Soaking-free pulping machine and method for controlling same

A technology that does not require soaking and control methods. It is applied in the directions of temperature control, electrical program control, and non-electric variable control. It can solve the problems of long pulping time, cumbersome pulping process, and unsatisfactory pulping effect. It achieves convenient operation, The effect of the simplicity of the pulping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

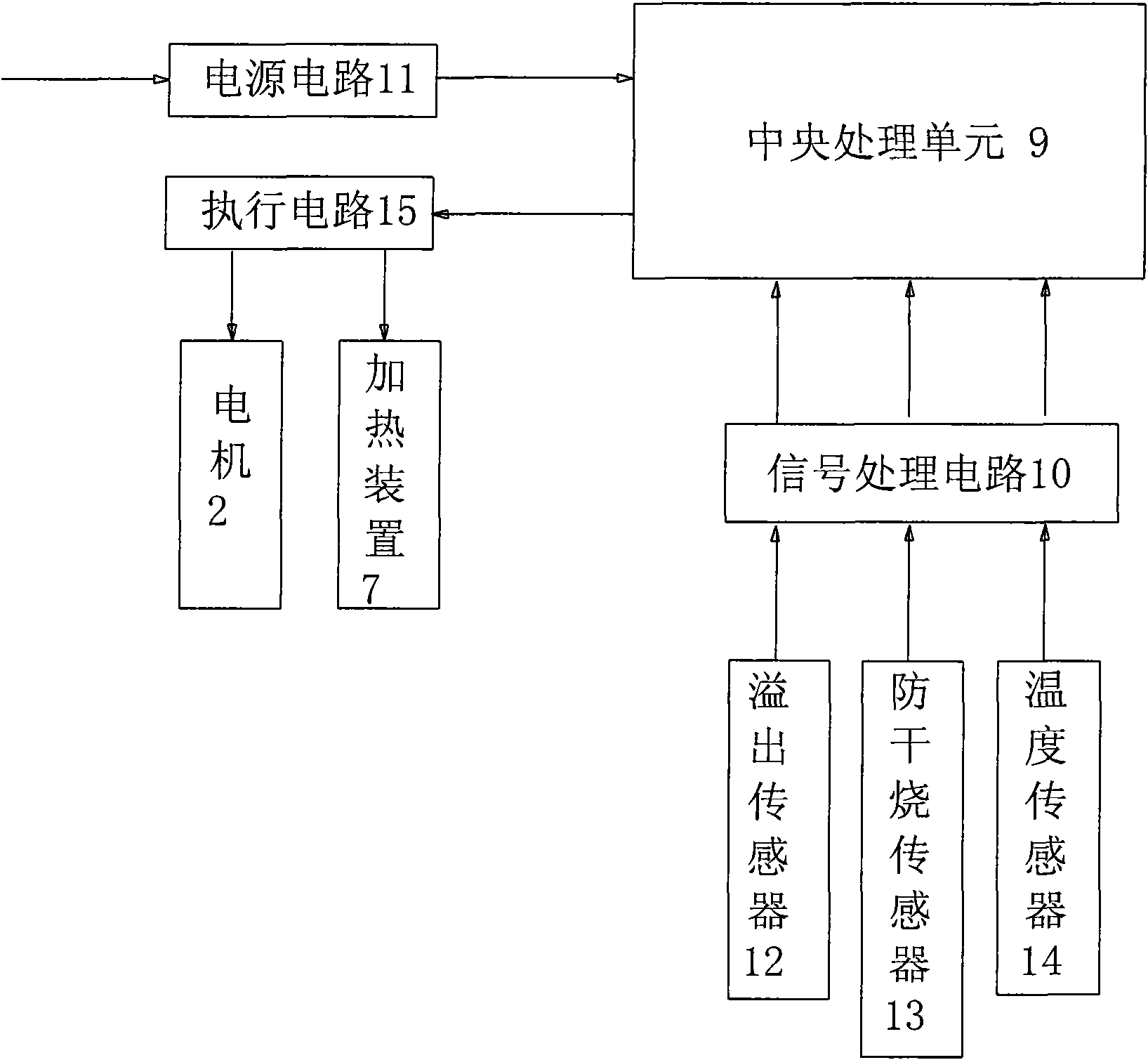

[0021] figure 1 It is a schematic diagram of the structure of the pulping machine of the present invention. The soybean milk machine is mainly composed of two parts: the machine head 1 and the container body 4. The motor 2, the control circuit and the control panel are arranged in the machine head 1. The stirring and pulverizing device 6 in this embodiment It is a crushing blade, and the crushing blade is installed on the rotating shaft of the motor 2, the anti-overflow device 3 adopts an anti-overflow probe, the anti-dry heating device 5 is an anti-dry heating probe extending into the inside of the container body 4, and the temperature sensing device 8 is a sensor. The temperature probe, in the present embodiment, adds a thermistor in the anti-dry probe, and monitors the temperature of the slurry with the resistance value of the resistor. The heating device 7 is a heat pipe extending downward from the machine head 1 to the inside of the cup body.

