Swivel table driving device with double worm and gear backlash mechanisms

A technology of rotary table and double worm gears, which is used in hoisting devices, components with teeth, portable lifting devices, etc. The high price of the motor can achieve the effect of high rotary positioning accuracy and repeat positioning accuracy, eliminating the backlash of the reverse drive, and low manufacturing and operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

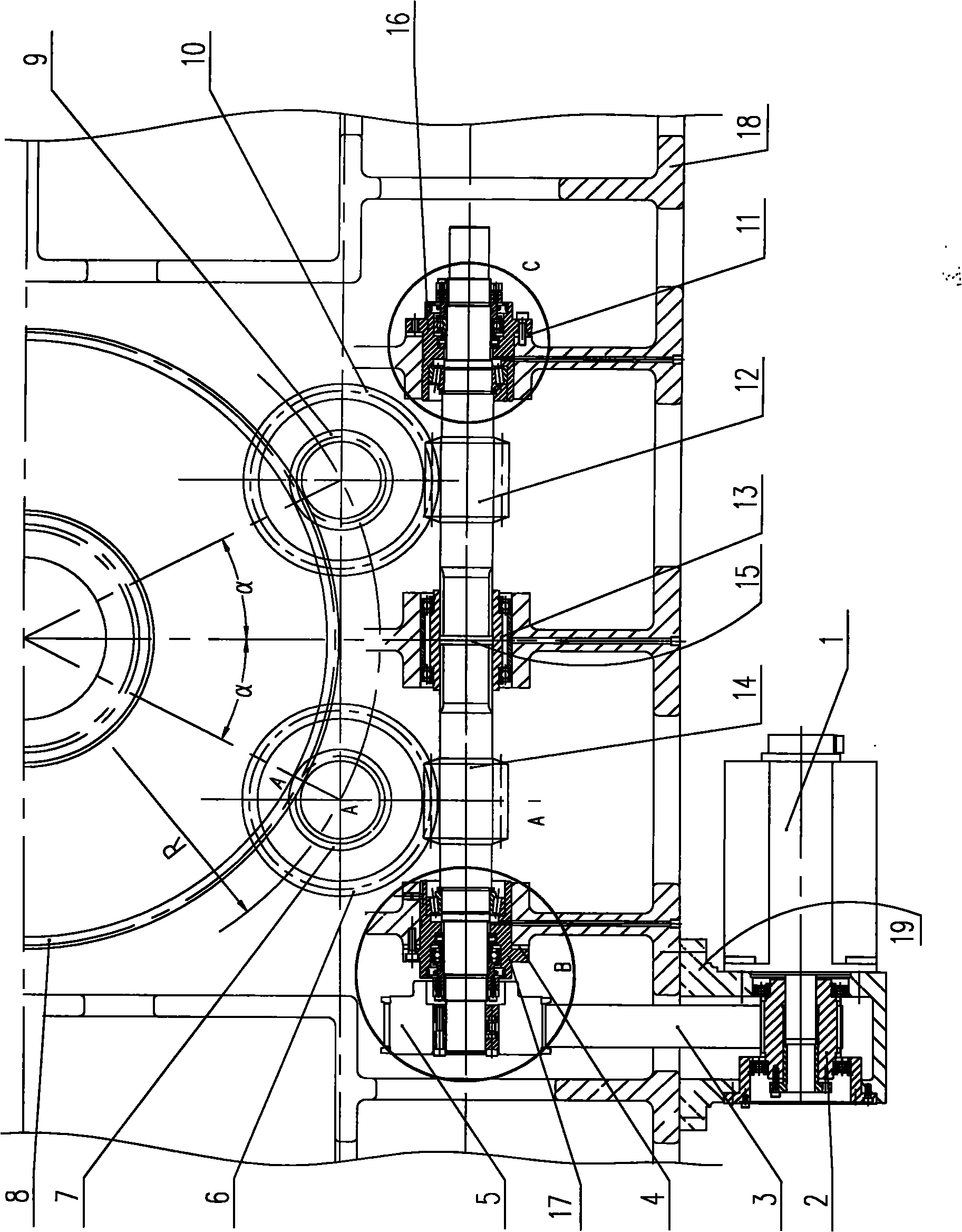

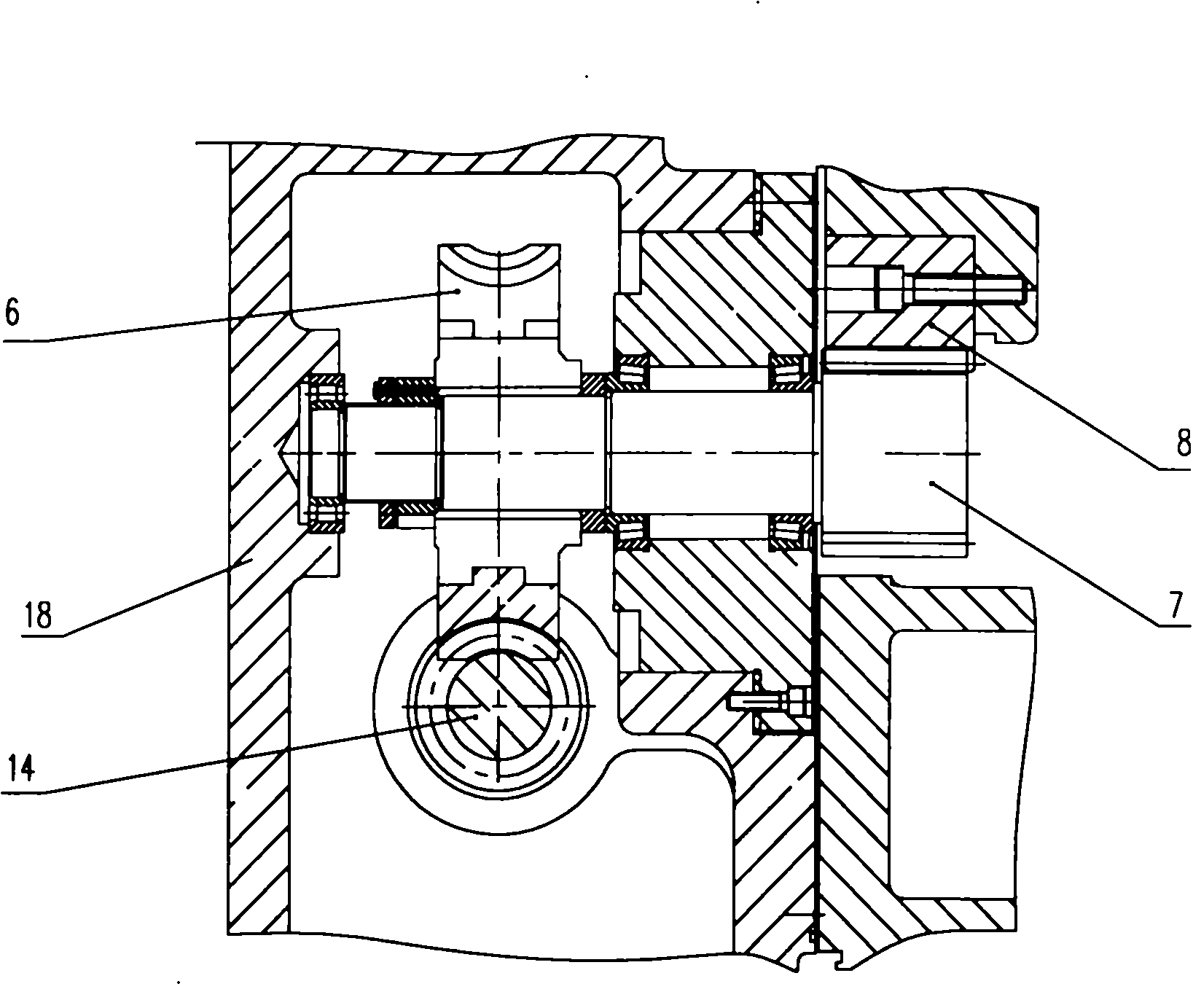

