Multiple ozone generating device

A technology for ozone generation and equipment, applied in the fields of electronics, electrochemistry, energy conservation and environmental protection, to achieve the effects of increasing ozone gas production rate, reducing raw material costs and operating costs, and avoiding decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

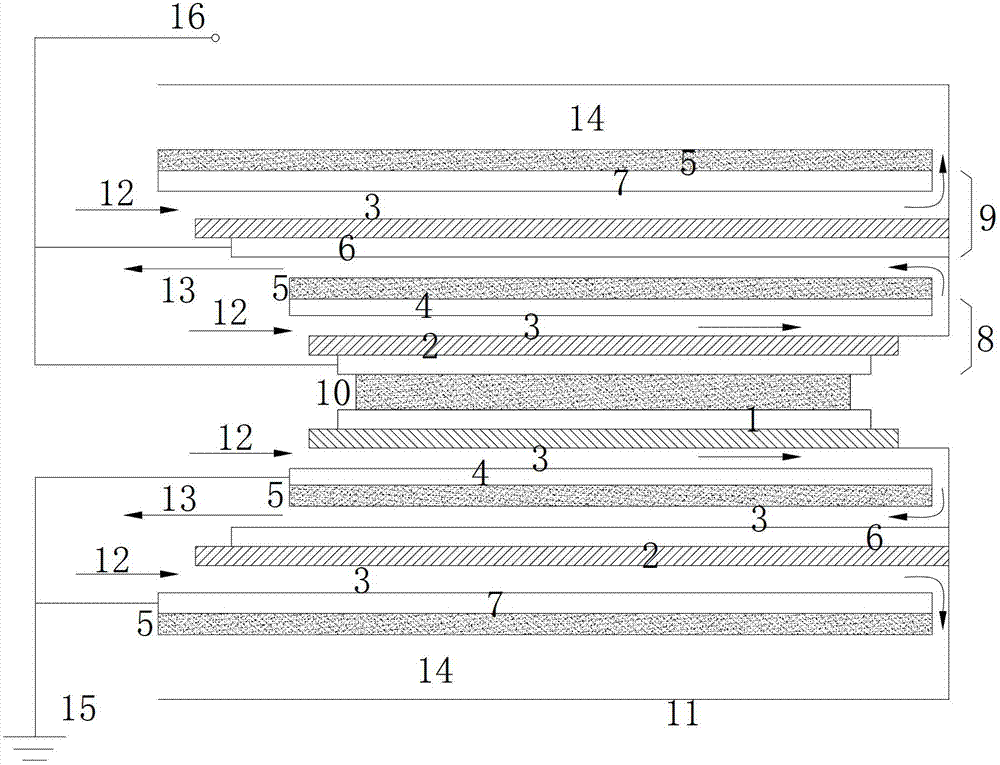

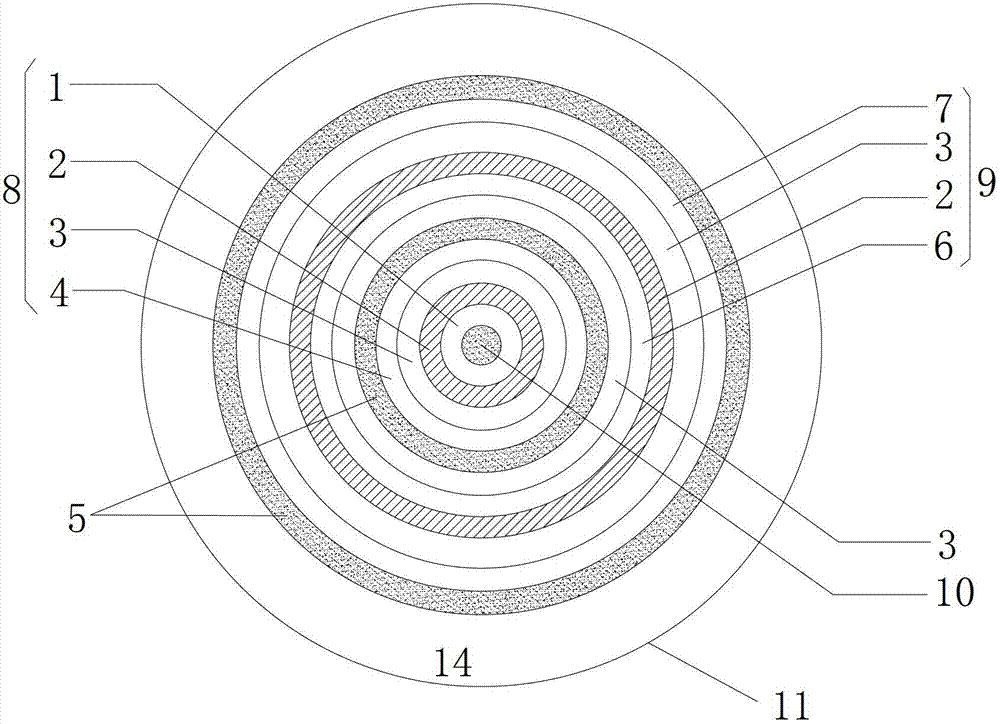

[0033] figure 1 It is a cross-sectional view of the multiple ozone generating equipment. figure 2 It is a side view of multiple ozone generating equipment. Such as Figure 1-2 As shown, the multiple ozone generating equipment is composed of multiple electrode pairs distributed in concentric circles from the inside to the outside.

[0034] Each of the electrodes includes an inner electrode and an outer electrode, the inner electrode is connected to a high-voltage terminal 16, the outer electrode is grounded 15, and a discharge gap 3 is formed between the inner electrode and the outer electrode. A discharge gap 3 is formed between the electrode pairs.

[0035] The cooling liquid is arranged on the outer side of the outer electrodes of the pair of electrodes and the innermost layer of the concentric circles.

[0036] The jacket is arranged on the outermost layer of the plurality of electrodes, and a stainless steel jacket 11 can be used.

[0037] Such as Figure 1-2 As sho...

Embodiment 2

[0051] Use the iodometric method specified in the CJ / T322-2010 "Ozone Generator for Water Treatment" standard to detect the concentration and output of ozone. Using this equipment, compared with the general corona discharge type ozone generating equipment, the ozone gas production rate should be increased by at least 30-40%, the ozone concentration can reach 60-170mg / L, and the power consumption per kilogram of ozone can be reduced to 15KWh. Power consumption per kilogram of ozone is reduced by 20-30%, and if the production of 20Kg / h equipment can reduce the area of equipment by 40m 2 About 20-40% reduction in floor space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com