are relatively good; additives can be saved by more than 40%, water for slurrying can be partially or wholly saved, and a stabilizer can be saved by 100%; and while the heat value of the sludge is fully utilized, an effective technical path is provided for reclamation, reduction and harmlessness of the sludge.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Manufacturing method of battery positive plate

ActiveCN110729483AShorten pulping timeSimple pulping processElectrode collector coatingLi-accumulatorsPolyurethane adhesivePhysical chemistry

The invention discloses a manufacturing method of a battery positive plate. According to the technical scheme, the method is characterized by comprising the following steps: S1, pulping, namely, adding 30-34 parts by weight of a waterborne adhesive into a stirring cylinder, adding 70-80 parts by weight of deionized water, carrying out stirring and dispersing for 8-12min at the speed of 90-110rpm,adding 7-9 parts by weight of a conductive agent, carrying out stirring and dispersing for 8-12min at the speed of 90-110rpm, carrying out stirring and dispersing for 100-140min at the speed of 1000-1400rpm, adding 23-27 parts by weight of deionized water and 160-200 parts by weight of lithium manganate, carrying out stirring and dispersing for 8-12min at the speed of 90-110rpm, carrying out stirring and dispersing for 25-35min at the speed of 900-1100rpm, adding 105-135 parts by weight of lithium manganate, carrying out stirring and dispersing for 8-12min at the speed of 90-110rpm, carrying out stirring and dispersing for 80-100min at the speed of 900-1100rpm, and adjusting the viscosity by using deionized water to obtain slurry; and S2, flaking, namely, uniformly coating an aluminum foilwith the slurry, and carrying out drying and compacting to obtain a positive plate. Because a waterborne polyurethane adhesive is used to manufacture the positive plate, the pulping time is shortened, the pulping process is simplified, the production cost is reduced, and environmental friendliness and no pollution are realized.

Owner:深圳中华自行车(集团)股份有限公司

Sludge incineration treatment method

InactiveCN110030561ASolve efficiency problemsSolve the costIncinerator apparatusSocial benefitsCombustion

The embodiment of the invention provides a sludge incineration treatment method. The sludge incineration treatment method comprises a sewage slurry associated burning incineration method and a synthetic sewage slurry atomization combustion method. The beneficial technical effects of the sludge incineration treatment method are embodied in: superiority: (1). simple slurry preparation process; (2).less slurry preparation equipment; (3). small floor space; (4). simple and convenient operation of the equipment; (5). reduction of production and operation cost; and (6) low requirements of fluidizedcombustion on quality standard of sewage slurry; efficiency: reducing cost and improving efficiency by stokehold slurry preparation, off-site slurry preparation reduction, storage, transportation andother processes; effectiveness: environmental protection technological process, win-win economic benefits, environmental benefits and social benefits; environmental protection: no wastewater discharge, no odor emission, and zero emission in production process; and advantage: respond to national environmental protection policy.

Owner:青岛振华绿能能源科技有限公司

Sodium silicate low-temperature reaction pulping technology

InactiveCN106758456AHigh whitenessHigh tensile strengthPulping with acid salts/anhydridesRaw material divisionFiberSodium silicate

The invention relates to a pulping technology and particularly relates to a sodium silicate low-temperature reaction pulping technology. The pulping technology mainly comprises the following steps: (1) cutting and dedusting the pulping raw material; (2) breaking; (3) screening; (4) adding water and sodium silicate and mixing; (5) squeezing water and washing; (6) pulp grinding; and (7) bleaching. In the technology provided by the invention, the pulping cost is low, and the equipment investment is small; on the premise of no pollution, fiber in the pulping raw material is separated out at low cost; the added sodium silicate replaces sodium hydroxide in traditional technology, the preparation technology is simpler, the pulping water is not discharged, the white pulp yield exceeds 60%, the pulp whiteness is high, the drainability is good, and the tensile strength is high.

