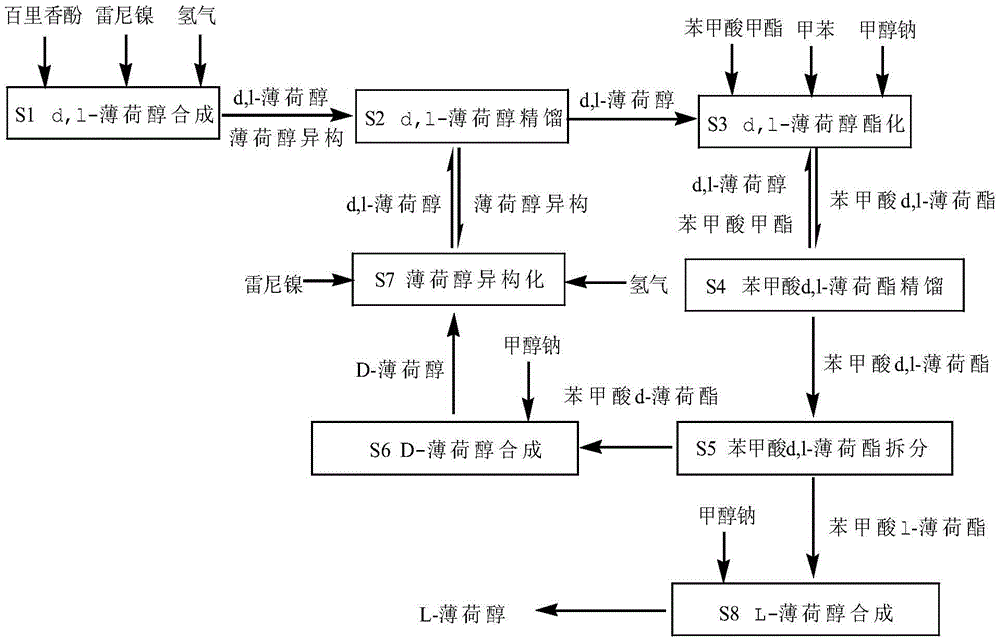

A synthetic process of L-menthol

A synthesis process, menthol technology, applied in the field of L-menthol synthesis process, can solve the problems of harsh reaction conditions, low efficiency, high reaction temperature and pressure, etc., to achieve improved esterification yield, easy operation, high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] S1. Synthesis of d,l-menthol

[0078] In a 5L hydrogenation kettle, 1923g of thymol and 57.7g of Raney nickel were added, and hydrogen gas was introduced. The molar ratio of hydrogen to thymol was 1:4, and the pressure of the kettle was 2MPa. The reaction temperature is 190°C, and the hydrogenation reaction generates 20.37% of d,l-neomenthol, 65.58% of d,l-menthol, 1.84% of d,l-neoisomenthol, and 10.21% of d,l-isomenthol.

[0079] S2, d,l-menthol rectification

[0080] The above reaction was rectified under reduced pressure to obtain d,l-menthol 1311.6g, l-isomenthol, d,l-neomenthol, d,l-neo-menthol isomeric mixture 648.4g, this step The yield is 98% of theoretical.

[0081] S3, d,l-menthol esterification

[0082] Add 5109g of methyl benzoate, 1953.5g of d,l-menthol, 30% sodium methoxide and toluene into a 20L esterification reactor, wherein the molar weight of methyl benzoate is 3 times that of d,l-menthol, 30% Sodium methoxide 4508g, molar weight is d, 2 times of ...

Embodiment 2

[0094] S1. Synthesis of d,l-menthol

[0095] In a 5L hydrogenation kettle, 1923g of thymol and 38.5g of Raney nickel were added, and hydrogen was introduced. The molar ratio of hydrogen to thymol was 1:4, and the pressure of the kettle was 2MPa. The reaction temperature was 170°C, and the hydrogenation reaction produced 22.37% of d,l-neomenthol, 62.26% of d,l-menthol, 1.22% of d,l-neoisomenthol, and 11.15% of d,l-isomenthol.

[0096] S2, d,l-menthol rectification

[0097] The above reaction was rectified under reduced pressure to obtain d,l-menthol 1245.2g, l-isomenthol, d,l-neomenthol, d,l-neoisomenthol isomeric mixture 694.8g, this step The yield is 97% of theoretical.

[0098] S3, d,l-menthol esterification:

[0099] Add 3306g of methyl benzoate, 1919.1g of d,l-menthol, 30% sodium methoxide and toluene into a 20L esterification reactor, wherein the molar weight of methyl benzoate is 3 times that of d,l-menthol, 30% Sodium methoxide 4428.8g, molar weight is 2 times of d, l...

Embodiment 3

[0111] S1. Synthesis of d,l-menthol

[0112] In a 5L hydrogenation kettle, 1923g of thymol and 19.2g of Raney nickel were added, hydrogen was introduced, the molar ratio of hydrogen to thymol was 1:4, and the pressure of the kettle was 1MPa. The reaction temperature was 160°C, and the hydrogenation reaction produced 21.60% of d,l-neomenthol, 58.36% of d,l-menthol, 1.39% of d,l-neoisomenthol, and 13.65% of d,l-isomenthol.

[0113] S2, d,l-menthol rectification

[0114] The above reaction was rectified under reduced pressure to obtain 1167.2 g of d,l-menthol, 732.7.4 g of isomeric mixtures of d,l-neomenthol, d,l-neomenthol, and 1,167.2 g of l-isomenthol, respectively. The step yield is 95% of the theoretical yield.

[0115] S3, d,l-menthol esterification

[0116] Add 3262g of methyl benzoate, 1870.6.5g of d, l-menthol, 30% sodium methoxide and toluene in a 20L esterification reactor, wherein the molar weight of methyl benzoate is twice that of d, l-menthol, 30 % sodium metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com