Method for extracting corn straw modified fine fibers by machinery-chemistry combined method

A technology of corn stalk and combination method, which is applied in the field of crop treatment, can solve the problems of not being energy-saving and environmentally friendly, occupying a large area, and low separation efficiency, and achieve the effects of easy replacement of parts, reduction of land occupation, and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

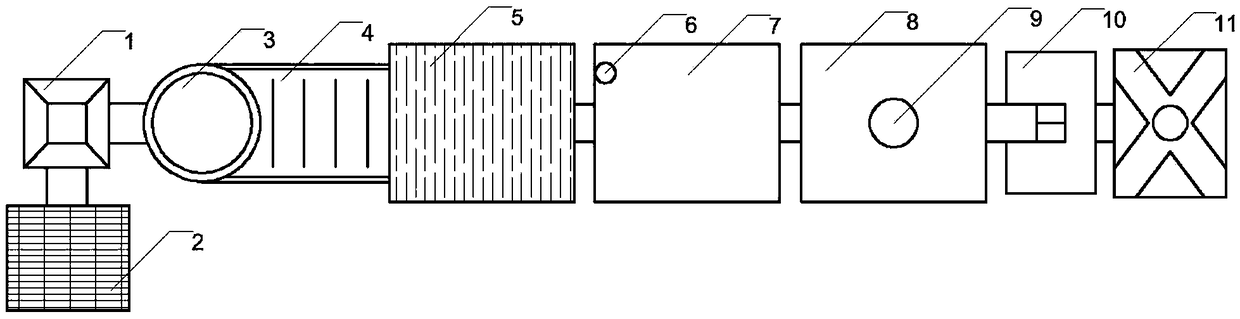

[0039] Such as Figure 1-7 The method for extracting the modified refined fiber of corn stalks by the mechanical-biological combination method comprises the following steps:

[0040] (1) by soaking in water, the water content of the corn stalk crude fiber reaches at least 70%;

[0041] (2) After draining, separate the fibers through the screw-stacking fiber rubbing and splitting machine, and separate the thick fibers into fine fibers by mechanical method; the screw-stacking fiber rubbing and splitting machine is 1 group;

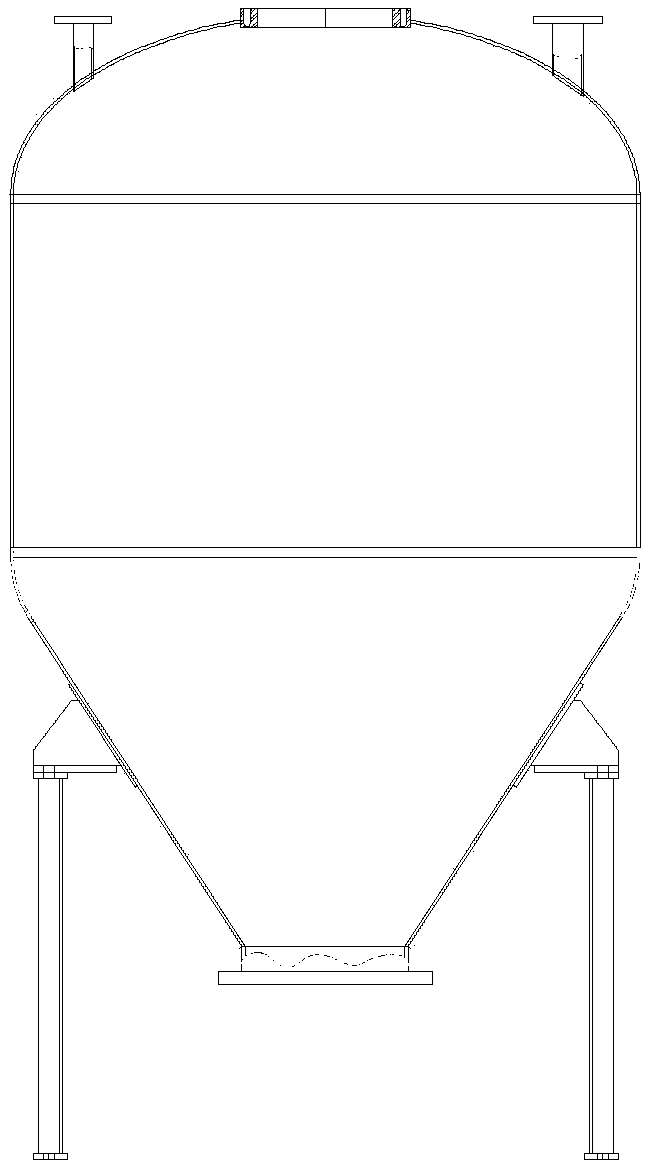

[0042] (3) Thin fibers are placed in a biological purifier, and the sugar molecules attached between the thin fibers and on the surface are removed by glucosophilic microorganisms to obtain biomodified fibers; the saccharophilic microorganisms are pseudomonas saccharophiles Bacillus Pseudomonassaccharophila genus; the number of biological purifiers is 1 group.

[0043] (4) inactivating the biologically modified fiber obtained in the above step (3) by means...

Embodiment 2

[0055] As an extension, the method for extracting modified refined fibers of corn stalks by a mechanical-biological combination method includes the following steps:

[0056] (1) by soaking in water, the water content of the corn stalk crude fiber reaches at least 70%;

[0057] (2) After draining, separate the fibers through the screw-stacking fiber rubbing and splitting machine, and separate the thick fibers into fine fibers by mechanical means; the screw-stacking fiber rubbing and splitting machines are 2 groups;

[0058] (3) Thin fibers are placed in a biological purifier, and the sugar molecules attached between the thin fibers and on the surface are removed by glucosophilic microorganisms to obtain biomodified fibers; the saccharophilic microorganisms are pseudomonas saccharophiles Bacillus Pseudomonassaccharophila genus; the number of biological purifiers is 3 groups.

[0059] (4) Inactivate the biologically modified fiber obtained in the above step (3) by means of steam...

Embodiment 3

[0064] As an extension, the method for extracting modified refined fibers of corn stalks by a mechanical-biological combination method includes the following steps:

[0065] (1) by soaking in water, the water content of the corn stalk crude fiber reaches at least 70%;

[0066] (2) After draining, separate the fibers through the screw-stacking fiber rubbing and splitting machine, and separate the thick fibers into fine fibers by mechanical means; the screw-stacking fiber rubbing and splitting machines are 2 groups;

[0067] (3) Thin fibers are placed in a biological purifier, and the sugar molecules attached between the thin fibers and on the surface are removed by glucosophilic microorganisms to obtain biomodified fibers; the saccharophilic microorganisms are pseudomonas saccharophiles Bacillus Pseudomonassaccharophila genus; the number of biological purifiers is 2 groups.

[0068] (4) inactivating the biologically modified fiber obtained in the above step (3) by means of ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com