Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61 results about "Mould Element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Viscoelastic material

InactiveUS20060004193A1Increase chain lengthSimplify discussionCapsule deliveryHigh humidityHard Capsule

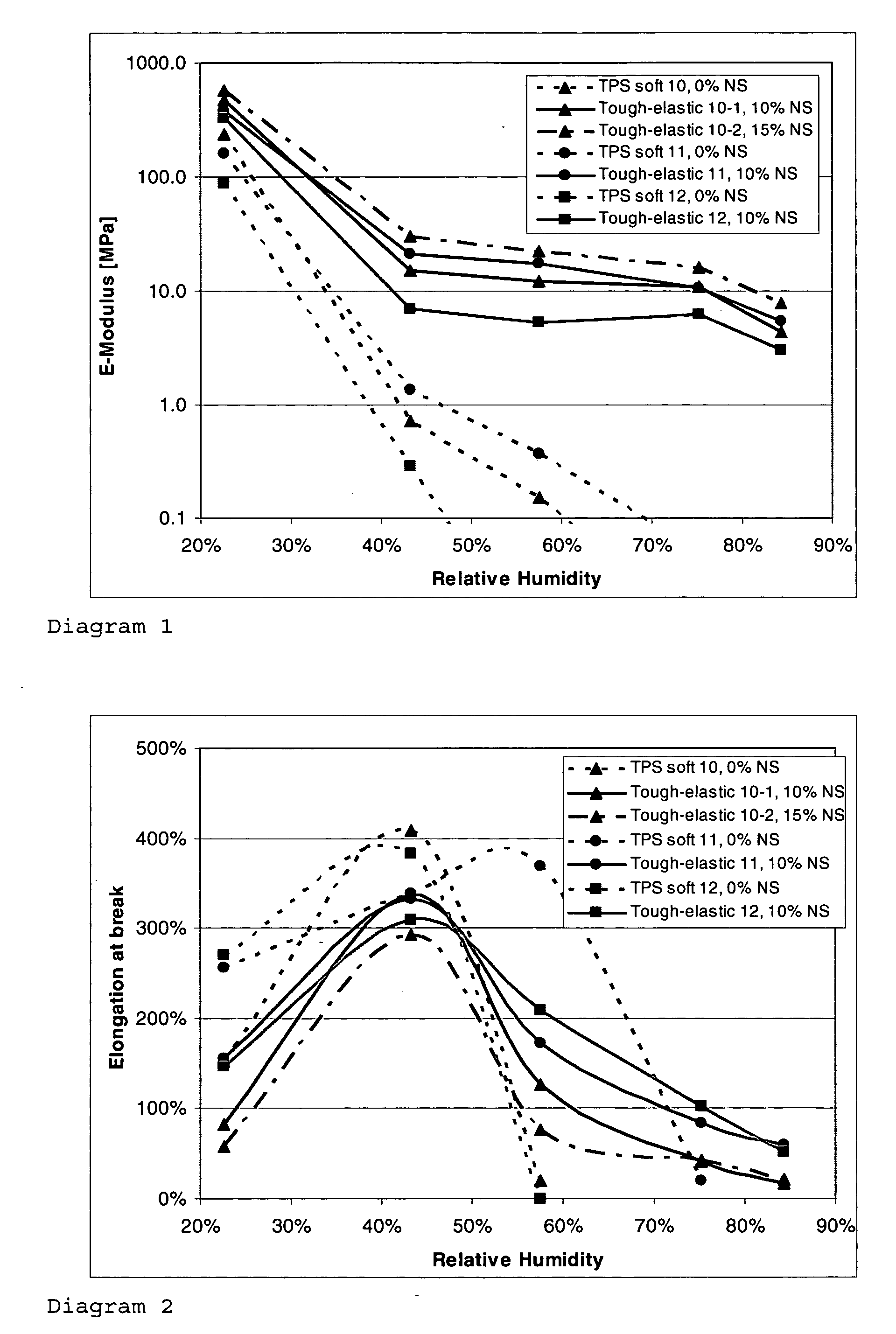

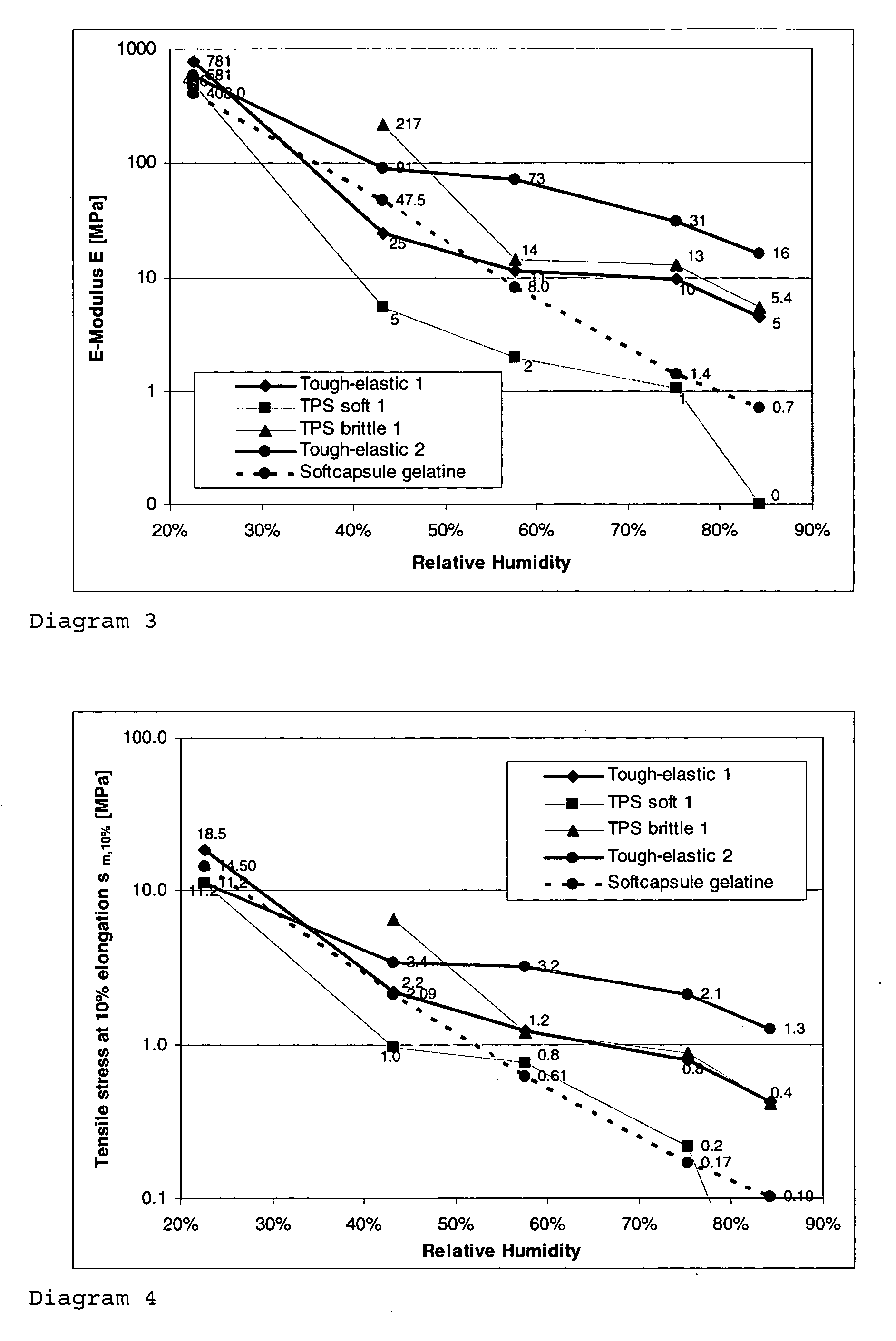

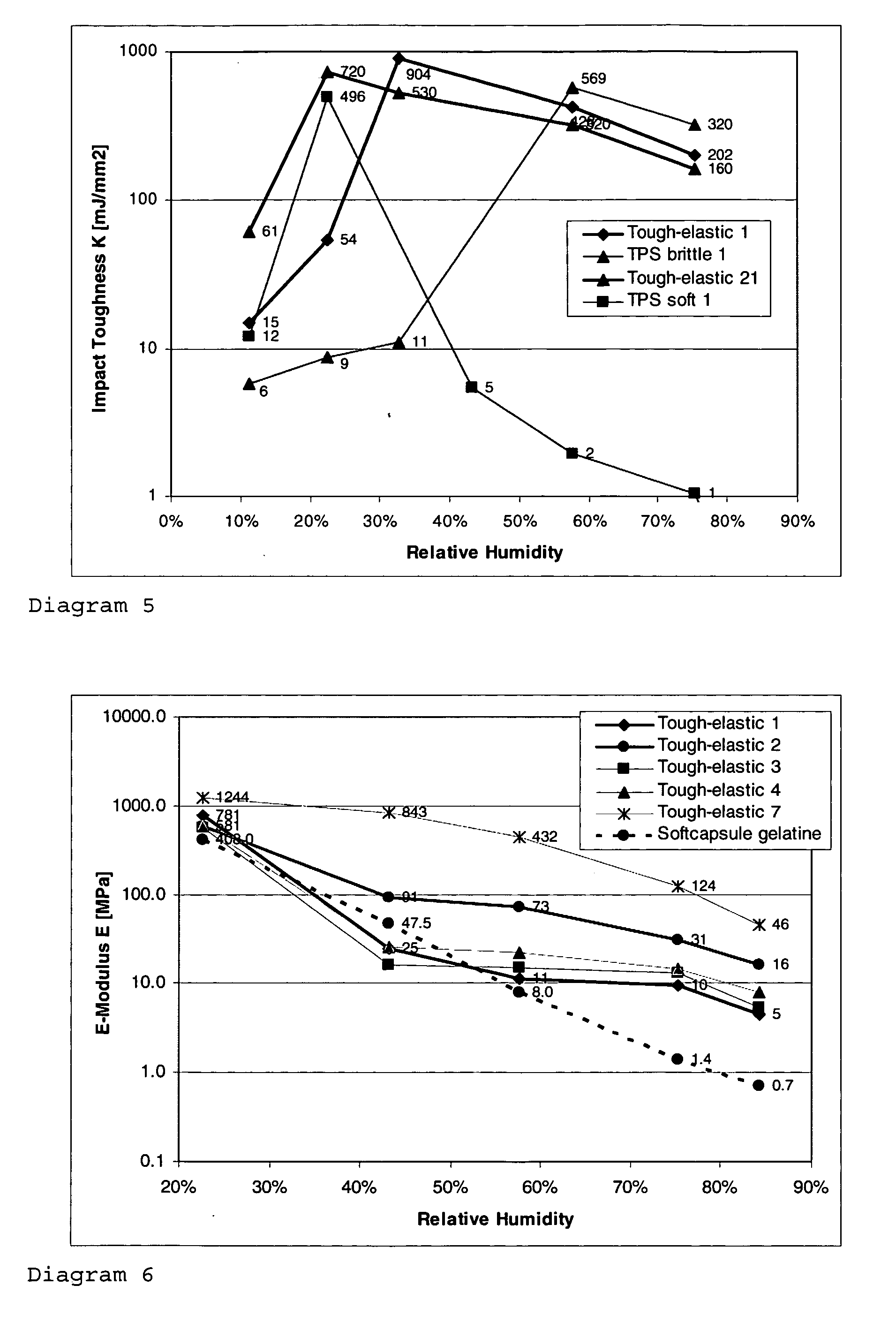

The invention relates to a tough-elastic material based on starch, which on the one hand has high impact toughness at low humidities, and on the other hand still has a high modulus of elasticity at high humidities and has a high elongation capacity in a broad range of humidities and on account of its property profile is suited to use as moulded elements such as for example for foils, films, fibres, injection-moulded articles, in particular as edible film and for the packaging of active ingredients, chemicals, aromas and perfumes as well as high-quality substitution of gelatine in the area of soft and hard capsules. The tough-elastic material can be obtained transparent and adjusted such that it dissolves on swelling in water or respectively disintegrates or remains intact.

