Cerium oxide polishing powder and preparation method thereof

A cerium oxide, polishing powder technology, applied in chemical instruments and methods, polishing compositions containing abrasives, other chemical processes, etc. Different abilities, no consideration of the material of the polishing object, etc., to achieve the effect of improving the effective utilization rate, improving the suspension, and improving the polishing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

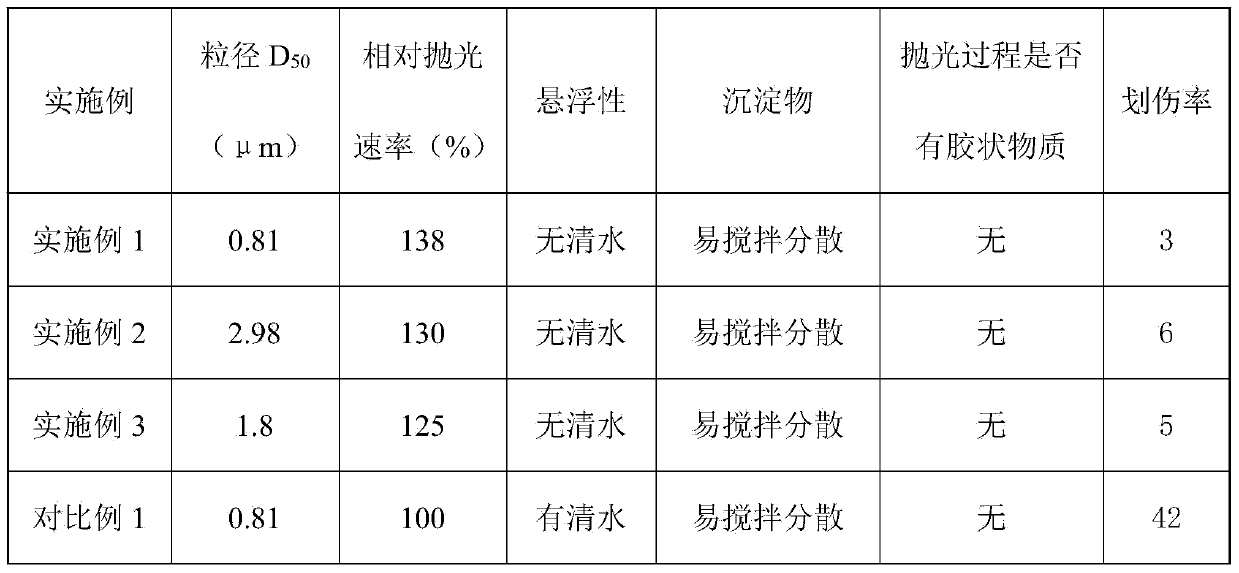

Embodiment 1

[0039] In 400kg pure water, add 100kg cerium carbonate (TREO is 45%, CeO 2 / TREO is 99.96%), slowly add hydrochloric acid under stirring conditions, until the pH is 1.5, filter to obtain a clear and transparent cerium chloride aqueous solution, and obtain solution A;

[0040] Add ammonium bicarbonate aqueous solution with a mass fraction of 5% slowly to solution A heated to 90°C until the pH is 6.5, and continue stirring for 4 hours after the addition.

