Sol-gel preparation method of porous nickel cobaltate material

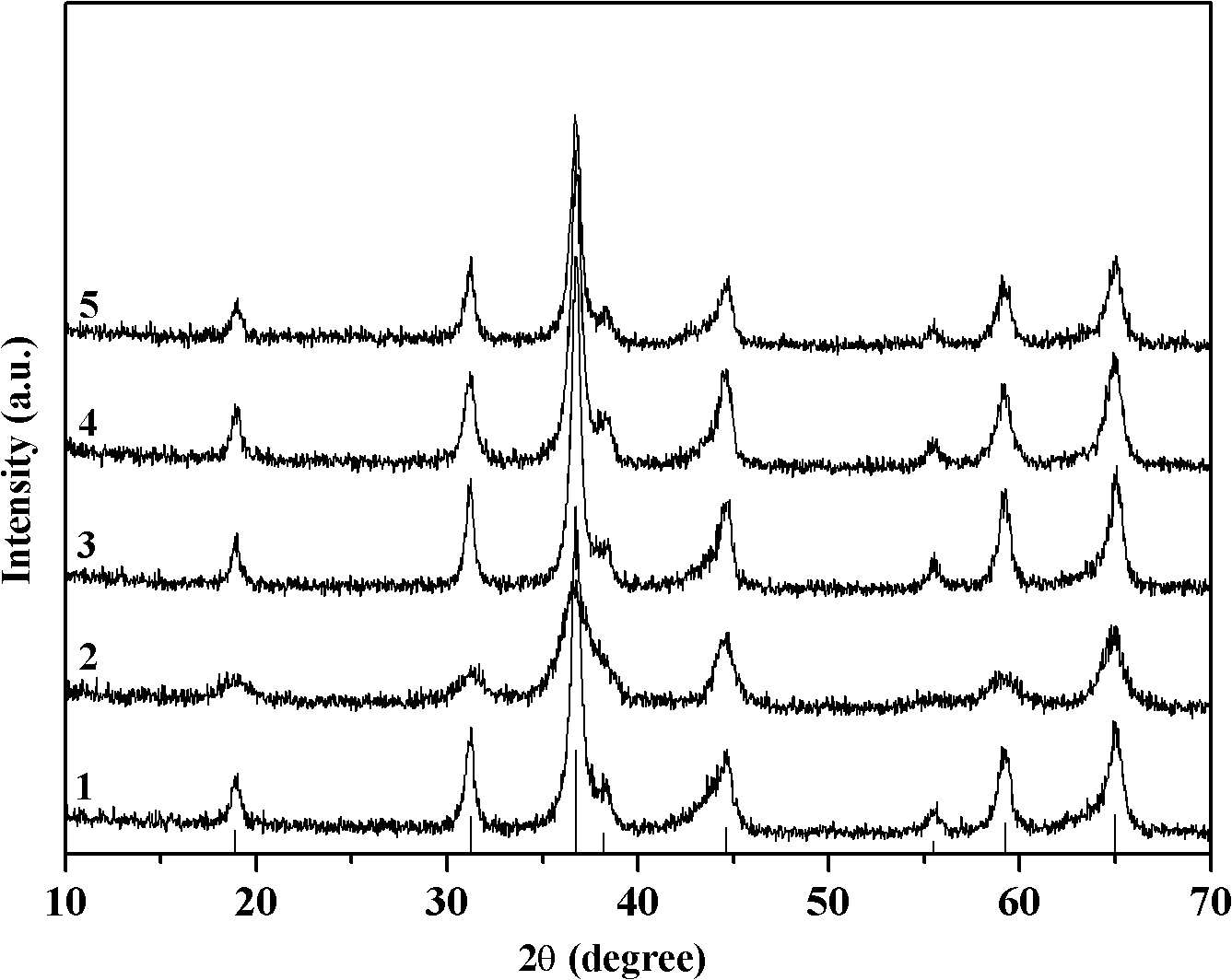

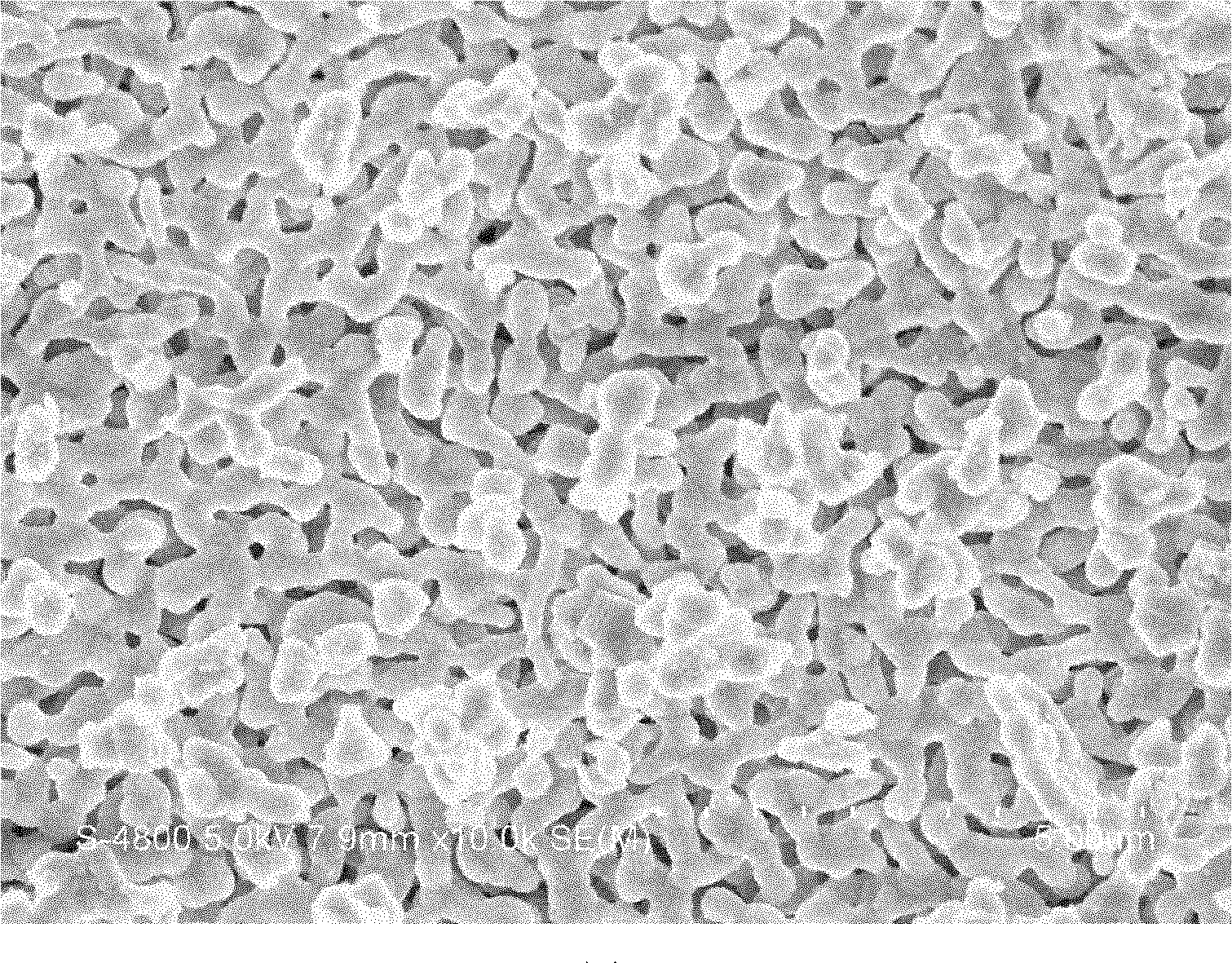

A technology of sol-gel and nickel cobaltate, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., can solve the problems of expensive, harmful, and non-environmentally friendly organic compounds, and achieve high crystallinity and simple process , the effect of uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The sol-gel preparation method of the porous nickel cobaltate material of the present embodiment operates according to the following steps:

[0023] Mix 50mL of cobalt acetate solution with a concentration of 0.32mol / L and 50mL of nickel acetate solution with a concentration of 0.16mol / L to form an aqueous solution of acetate, and then add 50mL of lemon with a concentration of 0.48mol / L to the aqueous solution of acetate Aqueous acid solution, dilute with distilled water so that the molar concentration of cobalt acetate in the mixed solution is 0.016mol / L, stir and mix evenly, place in a drying oven, dry at 120°C for 16 hours to obtain a precursor, and grind the obtained precursor Crush and pass through a 200-mesh sieve, and place it in a tube furnace for calcination at 400°C for 2 hours to obtain a porous nickel cobalt oxide material.

Embodiment 2

[0025] The sol-gel preparation method of the porous nickel cobaltate material of the present embodiment operates according to the following steps:

