Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Safe dismantling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

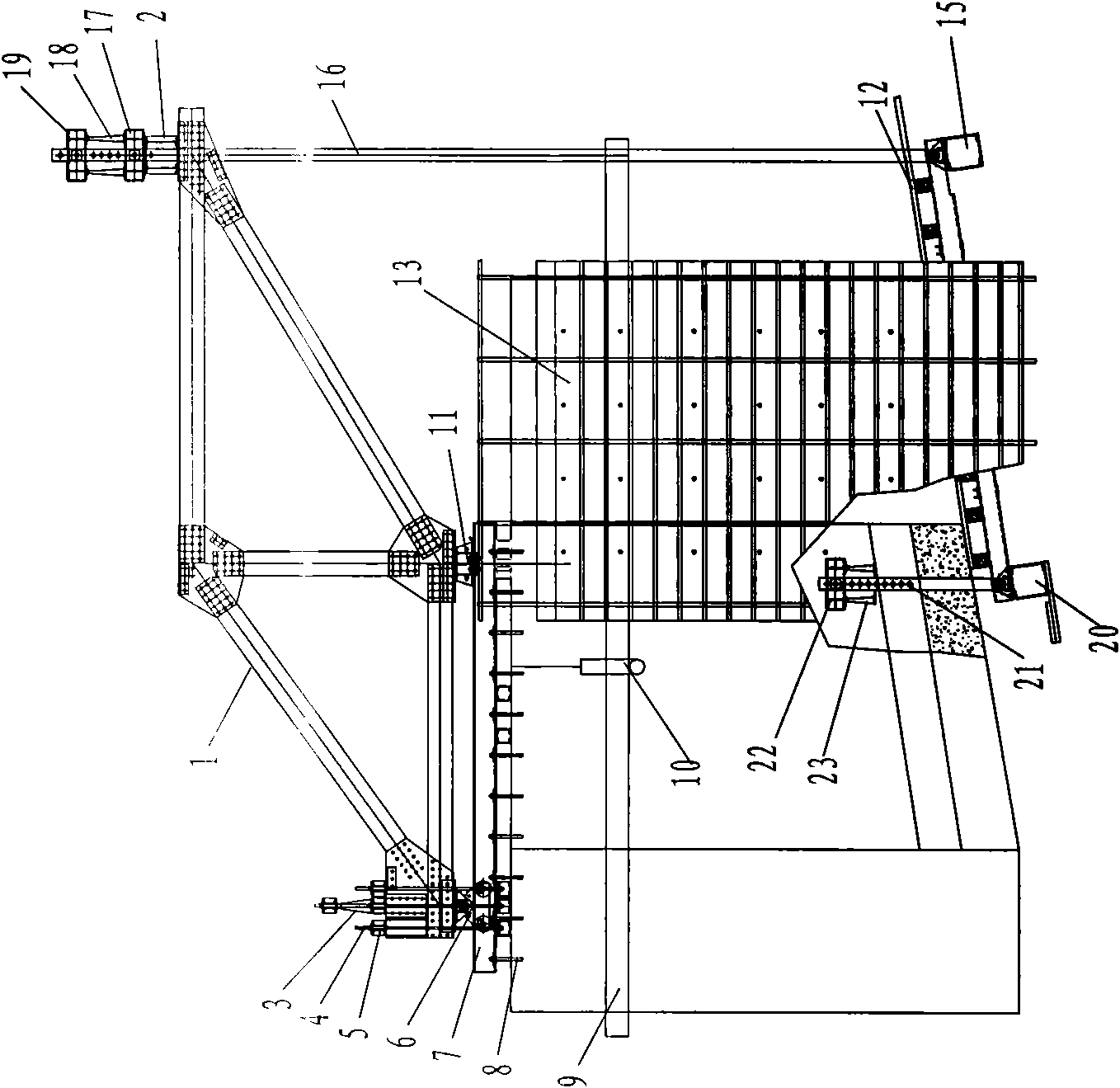

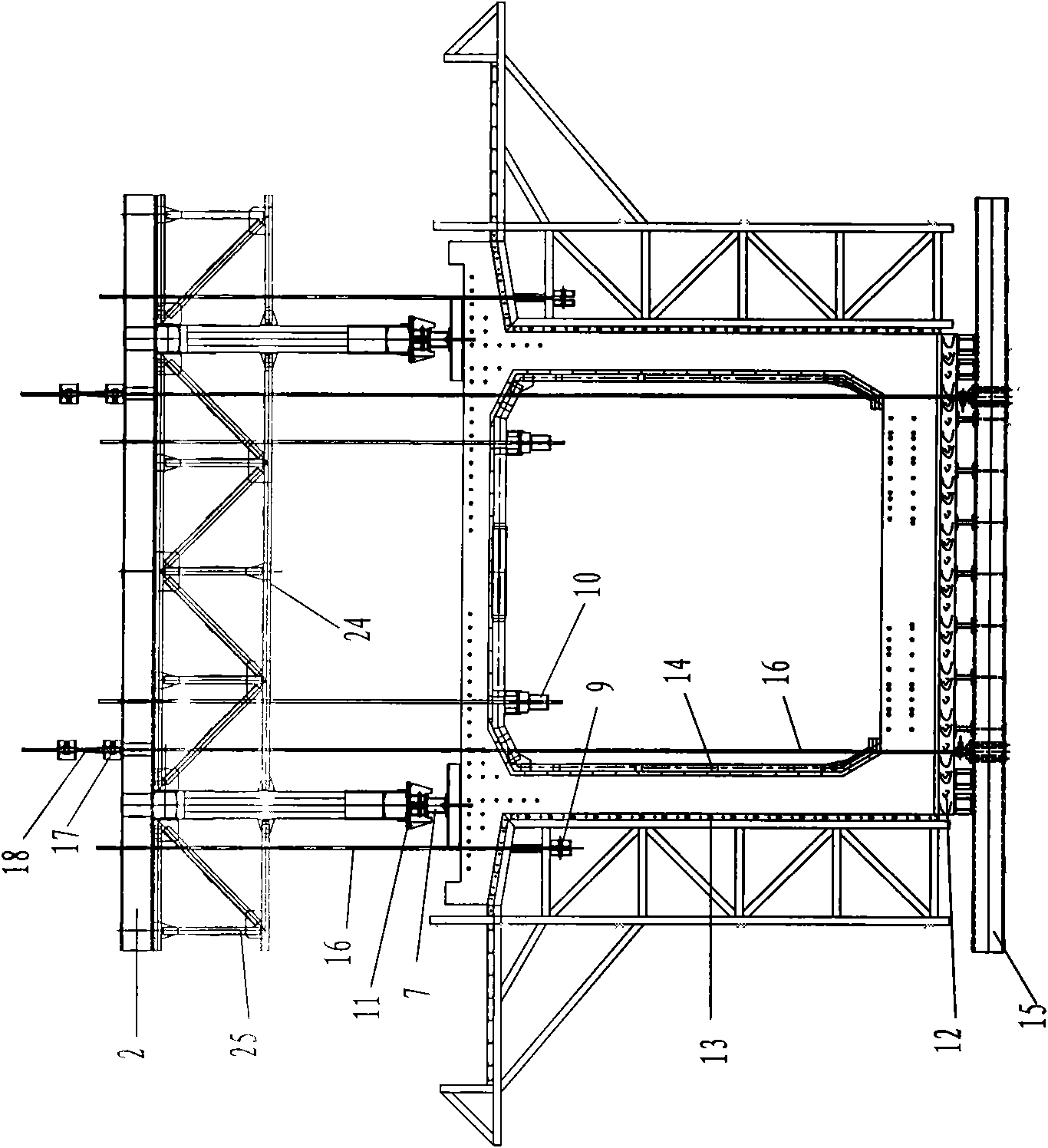

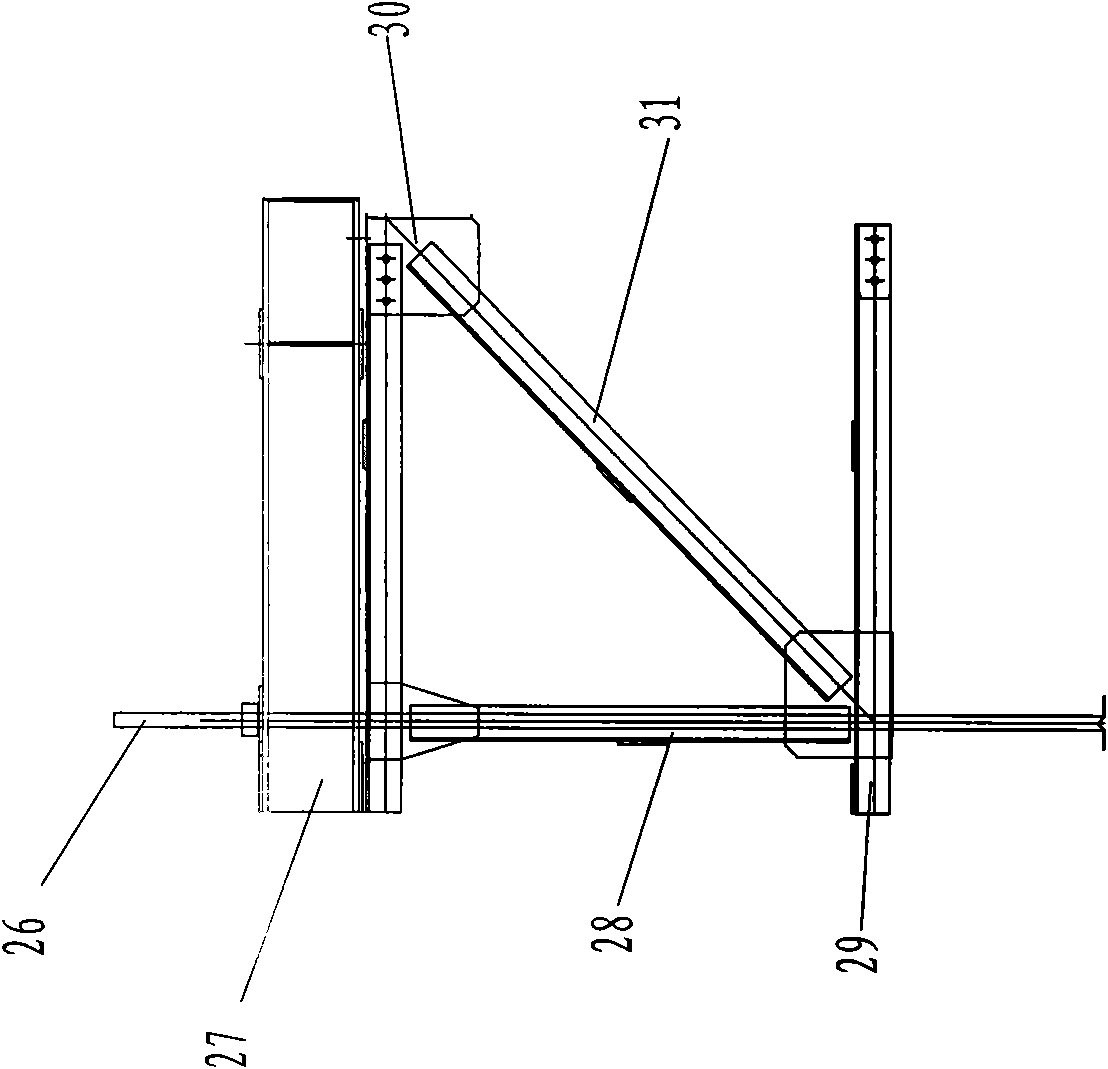

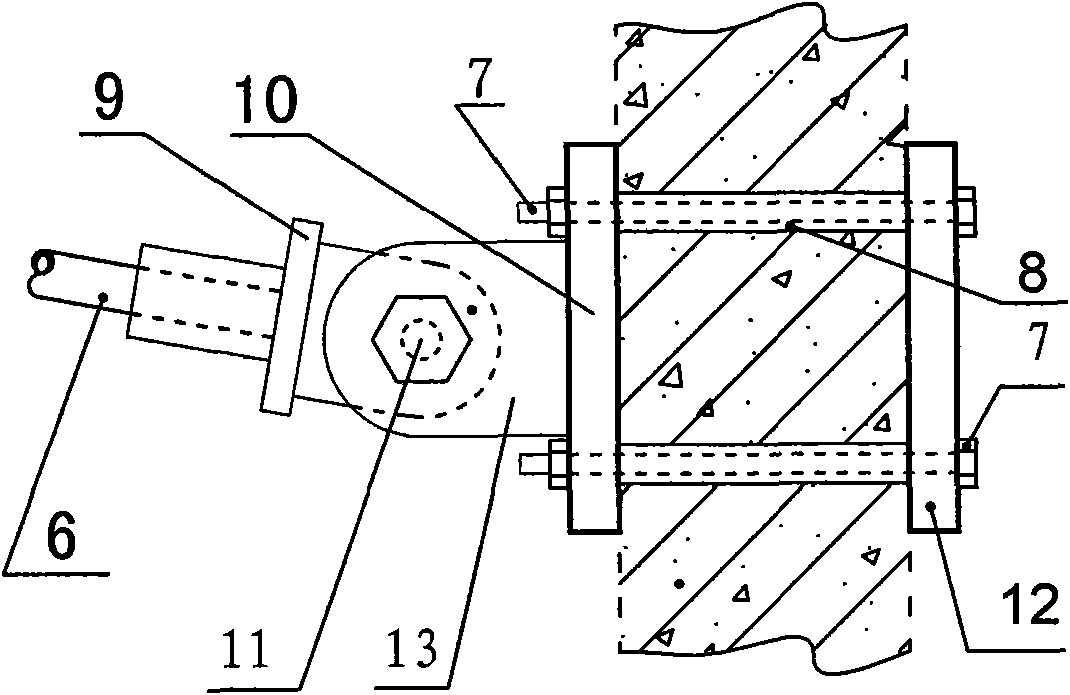

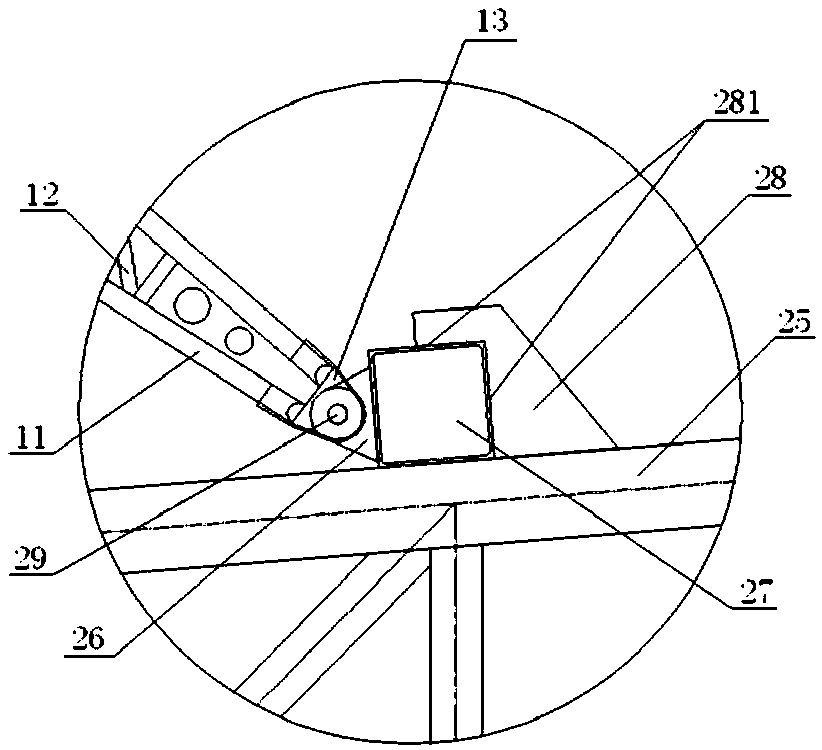

Receding construction method of cradle of continuous girder bridge made of prestressing concrete

The invention relates to a receding construction method of a cradle of a continuous girder bridge made of prestressing concrete, which is characterized in that the bridge surface of a bridge prefabricated by concrete is provided with a track and a door-shaped truss traveling device, and the width of a ceiling girder inside the door-shaped truss traveling device is wider than that of the bridge surface by 90cm-110cm; a front bottom cross beam and a rear bottom cross beam must extend to the outer side of an external mold by 45cm-55cm to form a main cradle truss, and an overhanging auxiliary door frame is additionally arranged outside the main cradle truss, after the construction of a closure segment of the bridge prefabricated by concrete is finished, and precise rolling deformed steel bars with the diameter of 32 outside a box girder positioned on the overhanging auxiliary door frame are connected with the rear bottom cross beam to disassemble a rear hanging strip; a bottom mold frame is separated from a beam body by utilizing a manual spiral type jack to loose the precise rolling deformed steel bars positioned on the door frame and the front bottom cross beam; a leading chain or a hoist are utilized to drive the main cradle truss so that the cradle recedes in a slideway to a first cast-in-situ segment; and a bottom mold and the external mold are fallen by the leading chain or the hoist to disassemble the main truss.

Owner:NO 1 ENG CO LTD OF CR11BG +1

High-rise building construction assembled overhanging safe guarding shed and construction method thereof

InactiveCN101555728AAvoid disadvantagesImprove carrying capacityBuilding material handlingArchitectural engineeringHigh rise

The invention discloses a high-rise building construction assembled overhanging safe guarding shed and a construction method thereof. The safe guarding shed is built by an overhanging main beam, a horizontal cross rod, a protective barrier, a stressed hinged seat, a reverse-drawing anchoring seat, a pull-back cable and the like, wherein, the overhanging main beam, the horizontal cross rod and the protective barrier are connected with each other to form a double-layer guarding shed, the stressed hinged seat and the reverse-drawing anchoring seat are respectively fixed on the main structure of the building, and one end of the overhanging main beam is connected with the stressed hinged seat; one end of the pull-back cable is connected with the reverse-drawing anchoring seat, and the other end thereof is connected with a reverse-drawing point arranged on the overhanging main beam. The safe guarding shed has simple and reasonable structure as well as simple and convenient method, leads the main beam of the shed body to be directly attached on the main structure of the building and extended to be a whole by assembly, and overcomes the defects of the traditional guarding shed, so as to improve the bearing capacity and shock resistant strength of the guarding shed, ensure the construction to be safe and be convenient and fast in mounting and demounting.

