Mechanical vapor recompression system of concentrated organic waste water and method

A technology of organic wastewater and mechanical steam, applied in the chemical industry, can solve the problems of reduced evaporation concentration ratio of MVR system, failure to meet discharge requirements, poor organic wastewater effect, etc., to improve wastewater treatment efficiency, occupy a small area, and compact equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to better illustrate the present invention, the present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples.

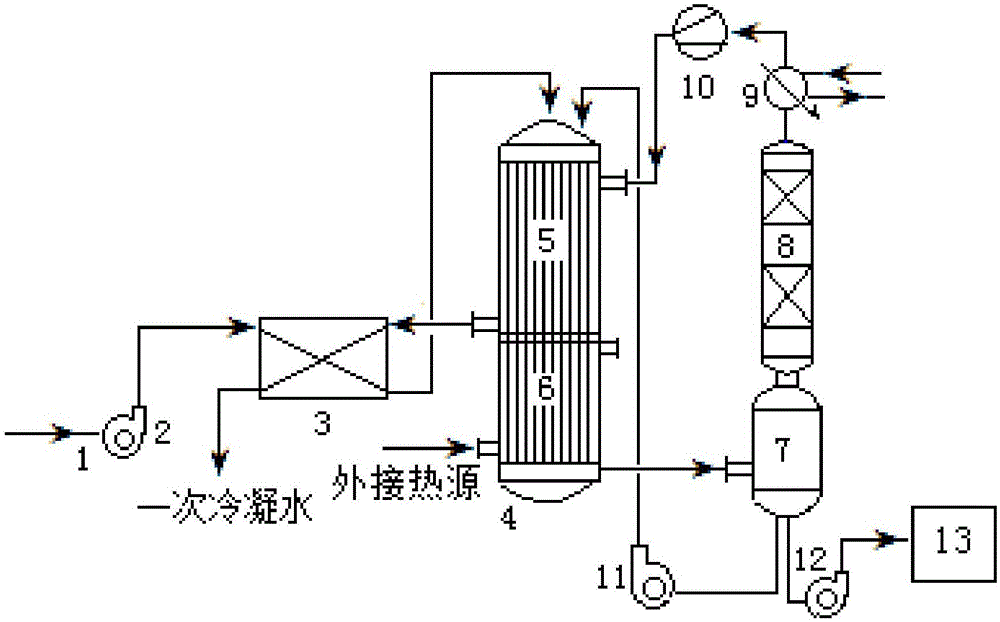

[0039] combined with figure 1 The described mechanical vapor recompression system for concentrating low-concentration chemical waste water,

[0040] A mechanical vapor recompression system for concentrating organic waste water, comprising an evaporator 4, a gas-liquid separator 7, a rectification tower 8, a steam compressor 10, a waste water inlet 1, a lift pump A 2 , a lift pump B 11 , a discharge through The pump 12, the heat exchanger 3, the evaporator 4 is composed of two independent primary evaporation units 5 and secondary evaporation units 6, the primary evaporation unit is adjacent to the outlet of the steam compressor through the pipeline, and the secondary evaporation unit is The evaporation unit is connected to an external heat source; the top of the gas-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com