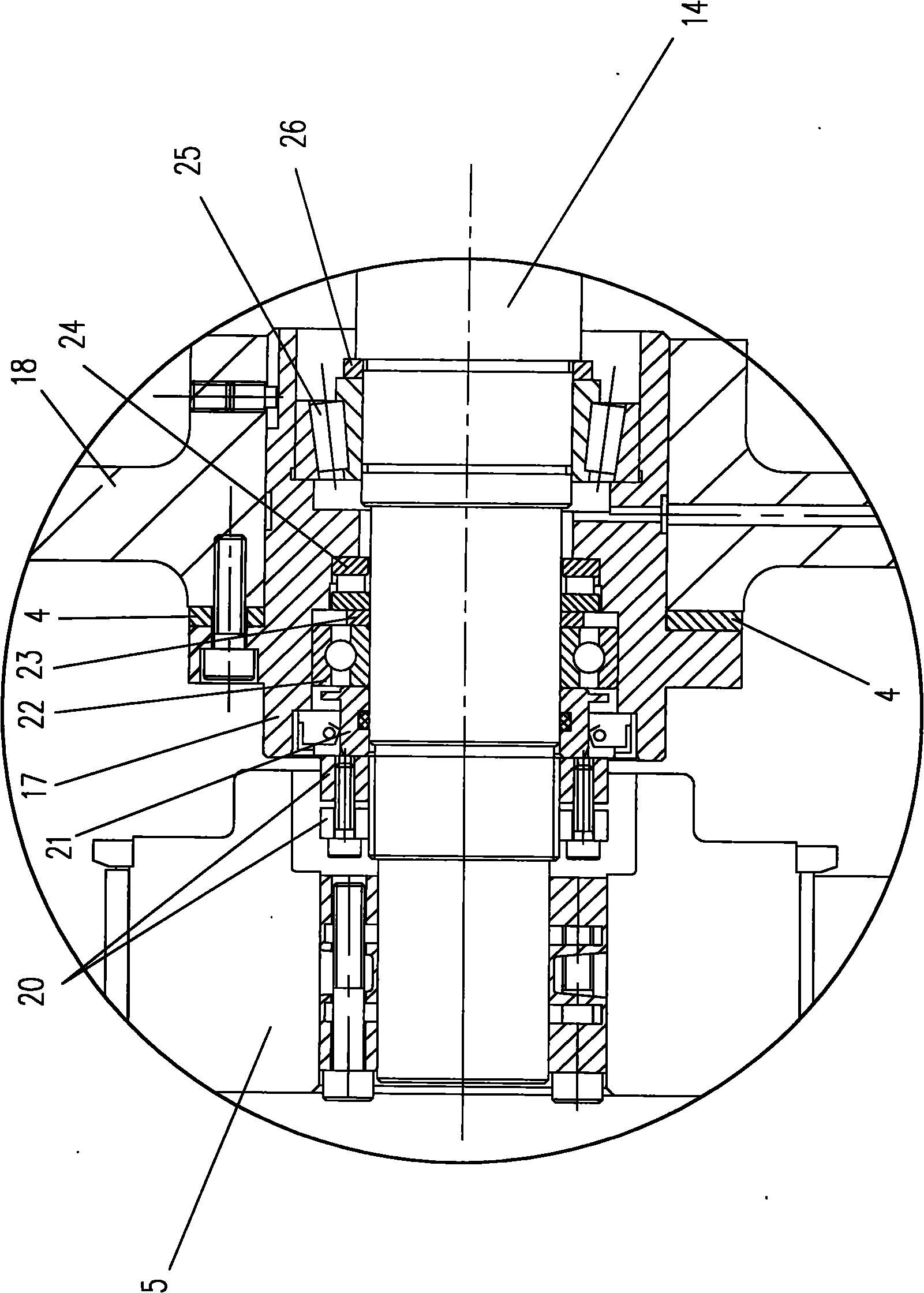

[0012] Such as figure 1 , 2 , 3 shows: 18 is the box body, 8 is the gear ring connected with the rotary table.

[0013] Two sets of worm gear transmission mechanisms are provided on the box body 18, the specific structure is as follows: the box body 18 is supported by a left worm 14 through a bearing, and the left worm wheel 6 and the left gear 7 matched with the left worm 14 are coaxially arranged and supported by bearings. On the case 18, the left gear 7 meshes with the ring gear 8. When the left worm 14 rotates, the left worm wheel 6 and the left gear 7 can drive the ring gear 8 to rotate. The left end of the left worm is fixedly installed with a large pulley 5; a motor seat 19 is bolted to the box body 18, and the motor 1 is fixedly connected with the motor seat 19 by bolts. The output shaft of the motor 1 is fixedly installed with a small pulley 2, synchronous The belt 3 is wound on the small pulley 2 and the large pulley 5 to form a transmission mechanism.

[0014] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com