Owner:刘长如

Mask paper suitable for sensitive skin, and preparation method thereof

InactiveCN109914147AEfficient degradationFacilitate cross-linkingNon-fibrous pulp additionWashing/displacing pulp-treating liquorsMicrowave radiometryFiber

The invention relates to mask paper suitable for sensitive skin, and a preparation method thereof, and discloses a process for papermaking by using Qianjinfang medicine residue, wherein the process comprises: microwave pretreatment, fermentation, washing, paper making, medicinal ingredient extracting, paper modification, and the like. According to the present invention, the Qianjinfang medicine residue is used as the raw material for preparing fibers, the Qianjinfang medicine residue simultaneously has the characteristics of herbaceous plants and shrub raw materials, the microwave radiation method and the biological method are combined, the microwave radiation process, the temperature and the time in the pulping process, the papermaking process and the like are scientifically controlled, the performance of the paper prepared by using the method is good, harmful chemicals are not introduced during the whole process so as to ensure the hygienic properties of the paper, and the medicinalingredients are extracted from the pulping filtrate and are applied on the paper, such that the finally obtained product is not irritating to people with sensitive skin.

Owner:ZHUZHOU QIANJIN PHARMA

Paper prepared from forestry and agricultural waste and method thereof

InactiveCN108130773AObvious advantage in delignification reactionObvious advantagesPulp properties modificationWater-repelling agents additionFiberAgricultural engineering

The invention relates to paper prepared from forestry and agricultural waste and a method thereof, and discloses a technology for preparing fiber through the forestry and agricultural waste. The technology comprises the steps of spiral squeezing processing, biological enzyme fermenting, papermaking, paper modifying and the like. The forestry and agricultural waste serves as raw materials for preparing fiber, then through the cooperation of ultrasonic waves and biological enzymes, the prepared fiber has high yield, high whiteness and a low kappa number, in the whole process, no harmful chemicalproducts are introduced, and the hygiene of the fiber is ensured. Since graphene dispersion liquid is added in the pulping process, the obtained product has high electric conduction and antibacterialperformance, and particularly has an effect of effectively inhibiting and killing staphylococcus aureus, escherichia coli and hemolytic streptococcus.

Owner:HUNAN UNIV OF TECH

Method and apparatus for preparing semisolid slurry for automobile aluminium wheel through compound modification refinement and electromagnetic stirring

Owner:JIANGSU KAITE AUTO PARTS

Method for preparing chemical raw materials and liquid fuels from biomass

ActiveCN110540856BImprove catalytic performanceSimple pulping processLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesPtru catalystDistillation

The invention discloses a method for preparing a chemical raw material and a liquid fuel from biomass. The method comprises the following steps: 1, subjecting a biomass raw material to a pyrolysis reaction so as to obtain pyrolysis products including pyrolysis gas, biological tar, pyrolyzed water and pyrolyzed semicoke; 2, preparing a first hydrogenation catalyst with the obtained pyrolyzed semicoke as a carrier and putting the prepared first hydrogenation catalyst aside for subsequent usage; 3, preparing slurry from the obtained biological tar, the first hydrogenation catalyst and hydrocarbonoil, allowing the obtained slurry to enter a slurry bed hydrogenation reactor for a hydrogenation reaction so as to obtain hydrogenated bio-oil, subjecting the obtained hydrogenated bio-oil to distillation separation to obtain light bio-oil, water and tail oil, and circulating a part of the obtained tail oil to replace the hydrocarbon oil for preparation of the slurry; and 4, carrying out catalytic cracking on the obtained light bio-oil to obtain the chemical raw material and the liquid fuel. The biomass conversion method provided by the invention is simple in slurry preparation and can be continuously operated, and the obtained products can be directly utilized.

