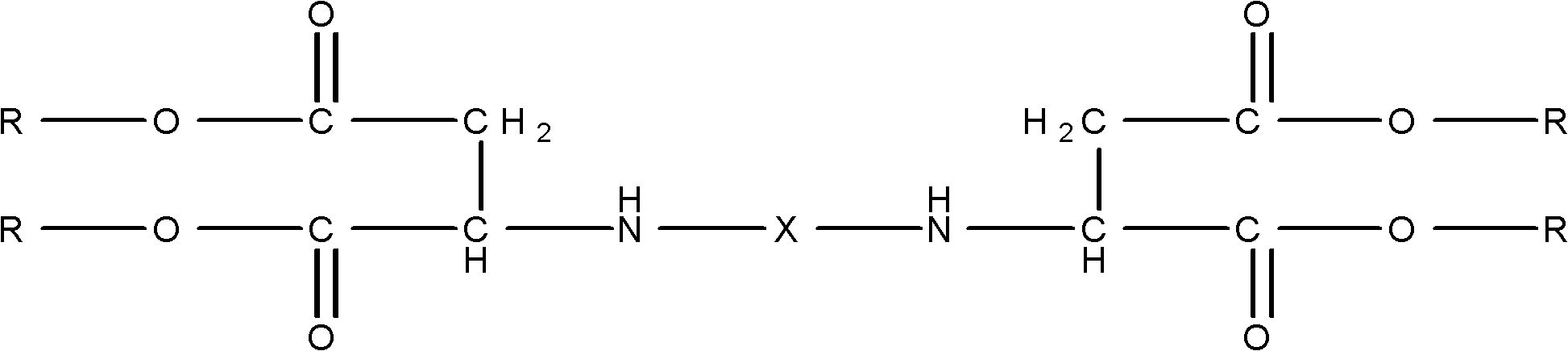

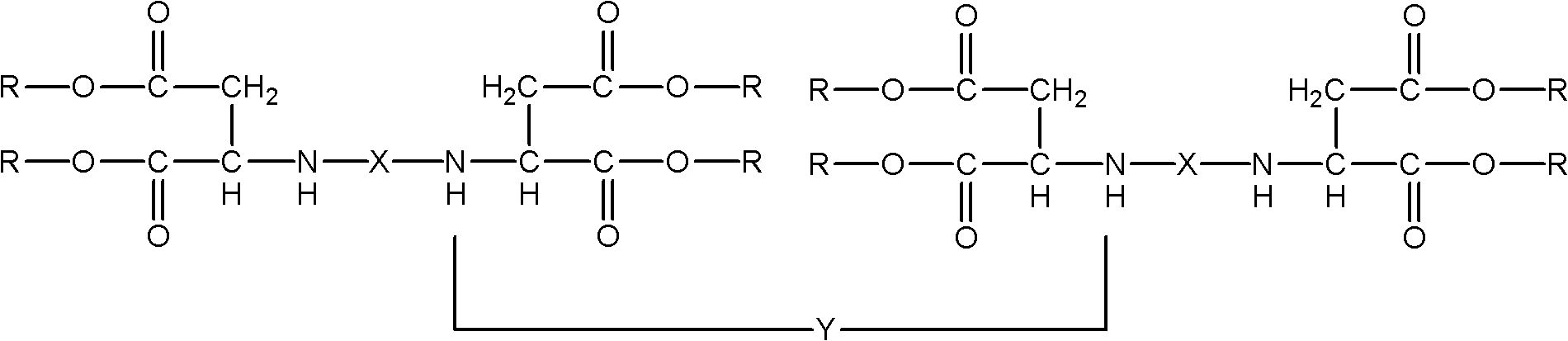

Polymerized modified polyaspartic acid ester compound and preparation method thereof

An aspartate, polymerized technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of high glass transition temperature, unusable, high price, etc., and achieves gel time increase and low investment cost. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A: Add polyoxypropylene ether diol with an average molecular weight of 1000 into a four-necked flask, the amount added is 500 grams, the amount of organotin catalyst added is 0.1-2 grams, HMDI raw material 262 grams, react at 60-100 ° C for 6 -8h, until the NCO value no longer decreases, and the prepolymer of isocyanate is obtained.

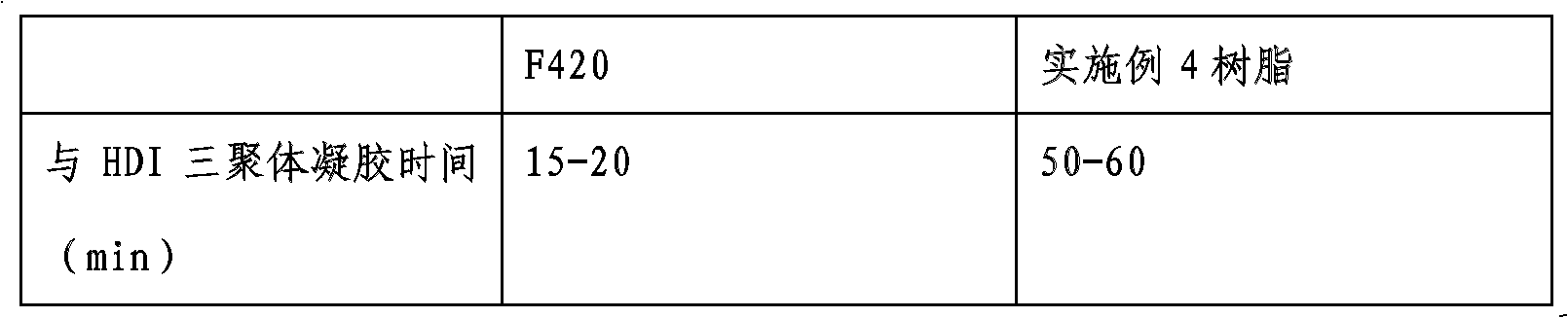

[0029] B: React 762 grams of the above-mentioned isocyanate prepolymer with 544 grams of F420 polyaspartic acid ester monomer, add one of esters, ketones, benzenes or their mixed solvents, adjust the solid content to 60%, at 50 Incubate at -80°C for 2-4 hours to obtain the product.

[0030] C, F420 polyaspartate monomer system product of Zhuhai Feiyang Chemical Co., Ltd., molecular weight 544. Equivalent to foreign brand NH1420.

Embodiment 2

[0032] A: Add a difunctional saturated polyester with a molecular weight of 2000 into a four-necked flask, the addition amount is 500 grams, organic bismuth catalyst 0.1-2 grams, isophorone diisocyanate (IPDI) 111 grams, and react at 60-100 ° C for 6 -8h, until the NCO value no longer decreases, and the prepolymer of isocyanate is obtained.

[0033] B: React 611 grams of the above-mentioned isocyanate prepolymer with 277 grams of F420 polyaspartic acid ester monomer, add one of esters, ketones, benzenes or their mixed solvents, adjust the solid content to 60%, at 50 Incubate at -80°C for 2-4 hours to obtain the product.

Embodiment 3

[0035] A: Add 920 grams of F220 polyaspartate monomer into a four-necked flask, add 250 grams of MDI isocyanate, add one of esters, ketones, benzenes or their mixed solvents, and adjust the solid content to 60%. Incubate at 50-80°C for 2-4 hours to obtain the product.

[0036] B: The above-mentioned F220 polyaspartate monomer system is a product of Zhuhai Feiyang Chemical Co., Ltd., with a molecular weight of 460.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com