Construction method for dismantling large-span pre-stressed cast-in-place box girder

A construction method and prestressing technology, which is applied in bridges, bridge materials, bridge maintenance, etc., can solve problems such as high risk, complex stress in the secondary system of the structure, and heavy weight of cutting blocks, so as to reduce potential safety hazards and ensure safety. Quick demolition, convenient and quick construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

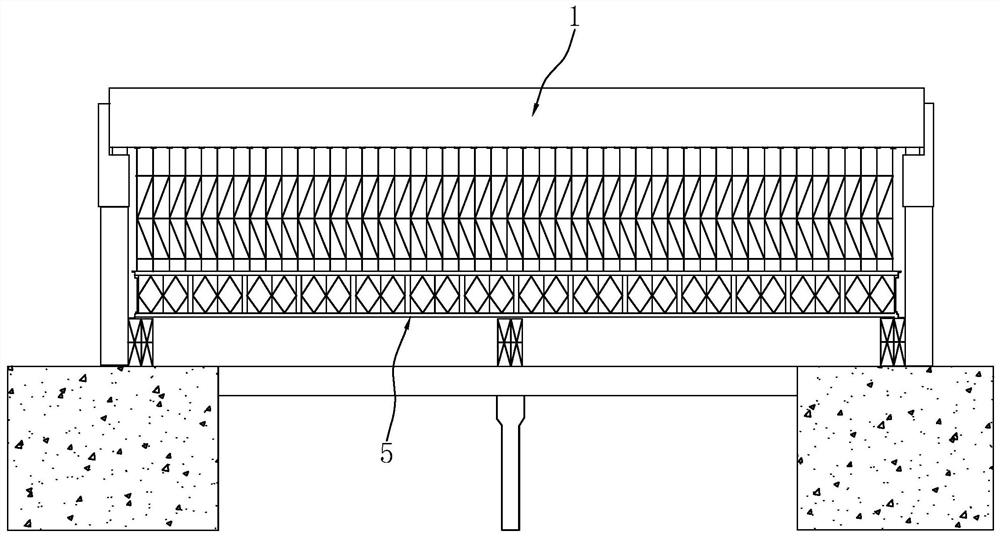

[0043] The following is attached Figure 1-9 The application is described in further detail.

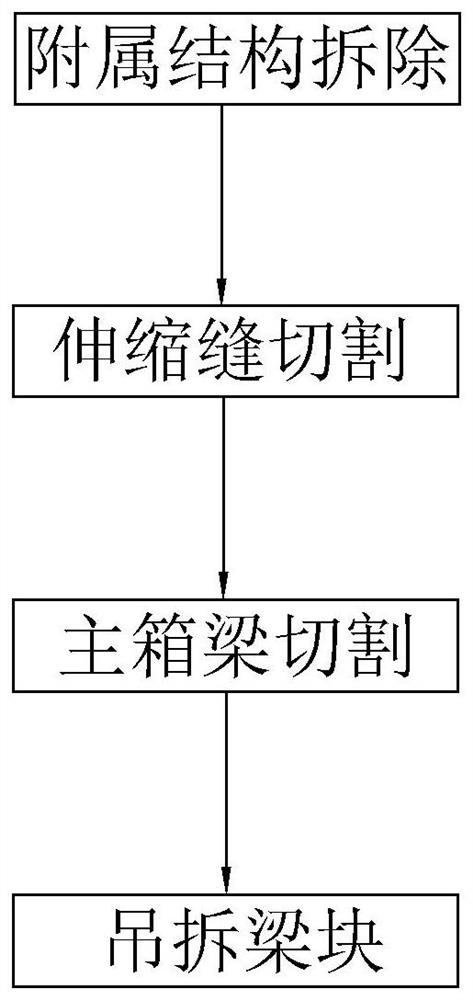

[0044] refer to figure 1 and figure 2 , for the embodiment of the present application discloses a construction method for demolition of long-span prestressed cast-in-place box girders, comprising the following steps:

[0045] S1. Construction preparation:

[0046] 1. Plan the site, designate the crushing area, and set up safe passages;

[0047] 2. For safe construction, do a good job of safety warnings, instructions and signs according to the requirements of double standards;

[0048] 3. River water is used for construction water;

[0049] 4. According to the power consumption of mechanical equipment, make preparations for power-on;

[0050] 5. Plan, prepare and try out construction machinery, construction materials and construction tools in advance;

[0051] 6. Conduct construction safety education for staff and provide detailed technical disclosure;

[0052] 7. Stack truc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com