Owner:INNOGEL AG

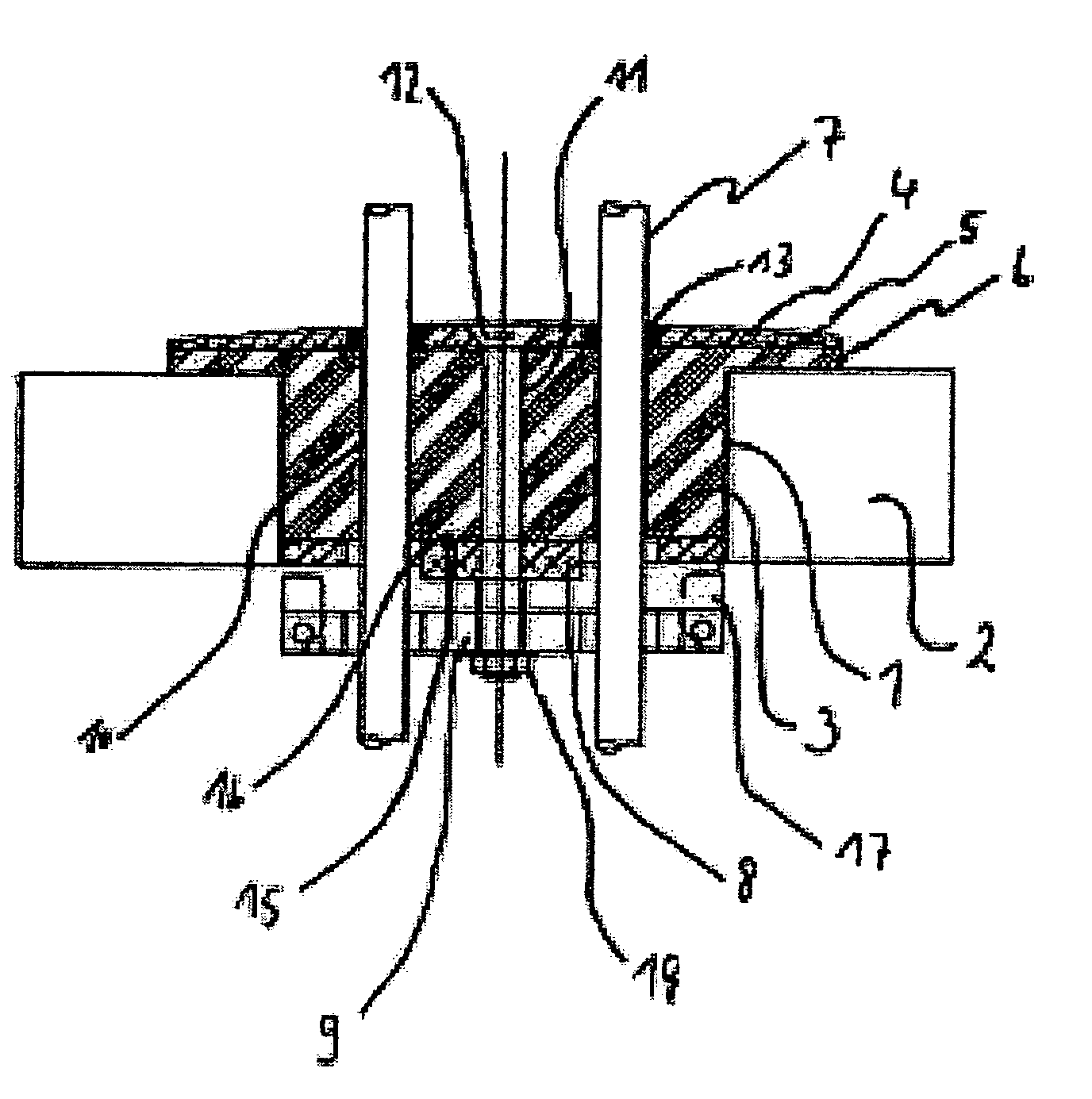

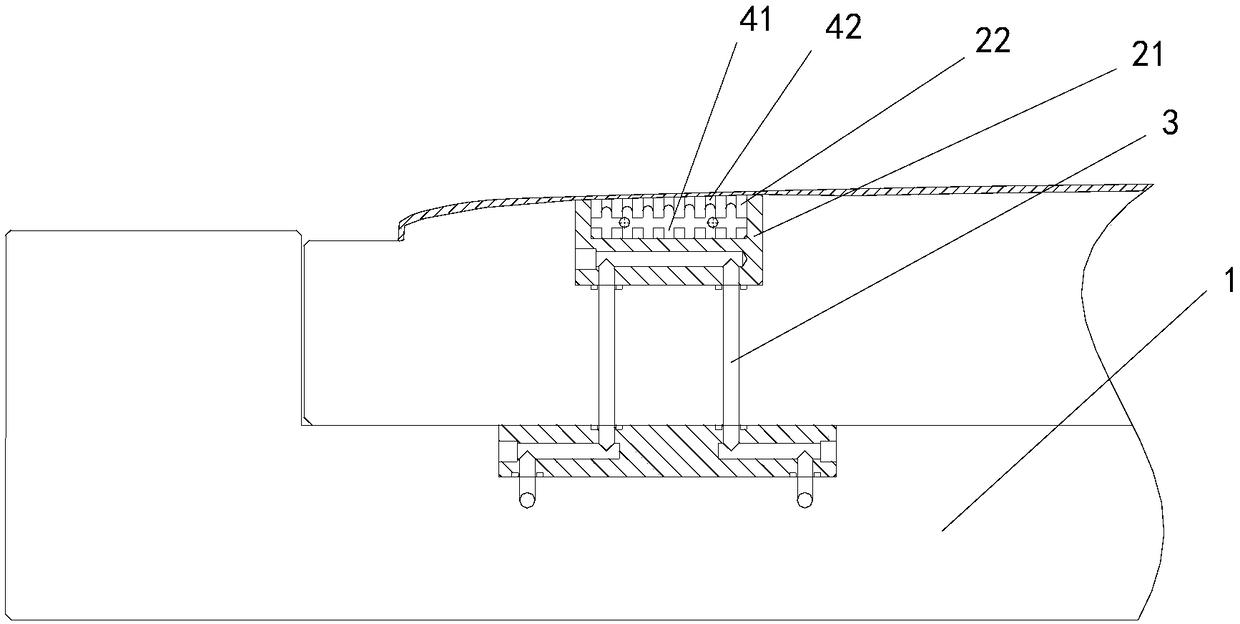

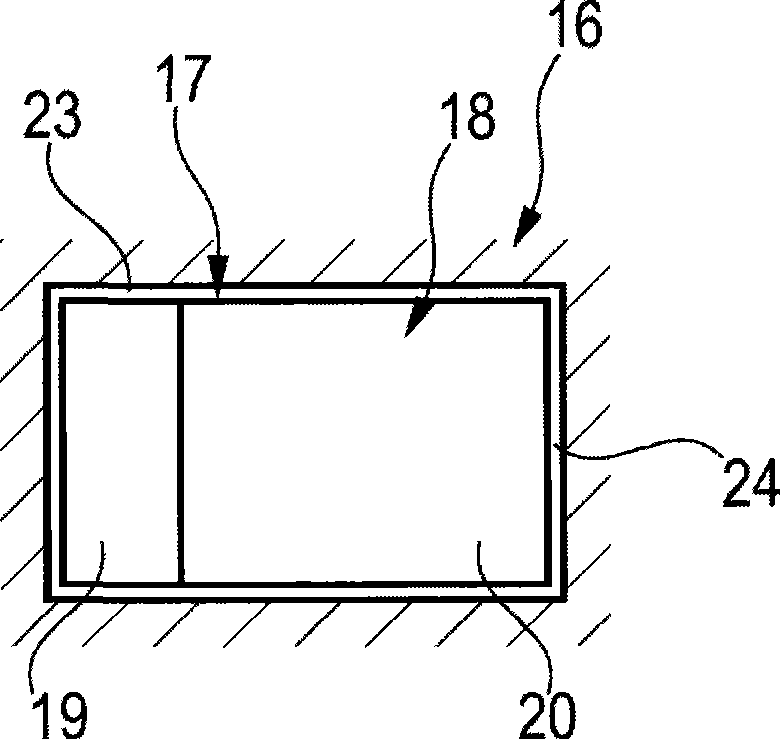

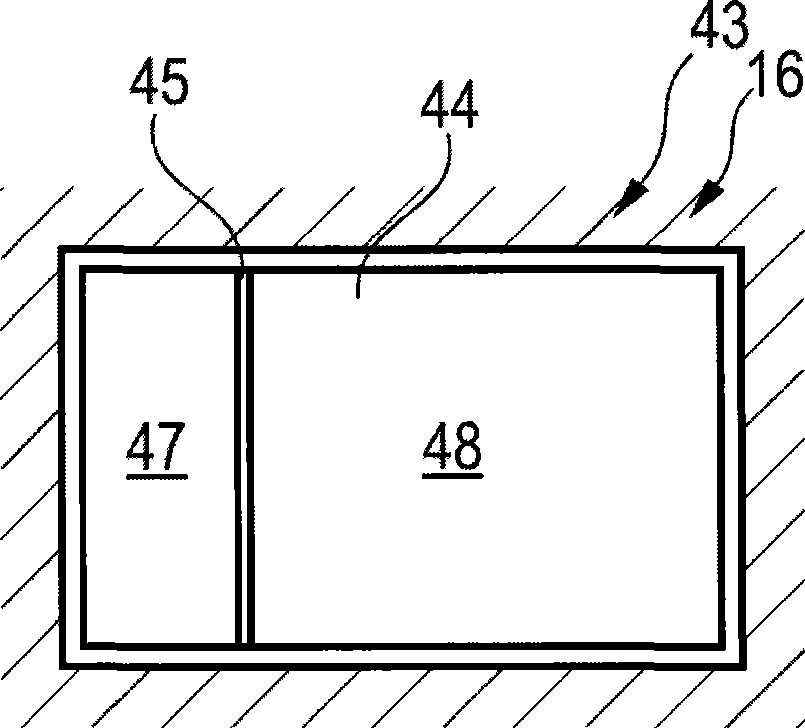

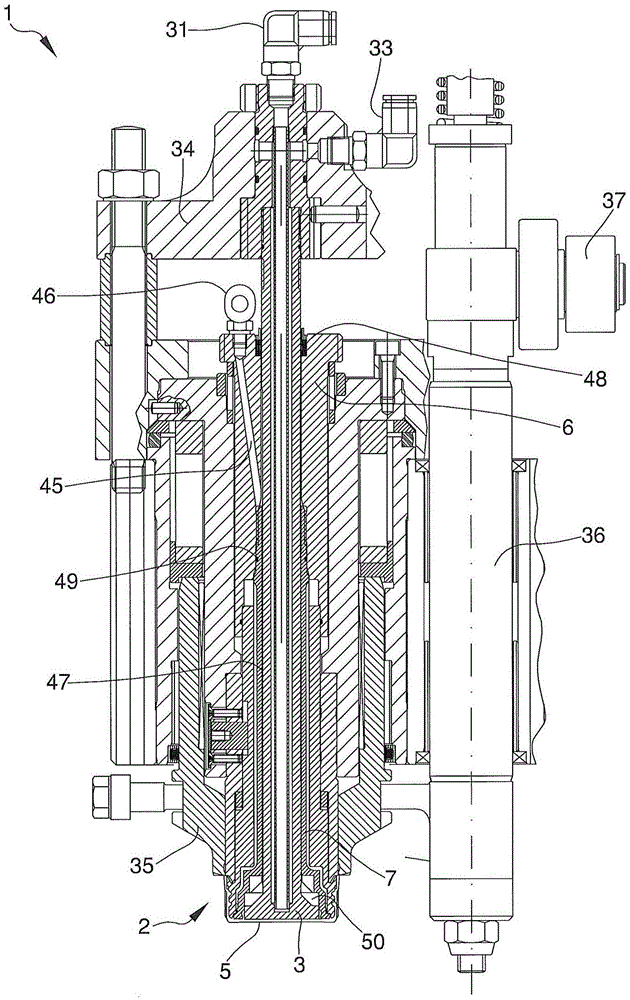

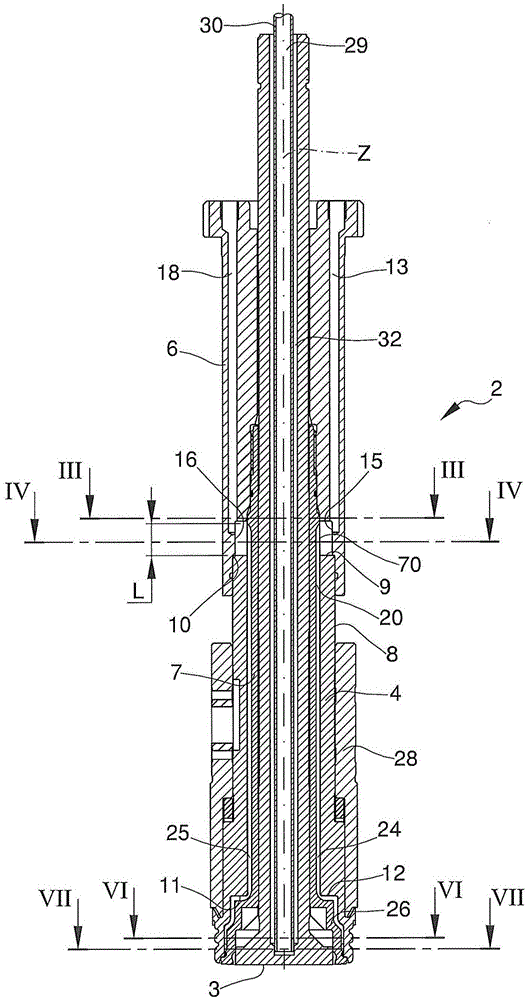

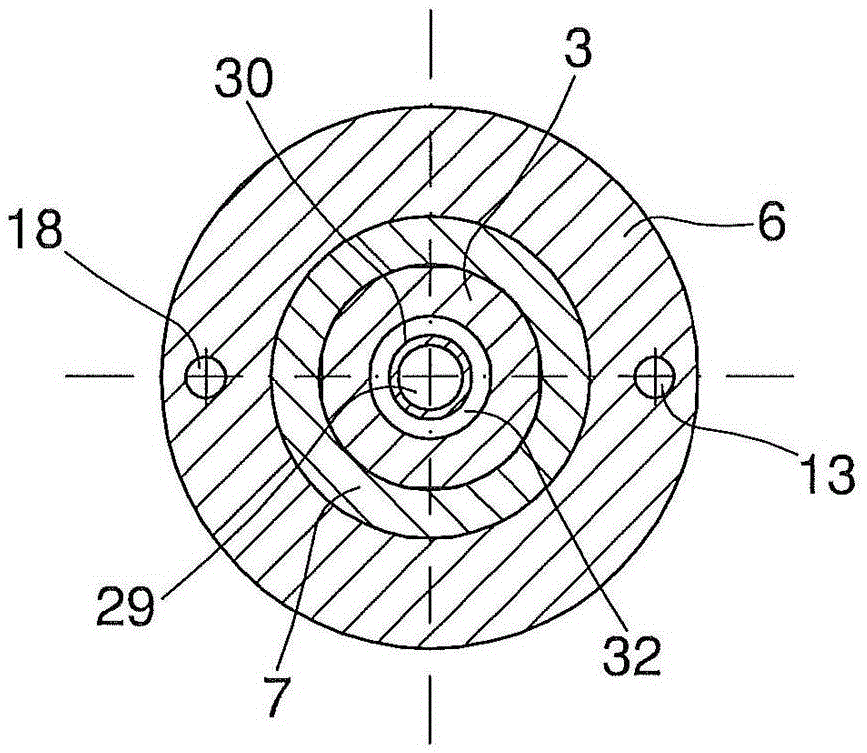

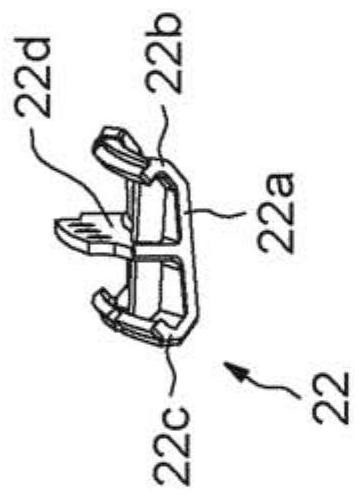

Fitting for a liquid-tight cable leadthrough

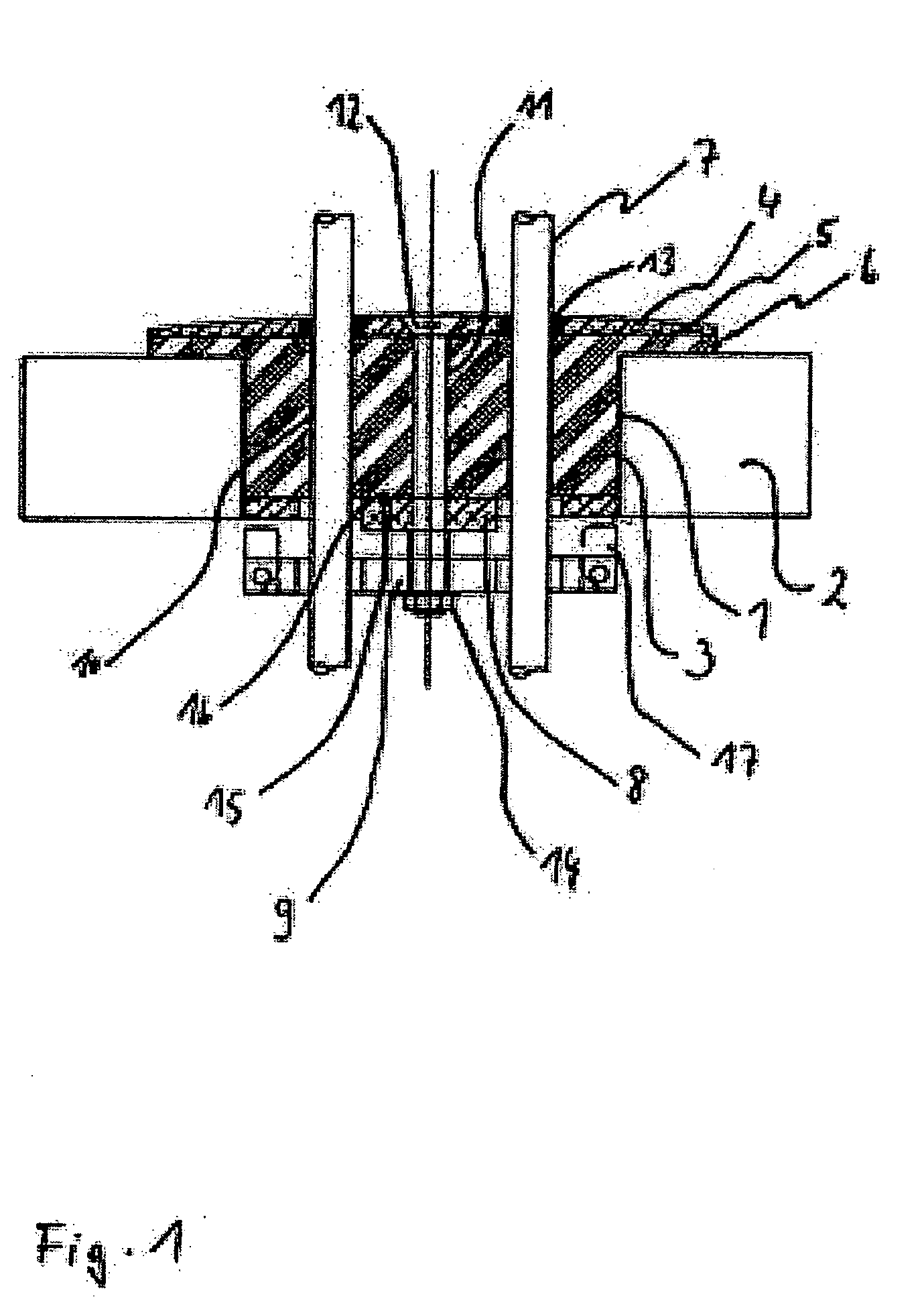

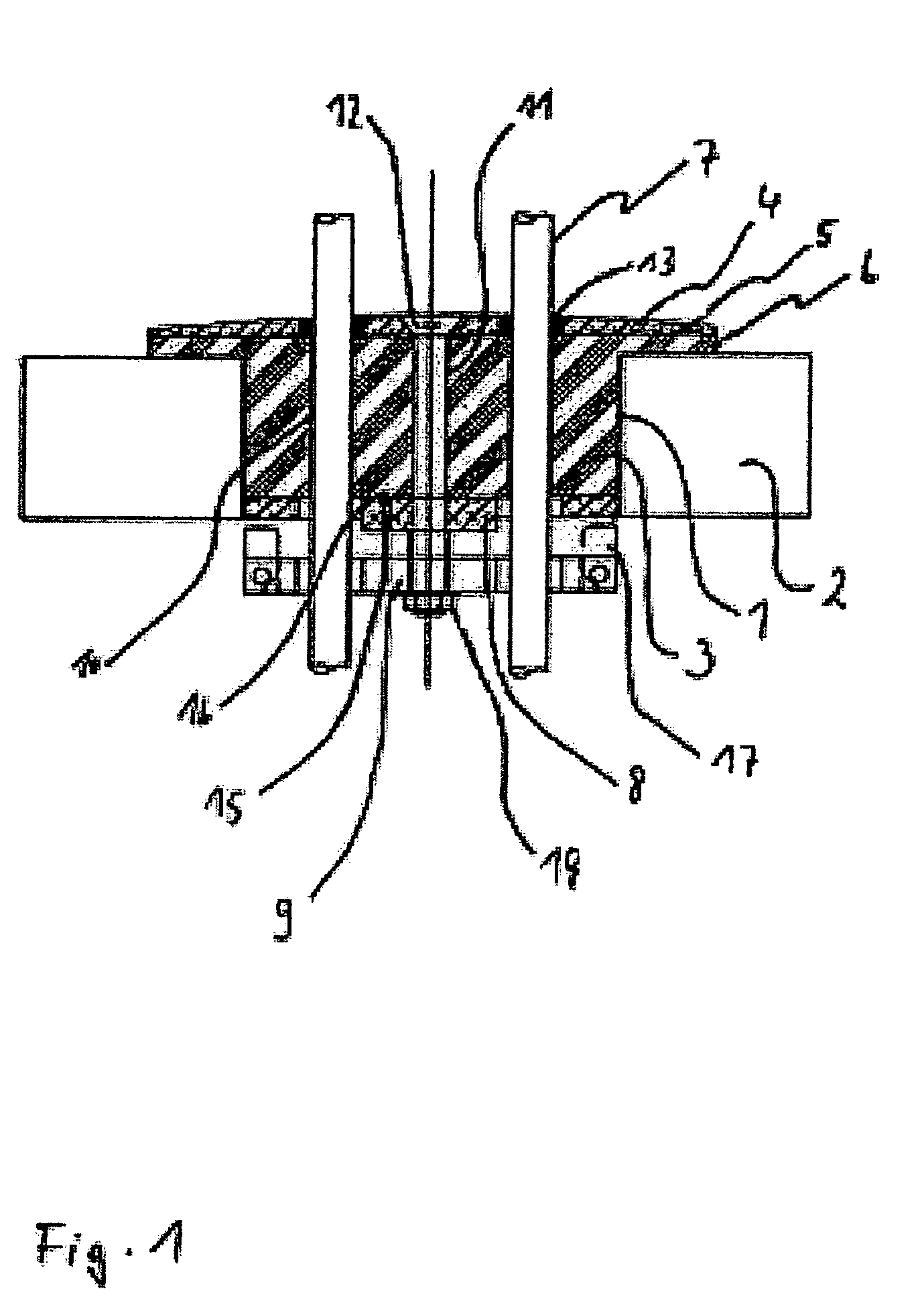

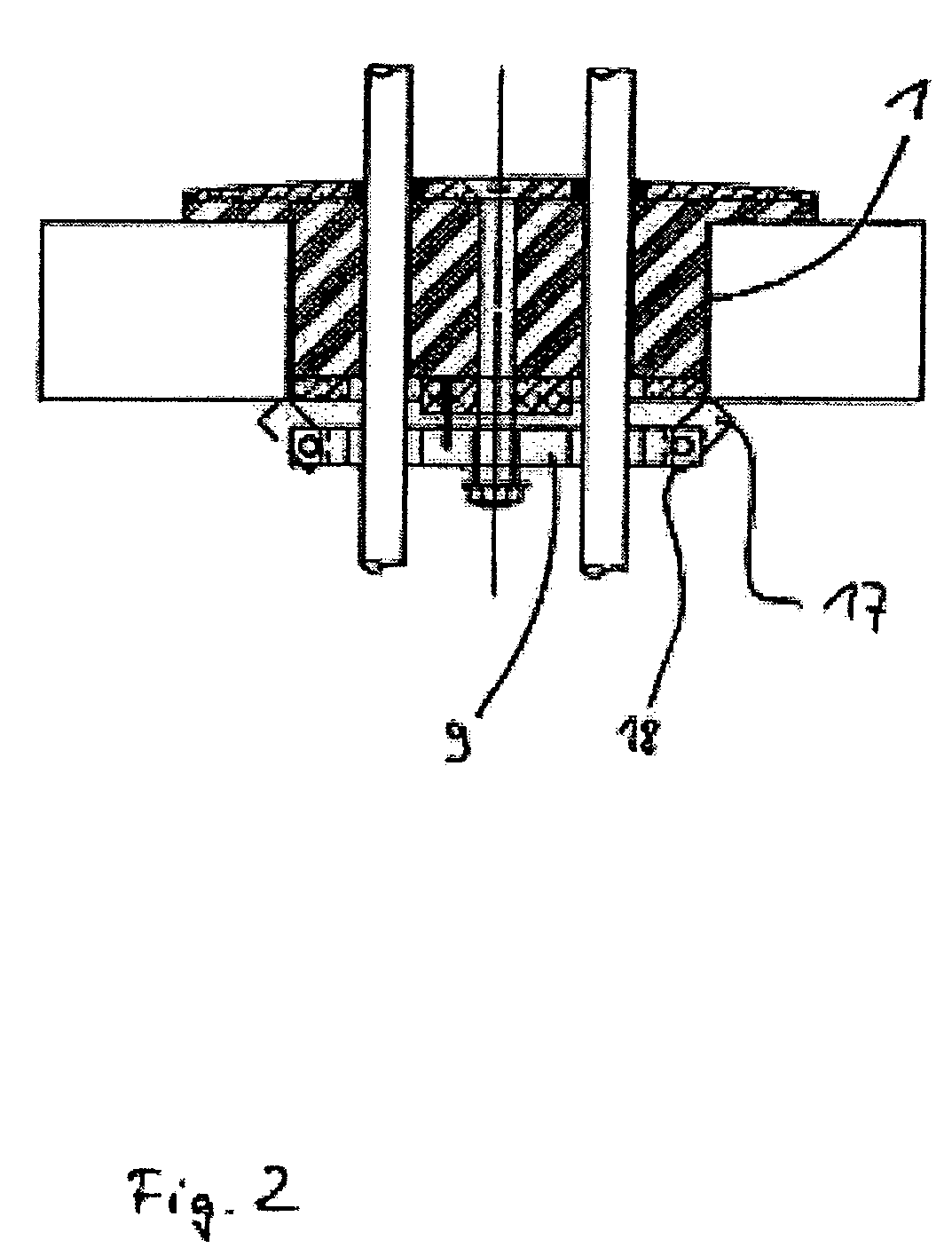

ActiveUS20060063418A1Easy to installImprove sealingContact members penetrating/cutting insulation/cable strandsMulti-purpose toolsEngineeringMould Element

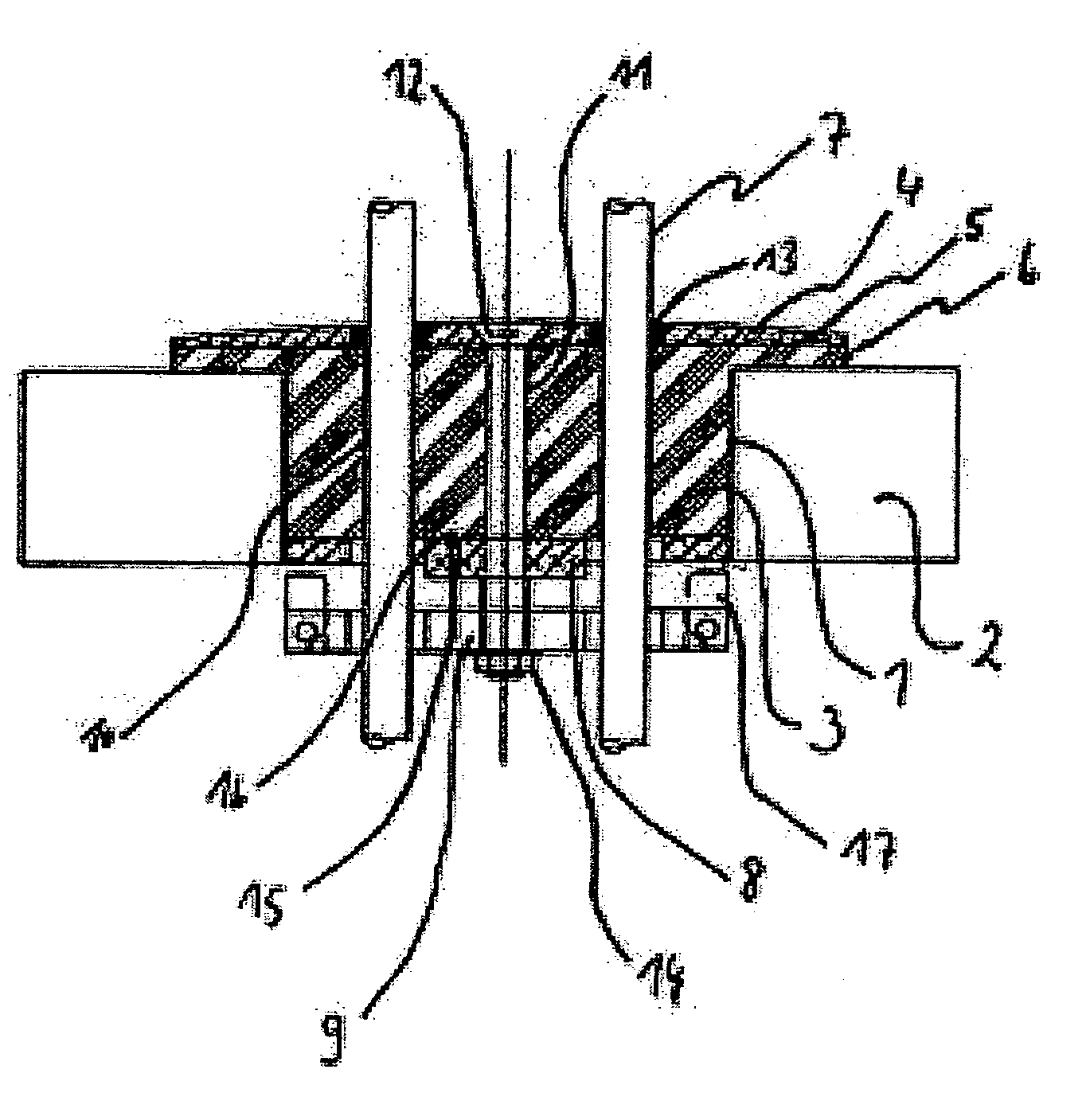

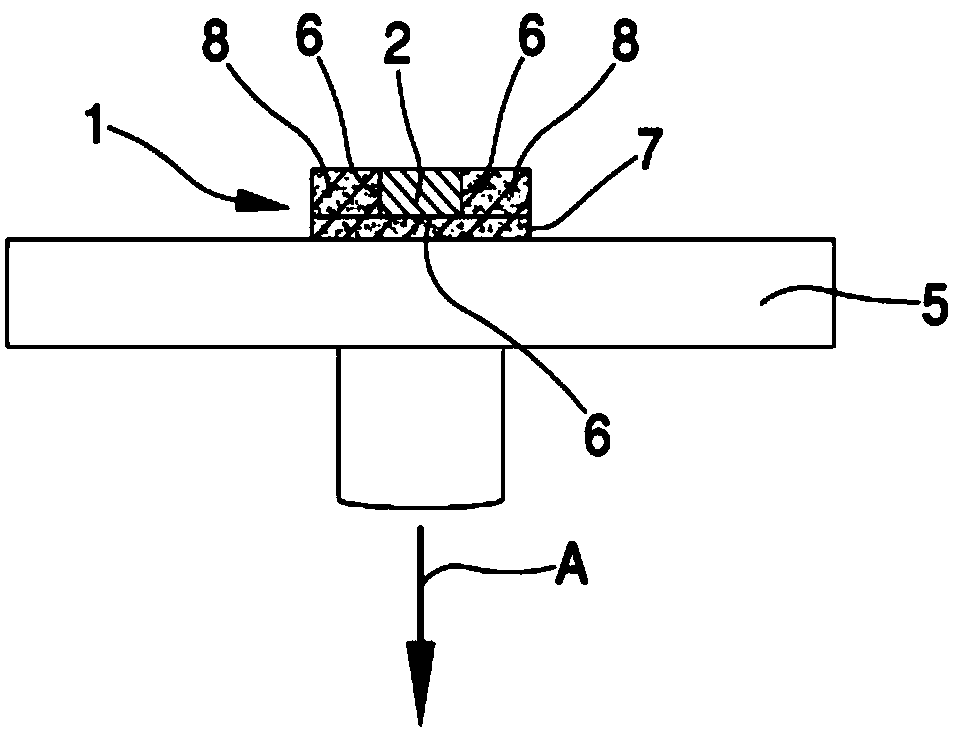

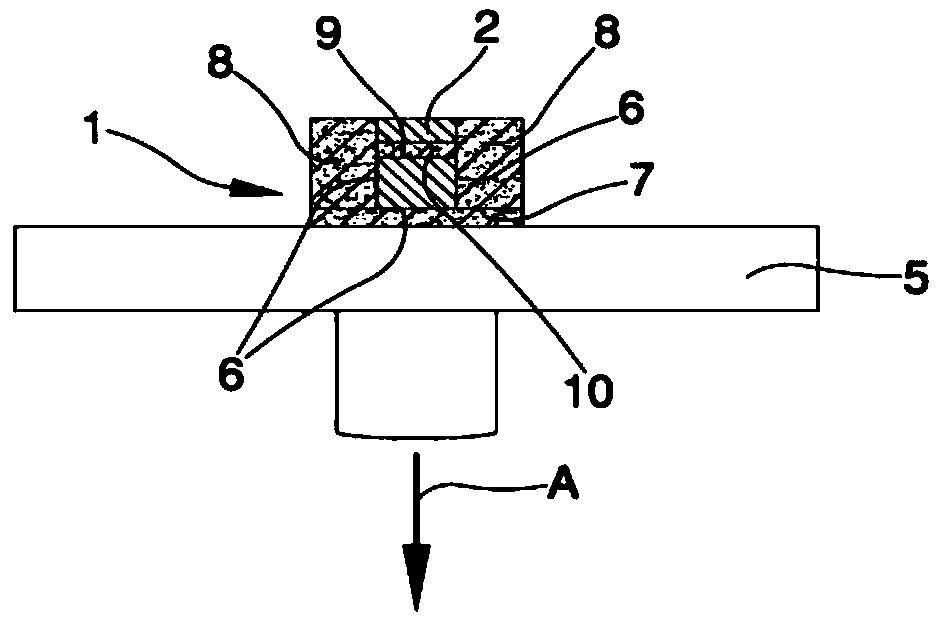

The invention relates to a fitting for a liquid-tight cable leadthrough in an opening (1) in a solid surface (2), which solid surface can be gripped from the back, wherein said fitting comprises an upper boundary plate (4) that covers the opening (1), an elastic moulded element (3) that flatly contacts and is connected to the upper boundary plate (4) and can be at least partially inserted into the opening (1), a lower boundary plate (8) that can be lead through the opening (1), wherein the lower boundary plate flatly contacts and is connected to the elastic moulded element (3) on the opposite side of the elastic moulded element (3) referred to the upper boundary plate (4), a locking plate (9) that can be moved relative to the lower boundary plate (8) and is providable with at least two pivoted locking elements (17), wherein said locking elements are supported between pairs of mounting limbs (20) by element of a bolt (22) and can be pivoted between a position in which the locking plate (9) can be lead through the opening (1) and a stopping position which they enables a gripping from the back of the solid surface (2), at least one clamping element for adjusting the spacing between the upper boundary plate (4) and the locking plate (9) against forces generated during a deformation of the elastic moulded element, and opening (10) that extends through the locking plate (9), the boundary plates (4, 8) and the elastic moulded element (3) and serves for accommodating a cable (7) to be lead through the solid surface (2).

