High-concentration organic waste innocent treatment system and process

A technology of harmless treatment and organic waste, applied in the field of environmental protection and energy saving, can solve the problems of unreasonable and effective development, consumption of non-renewable energy, difficult storage and transportation, etc., to achieve clean combustion treatment, improve energy supply and improve energy efficiency. The effect of consumption efficiency and long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

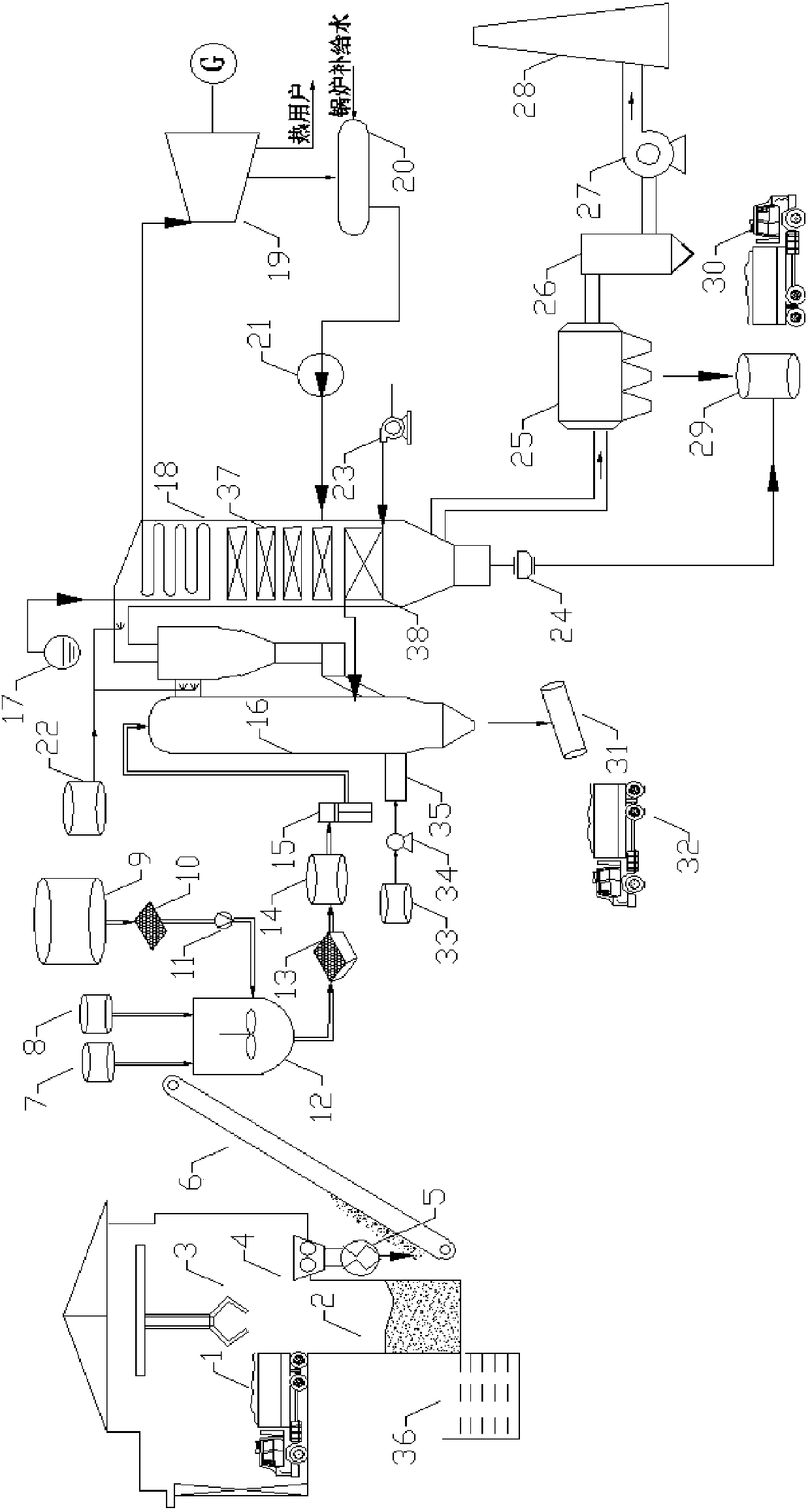

[0027] Process flow chart of the present invention is as figure 1 Shown, the system structural diagram of the present invention is as figure 2 As shown, a high-concentration organic waste harmless treatment process and system, firstly conduct a slurry-forming experiment on high-concentration organic waste, and measure the water content, apparent viscosity and flow characteristics of coal-water slurry to determine the high-concentration organic waste and The optimum ratio of coal slime, and the calculation of the addition amount of high-concentration organic waste, coal slime, water and dispersant, provide technical conditions for optimizing coal-water slurry fuel delivery and improving system stability.

[0028]On the basis of the above-mentioned pulping test, high-concentration waste is stored in the organic waste storage tank 9, which has a storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com