Owner:JIANGSU HUAJIAN CONSTR

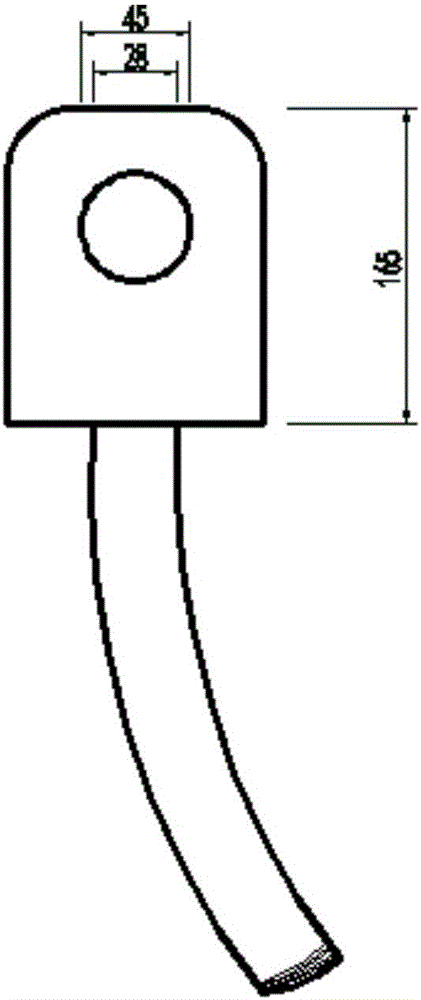

Detachable reused single-pore clamping piece type anchor rope anchorage device

The invention relates to a detachable reused single-pore clamping piece type anchor rope anchorage device which comprises a large tray, a primary anchor plate, a clamping piece and an anchor rope. The anchor rope is arranged in the middle, the clamping piece is arranged on the outer side of the anchor rope, the primary anchor plate is arranged on the outer side of the clamping piece, the large tray is arranged at the front end of the primary anchor plate, the anchor rope penetrates through a through hole of the large tray, and the primary anchor plate is formed by two oppositely open conical barrel. A secondary anchor plate is sleeved on the outer surface of the primary anchor plate, and the secondary anchor plate and the primary anchor plate are provided with limiting devices. The detachable reused single-pore clamping piece type anchor rope anchorage device has lock component detachable reused functions and is safe and convenient to dismantle, firm, reliable and easy to process, an installing method and device have no changes in comparison with conventional locks, a tray transmission force is uniform, material sources are wide, yielding anchoring of a soft rock roadway and post-exploitation retracement of a gate road support of a coal face can be achieved.

Owner:LIUZHOU HUAWEI FORCE MACHINERY

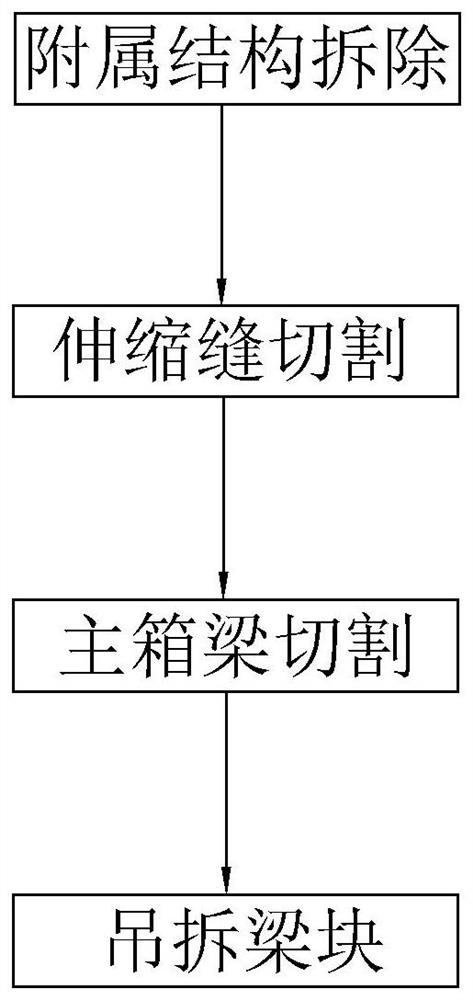

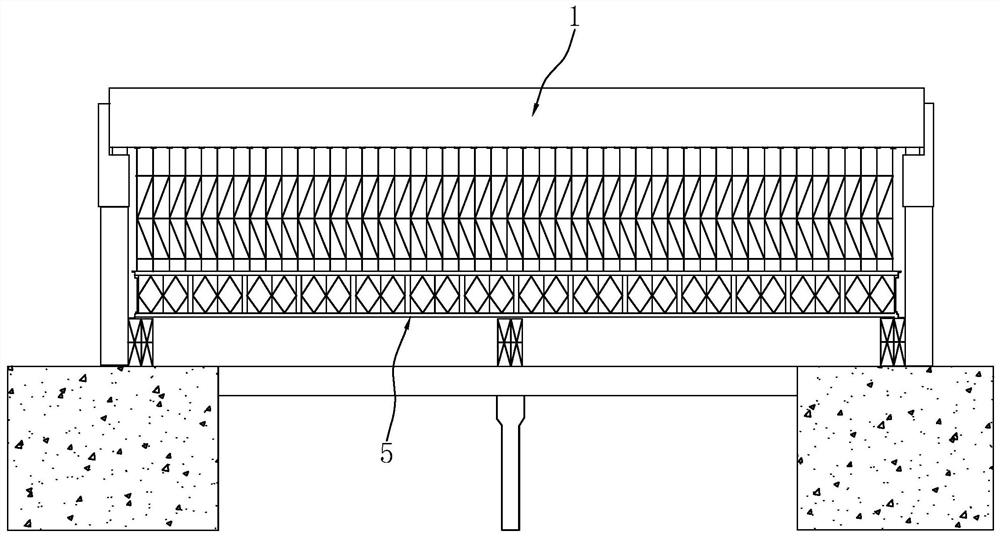

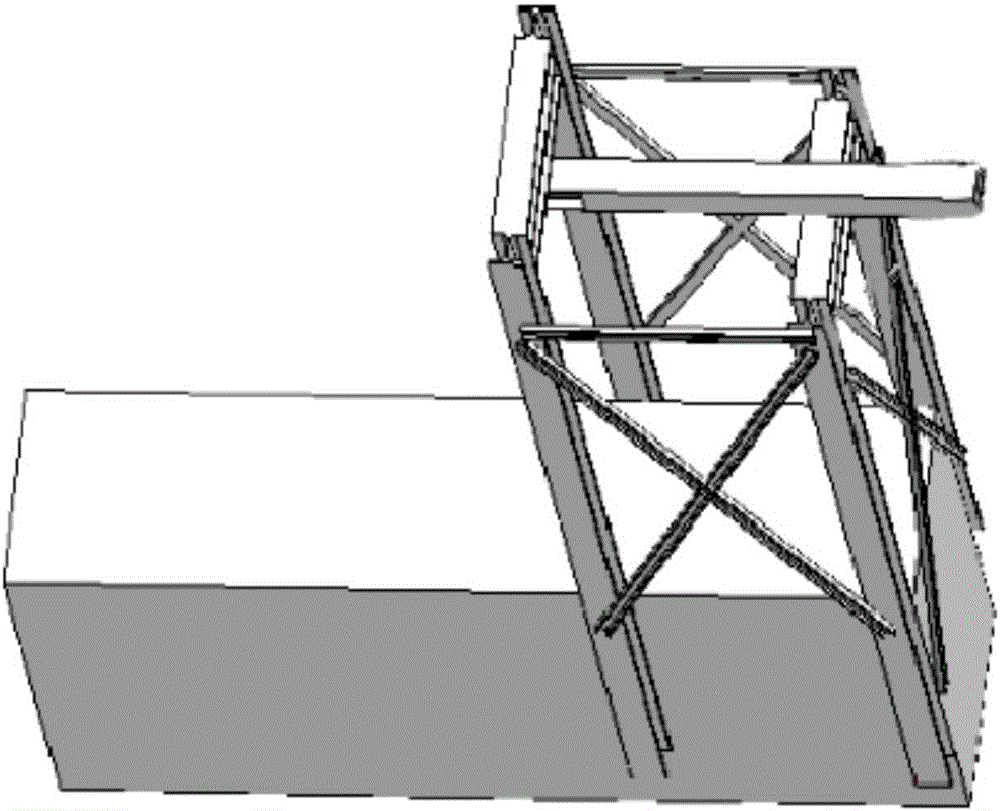

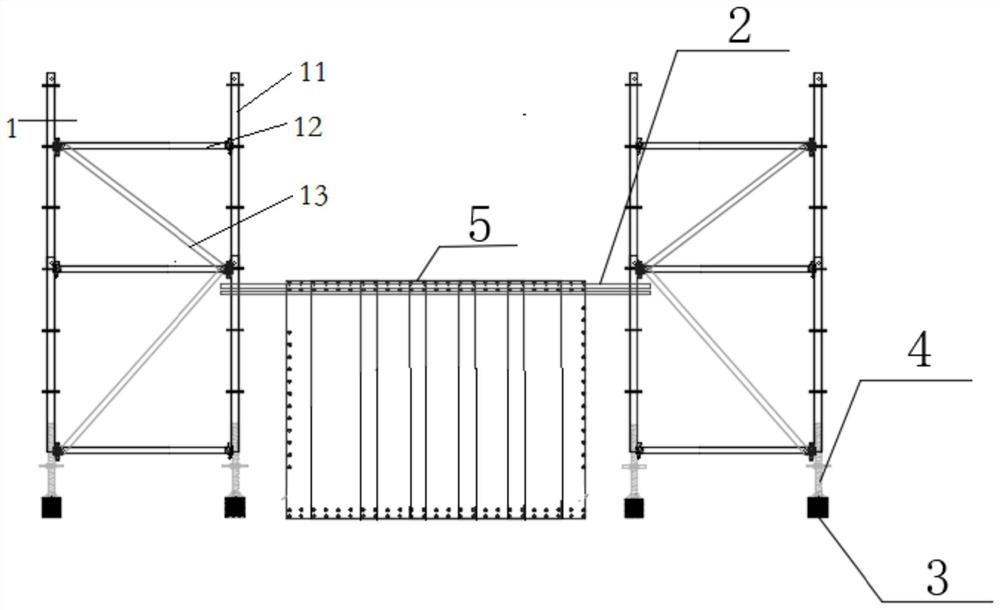

Construction method for dismantling large-span pre-stressed cast-in-place box girder

InactiveCN113235467ASafe dismantlingReduce the impactBuilding repairsBridge strengtheningAccessory structurePre stress

The invention relates to a construction method for dismantling a large-span pre-stressed cast-in-place box girder, which comprises the following steps: S1, dismantling an accessory structure, and dismantling bridge deck pavement and traffic facilities on a box girder; S2, cutting an expansion joint, breaking concrete at the expansion joint of the box girder, and cutting off connecting steel bars, angle steel and bolts at the expansion joint; S3, cutting the box girder, firstly, adopting a disk lock scaffold for building a dismantling scaffold which tightly abuts against the bottom plate of the concrete box girder and the wing plates on both sides, and cutting the box girder by adopting a diamond wire saw, wherein the dismantling sequence of the box girder is as follows: symmetrically cutting wing plates on two sides, releasing web steel strands, cutting a left web, cutting a box type top plate, cutting a right web and cutting a box chamber bottom plate; and S4, hoisting and dismantling the beam blocks, and specifically, transferring and abandoning the cut beam blocks to a designated place through hoisting equipment. The construction method has the effect of safely and rapidly dismantling the large-span pre-stressed cast-in-place box girder.

Owner:BEIJING MUNICIPAL CONSTR +1

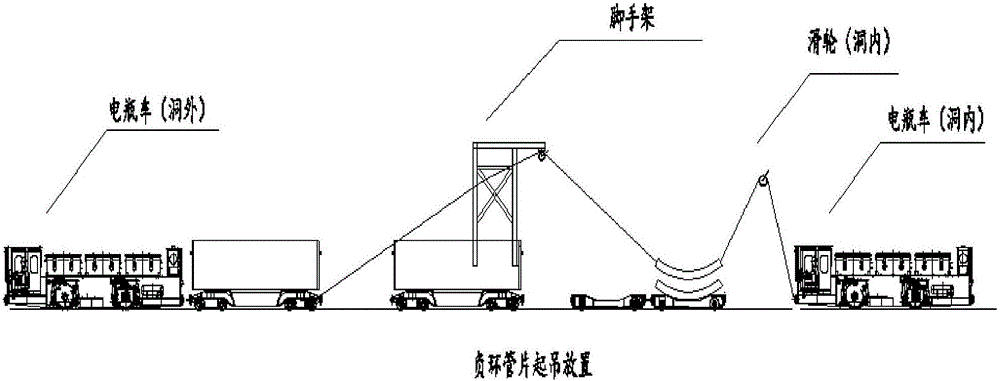

Technology for disassembling negative rings of TBM (tunnel boring machine) arrival hole

ActiveCN105781590AEasy to removeSafe dismantlingUnderground chambersTunnel liningShotcreteEngineering

The invention relates to a technology for disassembling negative rings of a TBM (tunnel boring machine) arrival hole. The technology is characterized in that firstly a set of complete negative ring disassembling and hoisting equipment is assembled, and is welded to form a steel bracket which is provided with a hoisting point; one steel rope is sequentially connected with a storage battery car outside the hole, penetrates through the hoisting point, and is used for hoisting pipe pieces through a hoisting bolt; a pulley inside the hole is fixed to the top of each of the pipe pieces through bolts; one end of another steel rope is connected with a storage battery car inside the hole and then goes around the pulley inside the hole, and the other end of the steel rope is used for hoisting the pipe pieces through hoisting bolts. The negative rings are disassembled through the following steps of (1) disassembling steel shotcrete; (2) assembling the hoisting equipment; (3) disassembling a reaction frame; (4) mounting the pulley inside the hole; and (5) disassembling the negative rings, wherein the negative rings are disassembled in a manner that the pipe pieces are separately disassembled, F pipe pieces and adjacent pipe pieces are disassembled at the same time, and the negative rings are disassembled in the disassembling sequence that the pipe pieces are sequentially and symmetrically disassembled from top to bottom. According to the technology disclosed by the invention, the pipe pieces are protected from being damaged in the disassembling process, so that the cyclic utilization number of times of the pipe pieces of the negative rings is increased; original construction machines and tools and original materials are utilized, the investment on the equipment and the materials is reduced, and the utilization rate of the negative rings is increased.

Owner:THE THIRD ENG CO LTD OF THE HIGHWAY ENG BUREAU OF CCCC

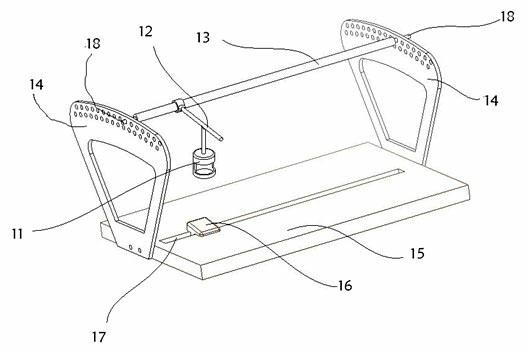

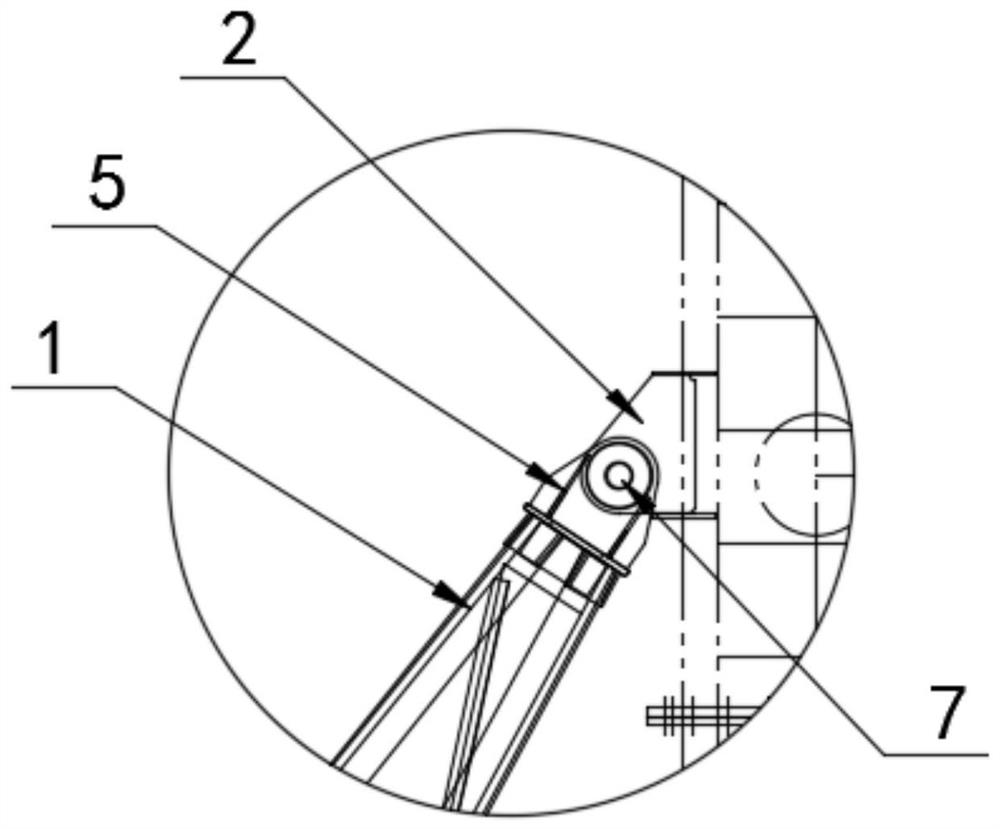

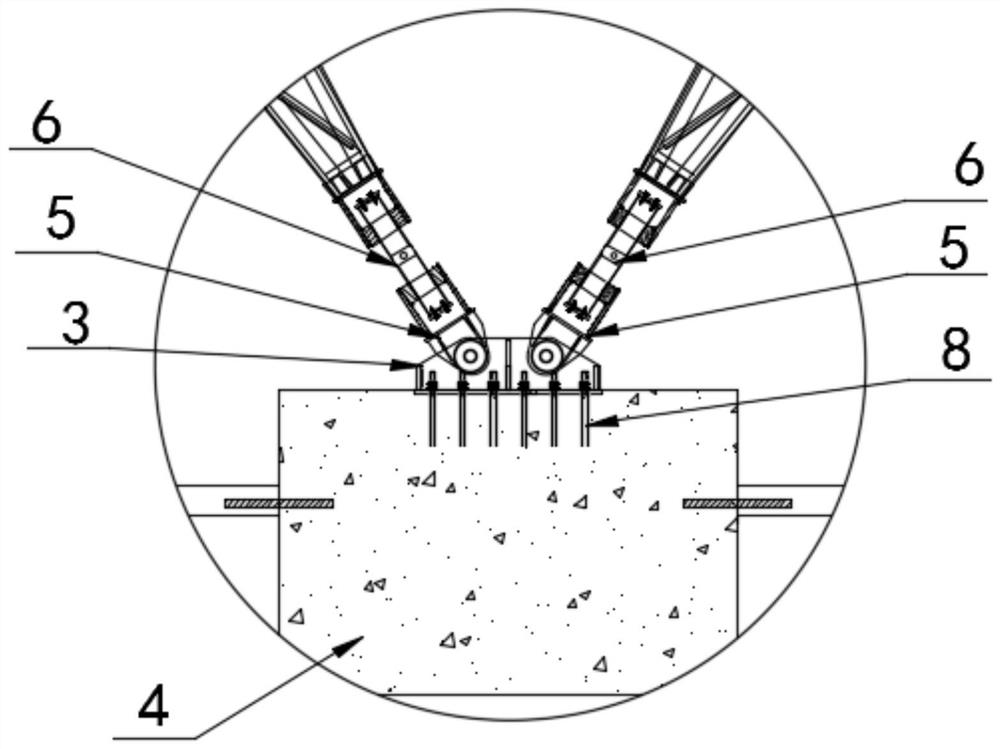

Auxiliary device for disassembling tower crane attachment bracket

The invention discloses an auxiliary device for disassembling a tower crane attachment bracket. The auxiliary device for disassembling the tower crane attachment bracket comprises a strip-type bracket, a front-end guide wheel, a middle guide wheel, a middle guide wheel adjusting shaft, an adjusting shaft support seat, a driving device and a steel wire rope, wherein the front-end guide wheel is arranged at the front part of the strip-type bracket; the middle guide wheel, the middle guide wheel adjusting shaft and the adjusting shaft support seat are arranged in the middle of the strip-type bracket; a wheel disc of the front-end guide wheel is vertically arranged; a wheel disc of the middle guide wheel is horizontally arranged in an initial installation state; a tangent line between the edge of the wheel disc of the middle guide wheel and the edge of the wheel disc of the front-end guide wheel is parallel to the extension direction of the strip-type bracket; one end of the steel wire rope is connected with the driving device; the other end of the steel wire rope sequentially penetrates through the middle guide wheel and the front-end guide wheel and is connected with an attachment bracket to be disassembled.