[0026] Mix 50mL of cobalt acetate solution with a concentration of 0.32mol / L and 50mL of nickel acetate solution with a concentration of 0.16mol / L to form an aqueous solution of acetate, and then add 50mL of lemon with a concentration of 0.48mol / L to the aqueous solution of acetate Aqueous acid solution, dilute with distilled water so that the molar concentration of cobalt acetate in the mixed solution is 0.016mol / L, stir and mix evenly, place in a drying oven, dry at 130°C for 12 hours to obtain a precursor, and grind the obtained precursor Crush and pass through a 200-mesh sieve, and calcinate at 350°C for 3 hours in a tube furnace to obtain a porous nickel cobaltate material.

Embodiment 3

[0028] The sol-gel preparation method of the porous nickel cobaltate material of the present embodiment operates according to the following steps:

[0029] Mix 50mL of cobalt acetate solution with a concentration of 0.32mol / L and 50mL of nickel acetate solution with a concentration of 0.16mol / L to form an aqueous solution of acetate, and then add 50mL of lemon with a concentration of 0.48mol / L to the aqueous solution of acetate Aqueous acid solution, dilute with distilled water so that the molar concentration of cobalt acetate in the mixed solution is 0.03mol / L, stir and mix evenly, place in a drying oven, dry at 125°C for 14 hours to obtain a precursor, and grind the obtained precursor Crush and pass through a 200-mesh sieve, and place it in a tube furnace for calcination at 380°C for 2 hours to obtain a porous nickel cobaltate material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com