A ceramic insulator device for high voltage capacitor

A technology of ceramic insulators and high-voltage capacitors, applied in the direction of suspension/strain insulators, etc., can solve the problems of unfavorable environmental protection, high price, and many materials, and achieve the effects of reducing costs, reasonable structure, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

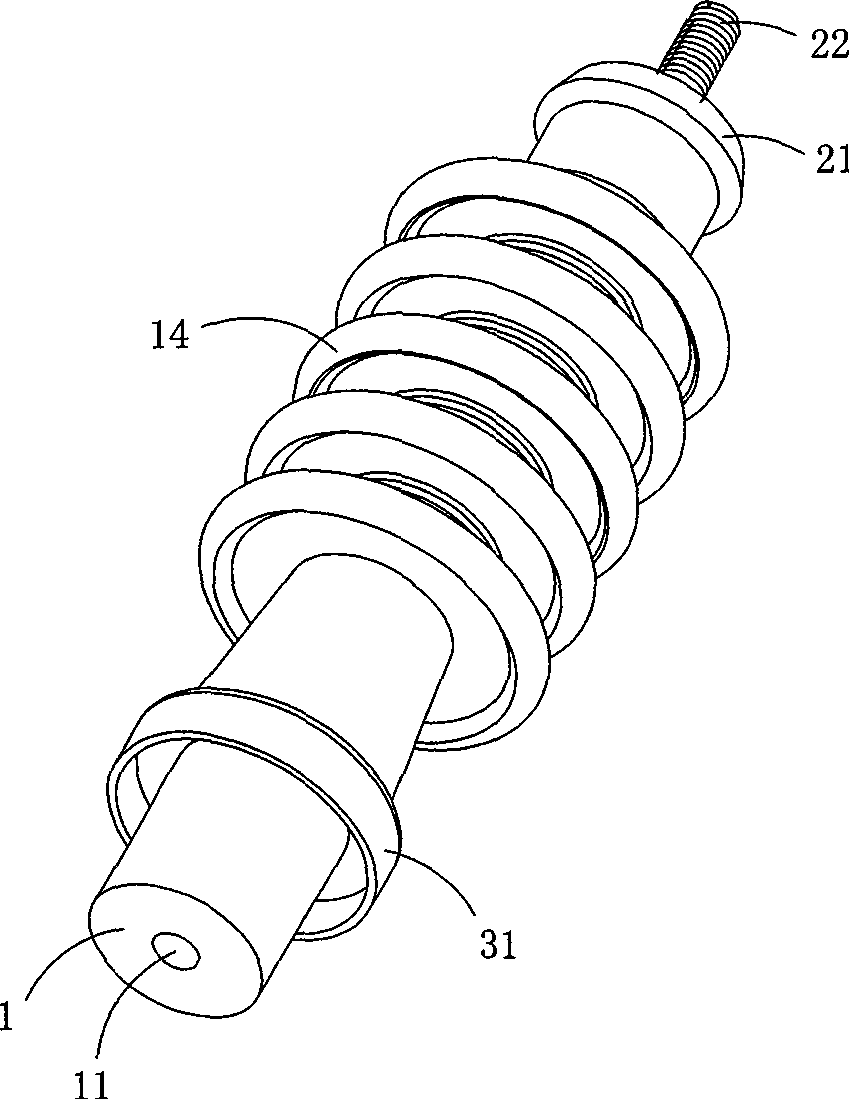

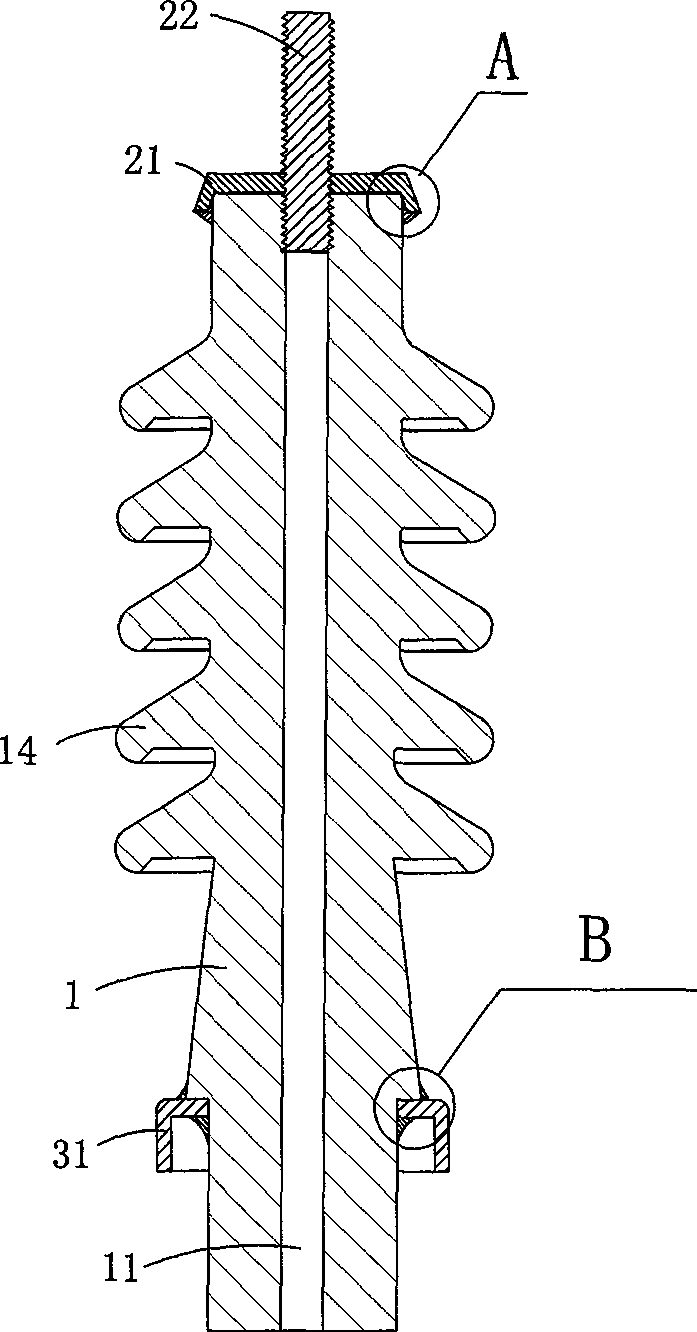

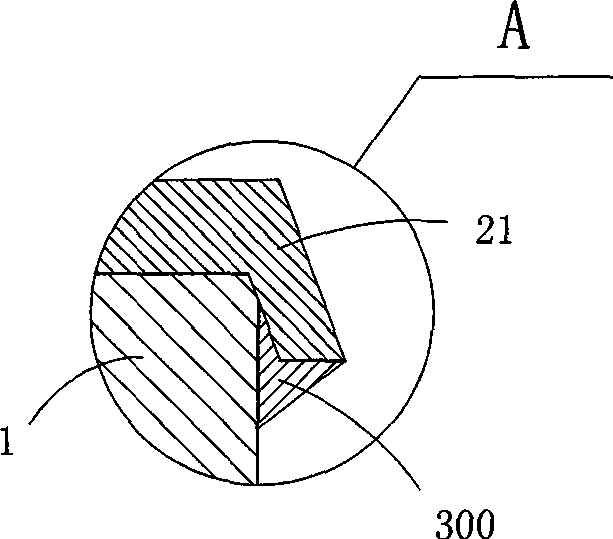

[0030] Figure 5 to Figure 13 A specific embodiment of the invention is shown in which, Figure 5 It is a schematic diagram of a three-dimensional structure of the present invention; Figure 6 yes Figure 5 A schematic diagram of the three-dimensional structure of the ceramic insulator device of the high-voltage capacitor shown when viewed from another angle; Figure 7 yes Figure 5 Schematic diagram of the exploded structure of the ceramic insulator device for the shown high-voltage capacitor; Figure 8 yes Figure 5 Schematic diagram of the half-section structure of the ceramic insulator device of the shown high-voltage capacitor; Figure 9 yes Figure 8 The enlarged schematic diagram of the local structure at C; Figure 10 yes Figure 8 The enlarged schematic diagram of the local structure at D; Figure 11 yes Figure 5 A schematic diagram of a three-dimensional structure of the metal mounting seat in the ceramic insulator device of the high-voltage capacitor show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com