Owner:AIRBUS OPERATIONS GMBH

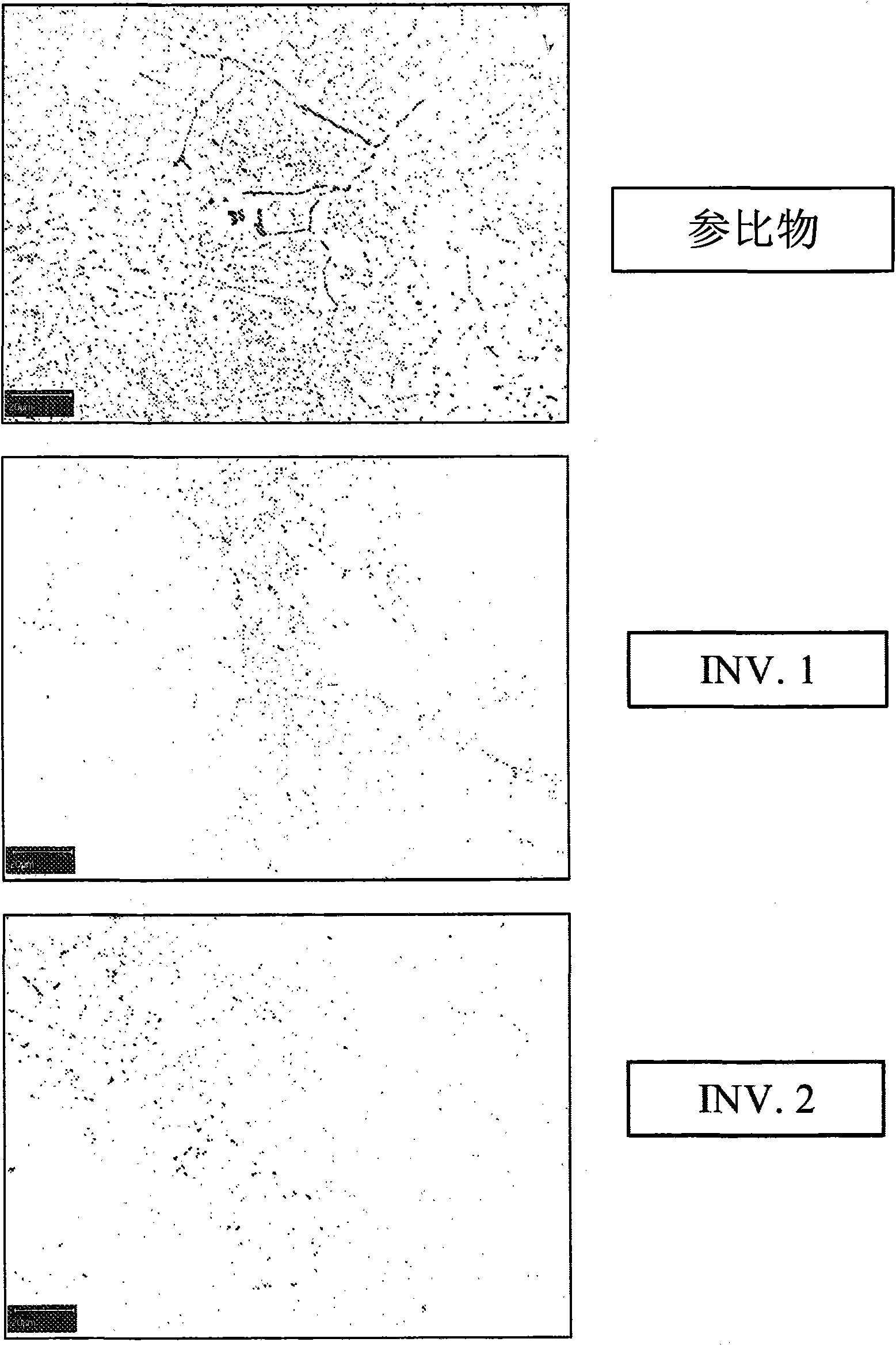

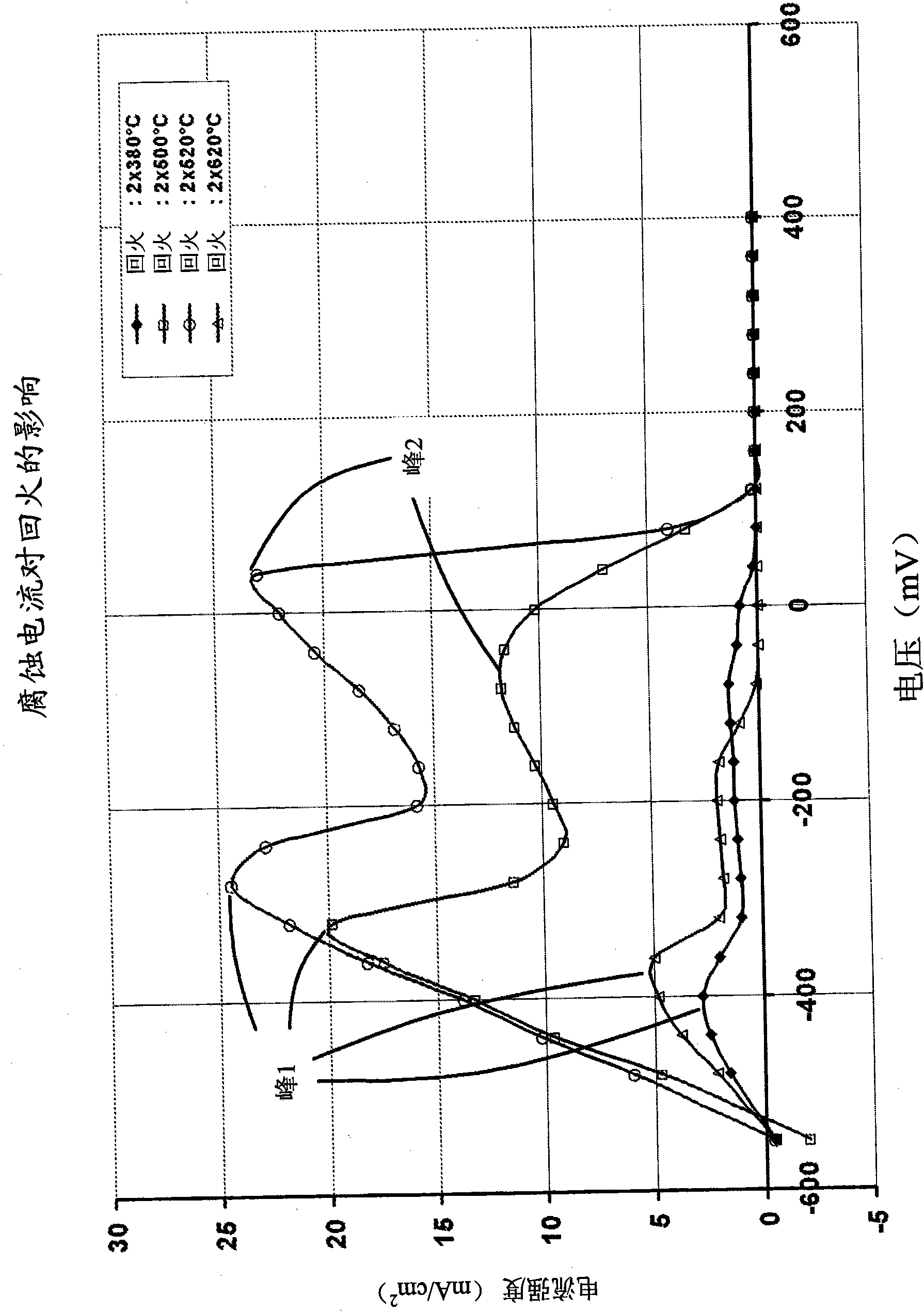

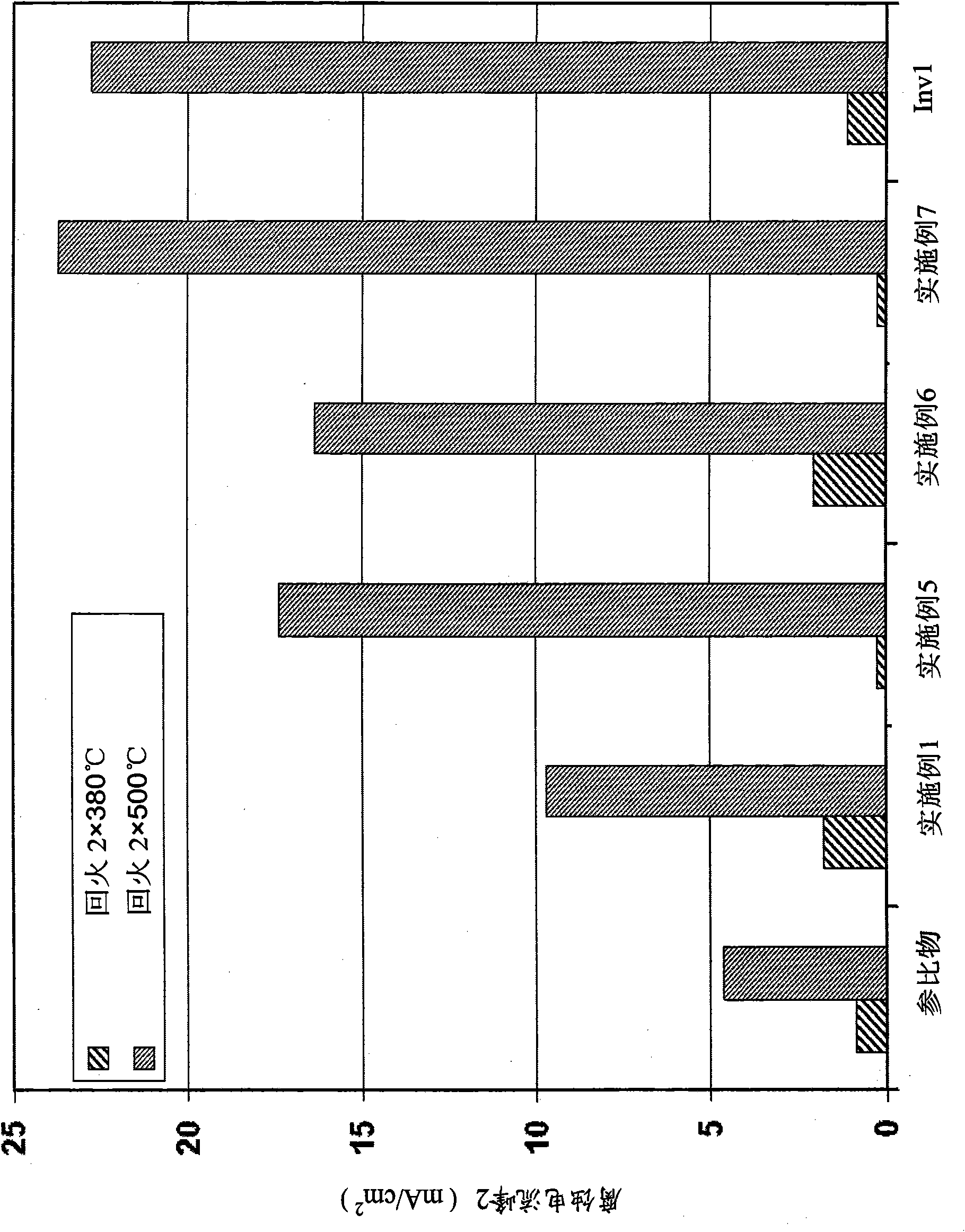

Martensitic stainless steel, method for making parts from said steel and parts thus made

InactiveCN101861407AReduce segregationLimit densityFurnace typesHeat treatment furnacesMetallurgyMartensitic stainless steel

The invention relates to a martensitic stainless steel characterised in that it comprises in weight percent: - 0.22% <= C <= 0.32% - 0.05% <= N <= 0.15%, with 0.33% <= C+N <= 0.43% - 10% <= Cr <= 12.4% - 0.10% <= V <= 0.40% - 0.10% <= Mo <= 1.0% - traces <= Ni <= 1.0% - traces <= Mn <= 1.0% - traces <= Si <= 1.0% - traces <= W <= 1.0% - traces <= Co <= 1.0% - traces <= Cu <= 1.0% - traces <= Ti <= 0.010% - traces <= Nb <= 0.050% - traces <= Al <= 0.050% - traces <= S <= 0.020% - traces <= O <= 0.0040% - traces <= P <= 0.03% - traces <= B <= 0.0050% - traces <= Ca <= 0.020% - traces <= Se <= 0.010% - traces <= La <= 0.040% - traces <= Ce <= 0.040%, the balance consisting of iron and impurities resulting from the production. The invention also relates to a method for producing a part made of such a steel and to the part thus obtained, as a mould element for the production of plastic articles.

