Dismounting method for pipe joints of immersed tube tunnel

A technology of immersed tube tunnels and pipe joints, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as low construction efficiency, unfavorable energy conservation and environmental protection, and high risks, and achieve the effect of safe demolition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific embodiments.

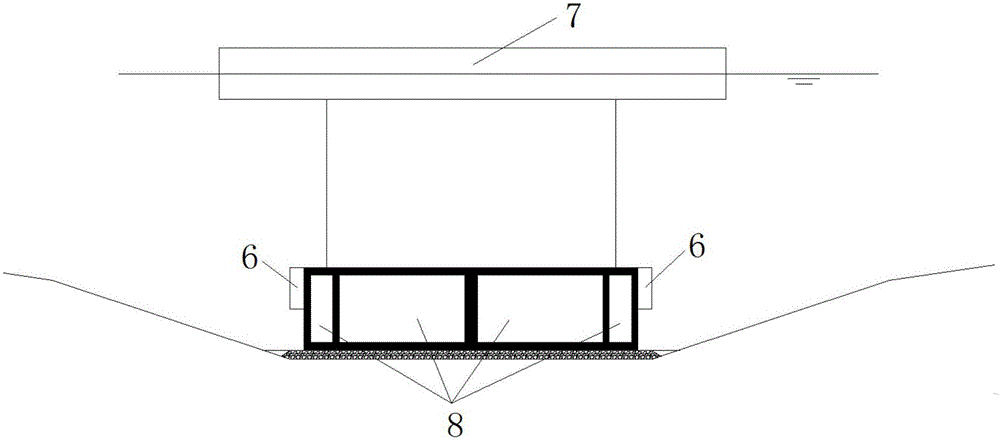

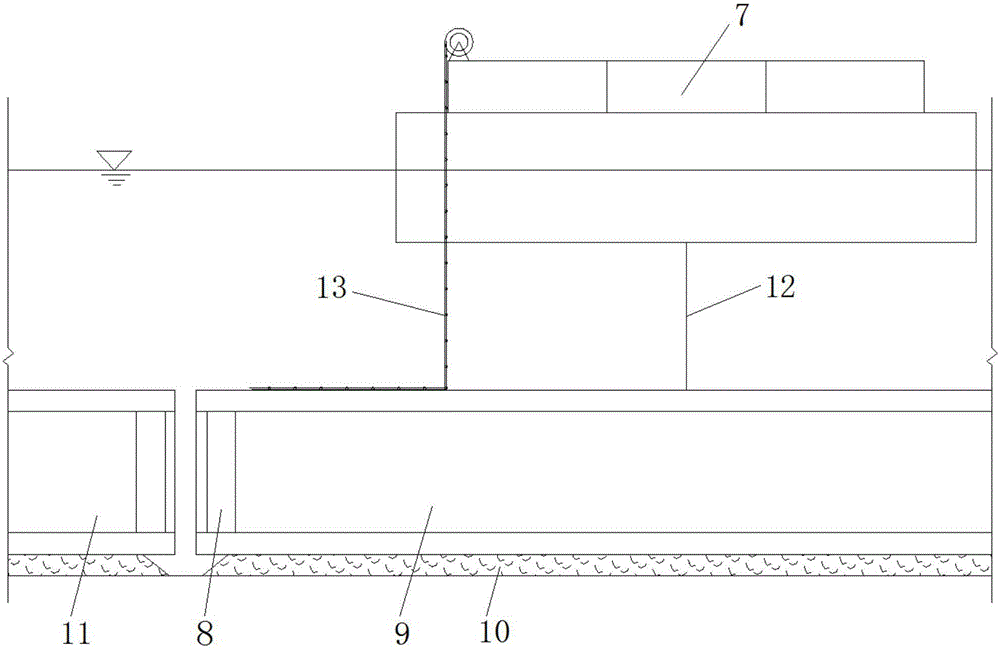

[0023] The overall construction idea of the pipe joints of the immersed tunnel is introduced as follows. The dismantling of the pipe joints adopts the overall floating construction method, which can completely float the pipe joints from the seabed and haul them to the designated area. The floating of the pipe joints forms a closed space by closing the pipe joints of the tunnel, thereby generating buoyancy. After 0.1-0.3m, fix it with the square barge. The immersed tube is dragged to the designated location by tugboat, and then the pipe joint is lowered to the designated area by square barge lifting equipment.

[0024] The method for removing pipe joints of immersed tube tunnels of the present invention includes the steps of installing a steel sealing door, removing the end thrust section and removing the tunnel pipe joints.

[0025] The step of installing the steel seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com