Dismantling method for concrete waist beam

A concrete and waist beam technology, applied in excavation, construction, infrastructure engineering, etc., can solve the problems of delayed construction period, high risk, long construction period, etc., and achieve the effect of saving construction cost, improving construction safety, and ensuring construction safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

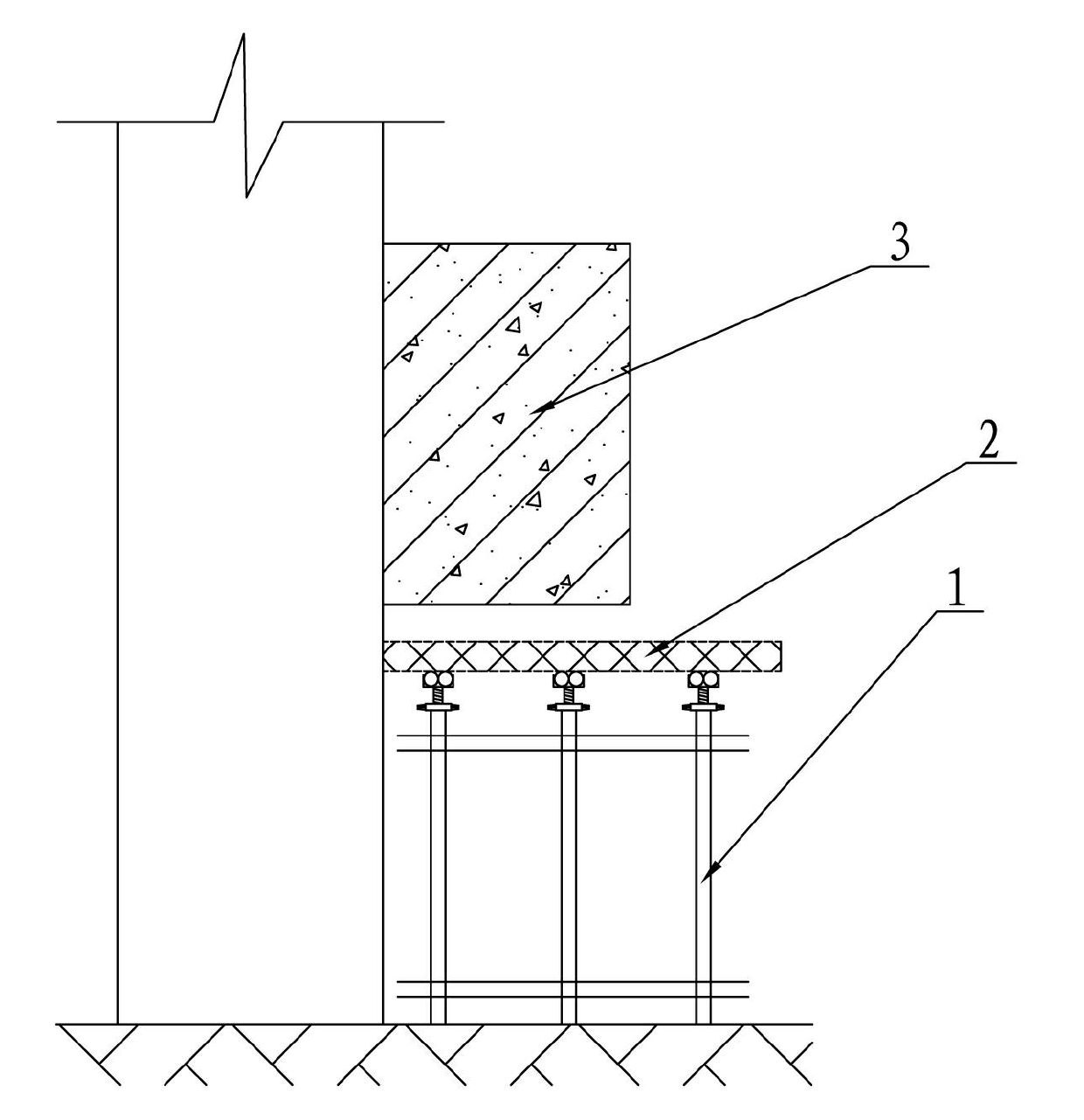

[0020] refer to Figure 1 ~ Figure 4 , the present invention is a method for dismantling a concrete lumbar beam, characterized in that it comprises the following steps:

[0021] 1) Set up a support frame below the waist beam 3 and / or install a suspension device above the waist beam 3;

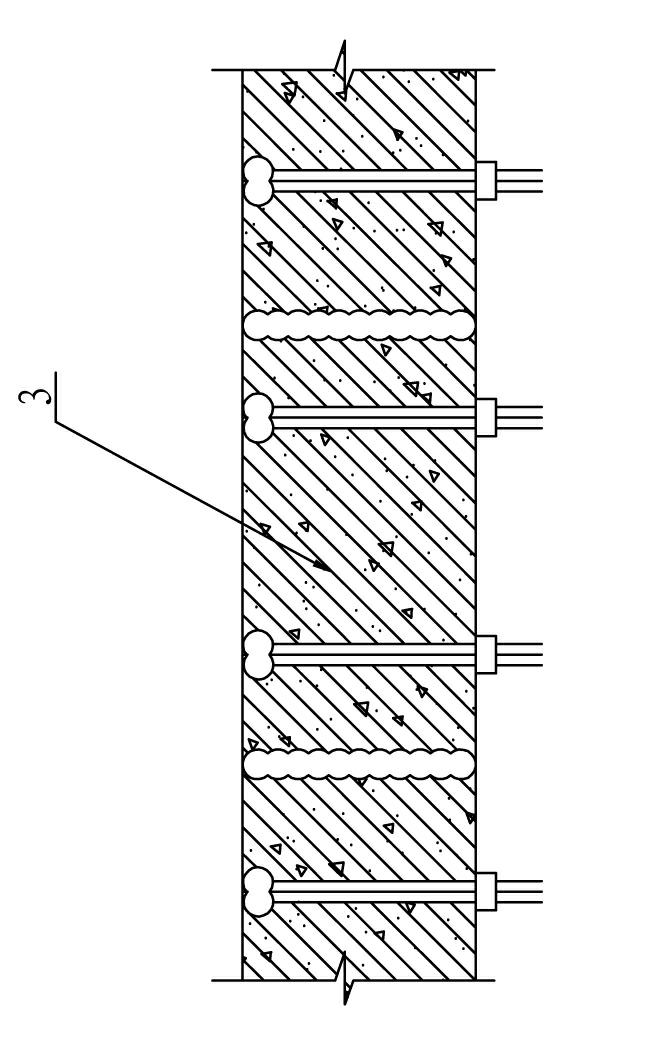

[0022] 2) Disconnect the waist beam 3 into several sections along the length direction where the waist beam 3 is located;

[0023] 3) Chisel a groove 4 on the disconnected waist beam segment;

[0024] 4) Put the jack 5 in the groove 4, pressurize and push through the jack, so that the waist beam segment is separated from the foundation pit enclosure structure;

[0025] 5) Lift out the waist beam segment by a crane.

[0026] The removal method of this concrete waist beam is to cut the waist beam 3 into several sections, and then by chiseling grooves 4 in each section, put jacks 5 in the grooves 4 to open the sections of the waist beam to align the waist beam 3 The support frame and / or the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com