Owner:AUBERT & DUVAL FR

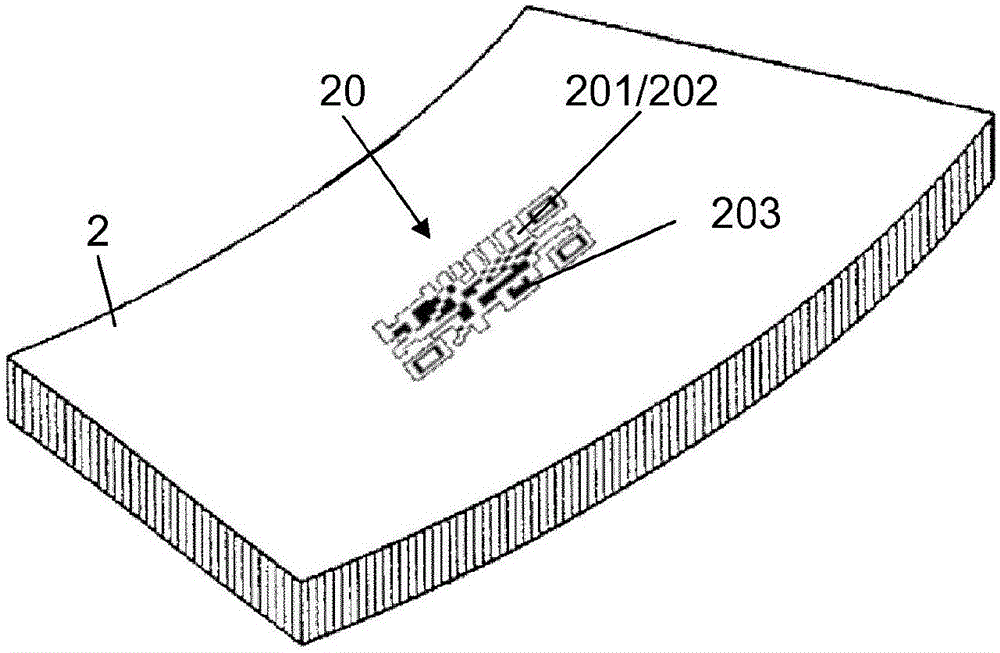

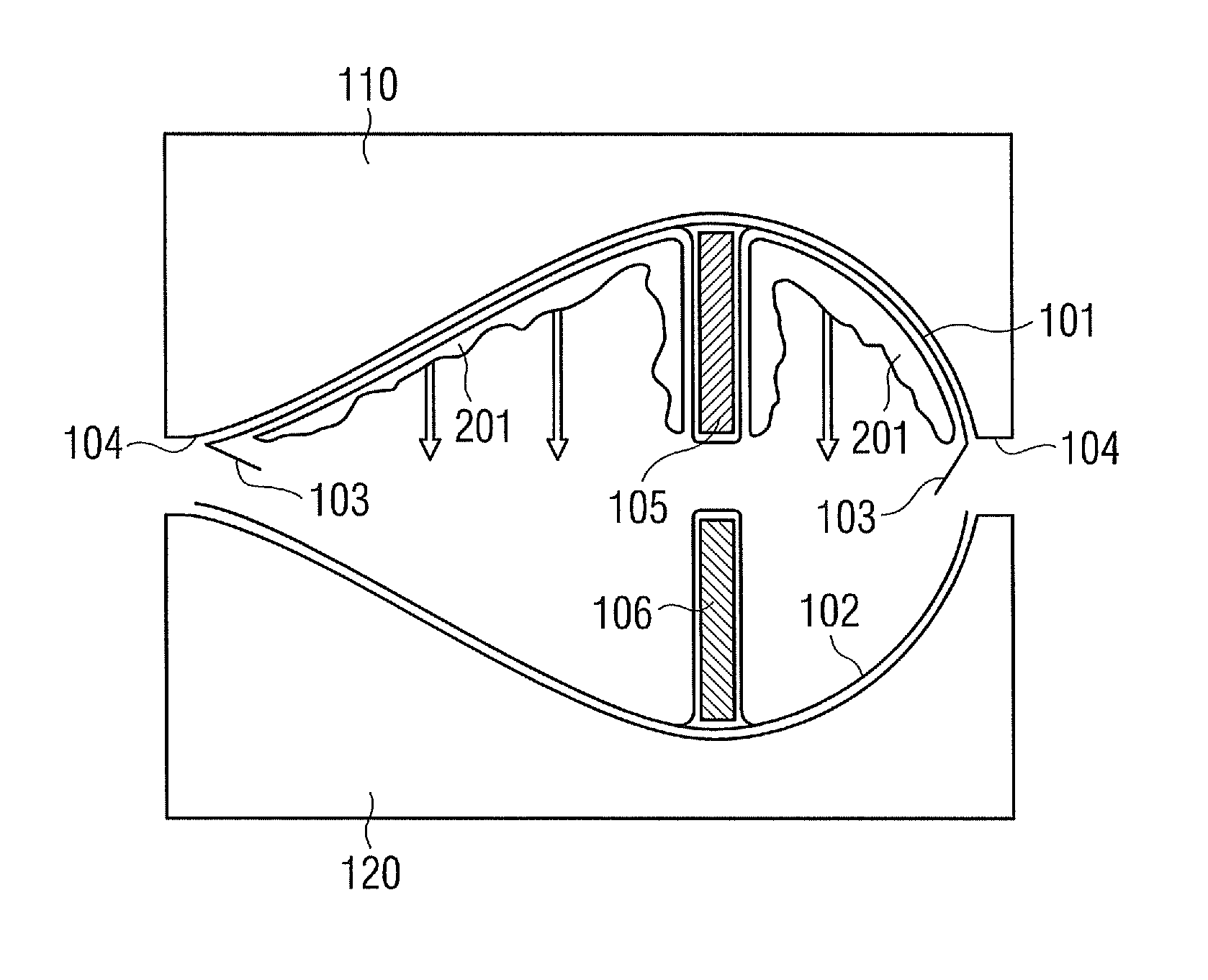

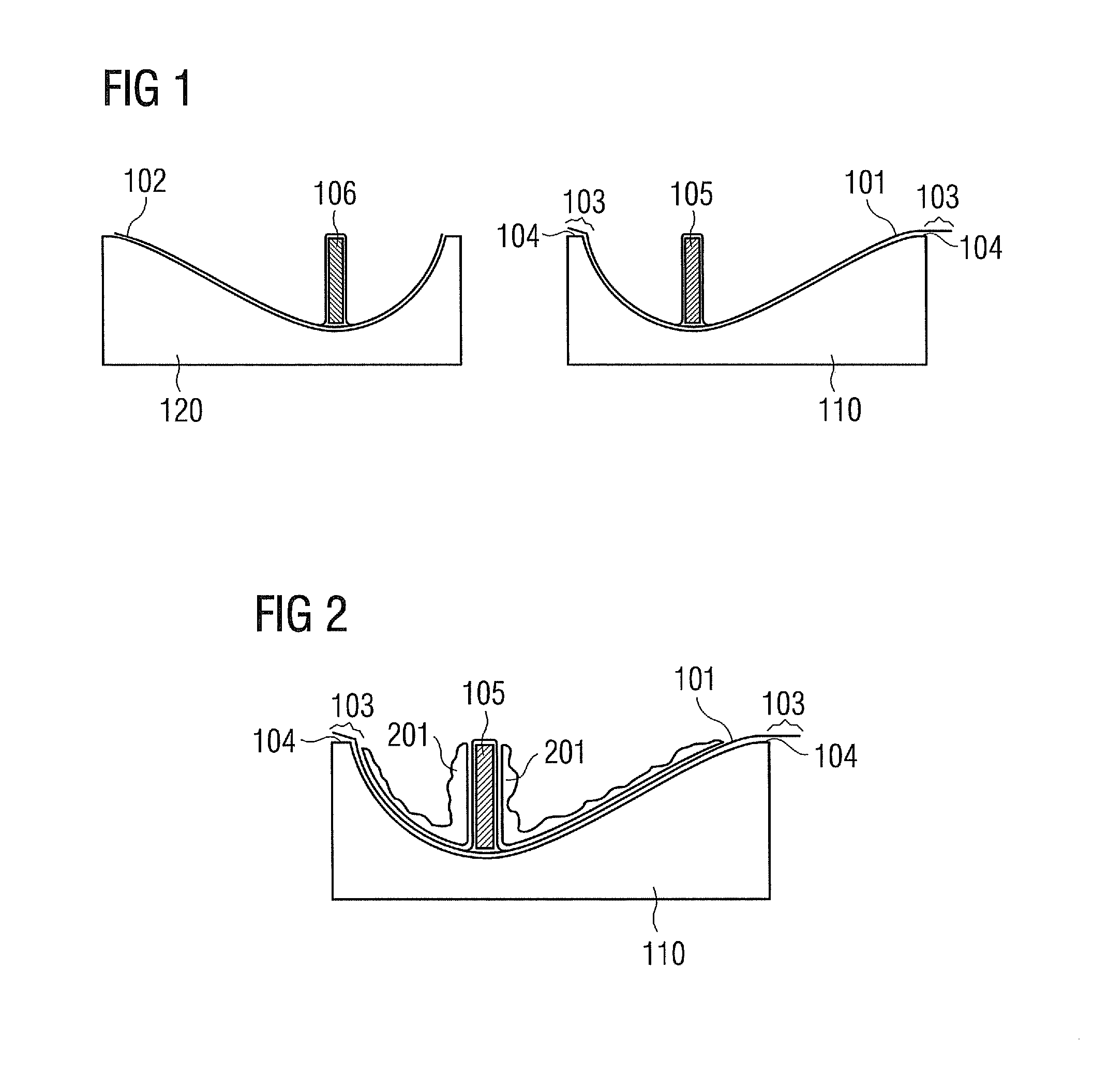

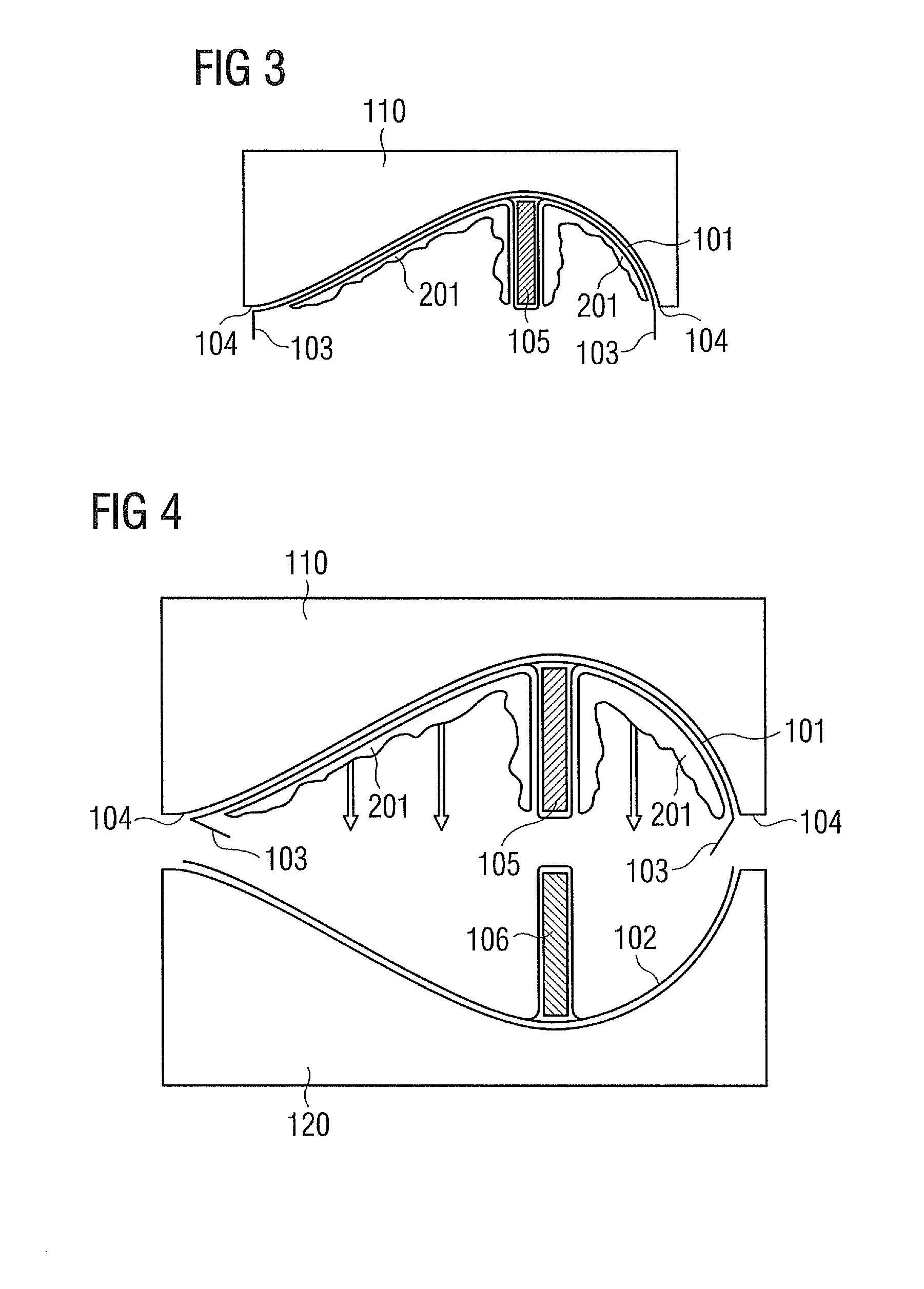

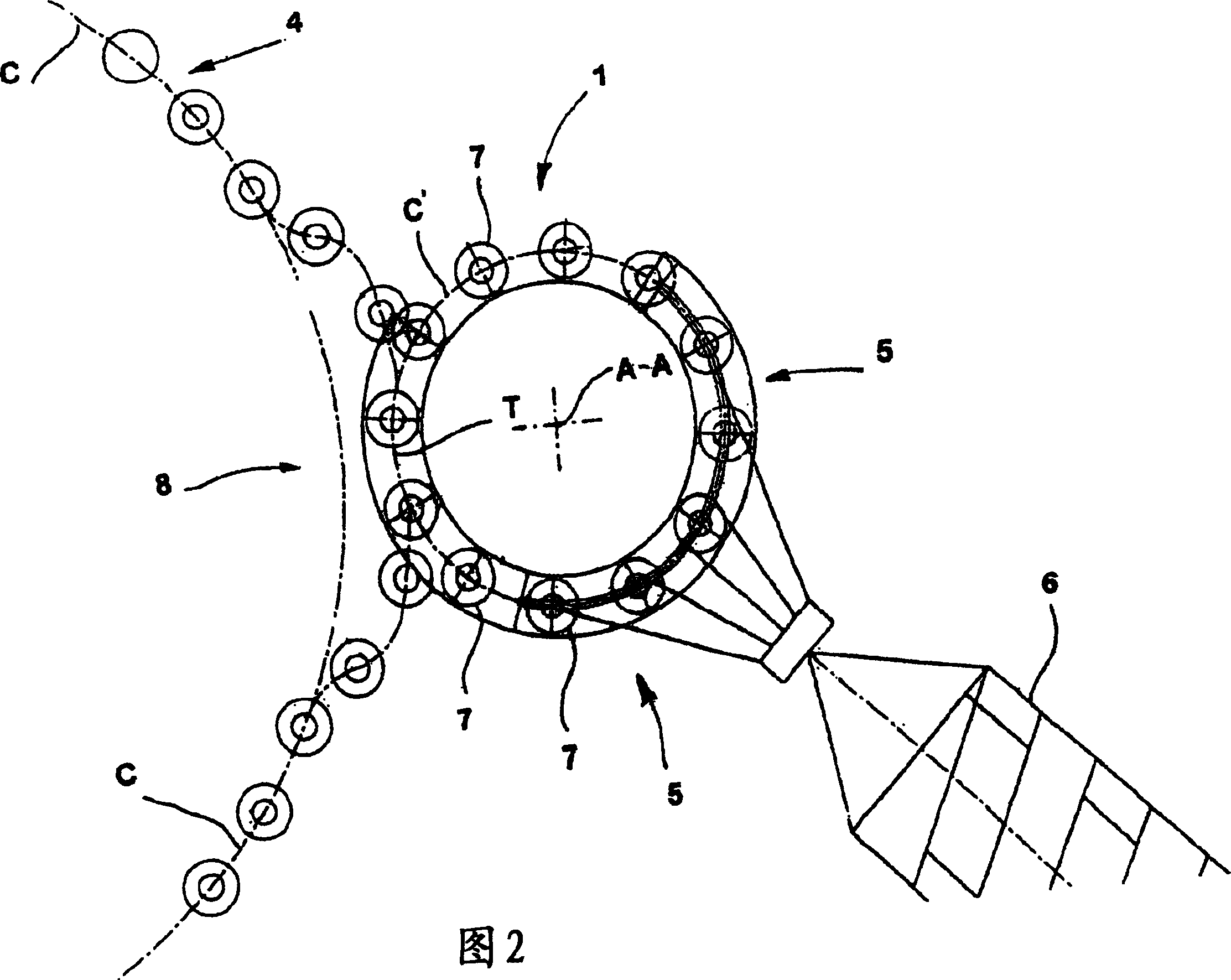

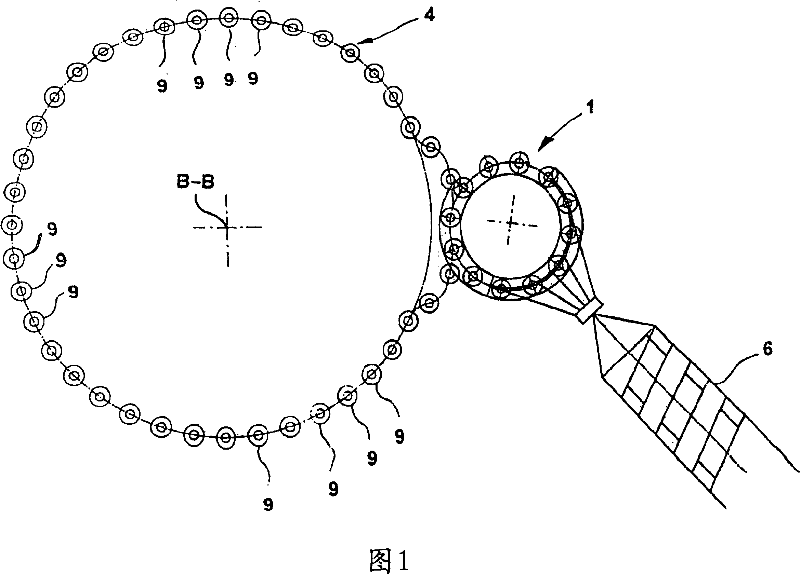

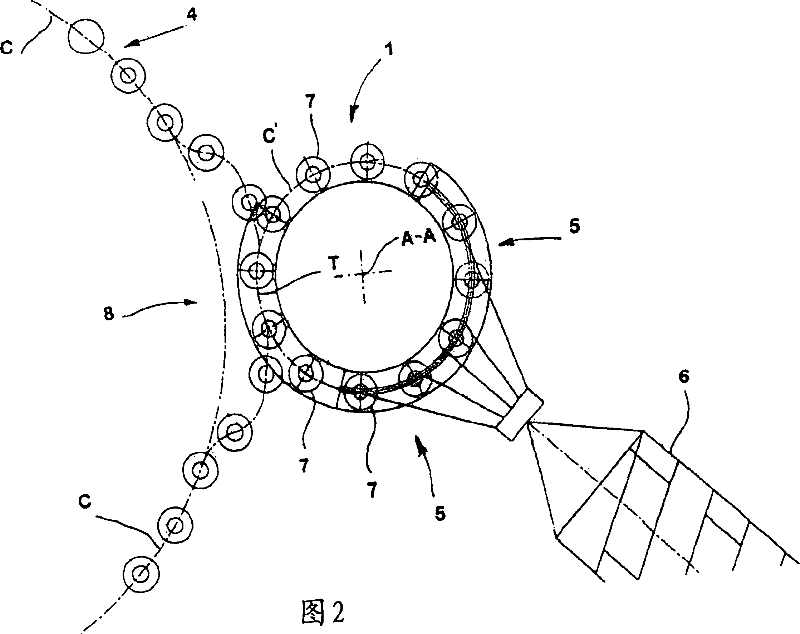

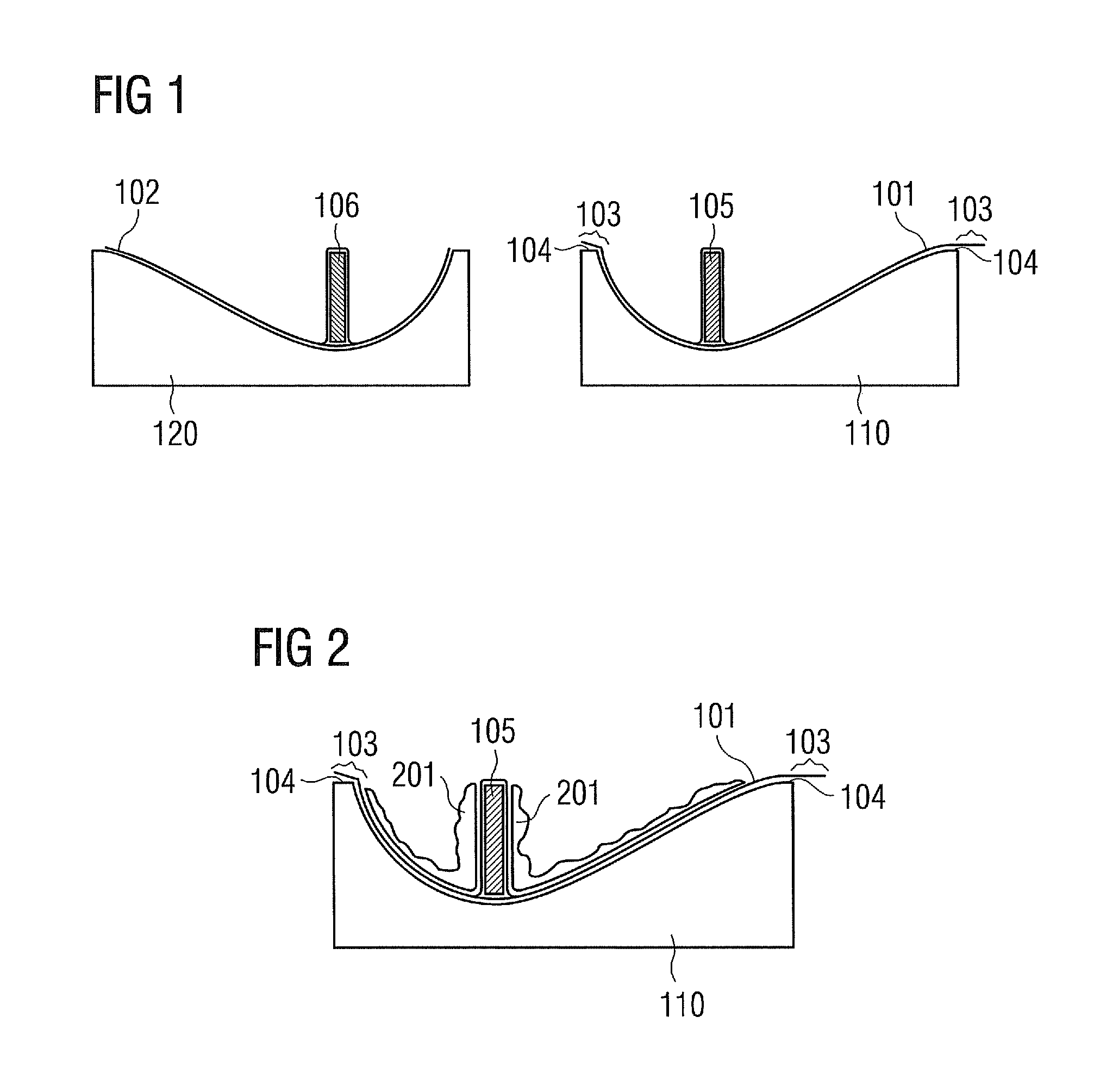

Mould element for a tyre mould comprising a mark

The invention relates to a mould element (2) for a tyre mould comprising a mark (20), said mould comprising a shell intended to mould the sidewall (10) of the tyre (1). The mould element (2) is characterised in that it takes the form of a removable insert intended to be mounted in a housing in the shell, and in that the mark (20) is intended to mould an encoded matrix symbol onto the tyre, such that it contrasts with the sidewall of the tyre, said mark (20) comprising a first set of cavities (201) or projections (202) designed to mould the dark parts of the encoded matrix symbol (5).