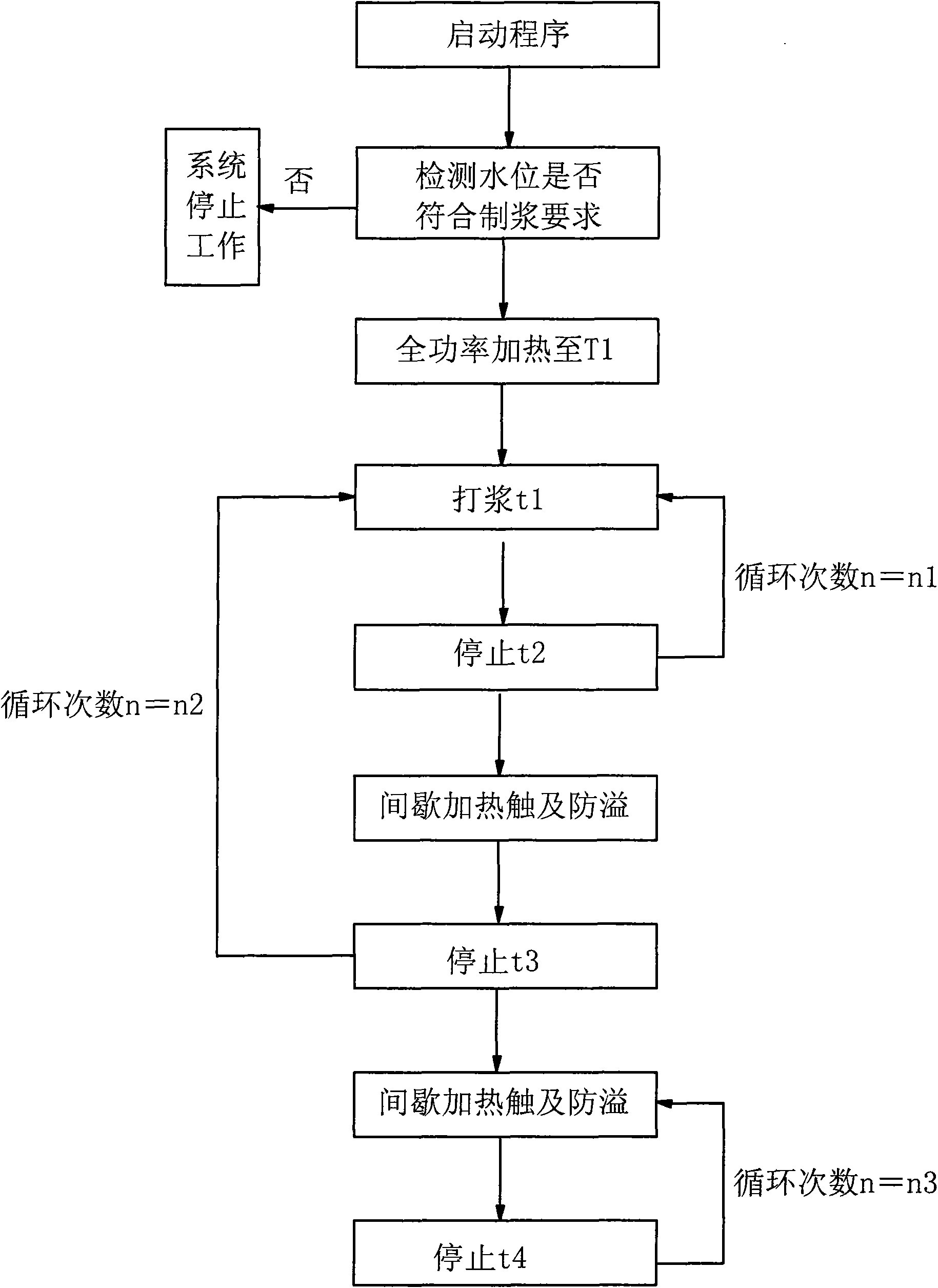

[0022] figure 2 It is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com