Owner:黑龙江省龙油石油化工股份有限公司

Anti-inflammatory paper and preparation method thereof

InactiveCN109914157AEfficient degradationObvious advantagesSpecial paperPaper coatingFiberMicrowave radiometry

The invention relates to anti-inflammatory paper and a preparation method thereof, and discloses a process for papermaking by using Qianjinfang medicine residue, wherein the process comprises: microwave pretreatment, fermentation, washing, paper making, extraction of medicinal ingredients from filtrate, paper modification, and the like. According to the present invention, the Qianjinfang medicineresidue is used as the raw material for preparing fibers, the Qianjinfang medicine residue simultaneously has the characteristics of herbaceous plants and shrub raw materials, the microwave radiationmethod and the biological method are combined, the microwave radiation process, the temperature and the time in the pulping process, the papermaking process and the like are scientifically controlled,the paper prepared by using the method has good performance, harmful chemicals are not introduced during the whole process so as to ensure the hygienic properties of the paper, and the medicinal ingredients are extracted from the pulping filtrate and are applied on the paper, such that the finally obtained product has good anti-inflammatory effect.

Owner:ZHUZHOU QIANJIN PHARMA

Technology for preparing ryegrass slurry by pharmaceutical soak without boiling

InactiveCN1321242CLow viscosityPulp bleaching has no effectCellulose material pulpingSulfurPapermaking

The present invention is one digestion-free wheat straw-soaking pulp making process. The present invention treats wheat straw and similar papermaking material with the soaking chemical comprising sulfur 20-50 weight portions, magnesium carbonate 10-30 weight portions, aluminum hydroxide 10-30 weight portions and magnesia 30-60 weight portions. During soaking, the material consists of wheat straw in 100 weight portions, sodium hydroxide 5-15 weight portions, hydrogen peroxide 1-5 weight portions, the soaking chemical 0.1-1 weight portions and water 60-85 weight portions. Compared with traditional digesting pulp making process, the present invention has simple technological process, low production cost, high pulp quality, no waste water exhaust, high pulp yield and other advantages.

Owner:刘长如 +1

Paper for young, tender and sensitive skin, and preparation method thereof

InactiveCN109914156AHigh whitenessEfficient degradationSpecial paperWater-repelling agents additionFiberMicrowave radiometry

The invention relates to paper for young, tender and sensitive skin, and a preparation method thereof, and discloses a process for papermaking by using Qianjinfang medicine residue, wherein the process comprises: microwave pretreatment, fermentation, washing, paper making, medicinal ingredient extracting, paper modification and the like. According to the present invention, the short fiber is prepared by using the Qianjinfang medicine residue, and the long fiber property of the cotton fiber is combined, such that the prepared paper has good tensile property; the prepared paper has remarkable wet strength through internal sizing and surface application; by using the microwave radiation method and the biological method, harmful chemicals are not introduced during the whole process, such thatthe hygienic characteristics of the paper are ensured, and the paper has good softness; and the medicinal ingredients are extracted from the pulping filtrate and are applied to the paper, such that the microbial infections can be prevented, and the paper does not have any irritation and side effects on the skin mucosa, and is suitable for people with young, tender and sensitive skin.

Owner:ZHUZHOU QIANJIN PHARMA

Kitchen paper prepared from medicine residue fiber material, and preparation method thereof

The invention relates to kitchen paper prepared from a medicine residue fiber material, and a preparation method thereof, and discloses a method for preparing kitchen paper from a medicine residue fiber material, wherein the method comprises: fermentation, puffing, extracting of medicinal ingredients from filtrate, papermaking, paper modification, and the like. According to the present invention,the Qianjinfang medicine residue is used as the raw material, the biological method and the microwave radiation technology are combined, the puffing treatment process is additionally set in the preparation process, and the coordinated action among various strains and enzymes is used, such that a variety of lignin in the medicine residue are effectively degraded while the firm tubular cells are relaxed and softened, the cell wall is thin at the hypha growth place, the problems of poor softness and poor toughness of the existing kitchen paper are solved, and the problem that the kitchen paper does not have the antibacterial function is solved; and the kitchen paper prepared by the method has strong antibacterial effect.

Owner:ZHUZHOU QIANJIN PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com