Iron-based catalyst as well as preparation method and application thereof

A catalyst and iron-based technology, applied in the field of coal chemical industry, can solve problems such as unsuitable for large-scale development and application, large water consumption, and long process flow, so as to improve the catalytic activity of direct coal liquefaction, avoid continuous production interruption, and shorten the process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] As described in the background technology section, the existing preparation methods of iron-based catalysts cannot effectively solve the problems of large water consumption, long and complicated process flow, high energy consumption and high cost, and are not suitable for large-scale development and application. In order to solve the above problems, the present invention provides a method for preparing an iron-based catalyst, the preparation method comprising: 1) mixing and reacting an iron-containing soluble salt solution with an alkaline aqueous solution to obtain a slurry initial product; Under the atmosphere, the primary product is loaded on the solid carrier in the form of spraying, and the crystal phase transformation is carried out to obtain the secondary product with FeOOH loaded on the surface of the solid carrier; and 3) under the nitrogen atmosphere, the secondary product is dried to obtain Fe system catalyst.

[0033] The preparation method of the iron-based...

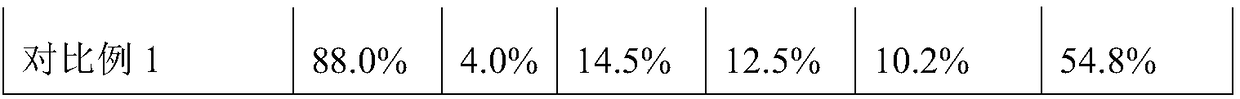

Embodiment 1

[0051] Slowly drip the ammonia solution with a concentration of 25wt% into 900g of ferrous sulfate solution with a concentration of 25wt%, stir rapidly, stop dripping when the pH value reaches 7.5, and slowly stir the formed slurry for use. Weigh 2000g of dry coal powder ground to a particle size of less than 150μm and place it in a stirred reactor with a volume of 8L, turn on the reactor to stir and heat with heat transfer oil. When the pulverized coal temperature rises to 80°C, 2L / min of air is introduced, and at the same time, the above-mentioned prepared slurry is transported to the nozzle on the upper part of the reactor through the plunger diaphragm pump for atomization, and the atomization pressure is adjusted to control the droplet diameter at Within 300μm, the mist is sprayed onto the surface of the stirred coal powder. After spraying, switch to nitrogen, increase the heating temperature of the reactor to raise the temperature of the coal powder to 180°C, keep it for ...

Embodiment 2

[0053] Prepare 900g of ferrous sulfate solution with a concentration of 25wt%, prepare 200g of ammonia solution with a concentration of 25wt%, pump the two solutions into a 2L beaker in parallel through a peristaltic pump to react, stir quickly, and control the pH of the reaction to 7.5 ±0.1, when the ferrous sulfate solution is completely fed, the feeding reaction is stopped, and the formed slurry is slowly stirred for use. Subsequent steps are the same as in Example 1. Labeled as Example 2# catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com