Owner:OCIETE DE TECH MICHELIN

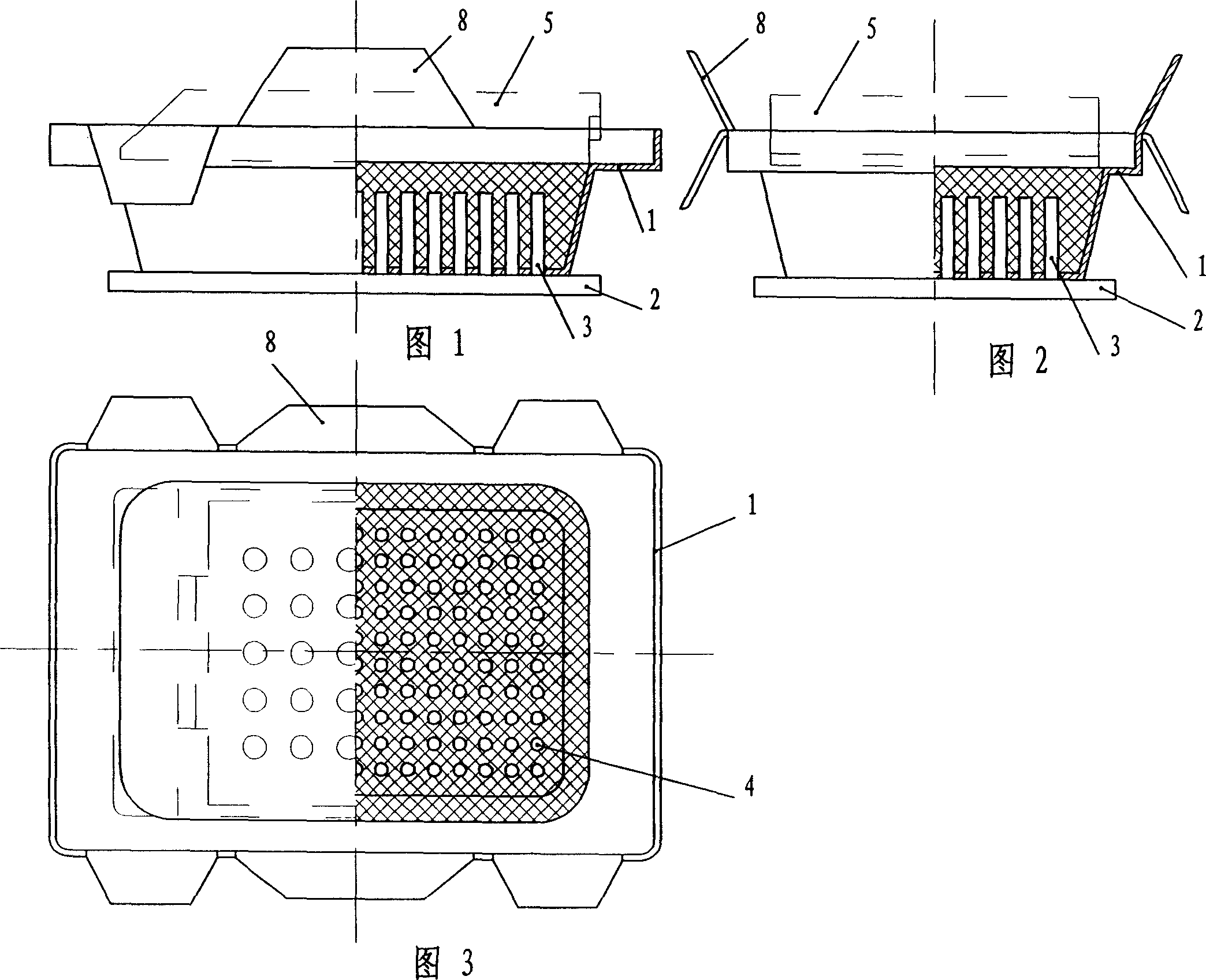

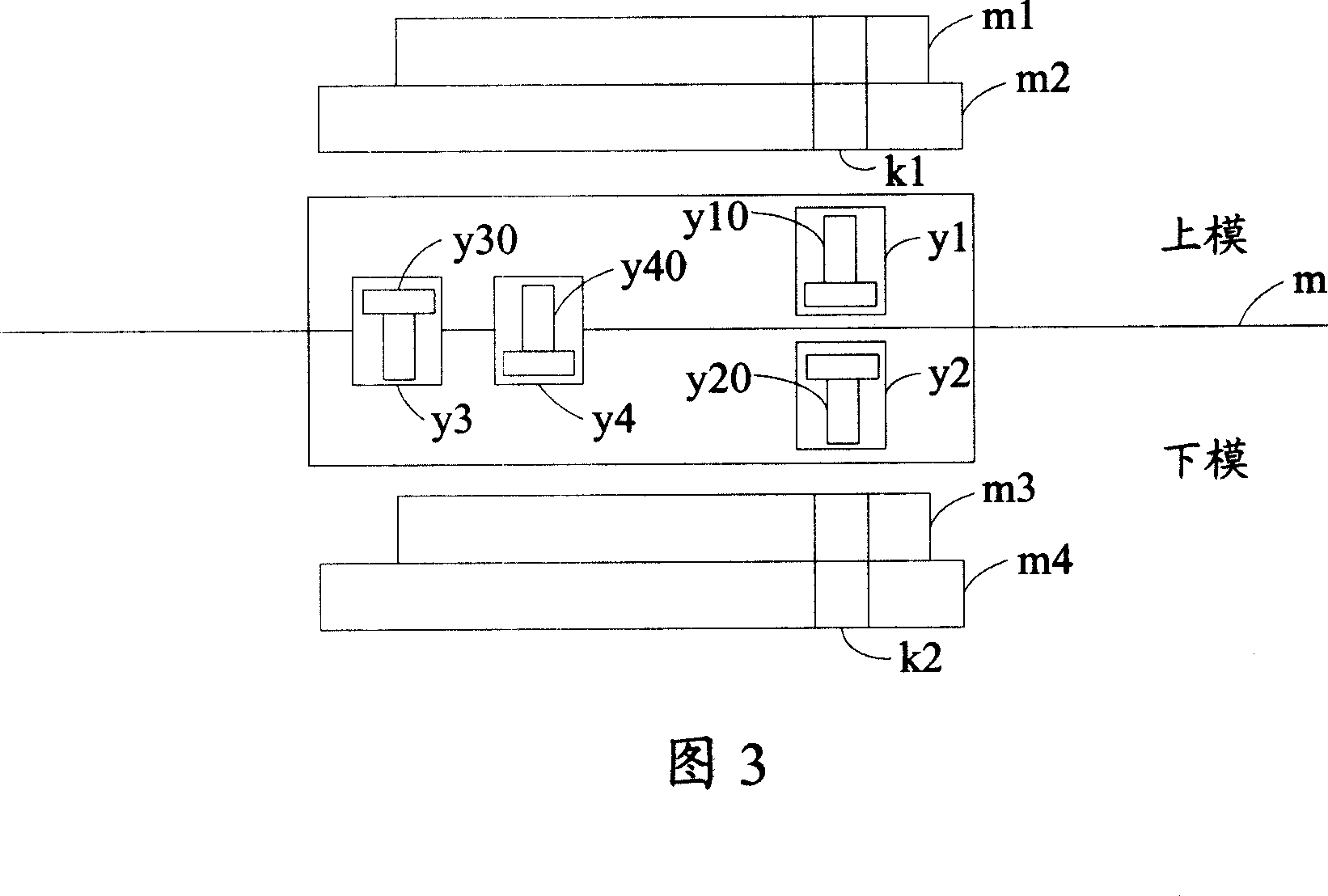

Wax module for organizing chip array

ActiveCN1920558AQuality improvementImprove production efficiencyFoundry moulding apparatusBiological testingWaxEngineering

The invention relates to an organized chip array wax block module, wherein it comprises mould element and array grid plate; said array grid plate is arranged with several post grids uniformly; the bottom of mould has array holes relative to the post grids; the post grids are through the bottom of mould element to pass the array holes into mould element groove; the array grid plate is movably matched with array hole; and there is a packing box movably matched with mould. In addition, the moulds can be two types that the groove bottom of mould has one upwards integrated post grid; the middle ofgroove has array hole plate and the array grid plate through the array hole; the lower surface of array grid plate has post grid, and upper surface has handle; the post grid is movably matched with array hole plate. The invention has the advantages that: it has high producing speed, high quality, and one-time molding; and it can increase the points of micro array, to plant more organized chips into one array wax block, to improve the producing efficiency and quality.

Owner:胡苹

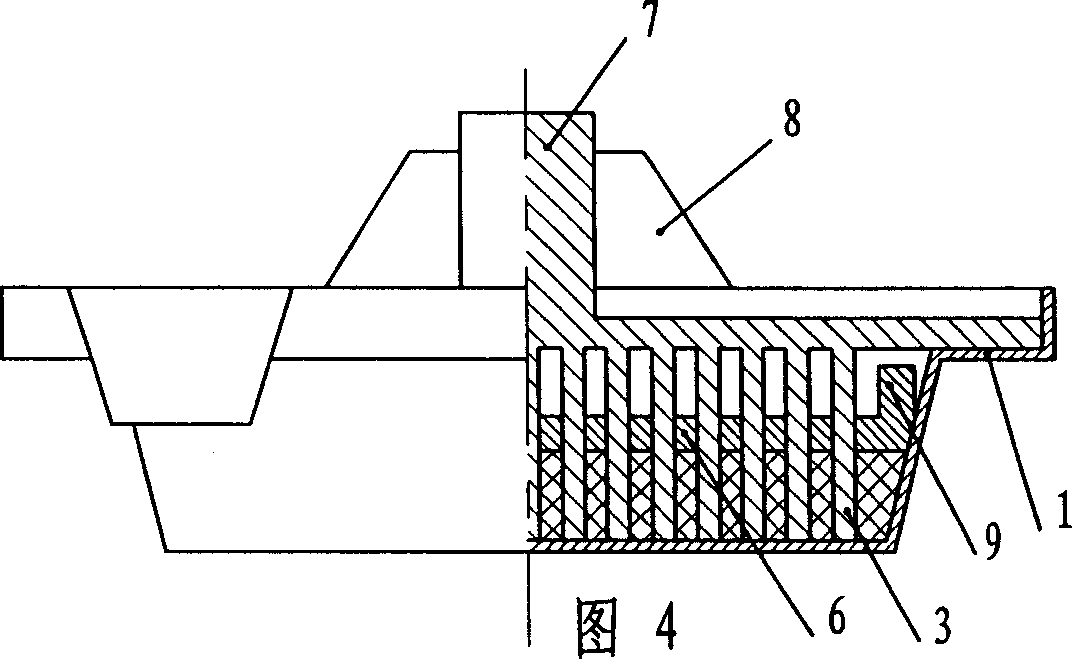

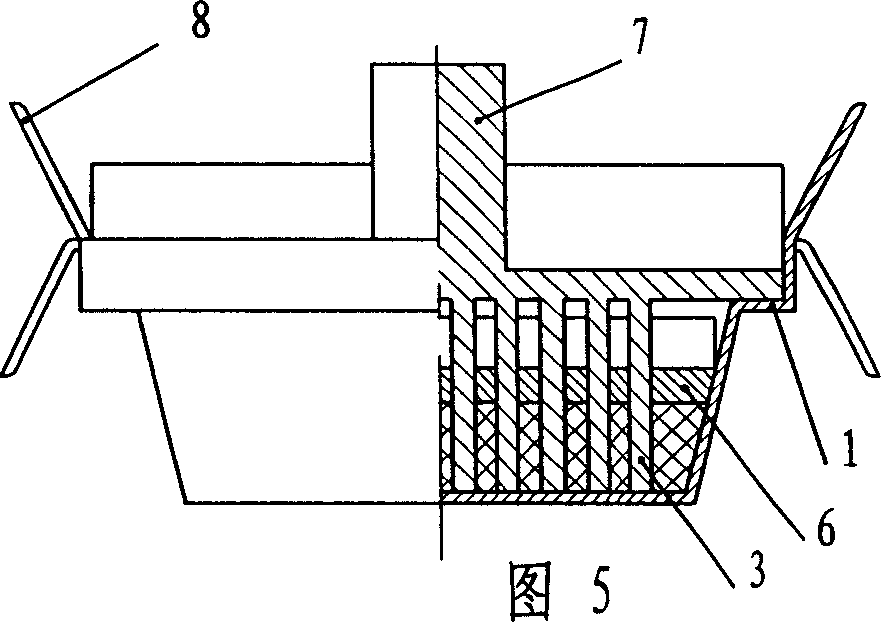

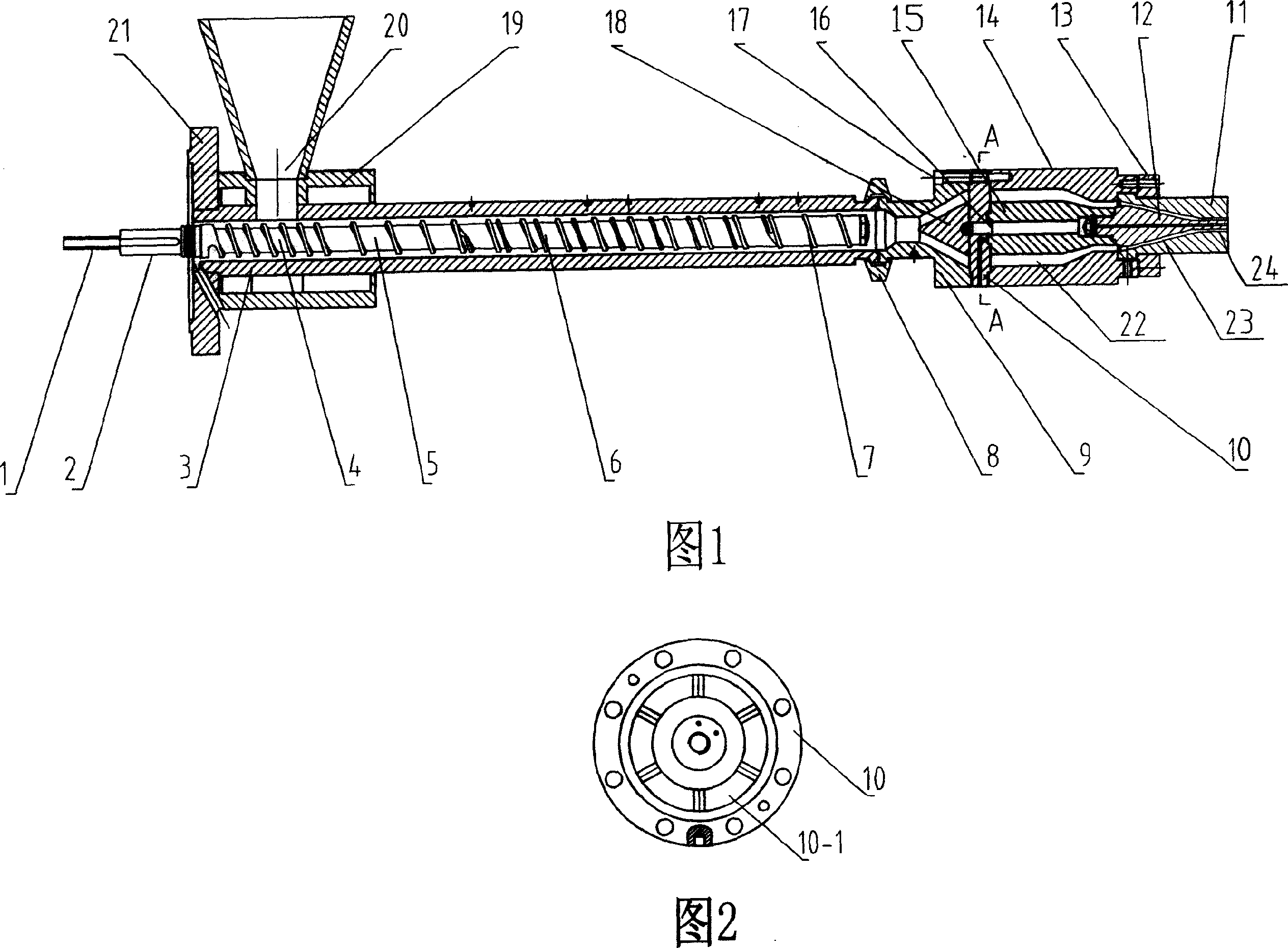

Special-purpose mould for cross-linked polyethylene tube

InactiveCN101015949AReasonable structural designSpeed up the flowTubular articlesEngineeringCross-linked polyethylene

