Full-automatic assembly machine of LED bulbs

A fully automatic and assembly machine technology, applied in assembly machines, manufacturing tools, metal processing, etc., can solve the problems of low production efficiency, high purchase costs, low product quality pass rate, etc., to achieve improved efficiency, poor repeat positioning accuracy, The effect of taking up a lot of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

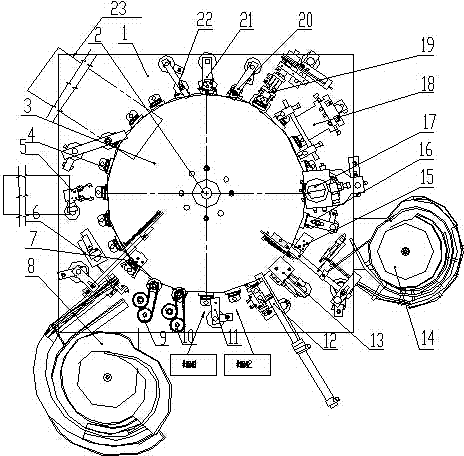

[0020] As shown in the figure, the main transmission mechanism is arranged at the bottom of the frame 1, and the station index plate 3 is connected to the main transmission mechanism through the main transmission shaft 2. There are 24 lamp holder fixing fixtures evenly distributed on the station indexing.

[0021] Set the lamp holder feeding manipulator 5 on the frame 1, automatically load the lamp holder into the lamp holder fixture 4 with the feeding transfer device (that is, the unloading transfer device of the upper LED bulb lamp holder automatic assembly machine), and arrange the wires of the lamp holder Device 6 bends the input wire (red) of the lamp holder, and straightens the input wire (white).

[0022] The lamp cap feeding manipulator 7 is set on the frame 1, and the lamp cap that is automatically loaded by the feeding device 8 through the electromagnetic vibration warehouse is accurately placed on the lamp holder, and the lamp cap rotating device-9 performs the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com