Kitchen paper prepared from medicine residue fiber material, and preparation method thereof

A technology of kitchen paper and fiber materials, applied in fiber raw material processing, paper, papermaking, etc., can solve the problems of poor softness and toughness, insufficient softness and toughness, etc., achieve good water absorption, good durability, and The effect of simple pulping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

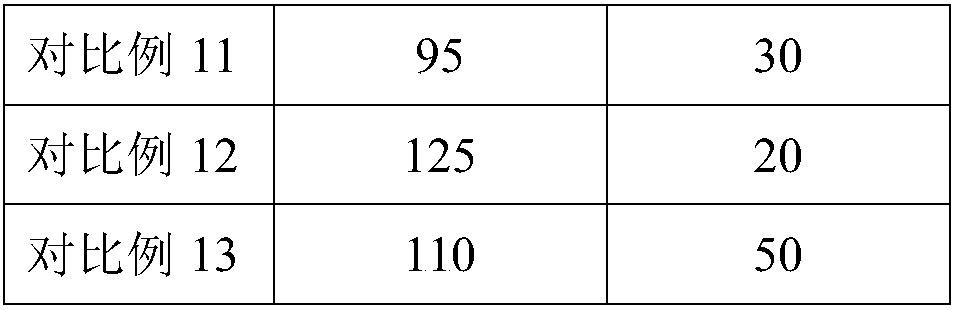

Examples

Embodiment 1

[0039] This embodiment provides a method for preparing kitchen paper from the dregs fiber material, and the specific operation steps are as follows:

[0040] S1. Fermentation: put Qianjinfang medicine dregs with a water content of 25% in a fermentation tank, add 2 kg / ton of biological compound enzyme, stir evenly, and treat with microwave radiation under aerobic conditions with a microwave power of 1500W , the microwave time is 100min, and the Qianjinfang medicinal residue material is fermented to obtain a coarse slurry and a filtrate;

[0041] S2. Washing: Repeatedly soak, disperse and wash the coarse slurry in step S1 with water until the washing water is neutral, then dehydrate and seal to obtain a semi-finished fiber product;

[0042] S3. Expansion: the fiber semi-finished product obtained in step S2 is placed in an extruder for expansion treatment, the expansion temperature is 100° C., and the expansion time is 20 minutes to obtain expanded dregs fiber;

[0043] S4. Extr...

Embodiment 2

[0049] This embodiment provides a method for preparing kitchen paper from the dregs fiber material, and the specific operation steps are as follows:

[0050] S1. Fermentation: Put Qianjinfang medicine dregs with a water content of 45% in a fermentation tank, add 4 kg / ton of biological compound enzymes, stir evenly, and treat with microwave radiation under aerobic conditions with a microwave power of 1000W , the microwave time is 200min, and the Qianjinfang medicinal residue material is fermented to obtain a coarse slurry and a filtrate;

[0051] S2. Washing: Repeatedly soak, disperse and wash the coarse slurry in step S1 with water until the washing water is neutral, then dehydrate and seal to obtain a semi-finished fiber product;

[0052] S3. Expansion: the fiber semi-finished product obtained in step S2 is placed in an extruder for expansion treatment, the expansion temperature is 120° C., and the expansion time is 10 minutes to obtain expanded dregs fiber;

[0053] S4. Ext...

Embodiment 3

[0059] This embodiment provides a method for preparing kitchen paper from the dregs fiber material, and the specific operation steps are as follows:

[0060] S1. Fermentation: Put Qianjinfang medicine dregs with a water content of 35% in a fermentation tank, add 3 kg / ton of biological compound enzymes, stir evenly, and treat with microwave radiation under aerobic conditions, with a microwave power of 1400W , the microwave time is 120min, and the Qianjin Recipe medicinal residue material is fermented to obtain a coarse slurry and a filtrate;

[0061] S2. Washing: Repeatedly soak, disperse and wash the coarse slurry in step S1 with water until the washing water is neutral, then dehydrate and seal to obtain a semi-finished fiber product;

[0062] S3. Expansion: the fiber semi-finished product obtained in step S2 is placed in an extruder for expansion treatment, the expansion temperature is 110° C., and the expansion time is 15 minutes to obtain expanded dregs fiber;

[0063] S4....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com