Owner:NANTONG DAXIN ENG

Detaching method for existing rolling line underground space concrete structure

ActiveCN103470068AGuaranteed normal outputQuality assuranceBuilding repairsProduction lineTransportation capacity

The invention discloses a detaching method for an existing rolling line underground space concrete structure and belongs to the technical field of metallurgy production device installing. By means of the method, the existing rolling line underground space concrete structure can be detached fast, efficiently and safely under the condition that production is not stopped. According to actual conditions of the underground space concrete structure required to be detached, by combining conditions of a rolling production line required to be installed at a later procedure, a load bearing supporting point and a detaching area are determined, and detaching is conducted by using a rope saw cutting method according to conditions of field hoisting, transportation capacity and hoisting space. In a detaching process, according to determined maximum weight, largest shape and detaching sequence of each concrete block, saw cutting holes are drilled in the underground space concrete structure, corresponding supporting frames are erected, ropes penetrate the holes, and the concrete structure is saw cut into concrete blocks to be transported out of an existing rolling line production field.

Owner:CHINA 19TH METALLURGICAL CORP

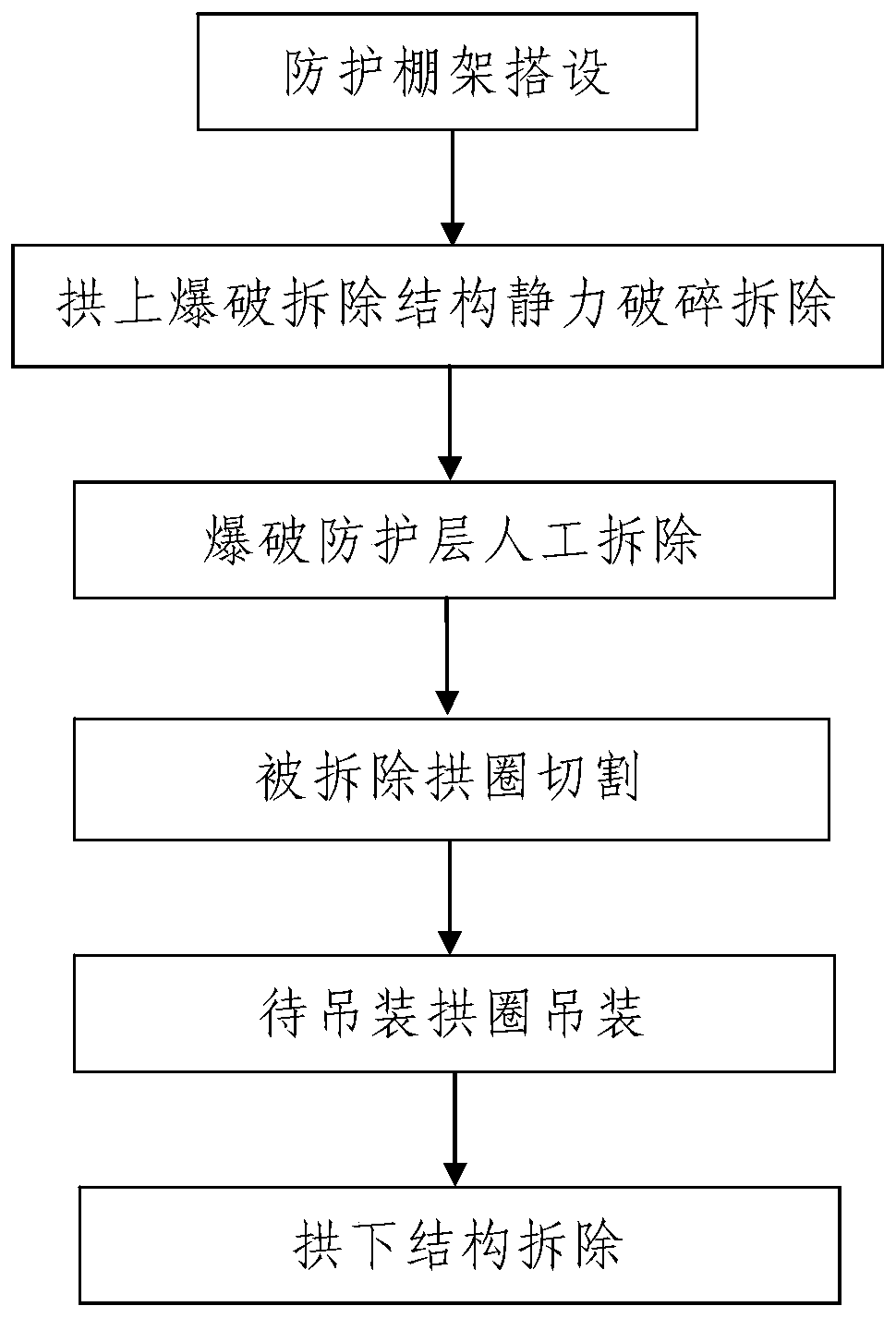

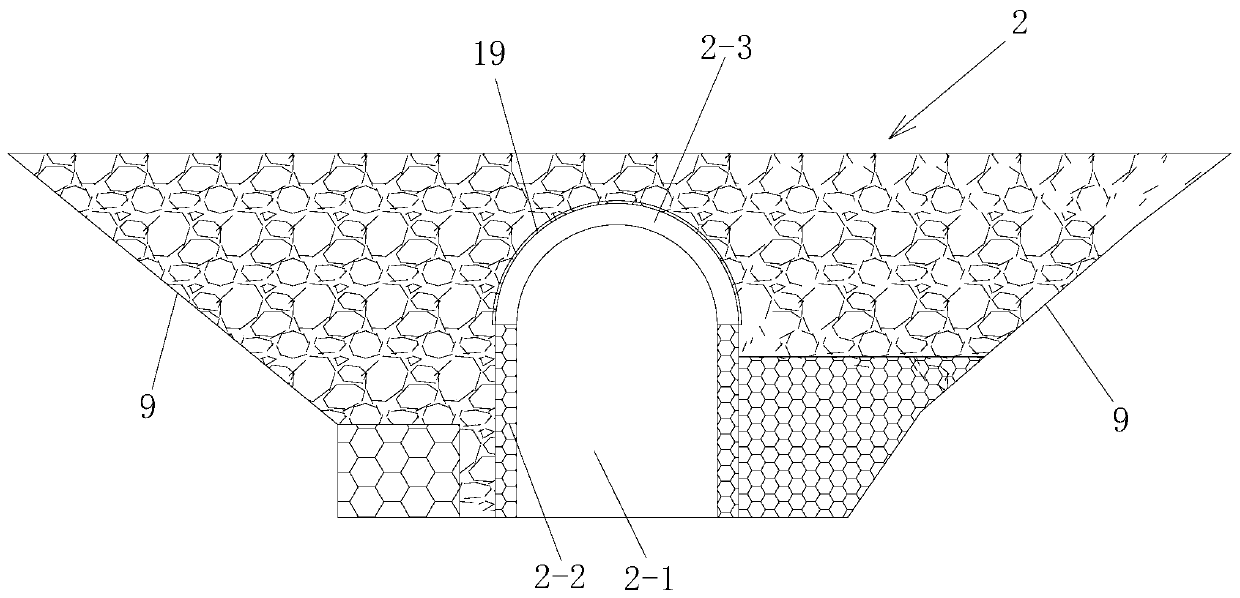

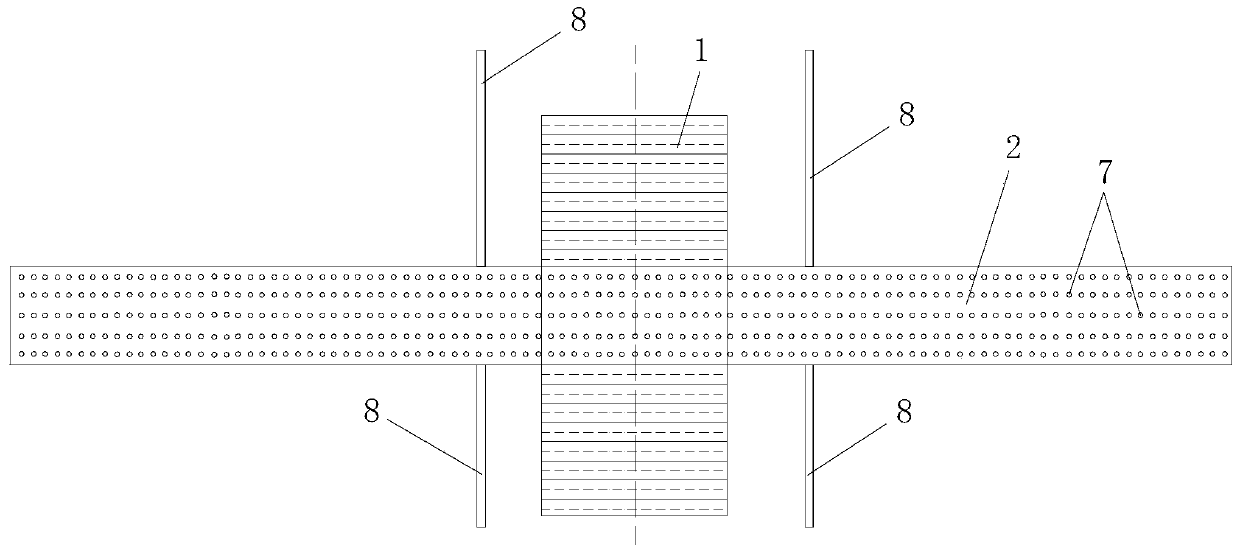

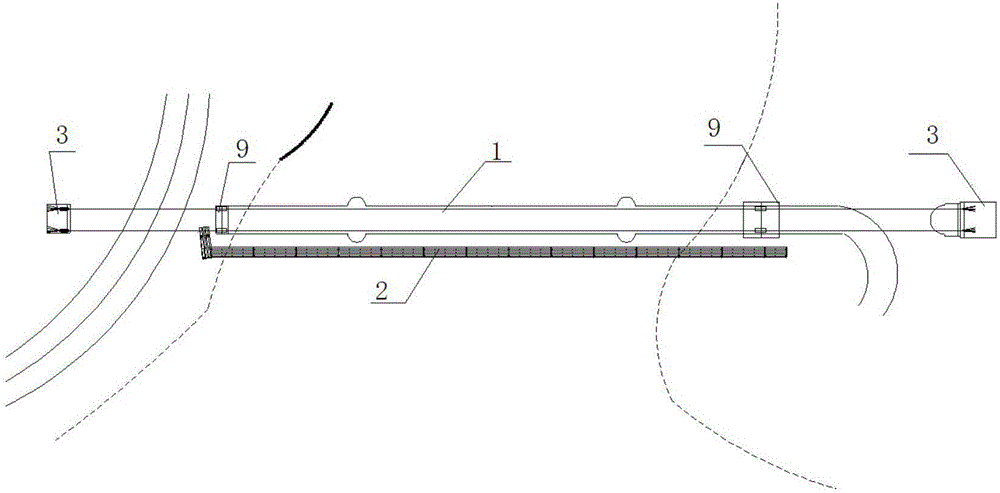

Demolition construction method for overpass existing line arch bridge

ActiveCN110904867AThe method steps are simpleReasonable designBuilding repairsBridge strengtheningArchitectural engineeringStructural engineering

The invention discloses a demolition construction method for an overpass existing line arch bridge. The demolition construction method comprises the steps: 1, erecting a protective shed frame; 2, carrying out static crushing demolition on the arch blasting demolition structure; 3, manually removing the blasting protection layer; 4, cutting the removed arch ring; 5, hoisting the arch ring to be hoisted; and 6, dismantling the under-arch structure. The method is simple, reasonable in design, easy and convenient to construct and good in using effect; the protection shed frames fixed to the frontside and the rear side of the removed arch bridge are adopted for effective protection, meanwhile, the structure on the arch of the removed arch bridge is removed in the mode that static crushing andmanual chiseling are combined, it is guaranteed that a plain concrete arch ring cannot be damaged in the static crushing process, and an existing spanned railway line cannot be disturbed. After the arch ring is exposed, the removed arch ring is cut and decomposed through a rope saw and then hoisted and removed, then the under-arch structures on the left side and the right side are rapidly removed,the construction period can be effectively shortened, the arch bridge removing efficiency is improved, and the removing process is safe and reliable.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP

Method for dismantling protective shed frame of gate-type pier capping beam of existing railway lines

ActiveCN107165062ASuperiorSolve puzzles that cannot be removedBuilding repairsBridge strengtheningRailway lineBuilding construction

The invention discloses a method for dismantling a protective shed frame of a gate-type pier capping beam of existing railway lines, and relates to the field of railway construction. According to the method, a steel pipe column is adopted in slotting; a carling of a D-shaped auxiliary beam is dropped inside the open slot of the steel pipe column, so that the height of the protective shed frame is decreased, and a working space is provided for dismantling a cross girder of the D-shaped auxiliary beam and oblique poles of the cross girder, and therefore the safety of existing railway lines is guaranteed, and meanwhile, the difficulty of taking out a pressed bearing bent cap of the protective shed frame is overcome. According to the method for dismantling the protective shed frame of gate-type pier capping beams of existing railway lines, after construction of the gate-type pier capping beam, the components positioned at the lower section of the gate-type pier capping beam, such as the D-shaped auxiliary beam, the steel pipe column, a joist steel, a scaffold and the like, are dismantled safely and quickly under the premise of guaranteeing the safety of the existing railway lines. The method for dismantling the protective shed frame of the gate-type pier capping beam of existing railway lines is suitable for large-scale promotion and application.

