Preparation method of surface-grafting anion chromatography stationary phase

An anion chromatography and surface grafting technology, which is applied in the field of preparation of surface grafted anion chromatography stationary phase, can solve the problems of low rigidity of organic matrix fillers, non-specific irreversible adsorption, easy expansion and contraction, etc., and achieve low cost , Narrow particle size distribution, uniform filler particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

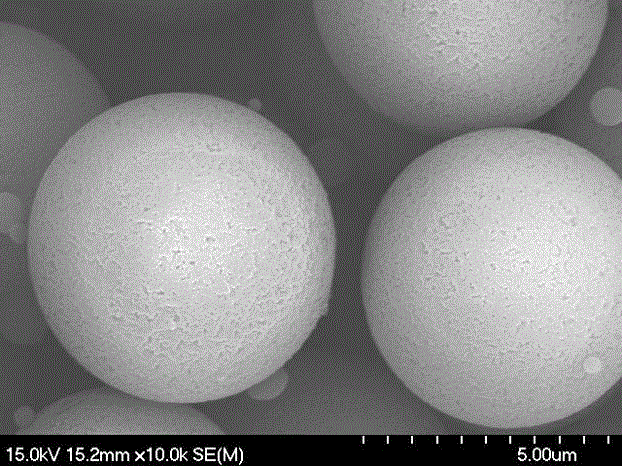

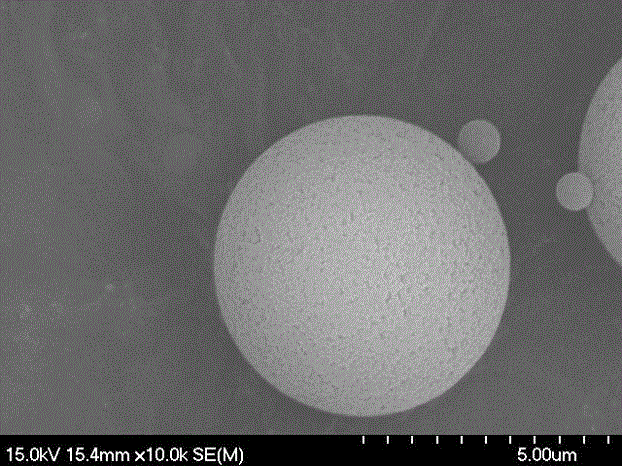

[0029] Embodiment 1: the making process of surface grafted polystyrene-divinylbenzene-glycidyl methacrylate filler is as follows, and its steps are:

[0030] 1. Synthesize monodisperse linear polystyrene seeds with a particle size of 1~3μm by dispersion polymerization first, the reaction medium is ethanol aqueous solution, the concentration is 75~100% (v / v), and the concentration of monomeric styrene is 5% of the total ~30% (m / m), the dosage of stabilizer polyvinylpyrrolidone is 0.5~4% (m / v) of the reaction medium, and the dosage of initiator azobisisobutyronitrile is 1~5% of the monomer dosage (m / m), the reaction temperature is 40~85°C, the stirring speed is 100~400 rpm, and the reaction time is 8~24 hours;

[0031] 2. Then prepare monodisperse polystyrene-divinylbenzene-glycidyl methacrylate microspheres with a crosslinking degree of 10-75% by seed swelling method. The monomer styrene concentration is 10~20% (m / m) of the total organic phase, and the monomer glycidyl methac...

Embodiment 2

[0035] Embodiment 2: with reference to the method and steps of embodiment 1

[0036] 1. Synthesize monodisperse polystyrene seeds with a particle size of 1.8 μm by dispersion polymerization first, the concentration of monomeric styrene is 25% (m / m) of the total amount, and the amount of stabilizer polyvinylpyrrolidone is 1.6% of the reaction medium ( m / v), the amount of initiator azobisisobutyronitrile is 2.2% (m / m) of the monomer amount, the reaction medium is 90% ethanol aqueous solution, the reaction temperature is 80°C, the stirring speed is 300 rpm, and the reaction time 24 hours;

[0037] 2. Then monodisperse polystyrene-divinylbenzene-glycidyl methacrylate microspheres with a crosslinking degree of 50% were prepared by the seed swelling method. The monomer styrene concentration is 14% (m / m), the monomer glycidyl methacrylate concentration is 3% (m / m) of the total organic phase, and the amount of emulsifier sodium lauryl sulfate is 2.5% (m / m), the amount of stabilizer...

Embodiment 3

[0042] 1. Synthesize monodisperse polystyrene seeds with a particle size of 1.8 μm by dispersion polymerization first, the concentration of monomeric styrene is 25% (m / m) of the total amount, and the amount of stabilizer polyvinylpyrrolidone is 1.6% of the reaction medium ( m / v), the amount of initiator azobisisobutyronitrile is 2.2% (m / m) of the monomer amount, the reaction medium is 90% ethanol aqueous solution, the reaction temperature is 80°C, the stirring speed is 300 rpm, and the reaction time 24 hours;

[0043] 2. Then, monodisperse polystyrene-divinylbenzene-glycidyl methacrylate microspheres with a crosslinking degree of 50% were prepared by the seed swelling method, and the monomer styrene concentration was 14% (m / m). The concentration of monomeric glycidyl methacrylate is 2% (m / m) of the total organic phase, the amount of emulsifier sodium lauryl sulfate is 2.5% (m / m), and the amount of stabilizer polyvinyl alcohol is 1.5% ( m / m), the amount of initiator benzoyl pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com