The invention relates to a crosslink polyethylene tube special mould, which comprises an extruder and a shaping mould. The extruder is formed by a screw barrel and a screw in the barrel, and the shaping mould comprises a back mould connected at the tail of the screw barrel, while the back of the back mould is connected with a support plate with a diverting taper in the chamber of the back mould. Another side of the support plate is connected with a mould whose chamber contains a transition mould element fixed on the support plate, and the tail of the transition mould element is connected with a corn mould whose outer side is arranged with an opening mould, while a shaping space is between the corn mould and the opening mould. The outside of the opening mould is disposed with an opening mould press plate. The invention has the advantages in stable material flow in the chamber, high extruding speed and high tube quality. And the invention uses small screw lifting angle, shallow screw groove or the like to improve quality and yield.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

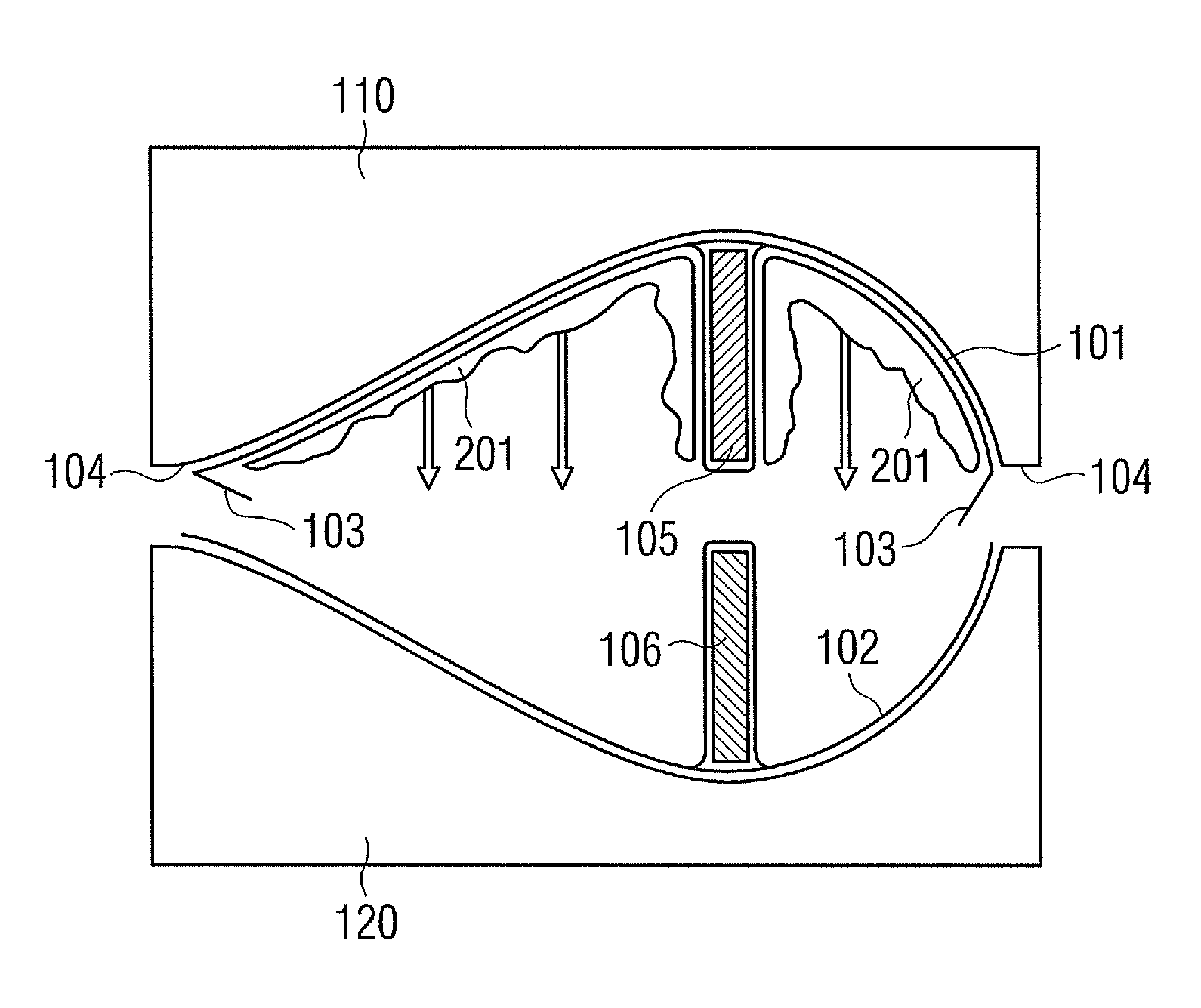

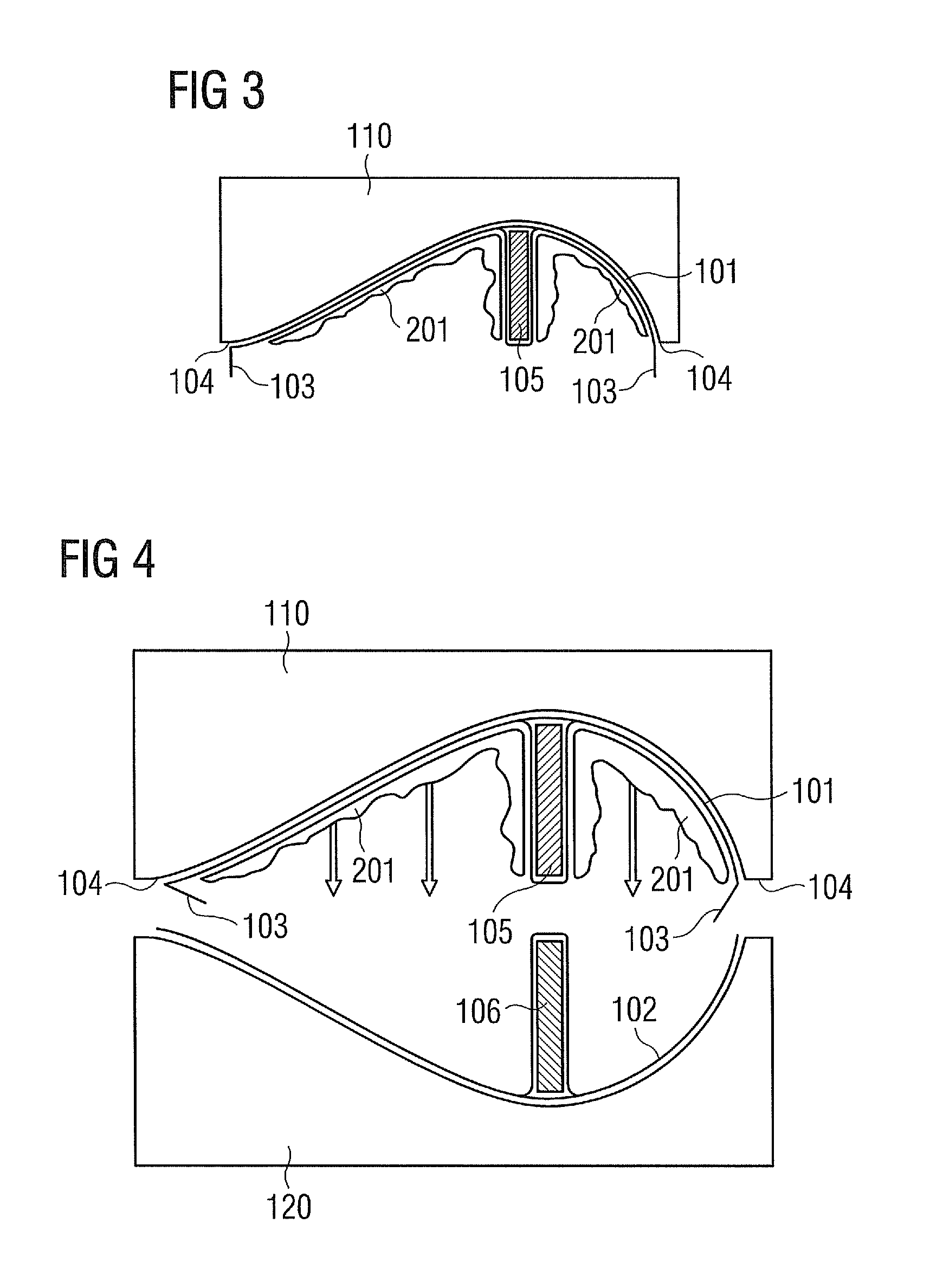

Method for manufacturing a wind turbine rotor blade

ActiveUS20120091627A1Simple manufacturing methodEasy to operateEngine manufactureLaminationEngineeringMould Element

A method for forming a profile for a hollow component is provided. A first composite fibre layer is laid out on a first surface corresponding to a first profile section of the component. A second composite fibre layer is laid out in a second surface corresponding to a second profile section of the component. A collapsed bag is laid out in onto the first composite fibre layer. The bag and the first composite fibre layer are fixed to the first surface. First and second mould elements are coupled such that the first surface and the second surface correspond to the first and second profiles. The bag is inflated such that the first composite fibre layer is pressed to the first surface and the second composite fibre layer is pressed to the second surface so that the first and second layers are coupled to form the profile.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

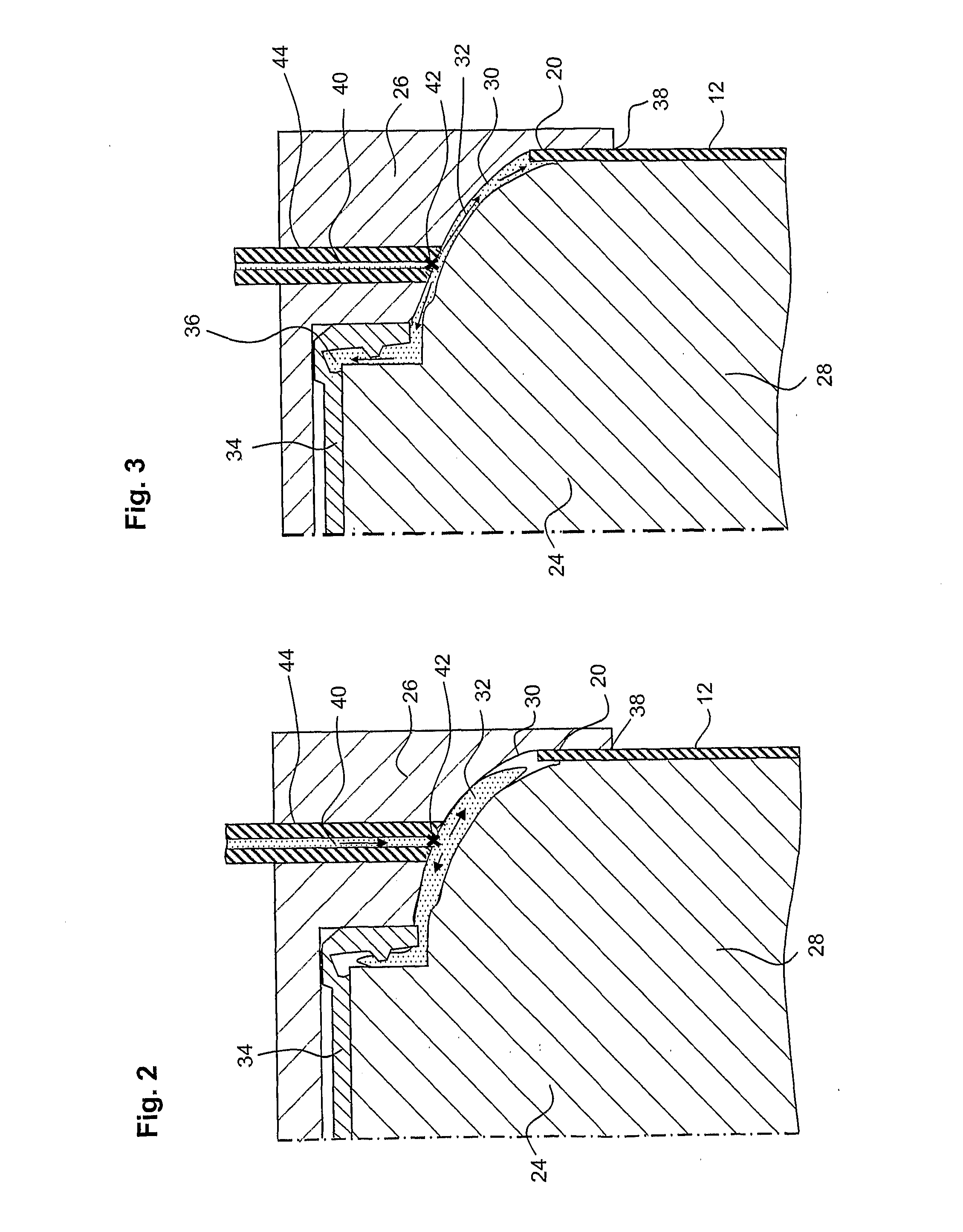

Fitting for a liquid-tight cable leadthrough

The invention relates to a fitting for a liquid-tight cable leadthrough in an opening (1) in a solid surface (2), which solid surface can be gripped from the back, wherein said fitting comprises an upper boundary plate (4) that covers the opening (1), an elastic moulded element (3) that flatly contacts and is connected to the upper boundary plate (4) and can be at least partially inserted into the opening (1), a lower boundary plate (8) that can be lead through the opening (1), wherein the lower boundary plate flatly contacts and is connected to the elastic moulded element (3) on the opposite side of the elastic moulded element (3) referred to the upper boundary plate (4), a locking plate (9) that can be moved relative to the lower boundary plate (8) and is providable with at least two pivoted locking elements (17), wherein said locking elements are supported between pairs of mounting limbs (20) by element of a bolt (22) and can be pivoted between a position in which the locking plate (9) can be lead through the opening (1) and a stopping position which they enables a gripping from the back of the solid surface (2), at least one clamping element for adjusting the spacing between the upper boundary plate (4) and the locking plate (9) against forces generated during a deformation of the elastic moulded element, and opening (10) that extends through the locking plate (9), the boundary plates (4, 8) and the elastic moulded element (3) and serves for accommodating a cable (7) to be lead through the solid surface (2).