Owner:中铁七局集团第一工程有限公司

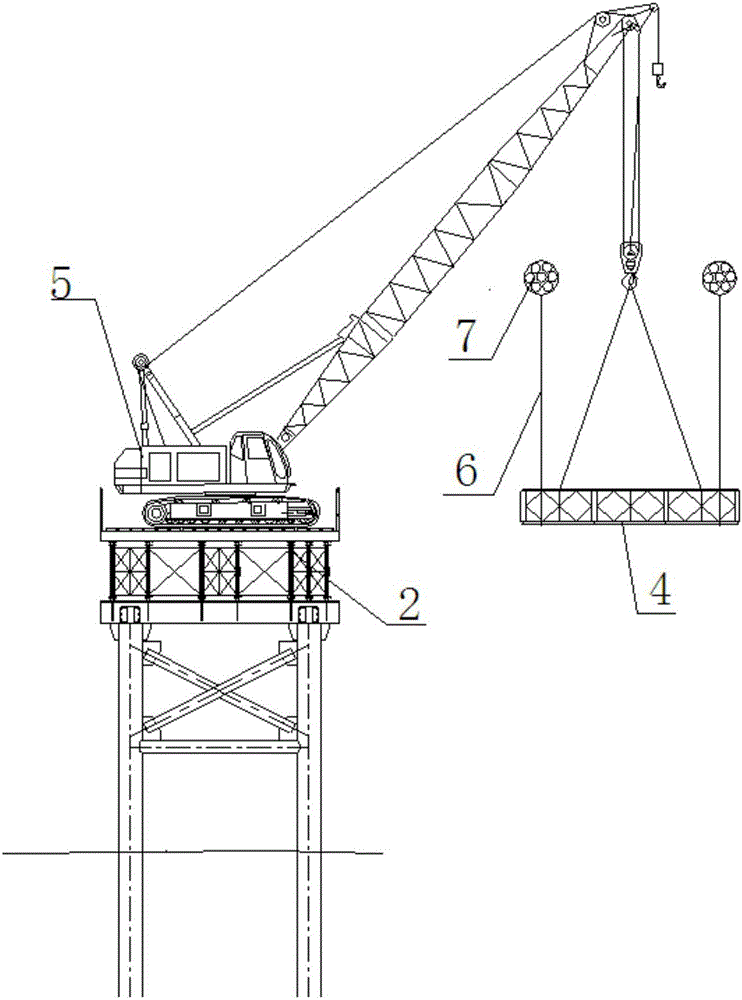

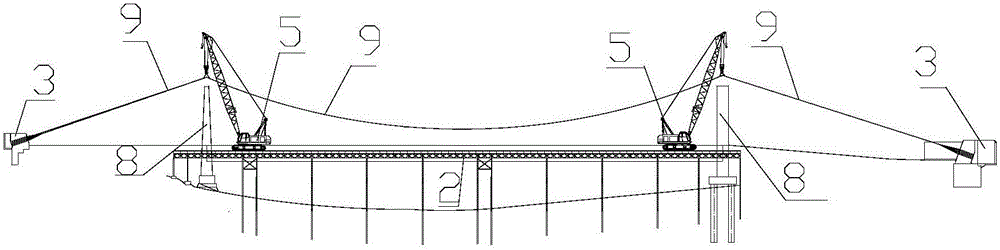

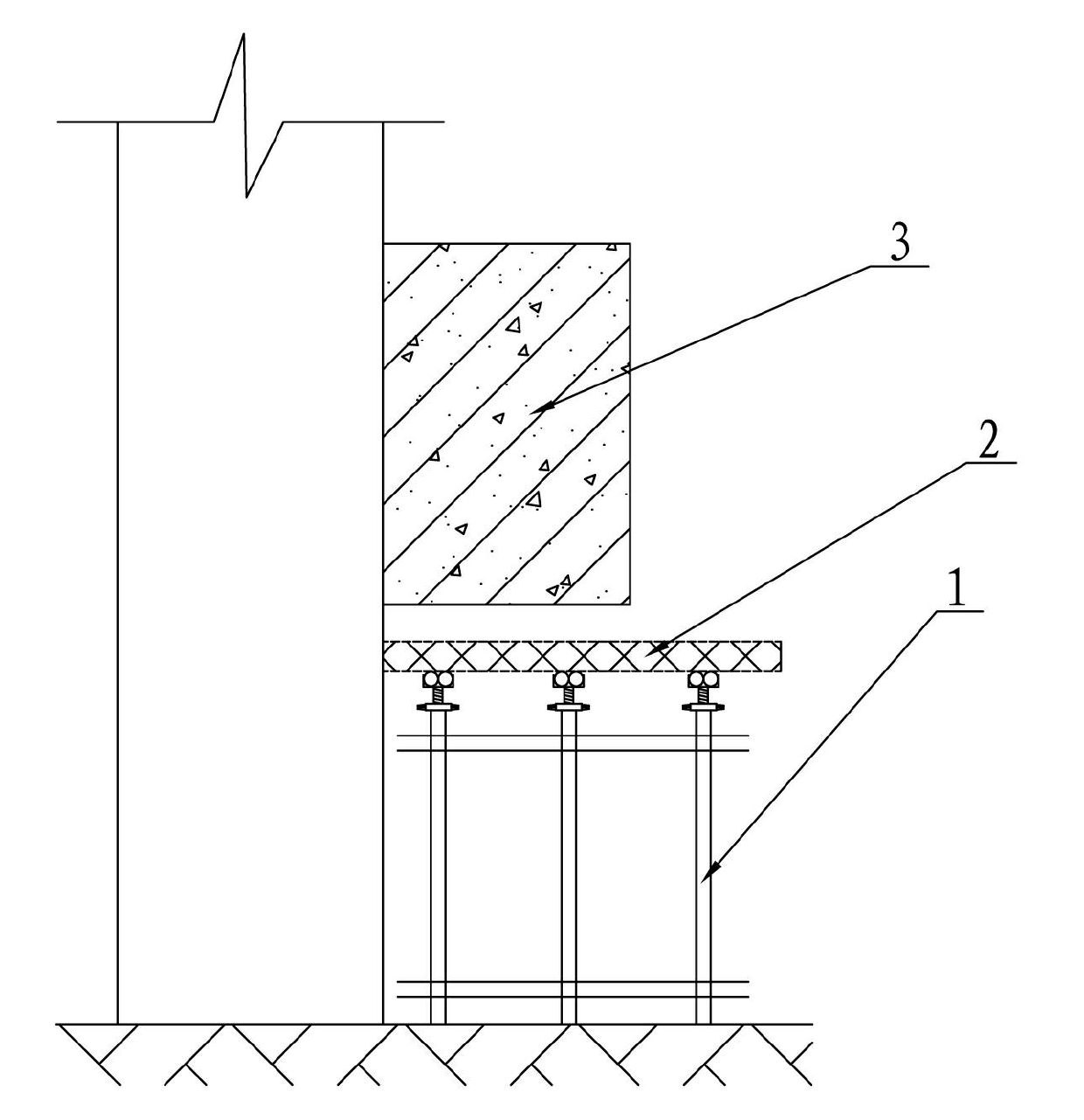

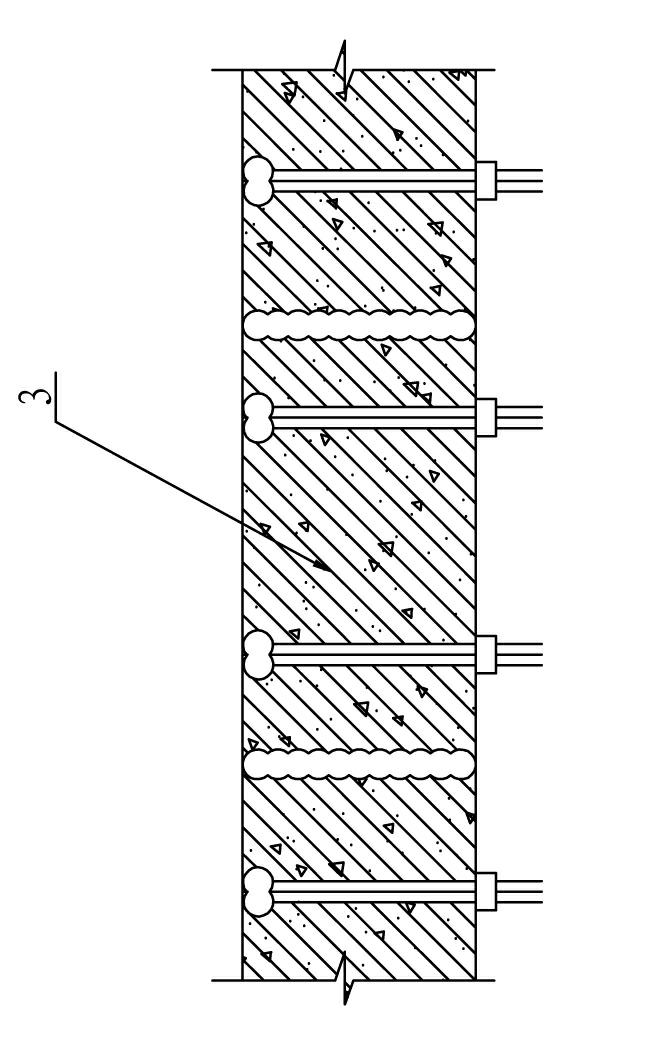

Suspension bridge superstructure demolition and replacement installation method

ActiveCN105887701ASafe dismantlingEasy to dismantleSuspension bridgeBridge erection/assemblyEngineeringSurveyor

The invention provides a suspension bridge superstructure demolition and replacement installation method. The suspension bridge superstructure demolition and replacement installation method comprises the following steps: a. erecting a trestle in parallel with a suspension bridge on the outer side of the suspension bridge, wherein the two ends of the trestle are connected with bridge approaches at the two ends of the corresponding suspension bridge; b. inspecting anchorages at the two ends of the suspension bridge and making sure that the anchorages are in a normal working state; c. demolishing original stiffening girders at an upper portion of the suspension bridge section by section; d. demolishing original suspenders and original cable clamps corresponding to the original stiffening girders; e. lifting a main cable through a crawler crane to realize the demolition of the original main cable at the upper portion of the suspension bridge; f. lifting a new main cable through the crawler crane to realize installation; g. installing new cable clamps and new suspenders at corresponding positions through surveying and setting-out; h. lifting each new stiffening girder section to a designated position by section through the crawler crane, and after all new stiffening girder sections are completely installed, connecting all sections to form an integral body. The suspension bridge superstructure demolition and replacement installation method shortens the demolition and replacement construction period of the suspension bridge superstructure to the utmost extent, and reduces the negative influence caused by the demolition and replacement of the suspension bridge superstructure.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

Method for installing or removing high voltage bushing by using C-shaped hoseclamp cross binding strap

The invention relates to a method for installing or removing a high voltage bushing by using a C-shaped hoseclamp cross binding strap, wherein the C-shaped hoseclamp cross binding strap comprises two main straps (1) having the same length, an annular auxiliary strap (2) and a hoseclamp strap (3) capable of being bent into a C shape, both ends of the two main straps (1) are respectively provided with a tool U-shaped ring (4) and a hanging ring (5), and a closed ring belt is folded and twisted and then is bent to form the hoseclamp strap (3). According to the present invention, with the use of the C-shaped hoseclamp cross binding strap to install or remove the high voltage bushing, it can be ensured that the main straps and the hoseclamp strap can closely attached to the high voltage bushing without displacement production, the repeated adjusting during the lifting process is not required, and the work is efficient and safe.

Owner:云南送变电工程有限公司

Dismantling method for concrete waist beam

InactiveCN102677680ASafe dismantlingReduce construction costsExcavations{BEAM BREAKS}Building construction

The invention discloses a dismantling method for a concrete waist beam. The dismantling method comprises the following steps of: cutting the waist beam into a number of subsections, then chiseling grooves in the subsections, and placing a lifting jack in the grooves to push the subsections of the waist beam open so that the waist beam is piecewise dismantled, wherein a support frame and / or a suspension device can prevent the waist beam from falling down on the ground after the waist beam breaks away from the grooves. The dismantling method has the advantages that the concrete waist beam can be safely and fast dismantled, and the construction safety can be better ensured while the construction cost is effectively saved; and the dismantling method is used for the field of building construction.

Owner:GUANGDONG FOUND ENG GRP CO LTD +1

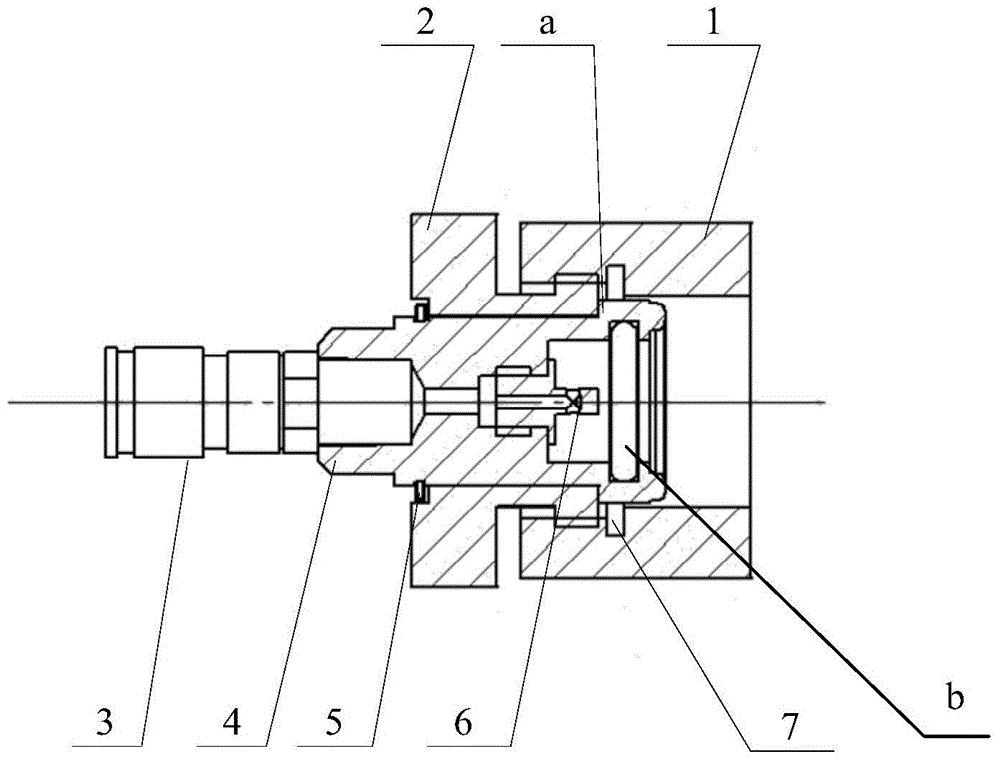

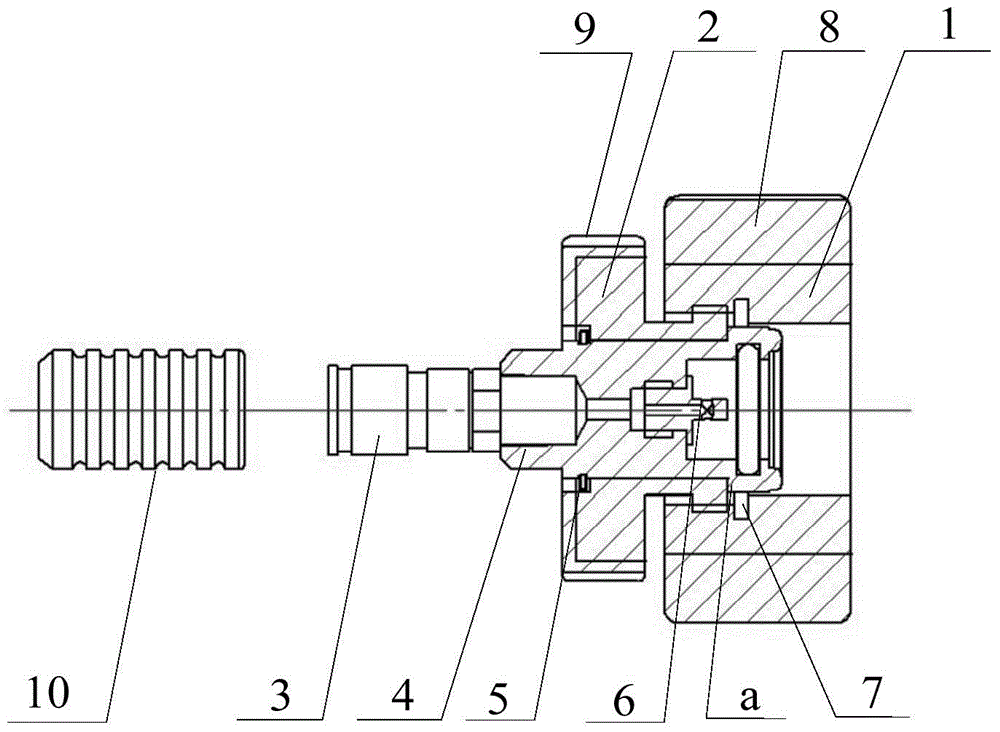

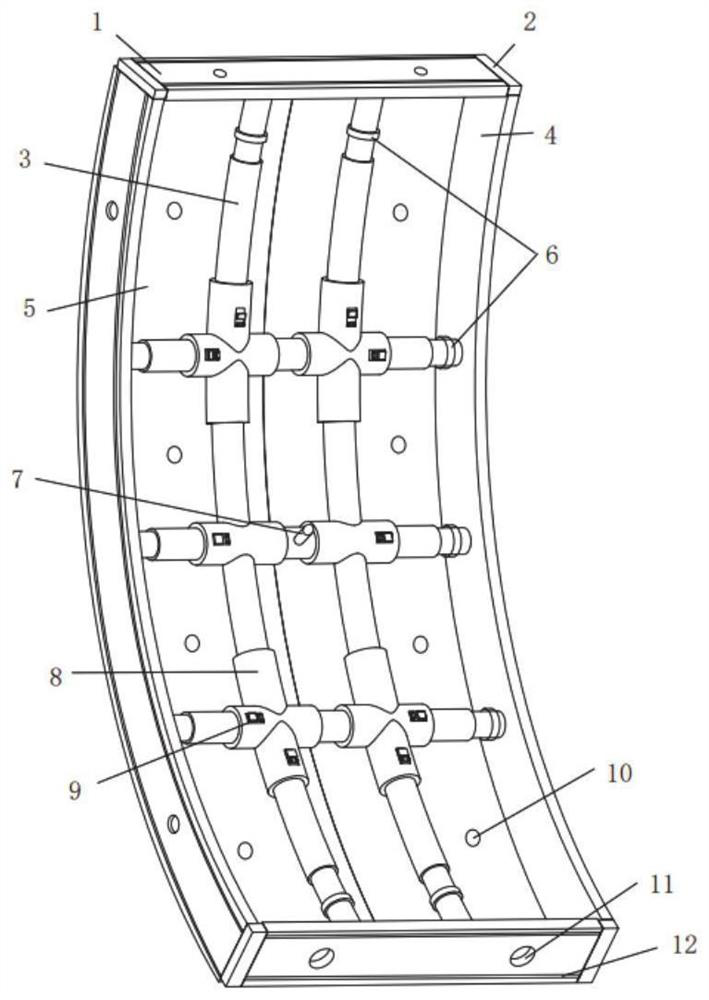

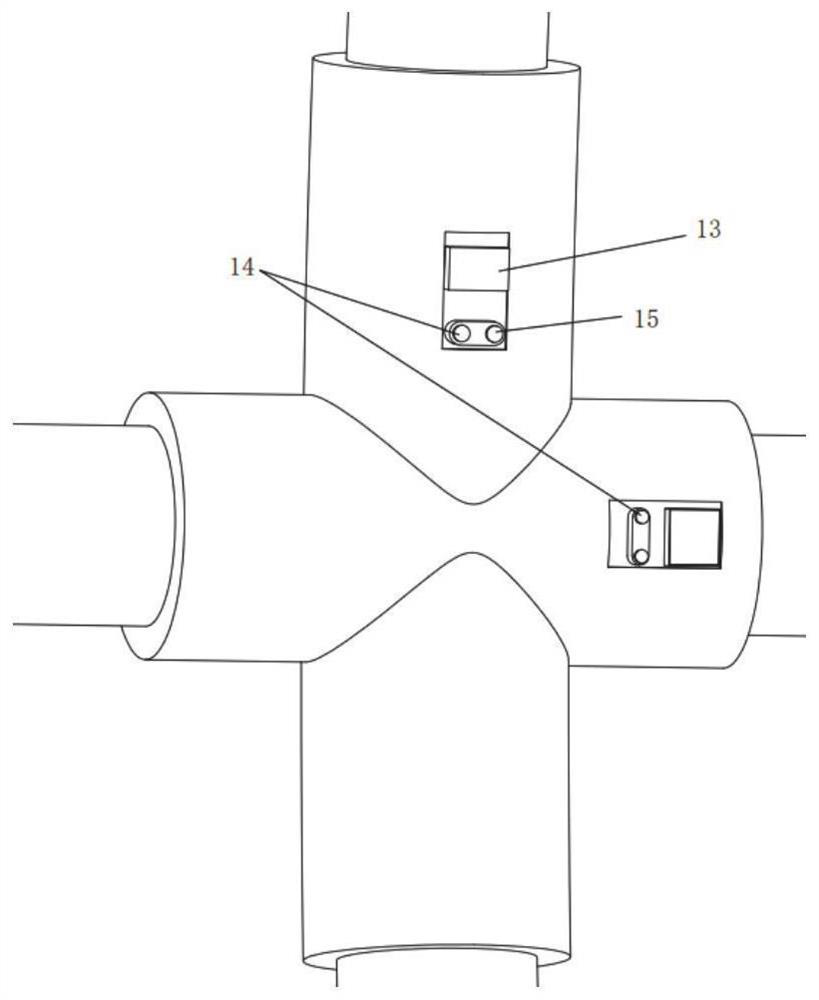

Gas taking connector and online gas taking method

InactiveCN104458345ANo leaksAccurate control of accessWithdrawing sample devicesMechanical engineeringEngineering

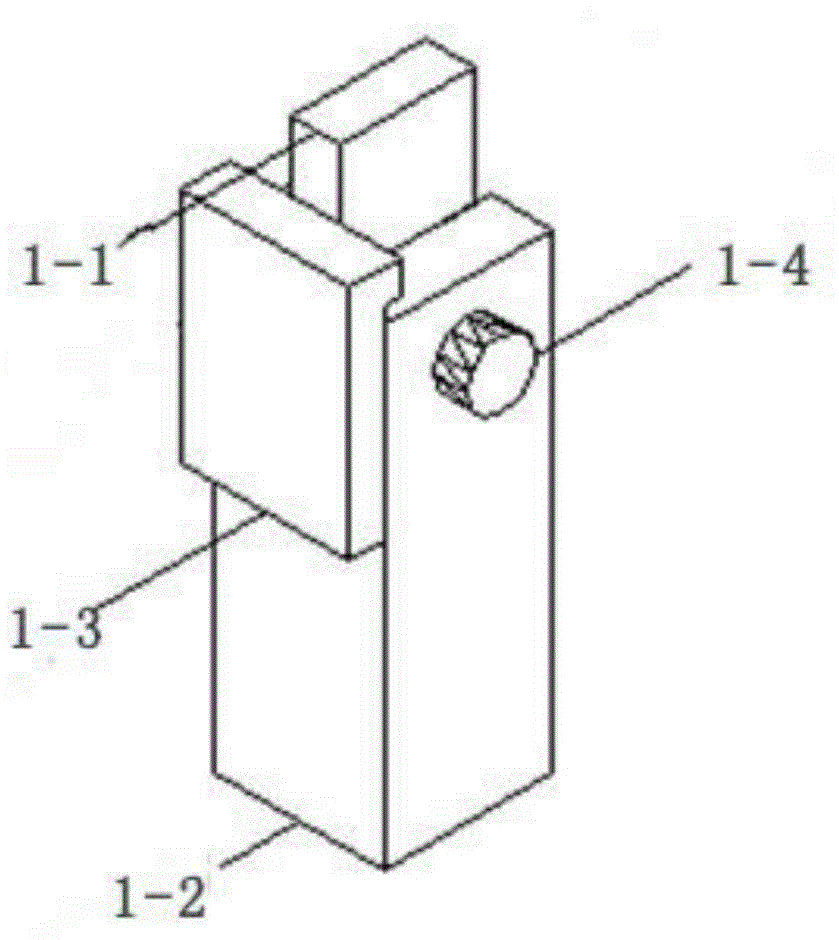

The invention relates to a gas taking connector and an online gas taking method. The gas taking connector comprises a fixed nut, a valve core with a gas taking ejector pin, a propelling part and a quick connector with an automatic sealing structure, wherein the gas taking ejector pin is fixed in the valve core, a through air duct is formed along the axial direction of the valve core, a pin head part stretches out of the front end of the valve core, and the front part and the rear part of the valve core are respectively provided with a baffle mechanism; the propelling part is arranged outside the valve core in a sleeving manner and snapped between the baffle mechanisms on the front part and the rear part of the valve core, the periphery of the propelling part is provided with outer threads which are matched with the inner threads of the fixed nut, and the propelling part is also provided with a propelling control part so as to drive the valve core to move in the fixed nut; one end of the quick connector can be connected with the tail end of the valve core in a sealing manner. By adopting the gas taking connector and the online gas taking method, the gas leakage in the gas taking process can be maximally eliminated, and the potential danger caused by the fault operation of people in the detection process can be prevented by virtue of the normalized operation method.

