Intelligent thickness gauge

A technology of intelligent thickness gauge and detection head, which is applied in the direction of instruments, measuring devices, optical devices, etc., can solve the problems of sensor zero drift, difficult online detection, complex structure, etc., and achieve the effect of compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

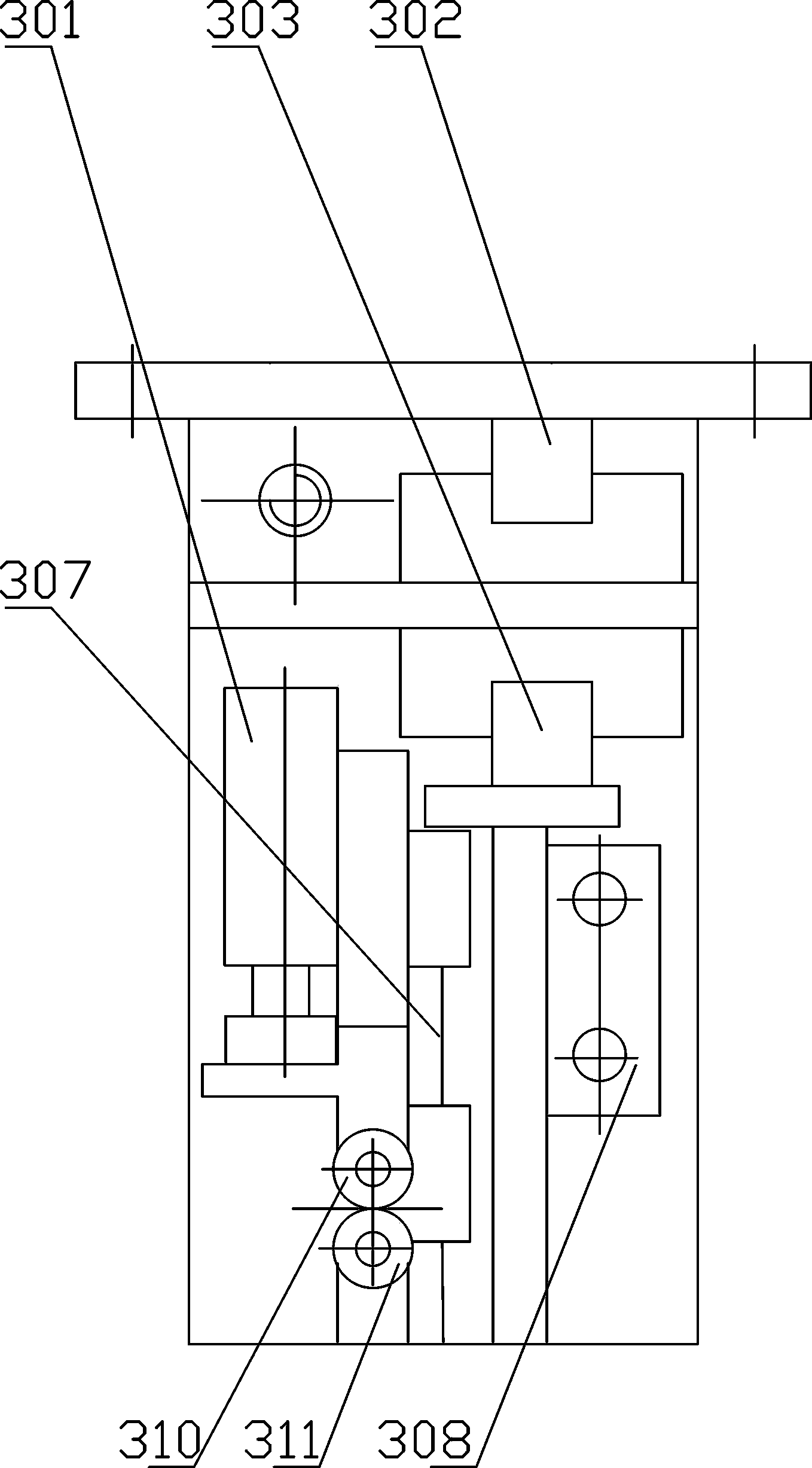

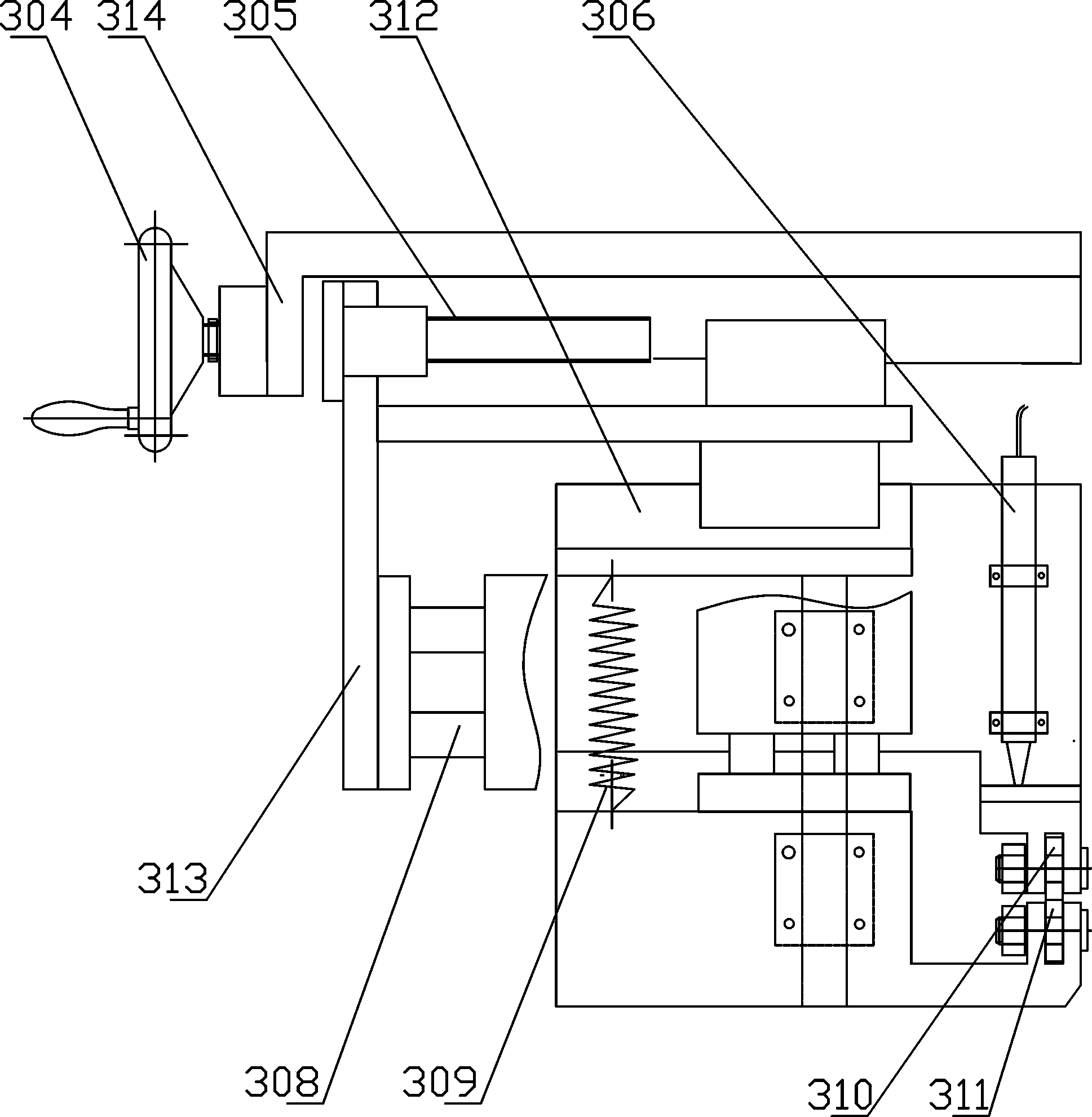

[0024] Such as figure 1 , 2 Among them, an intelligent thickness gauge, the upper detection roller 310 and the lower detection roller 311 are both slidably installed on the detection lifting guide rail 307 through the base; the upper detection roller 310 and the lower detection roller 311 in this example adopt high-precision bearings.

[0025] The base of the upper detection roller 310 and the base of the lower detection roller 311 are installed on the frame by springs, so that the detection point between the upper detection roller 310 and the lower detection roller 311 floats; thus, the structure is adapted to the change of the workpiece thickness specification, That is to say image 3 When the mechanical arm 2 traverses through the thickness detection device 3 of the present invention, the detection point between the upper detection roller 310 and the lower detection roller 311 will change with the position of the lower end of the mechanical arm 2, so it will not be affecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com