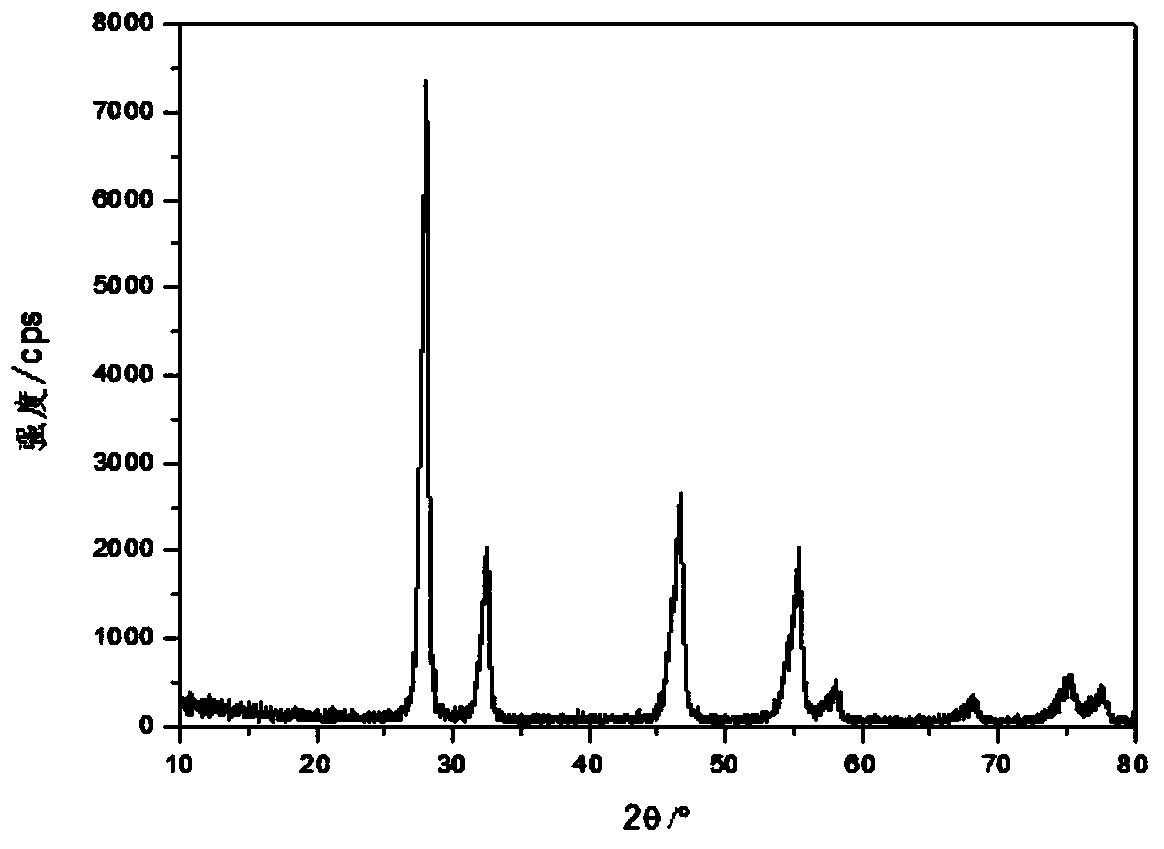

[0041] Then dehydrated by centrifugation, and then roasted at 800 ° C for 5 hours to obtain 450 kg of cerium oxide; add 225 g of phosphate salts with a mass fraction of 50% each of sodium dihydrogen phosphate and disodium hydrogen phosphate, and pulverize by airflow until the D50 is 1.0 μm to obtain The rare earth polishing powder. figure 1 It is an XRD schematic diagram of the rare earth polishing powder obtained in Example 1 of the present invention.

Embodiment 2

[0043] In 234kg of pure water, add 100kg of cerium carbonate (TREO is 50%, CeO 2 / TREO is 99.99%), slowly add hydrochloric acid under stirring conditions, until the pH is 2.5, filter to obtain a clear and transparent aqueous solution of lanthanum cerium chloride, and obtain solution A;

[0044] Slowly add 10% aqueous ammonium bicarbonate solution into solution A heated to 95°C, and continue stirring for 2 hours after the addition. Then, it was dehydrated by centrifugation and roasted at 1000°C for 3 hours to obtain 500 kg of cerium oxide; 750 g of phosphate with a mass fraction of 50% each of sodium dihydrogen phosphate and disodium hydrogen phosphate was added, and it was pulverized by airflow until the D50 was 2.0 μm to obtain the described rare earth polishing powder.

Embodiment 3

[0046] In 400kg pure water, add 100kg cerium carbonate (TREO is 45%, CeO 2 / TREO is 99.98%), slowly add hydrochloric acid under stirring conditions, until the pH is 2.0, filter to obtain a clear and transparent aqueous solution of cerium chloride, and obtain solution A.

[0047] Slowly add ammonium bicarbonate aqueous solution with a mass fraction of 7% into solution A heated to 95°C until the pH is 7.0, and continue stirring for 4 hours after the addition.

[0048] Then it was dehydrated by centrifugation, and then roasted at 900°C for 4 hours to obtain 450 kg of cerium oxide; 450 g of phosphate salts with a mass fraction of 50% each of sodium dihydrogen phosphate and disodium hydrogen phosphate were added, and it was pulverized by airflow until the D50 was 1.5 μm to obtain The rare earth polishing powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com