Owner:STATE GRID GANSU ELECTRIC POWER CORP +3

Tunnel connection channel rapid construction method based on telescopic steel pipe piece

ActiveCN112324474ASafe dismantlingShorten construction timeUnderground chambersTunnel liningGlass fiberFiber

The invention relates to a tunnel connection channel rapid construction method based on a telescopic steel pipe piece, and belongs to the technical field of computer image processing. The tunnel connection channel rapid construction method comprises the following steps that the telescopic steel pipe piece is installed, a bottom bearing plate of the telescopic steel pipe piece extends outwards until the external size of the pipe piece is consistent with that of a concrete pipe piece, and the bottom bearing plate is hoisted to a preset position and connected with prefabricated concrete pipe pieces on the periphery in a through seam splicing mode; before a transverse channel is excavated, glass fiber grouting anchor rods are punched through grouting holes in the bottom bearing plate, and surrounding rock at a rear connecting channel of a steel pipe piece wall is grouted and reinforced; after the surrounding rock reinforcement is completed, the telescopic steel pipe piece is dismantled, and an initial stage of the connection channel is excavated; and finally, the middle stage of the connection channel is excavated until the connection channel is conducted. According to the tunnel connection channel rapid construction method based on the telescopic steel pipe piece, the pipe piece is safely and rapidly disassembled through automatic contraction of the steel pipe piece, and the construction time of the shield connection channel is shortened; and meanwhile, the steel pipe piece can be repeatedly used, and the construction cost is reduced.

Owner:CHINA RAILWAY SHISIJU GROUP CORP +2

Building demolition method using self-expansion effect of expansion agent

The invention discloses a building demolition method using a self-expansion effect of an expansion agent. The building demolition method using the self-expansion effect of the expansion agent comprises the following steps that step 1, the number of falling layers, destruction layers and destroying layers of a building to be demolished is calculated; step 2, stand columns of the destruction layersare marked; step 3, pouring holes are formed; step 4, oil storage holes are formed; step 5, expansion agent mixtures are prepared; step 6, the expansion agent mixtures are poured; step 7, openings ofthe pouring holes are closed by sealing devices; and step 8, burning devices are arranged to burn the stand columns, the stand columns are completely destroyed, and the demolition of the building is realized. According to the building demolition method using the self-expansion effect of the expansion agent, the problems of long demolition cycle, high demolition cost and high danger can be solved,and the momentum generated by the self-weight falling from the upper part of the building is used for destroying the entire building, the demolition of the building is realized in safety and controllability modes, the demolition cycle is short, the operation is simple, the demolition cost is low, and the safety and reliability are achieved.

Owner:CHINA THREE GORGES UNIV

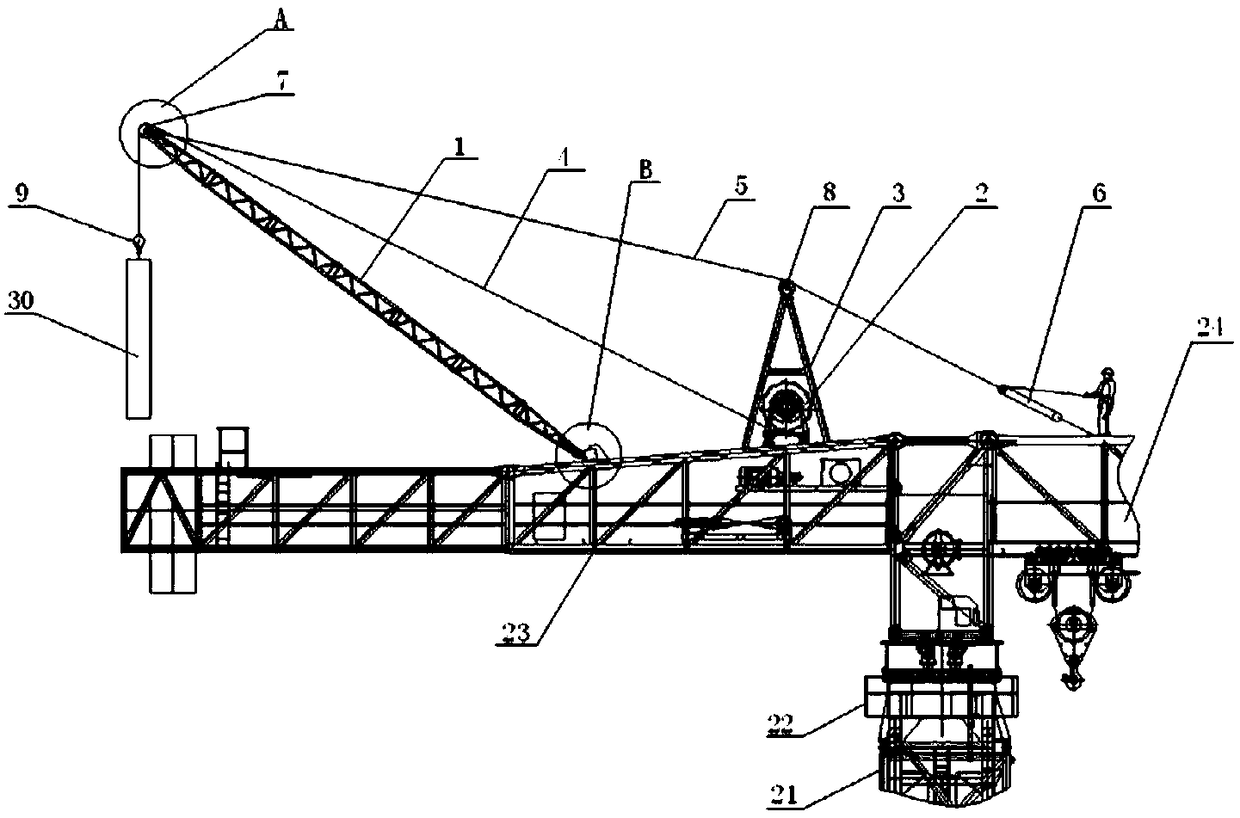

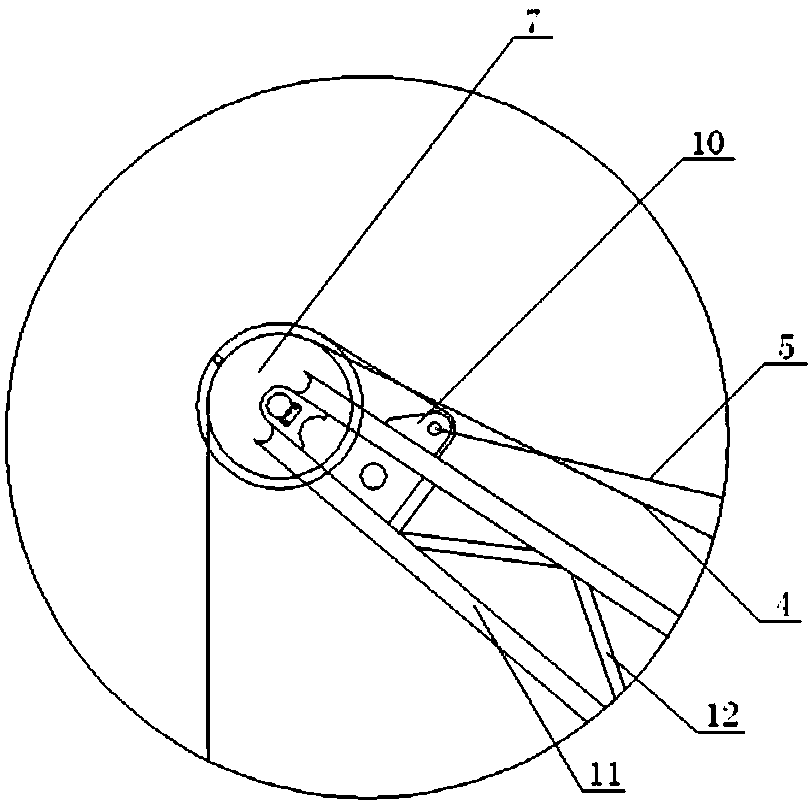

Self-disassembly device of upper mechanism of crane, crane and self-disassembly method

The invention discloses a self-disassembly device of an upper mechanism of a crane, the crane and a self-disassembly method. The device comprises a derrick mast, a hoist, a support, a lifting steel wire rope arranged on the hoist, an amplitude-variation steel wire rope and a pull calabash. A hinge part is arranged at the lower end of the derrick mast, a first pulley is arranged at the upper end ofthe derrick mast, and a second pulley is arranged on the support; the lifting steel wire rope penetrates through the first pulley, a lifting hook is connected to the outer end of the lifting steel wire rope, and one end of the amplitude-variation steel wire rope is connected to the upper side of the derrick mast, penetrates through the second pulley and is connected with the pull calabash. According to the self-disassembly device, the derrick mast is stable in structure and low in weight and is conveniently assembled and disassembled on the tower crane during disassembly, the pull calabash can be adopted for the derrick mast for amplitude-variation adjustment, the device can adapt to disassembly of different parts and is easy to operate and convenient to use, the \ time of disassembling the tower crane is greatly shortened, and the working efficiency is improved.

Owner:中昇建机(南京)重工有限公司

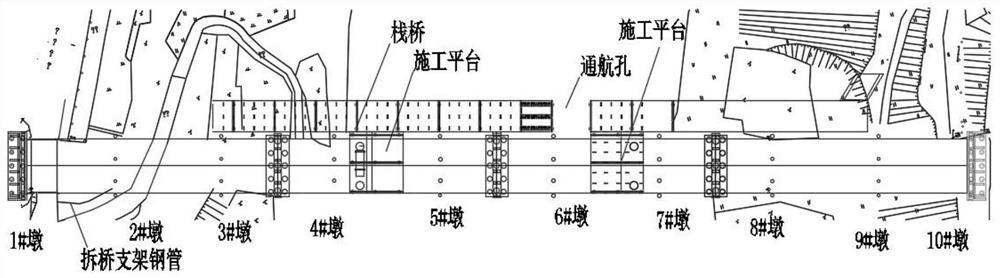

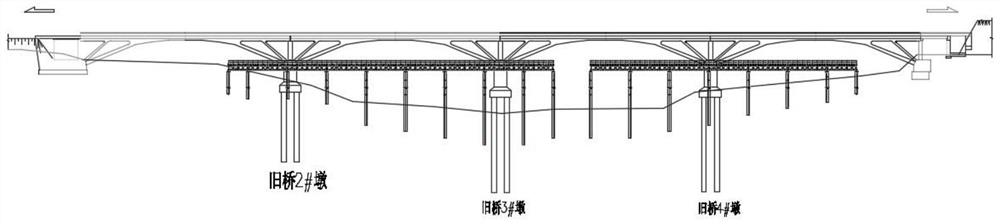

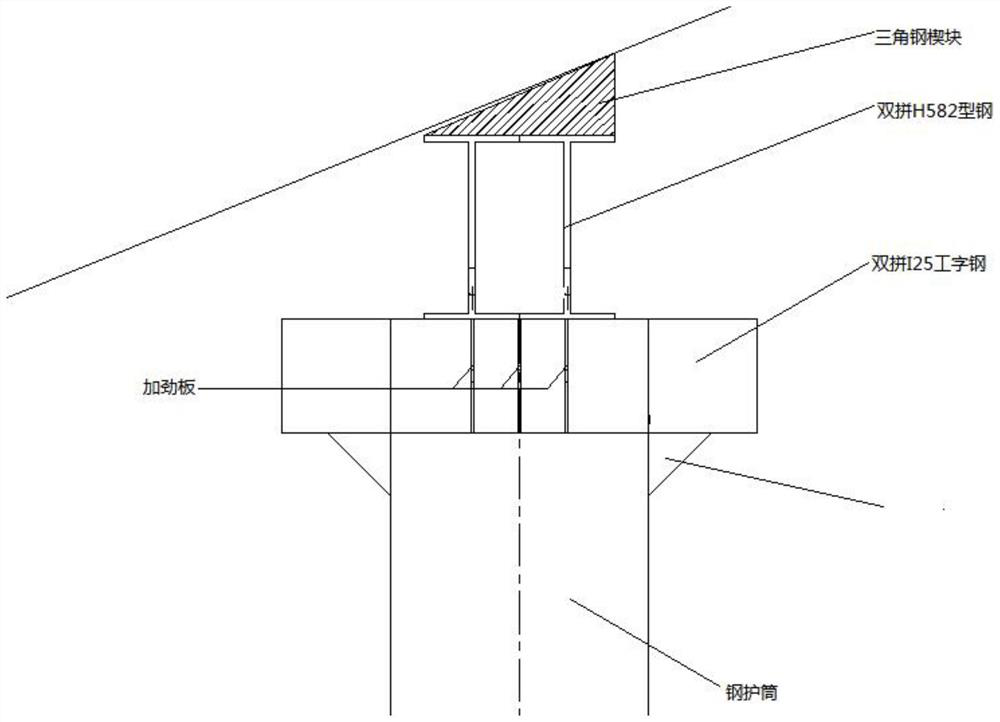

Unbalance-load-free quick dismantling method for multi-span concrete rigid frame arch bridge

ActiveCN111778883AThe removal method is safe and reliableDemolition bridge speed blockBuilding repairsBridge strengtheningMechanical crushingBridge deck

The invention discloses an unbalance-load-free quick dismantling method for a multi-span concrete rigid frame arch bridge. The method comprises the following steps: erecting an old bridge demolition construction trestle platform, erecting an old bridge arch rib supporting frame, demolishing bridge deck accessories, demolishing bridge deck slabs, demolishing transverse tie beams, demolishing main arch ribs, demolishing bridge piers and demolishing bridge abutment. The unbalance loading of the middle pier is eliminated by erecting the arch rib support frame, the scientific demolition sequence isset, and reasonable dismantling equipment is used, so the defects of secondary cleaning, large construction potential safety hazard, heavy dismounting noise and dust, heavy secondary cleaning pollution and the like after integral collapse by using large-scale mechanical crushing or blasting in a traditional demolition method are overcome, dismounting can be carried out safely, efficiently and environmentally friendly, the green construction concept is met, the purposes of reducing noise, reducing pollution and reducing disturbance to the surrounding environment are achieved, the old bridge dismounting construction technology is enriched, and good reference significance is achieved for similar projects.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

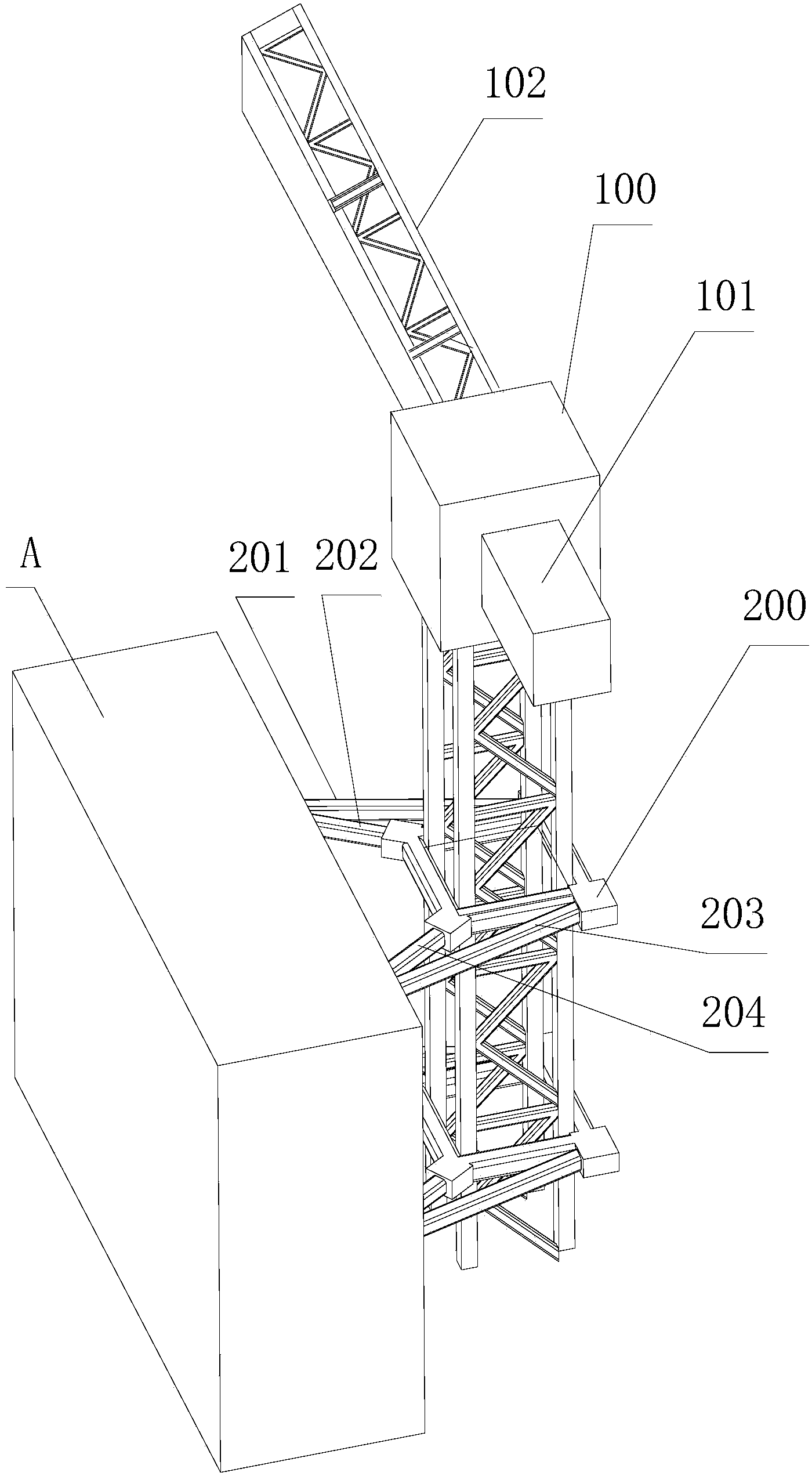

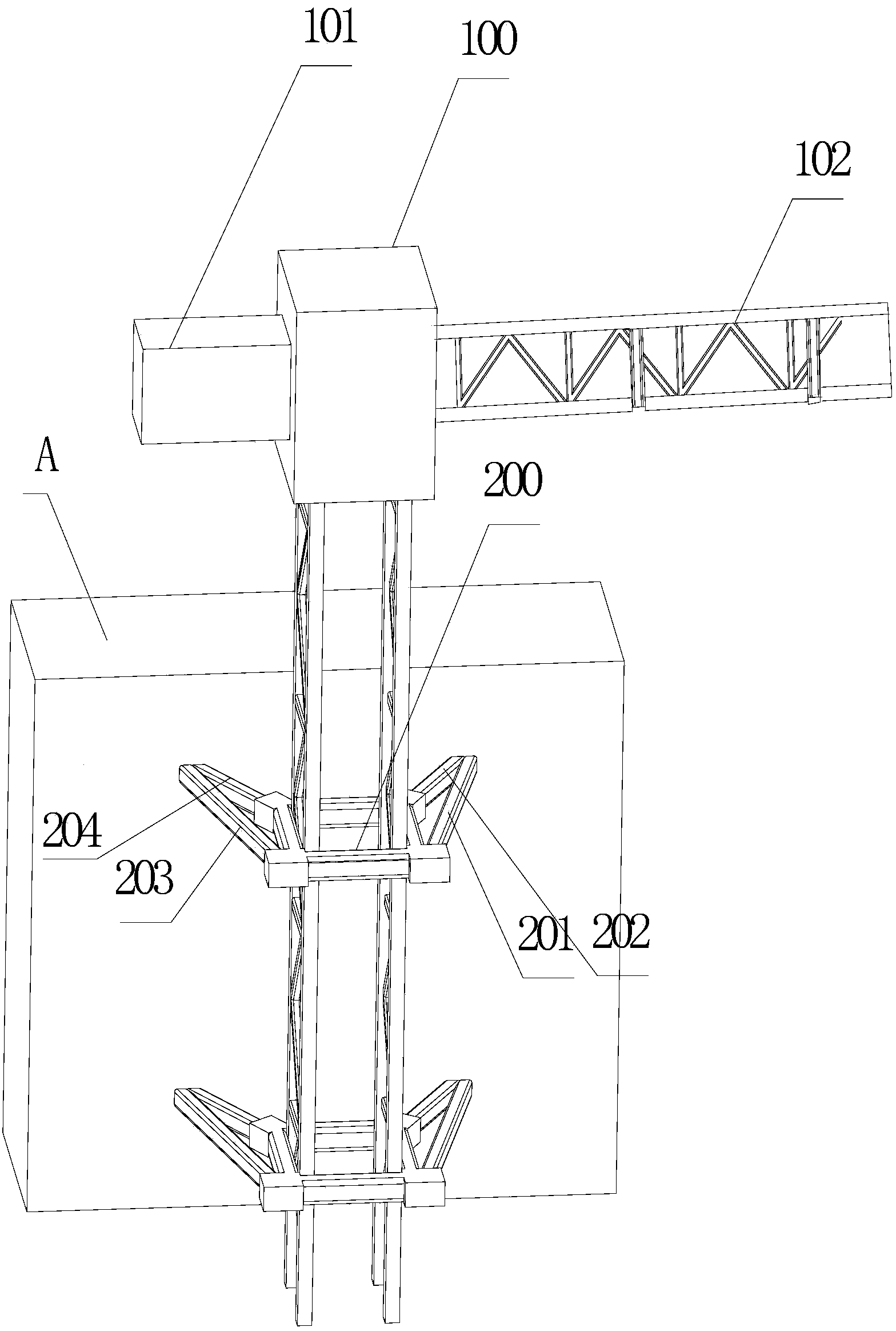

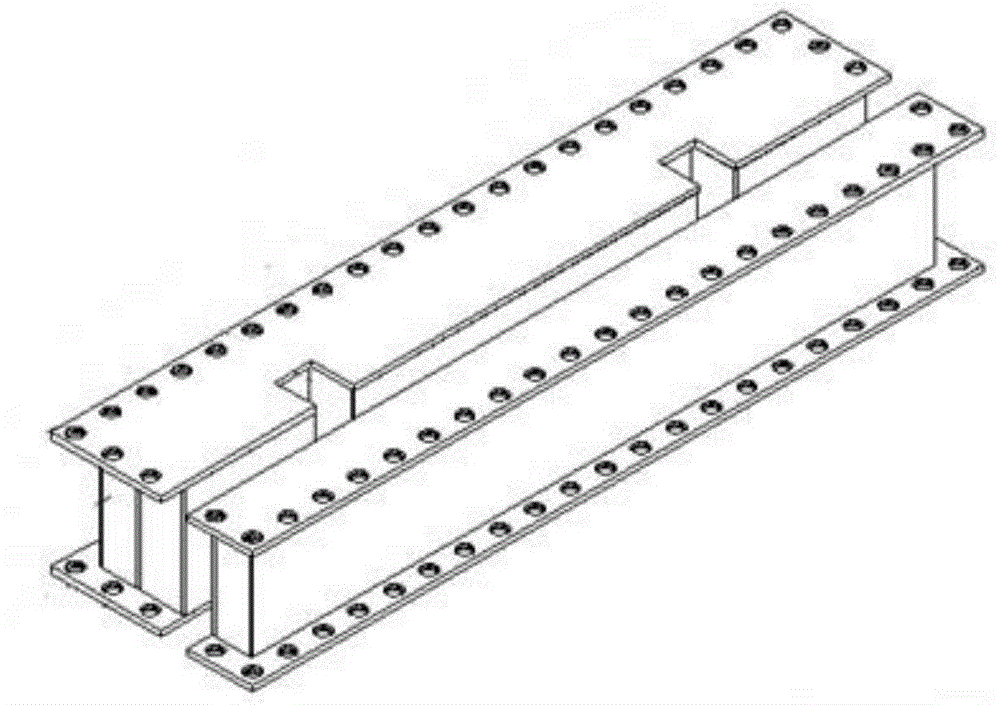

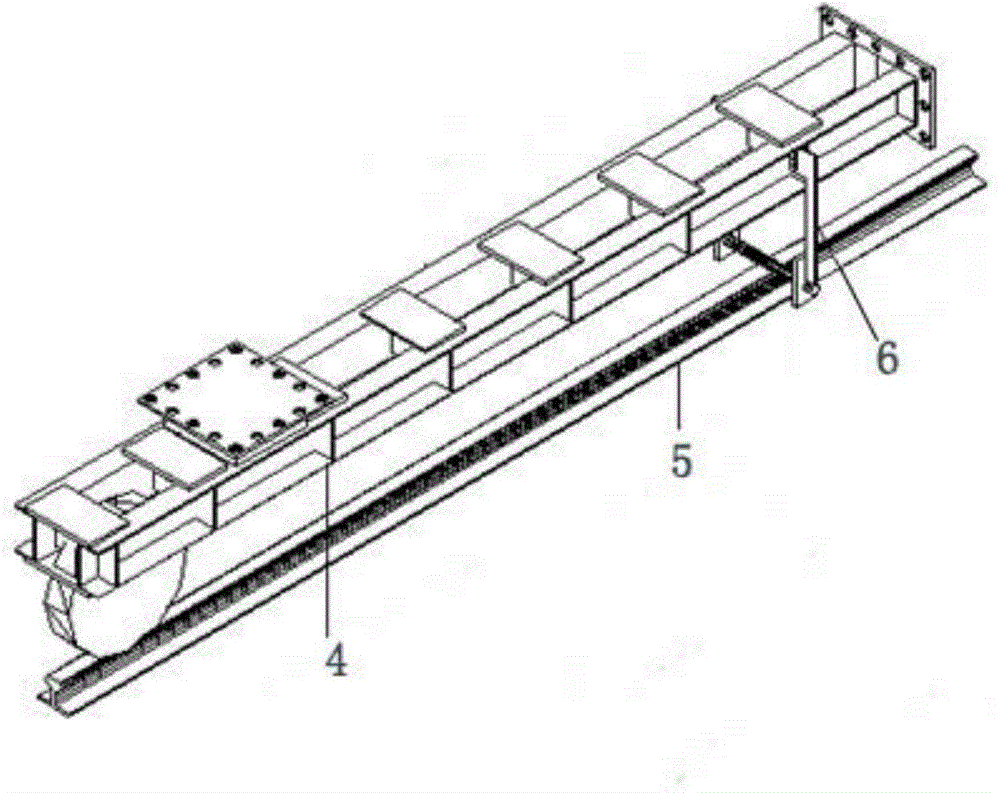

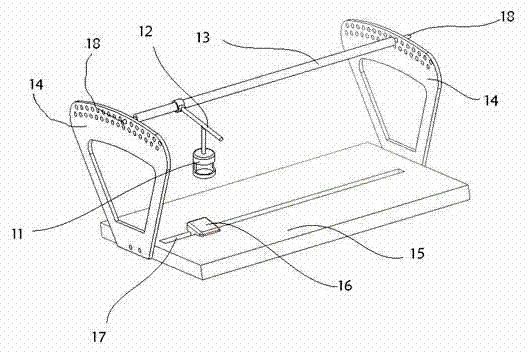

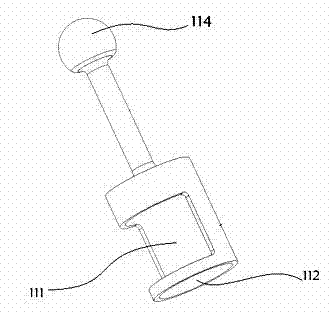

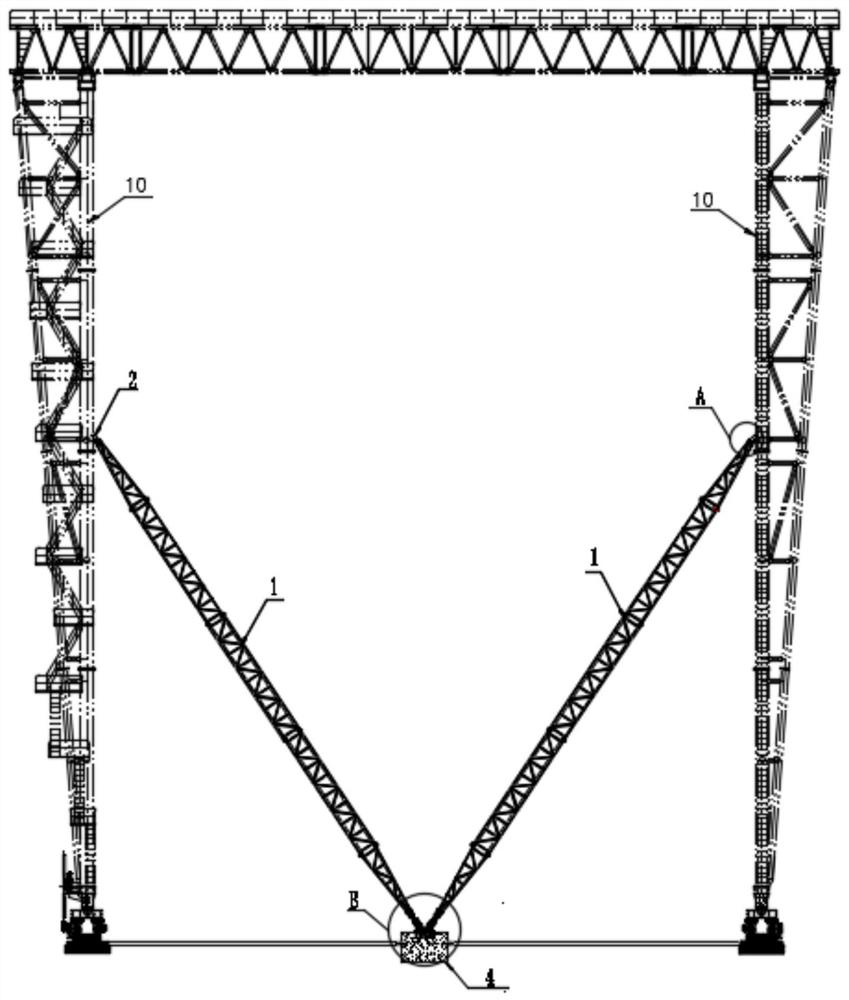

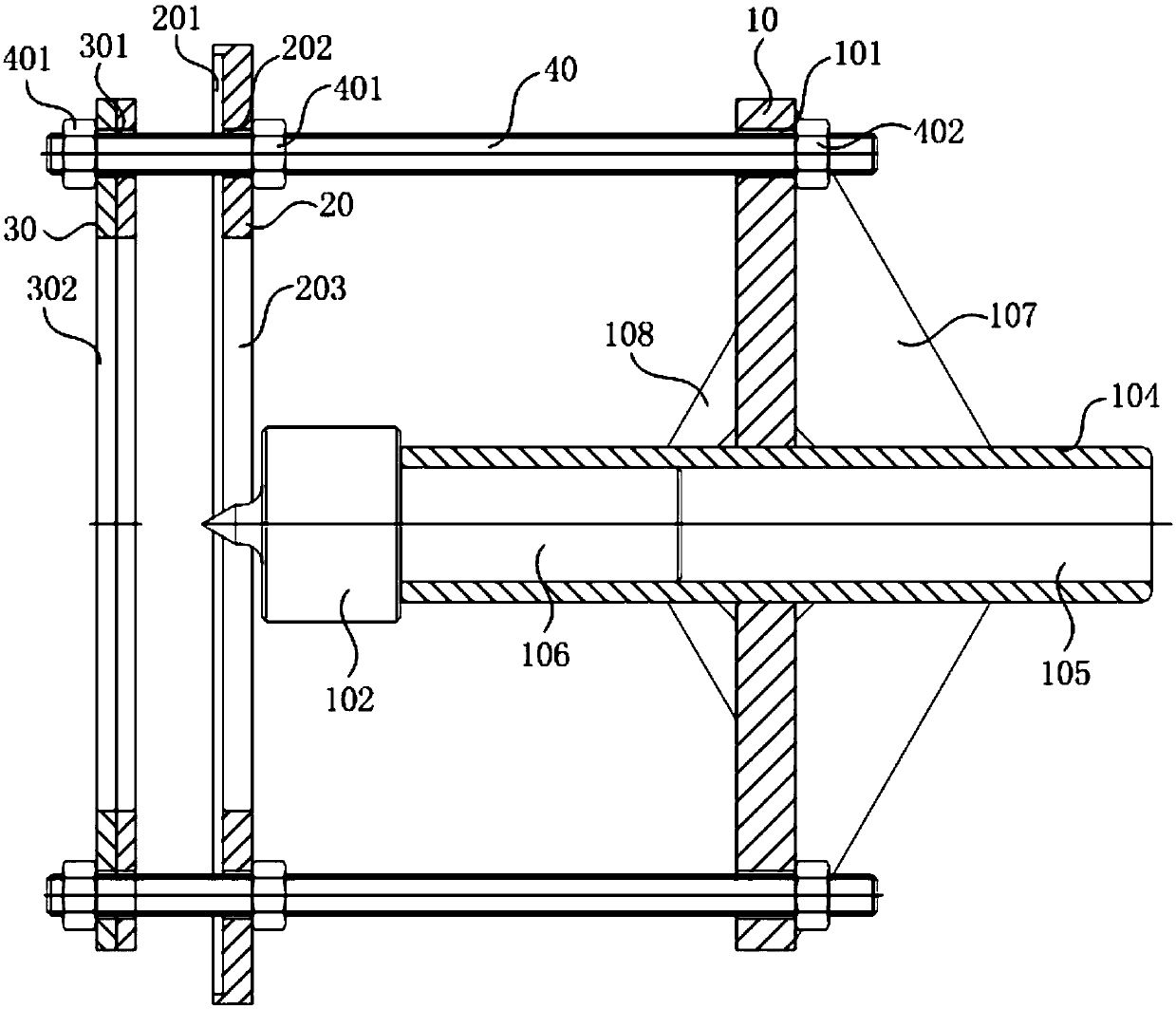

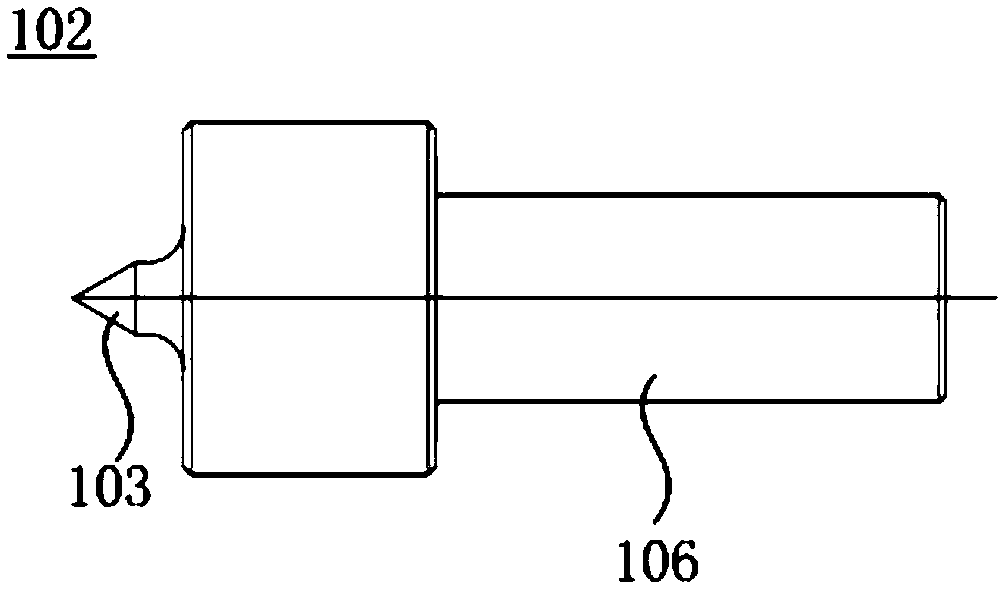

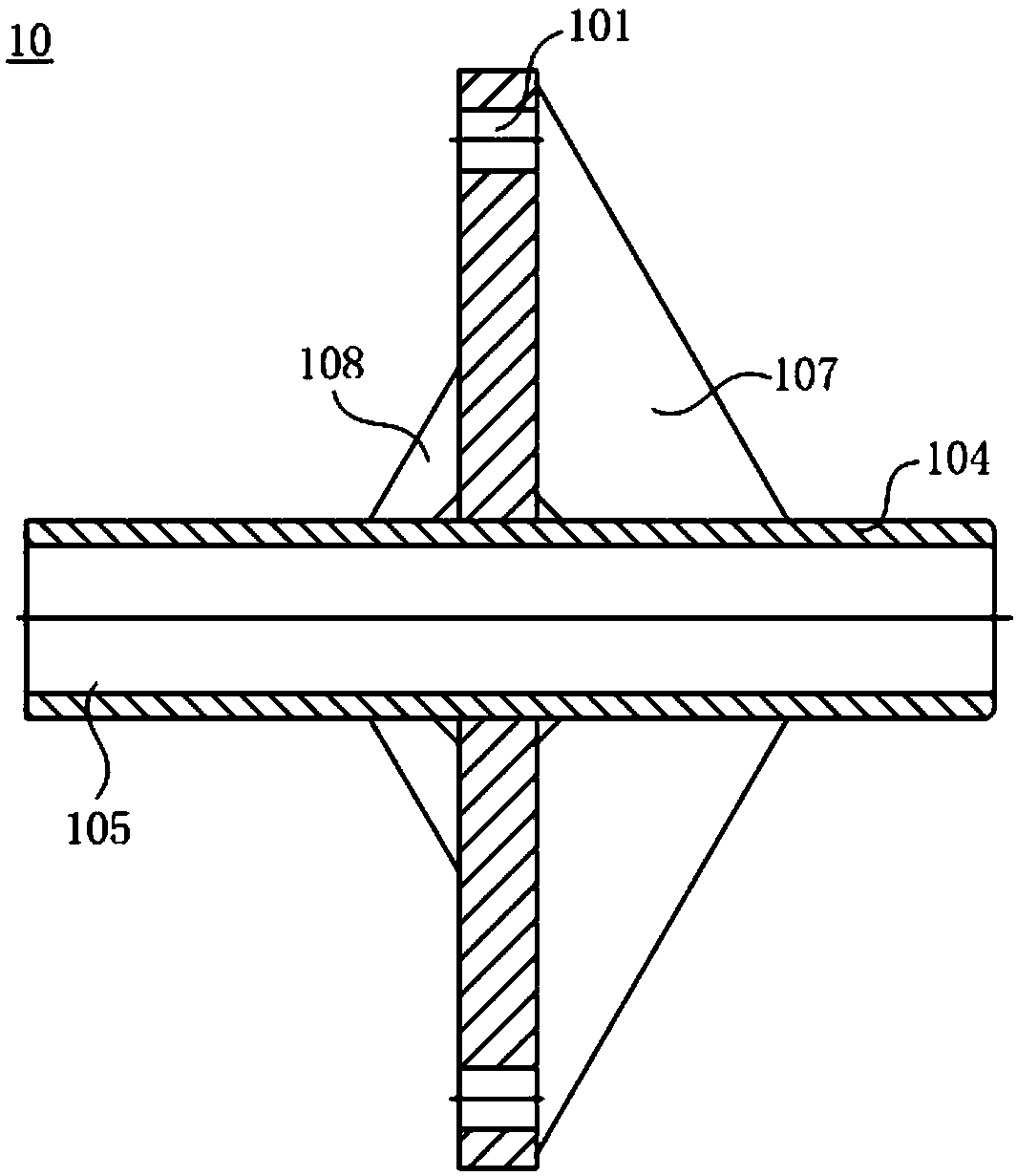

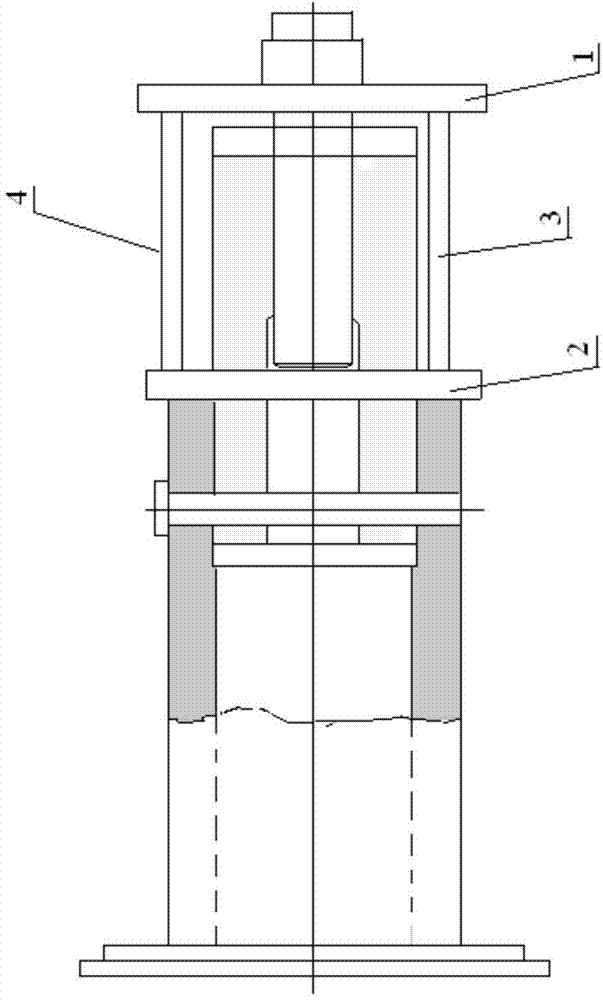

Construction method and device for installing and disassembling gantry crane in radial type

ActiveCN104416352AEasy to useEasy to installMetal working apparatusWelding apparatusGantry craneCivil engineering

The invention provides a construction method and device for installing and disassembling a gantry crane in radial type. The device comprises a rail, a gantry crane landing leg, a girder, a patand, and an assistant device mounted on the gantry crane body. While the device is used for constructing, the method comprises three steps of making the assistant device, installing the gantry crane and disassembling the gantry crane. The method and device can install and disassemble the gantry crane more conveniently, save the installing and disassembling cost, and improve the installing and disassembling safety of the gantry crane.

Owner:CHINA FIRST METALLURGICAL GROUP

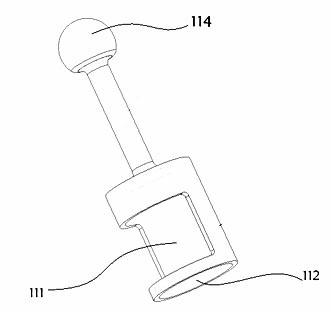

Engine valve locking piece assembling and disassembling tool

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

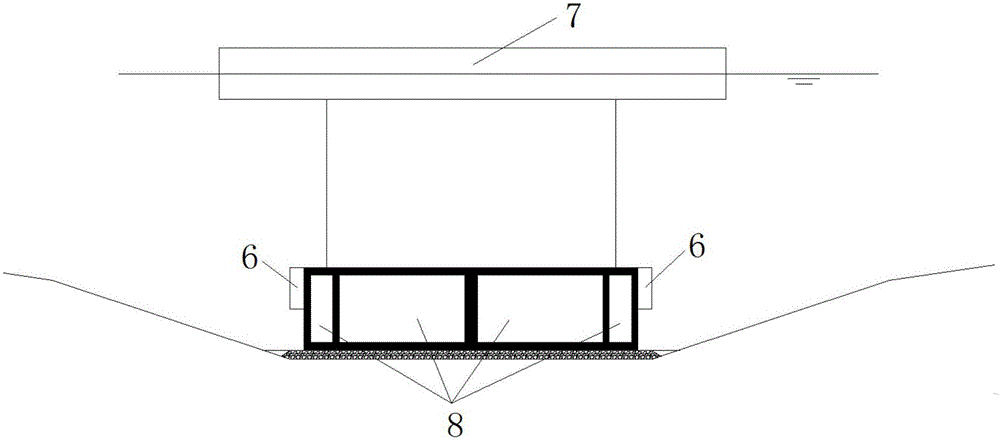

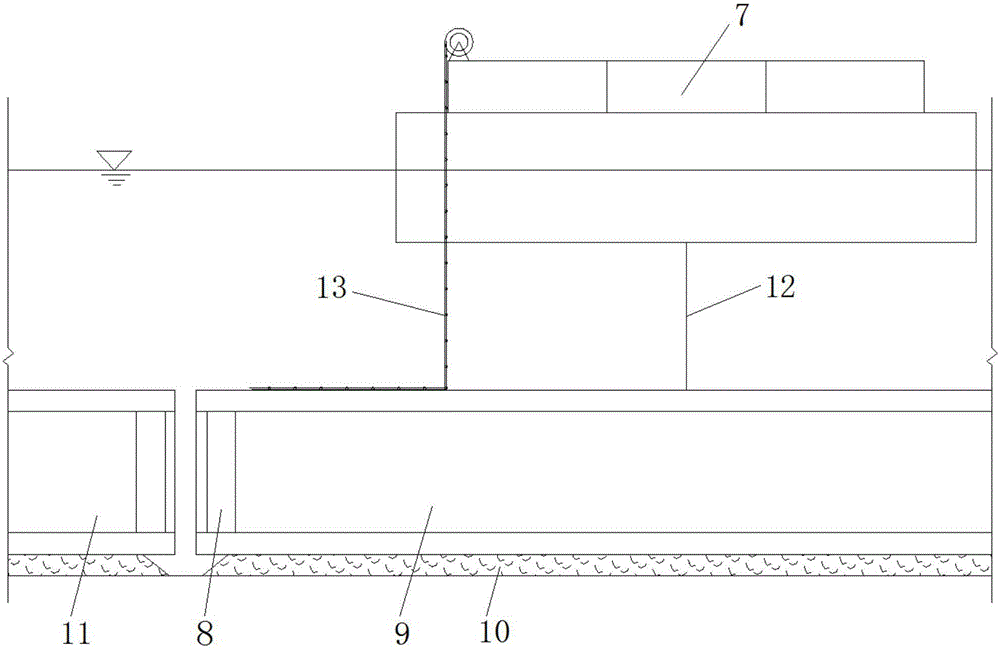

Dismounting method for pipe joints of immersed tube tunnel

InactiveCN105926679ASafe removalSmooth demolitionArtificial islandsUnderwater structuresHydraulic engineeringImmersed tube

The invention relates to a dismounting method for pipe joints of an immersed tube tunnels, and belongs to the technical field of hydraulic engineering. An immersed tube tunnel dismounting technology is absent at present, and therefore, a waste immersed tube tunnel cannot be dismounted, so that influence is generated on a marine environment. The dismounting method fills the technical blank. The dismounting method comprises a step of mounting a steel sealing door, a step of dismounting an end part anti-thrust section and a step of dismounting tunnel pipe joints. The dismounting method is used for dismounting the immersed tube tunnel.

Owner:CCCC FIRST HARBOR ENG

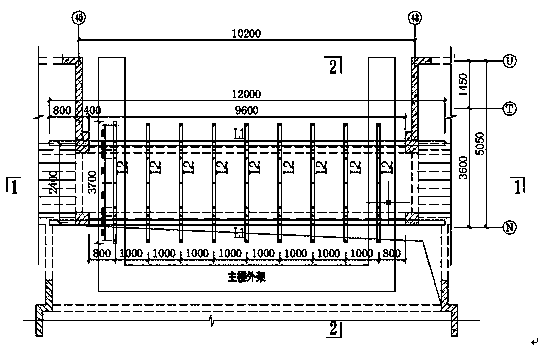

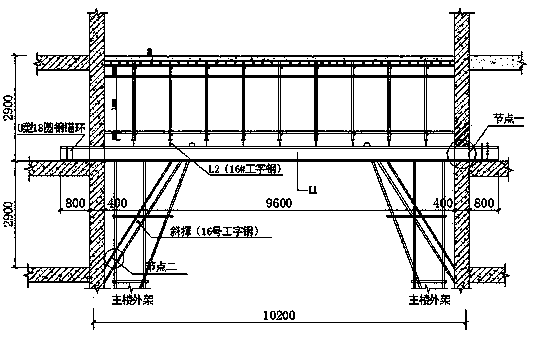

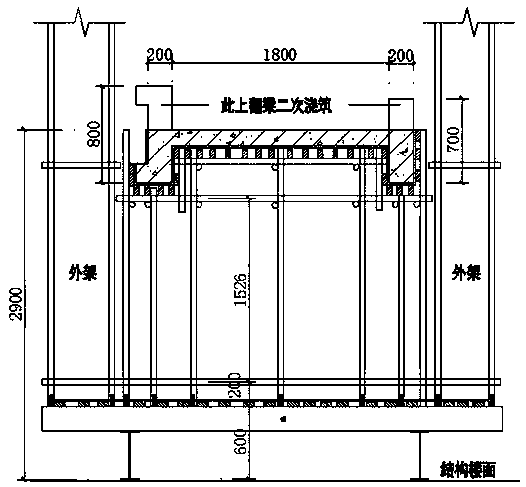

High-rise residential long-span interval corridor high-altitude formwork steel platform construction method

ActiveCN110512719AEasy to install and removeQuick installation and removalForms/shuttering/falseworksSupport removalLong span

The invention relates to a high-rise residential long-span interval corridor high-altitude formwork steel platform construction method. The construction method includes the following steps: step 1: asteel platform is deep designed and processed; step 2: hoisting and anchoring of a section steel main beam are conducted; step 3: installation of a section steel secondary beam is conducted; step 4: inclined support setting of the section steel main beam is conducted; step 5: plane protection setting is conducted; step 6: external protection frame erection is conducted; step 7: formwork support frame erection is conducted; step 8: beam and slab formwork installation is conducted; step 9: beam and slab reinforcement binding is conducted; step 10: concrete pouring is conducted; step 11: formworkremoval is conducted; step 12: corridor decoration construction is conducted; step 13: peripheral support removal is conducted; and step 14: steel beam removal is conducted. According to the technical scheme, a large-span steel beam is used as a main force-bearing component of a supporting platform, and a certain number of transverse connection steel secondary beams are set among steel beams to form a complete and reliable structural construction formwork steel platform.

Owner:NANJING CONSTR ENG GRP

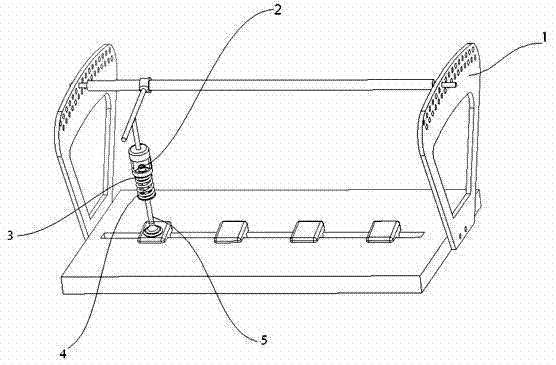

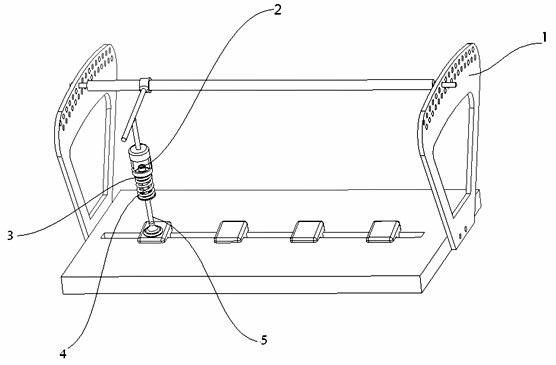

Engine valve locking piece assembling and disassembling tool

The invention provides an engine valve locking piece assembling or disassembling tool comprising a pressure head, a compression rod, an adjusting sliding rod, a dividing disc, a flat base and a cushion block, wherein the flat base has a large plane on which a guide slot is arranged, one or a plurality of cushion blocks are freely arranged in the guide slot in a slippage manner; each cushion block is a wedge, the wedge surface faces upwards and is vertical to an valve axis; the dividing disc is vertically fixed on two sides of the flat base, at least one row of holes are distributed on the upper end position of the dividing disc in a sector shape; two ends of the adjusting sliding rod are fixed in the corresponding holes on the dividing disc by lock pins; one end of the compression rod is provided with holes which are hinged with the adjusting sliding rod; the pressure head is connected below the middle part of the compression rod, a T-shaped structure is formed by the pressure head and the compression rod, and the lower part of the pressure head has a sleeve structure. By utilizing a lever principle, the engine valve locking piece assembling or disassembling tool reduces assembling pressure, adjusts the assembling angle through the scales of the dividing disc, so that the locking piece is simply and easily assembled or disassembled, other parts can be ensured not to be collided and crushed, and the whole assembling is more easily realized.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Method for dismantling standard sections of tower crane under limited space

The invention particularly discloses a method for dismantling standard sections of a tower crane under a limited space. The method is characterized by comprising the steps that a tower crane cargo boom and a dismantling platform are adjusted to be in the opposite directions; the tower crane cargo boom is used for lifting the two tower crane standard sections at the headmost end; counterweight blocks are fixed, a pulley is mounted on a counterweight arm, a steel wire rope of the cargo boom is changed onto the pulley, and dismantling work of the standard sections of the tower crane is started; after the standard sections are hoisted and buckled tightly by lifting hooks, a platform sliding bracket on a mounting and demounting platform is pushed outwards, at this moment, the standard sectionsare pushed out together on the platform sliding bracket, and the pushed-out standard sections are exactly at the vertical position below the lifting hooks; then the lifting hooks of the tower crane are lifted up in a control chamber, and the platform sliding bracket starts to be recycled; the dismantled standard sections start to be vertically hoisted on the ground; and the steps are repeated. Under the situation that a building affects normal dismantling of the standard sections of the tower crane and consequently the tower crane cargo boom and the mounting and demounting platform cannot be on the same side, the method can be used for dismantling work of the tower crane.

Owner:CHINA MCC20 GRP CORP

A method for dismantling the protective scaffolding of portal pier cover beams on existing railway lines

ActiveCN107165062BSuperiorSolve puzzles that cannot be removedBuilding repairsBridge strengtheningWorking spaceRailway line

The invention discloses a method for dismantling a protective shed frame of a gate-type pier capping beam of existing railway lines, and relates to the field of railway construction. According to the method, a steel pipe column is adopted in slotting; a carling of a D-shaped auxiliary beam is dropped inside the open slot of the steel pipe column, so that the height of the protective shed frame is decreased, and a working space is provided for dismantling a cross girder of the D-shaped auxiliary beam and oblique poles of the cross girder, and therefore the safety of existing railway lines is guaranteed, and meanwhile, the difficulty of taking out a pressed bearing bent cap of the protective shed frame is overcome. According to the method for dismantling the protective shed frame of gate-type pier capping beams of existing railway lines, after construction of the gate-type pier capping beam, the components positioned at the lower section of the gate-type pier capping beam, such as the D-shaped auxiliary beam, the steel pipe column, a joist steel, a scaffold and the like, are dismantled safely and quickly under the premise of guaranteeing the safety of the existing railway lines. The method for dismantling the protective shed frame of the gate-type pier capping beam of existing railway lines is suitable for large-scale promotion and application.

Owner:中铁七局集团第一工程有限公司

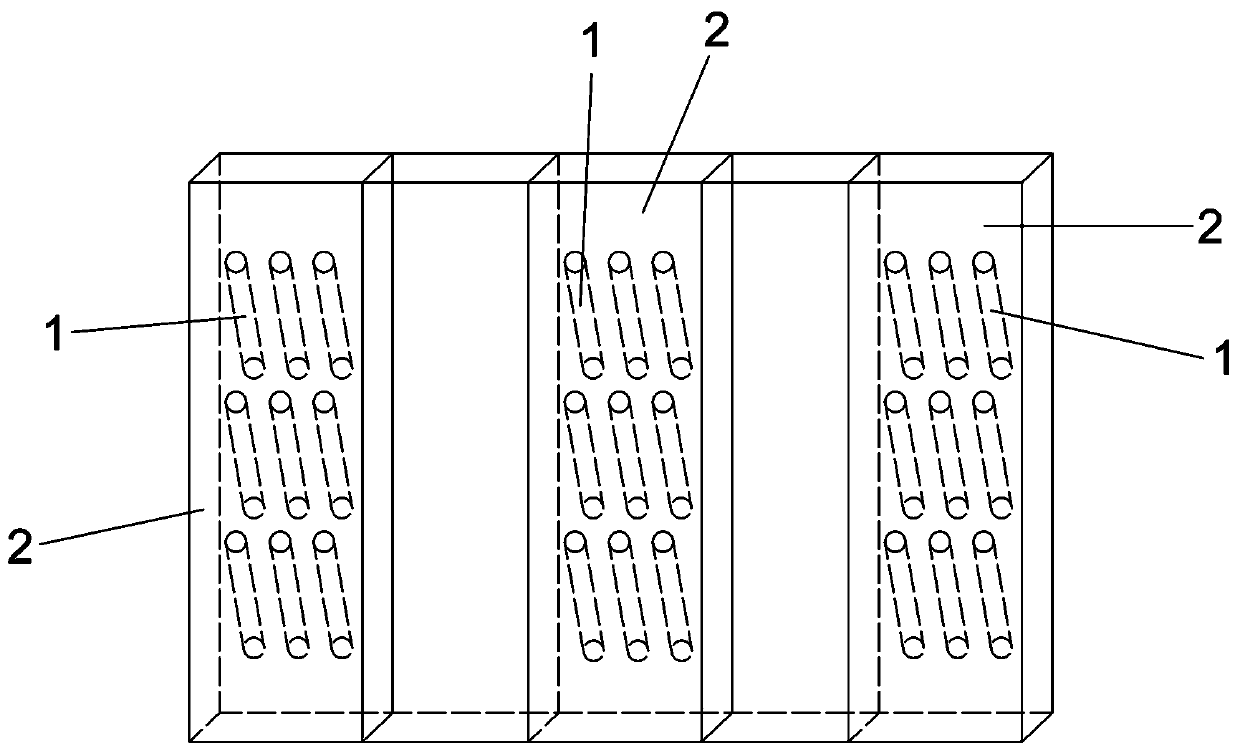

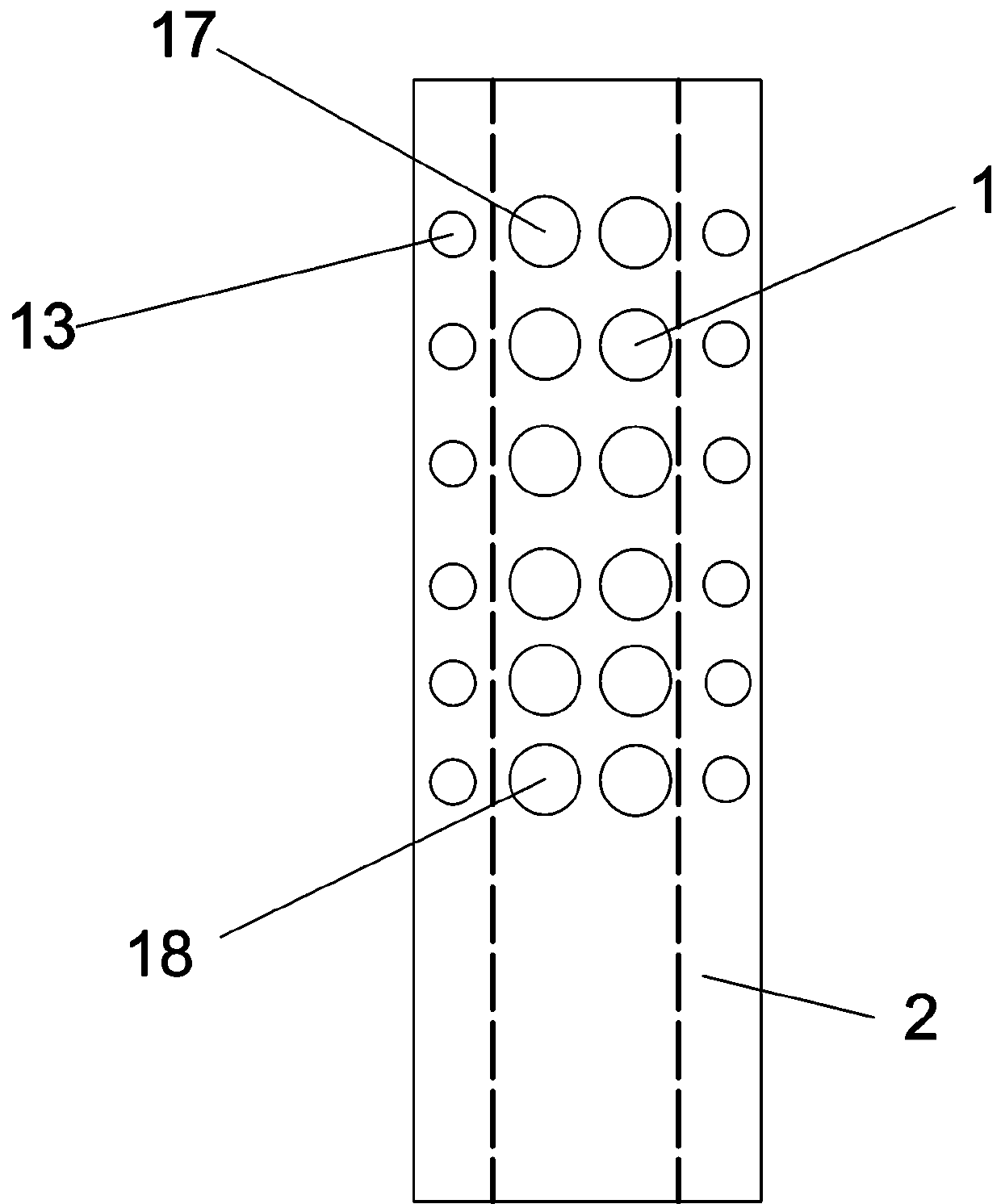

Cast-in-place box beam and cross beam multi-layer steel bar installation supporting system device and construction method thereof

The invention provides a cast-in-place box beam and cross beam multi-layer steel bar installation supporting system device and a construction method thereof. The cast-in-place box beam and cross beam multi-layer steel bar installation supporting system device comprises a supporting cushion structure. The adjustable bottom support is arranged on the supporting cushion structure; the disc buckle frame body is detachably connected with the adjustable bottom support; and the supporting cross rod is arranged on the disc buckle frame body. The whole device is simple in structure, stable, reliable and high in operability; the construction method is easy to operate, high in speed and remarkable in work efficiency; standardized manufacturing can be conducted, erecting and disassembling are convenient and safe, cyclic utilization is achieved, cost is saved, and the construction period is shortened; the whole device is clear in force transmission, high in bearing capacity and good in stability, effectively solves the problems of temporary supporting and positioning during binding and mounting of multiple layers of reinforcing steel bars of the cast-in-place box girder and the problem of operation of operators in a reinforcing steel bar cage, and greatly guarantees construction safety in the reinforcing steel bar mounting process.

Owner:CHINA MCC5 GROUP CORP

Method for assembling and disassembling portal crane and auxiliary supporting structure

PendingCN111908334AAssembly safetySafe dismantlingBase supporting structuresBraking devices for hoisting equipmentsArchitectural engineeringGantry crane

Owner:深圳路桥工程有限公司

Arc support combined template used for cast-in-place box beam and erecting method thereof

InactiveCN110158479ALight structureEasy and safe to set upBridge erection/assemblyEngineeringMechanical devices

The invention belongs to the technical field of bridge building engineering construction, and particularly discloses an arc support combined template used for a cast-in-place box beam and an erectingmethod thereof. The arc support combined template comprises multiple arc supports, the arc supports are evenly arranged in the direction of a bridge, and multiple pieces of square timber located on anarc body of the arc support are included and are evenly laid from the lower end to the upper end of the arc body; through the square timber, the arc supports are connected into a whole, the laying supporting face is provided for a side template of the cast-in-place box beam, the cross section of the arc body is in a square or oval shape, the arc body is in face contact with the square timber, theside template of the cast-in-place box beam is formed through sequential connection of multiple bamboo plywood, and the bamboo plywood is fixed to the upper surface of the square timber through nails. Due to use of the arc support combined template, the appearance of the cast-in-place box beam is attractive, the line type is smooth, in the construction, use of mechanical devices like a crane is little, and construction cost is low.

Owner:陕西路桥集团有限公司

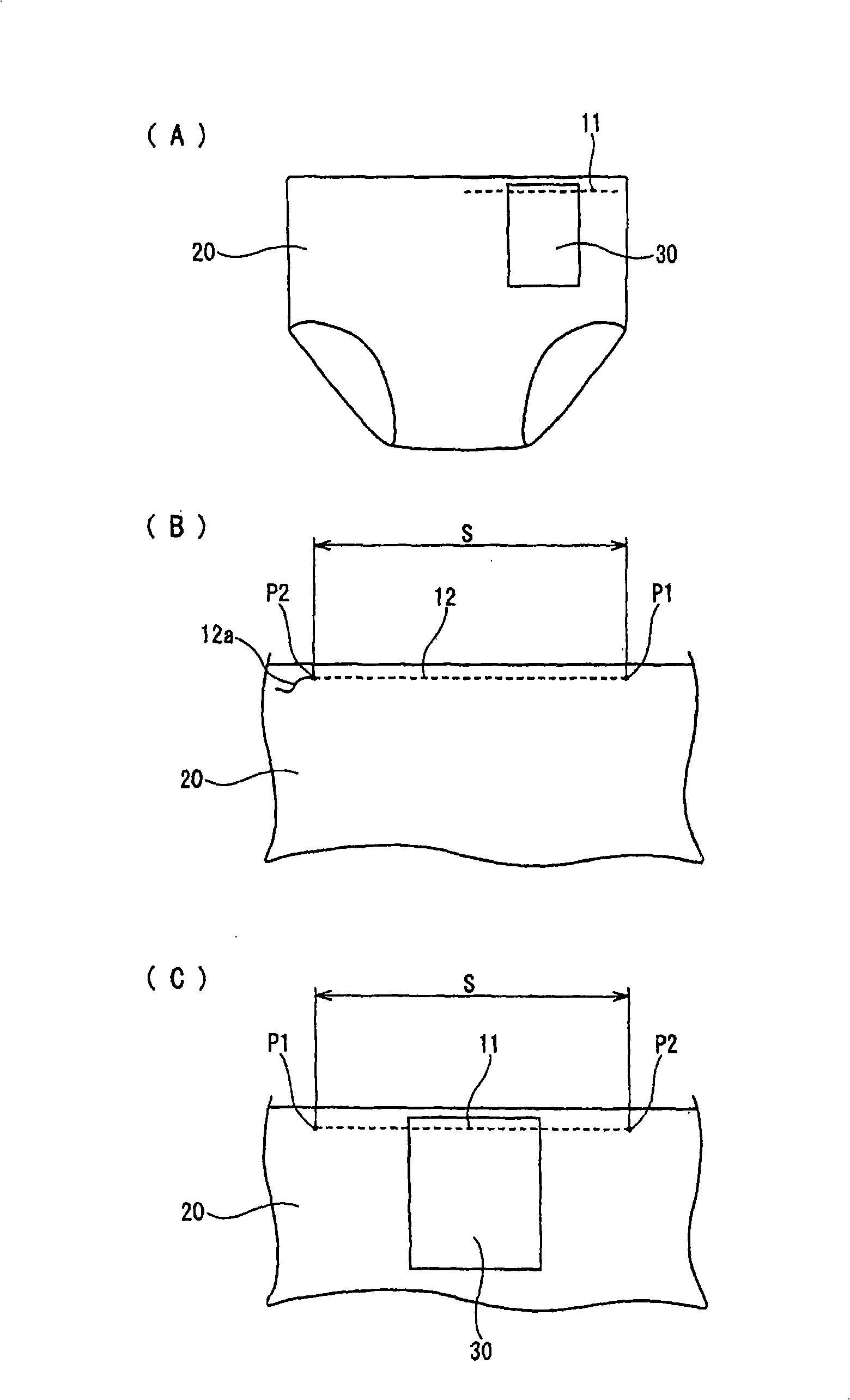

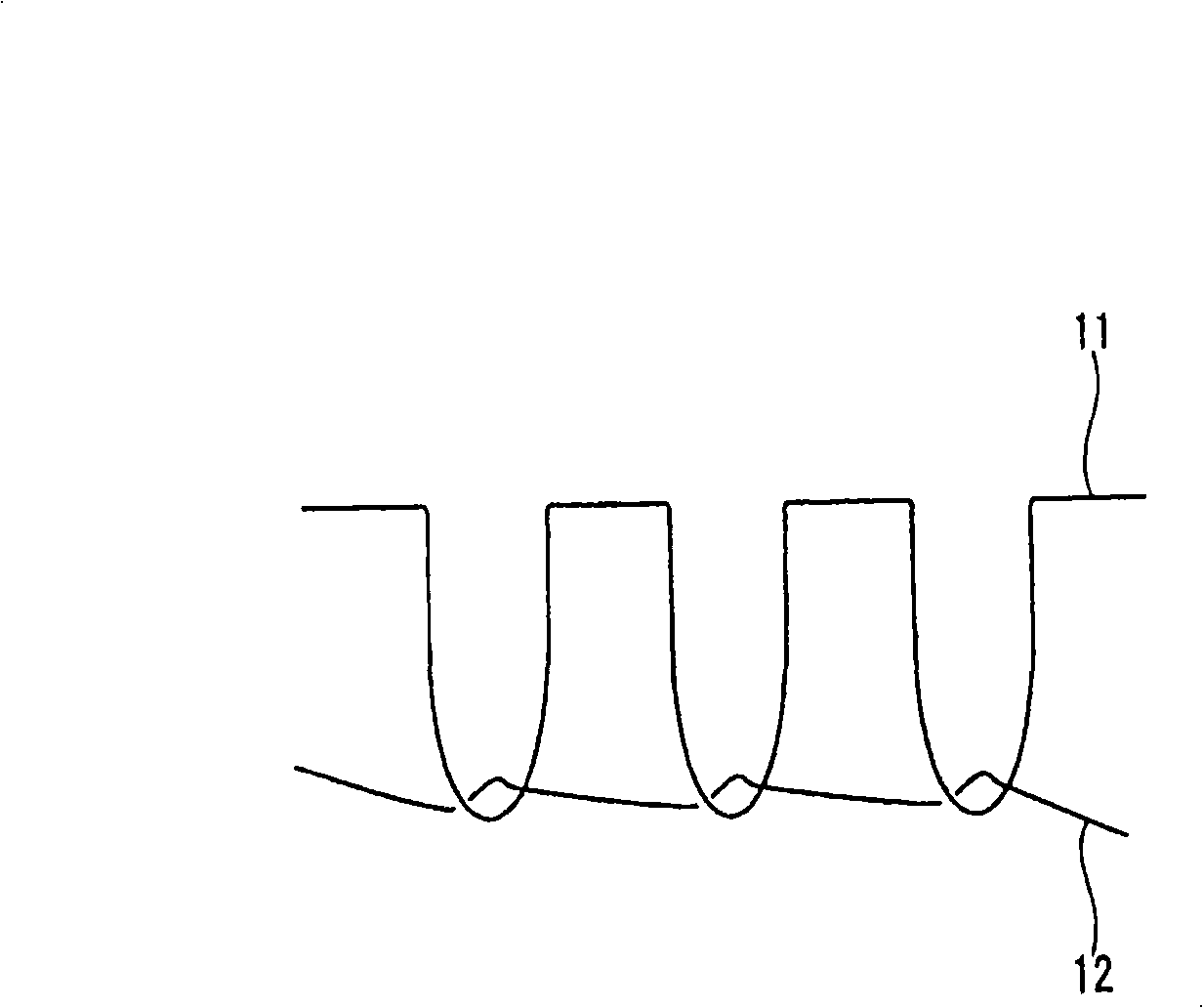

Structure for fixing label to clothing and method for removing label

A label fixing structure where a label is fixed to the front surface side of clothing by means of a sewing thread. The label is lock stitched by the sewing thread consisting of a needle thread exposed to the front surface side of the label and a bobbin thread exposed to the back side of clothing to be fixed with the label. Starting position and ending position of lock stitch are spaced apart by a predetermined dimension from the right and left ends. An unsewn raveling cord consisting of the needle thread or the bobbin thread and having a length of 0.3-2.0 cm is extended to a rear position continuous to the end-of-sewing position and / or a front position continuous to the start-of-sewing position and then the raveling cord is pulled and drawn out, thus removing the label from the clothing.

Owner:WACOAL

Coupling Removal Tool

The invention provides a coupling dismounting tool. The coupling dismounting tool comprises a base, an outer fixing disc, two sets of inner fixing discs, and at least two screws. The screws penetrate through first connecting holes, second connecting holes, pin holes of a coupling, and third connecting holes. On the coupling side, the screws are fixed to the coupling side through nuts; and on the base side, a nut is connected with each screw, and the nuts can be unscrewed so that the coupling can be driven by the outer fixing disc and the inner fixing discs to be disengaged from a shaft. The coupling dismounting tool has the advantages that pump couplings and motor couplings can be dismounted safely, the situation that the couplings are damaged due to operation such as knocking, prying and hitting, and consequentially using and centering are affected is avoided, and the service life of the couplings is prolonged; the accidents that people are injured or the couplings are damaged due to operating instability of three-jaw pullers and the like can be avoided, and safe production is guaranteed; and operation is convenient and fast, time and labor are saved, and working efficiency is improved.

Owner:SHANGHAI FIRST PUMP WORKS

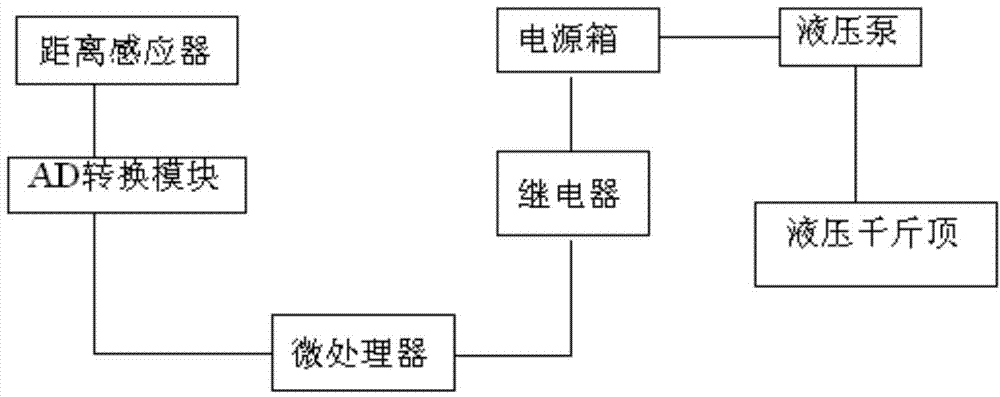

Device and method for dismantling shear pins of jacks

ActiveCN103707045ASafe dismantlingEfficient demolitionMetal working apparatusMaterial consumptionJackscrew

The invention discloses a device and a method for dismantling shear pins of jacks. The device for dismantling the shear pins of the jacks comprises an upper flange and a lower flange. Hydraulic jacks are arranged between the upper flange and the lower flange, a distance sensor is arranged on the upper flange and is connected with an input end of a microprocessor by an AD (analog and digital) conversion module, and an output end of the microprocessor is connected with control ends of the hydraulic jacks by relays. The device and the method have the advantages that the device is simple in structure, the shear pins can be safely and efficiently dismantled by the aid of the device and the method, accordingly, equipment safety and personal safety can be guaranteed, and stop and defect elimination time of units can be effectively shortened; the method for dismantling the shear pins of the jacks is simple, safe and effective and is easy to implement, replacement and maintenance construction periods of the shear pins of the jacks of upper frameworks can be shortened, and unnecessary labor and material consumption can be reduced.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com