Owner:AIRBUS OPERATIONS GMBH

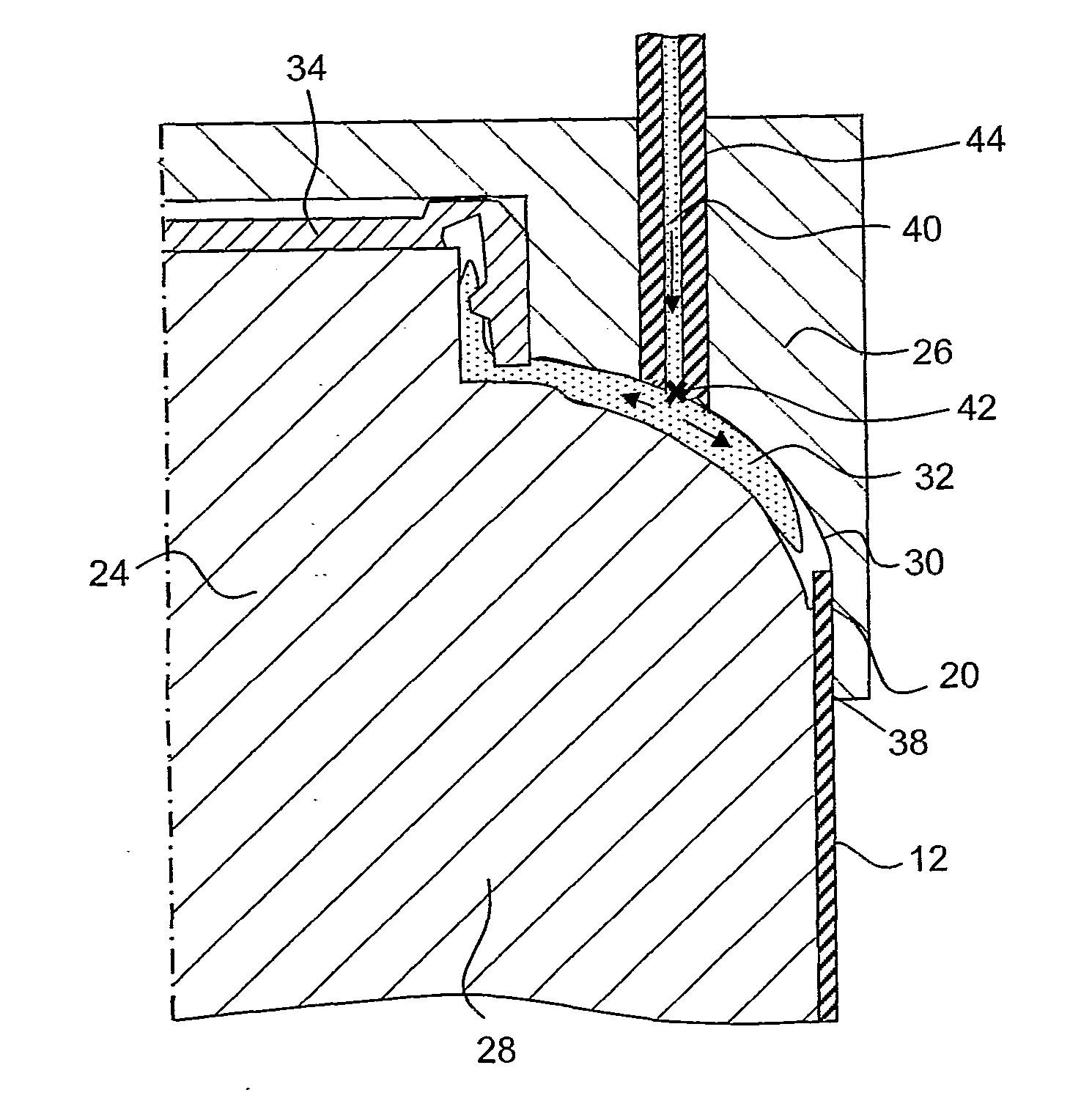

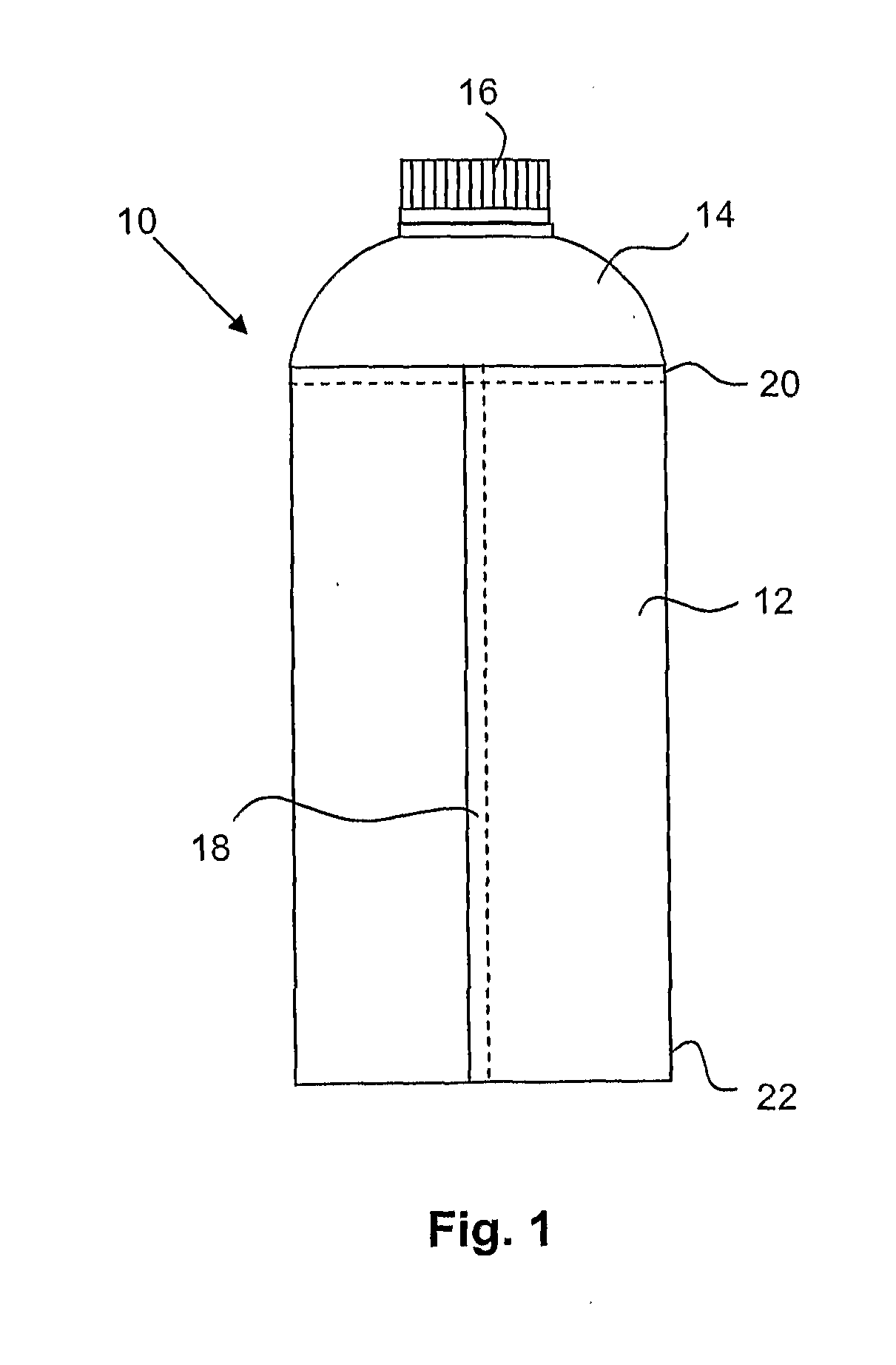

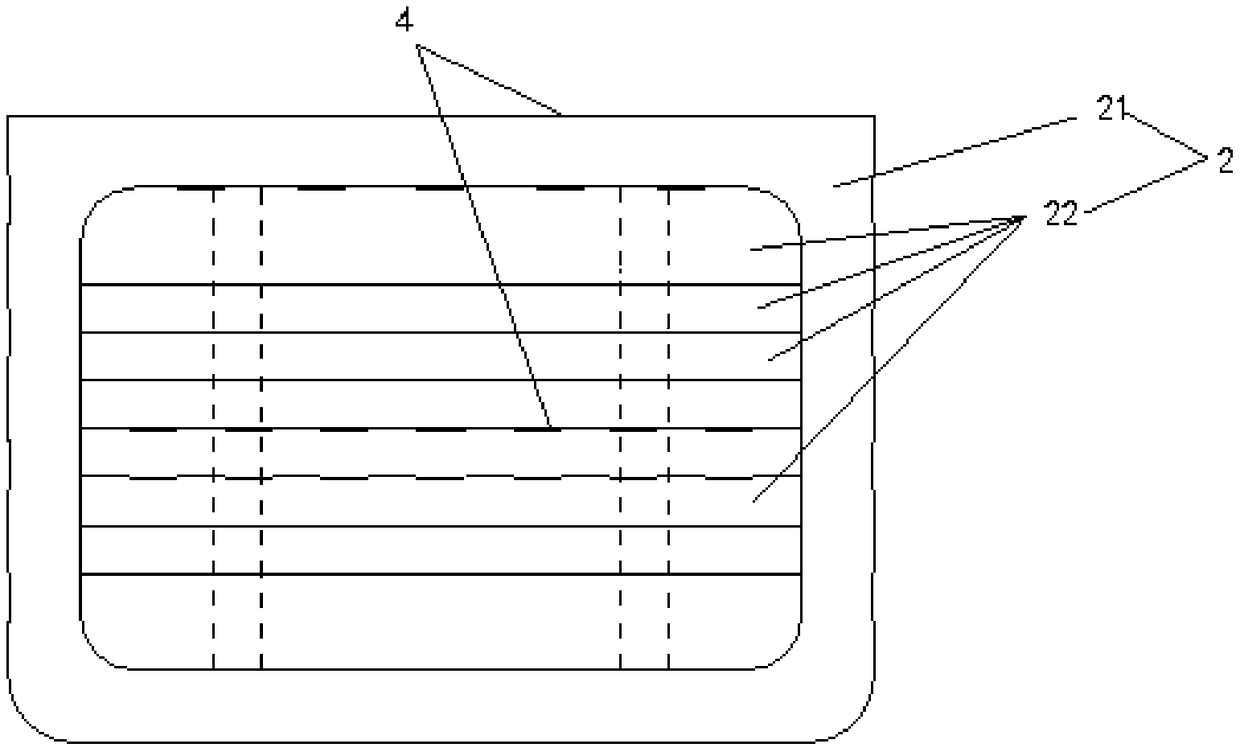

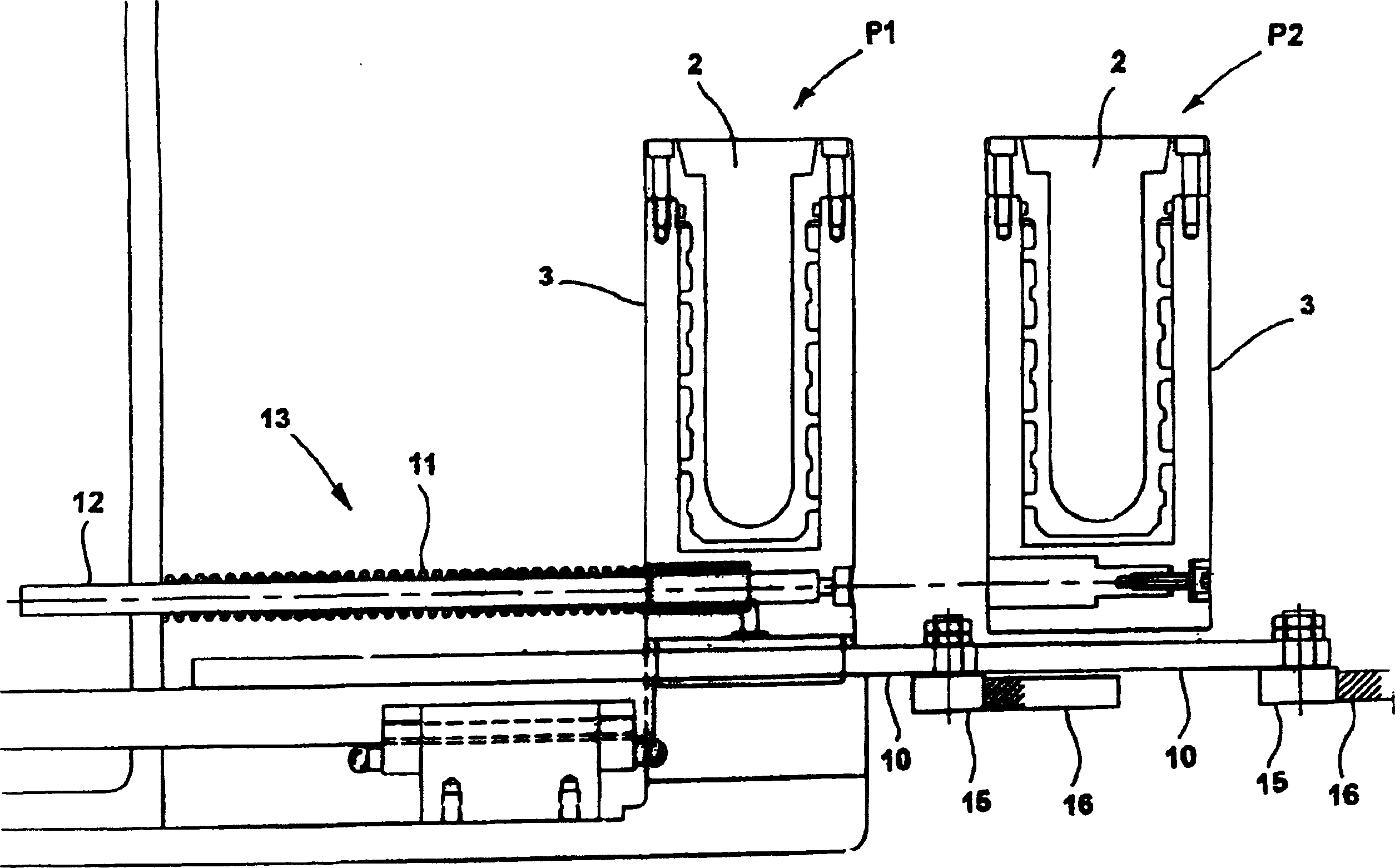

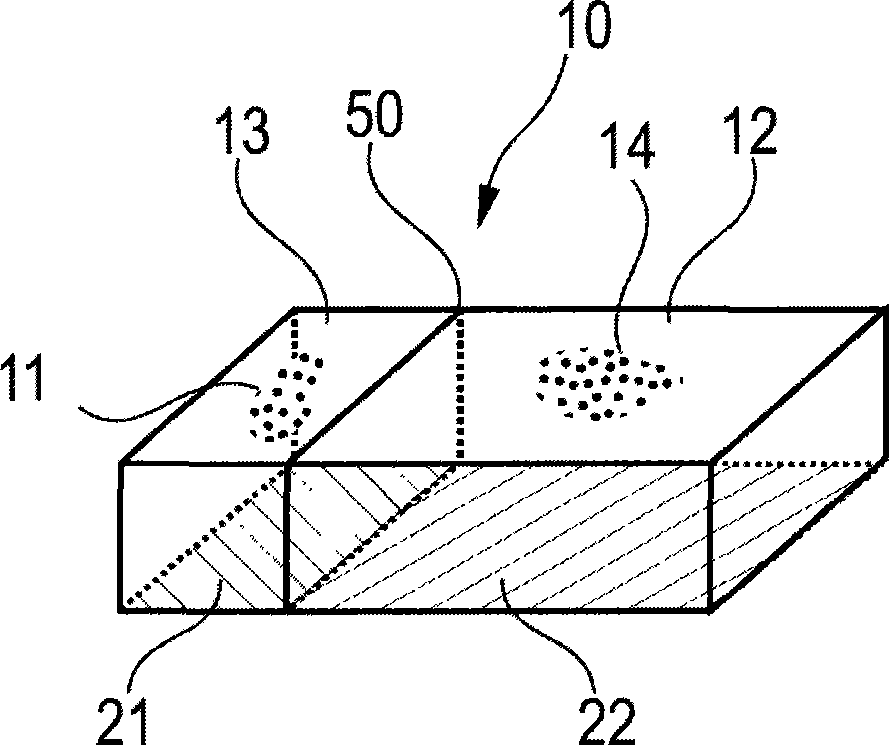

Apparatus for moulding a part of a packaging container

ActiveUS20100244317A1Improve stabilityHigh precisionTailstocks/centresConfectioneryEngineeringMould Element

An apparatus for moulding a thermoplastic package part(s) to an end portion of a container body includes inner and outer mould elements between which a mould cavity per package part is formed. At least one of these mould elements is at least partly freely suspended. When one package part is moulded with the mould elements, plastic melt is injected in a first number ≧1 of points in the cavity, an island of plastic melt for each point is formed inside the cavity, and the distribution of the points causes a force centre to pass through a surface defined by a parallel projection of each first number of islands on a plane orthogonal to a direction of the compression force, and when the first number >1, a second number of imaginary straight lines interconnecting a third number of parallel projections such that the surface is at its maximum.

Owner:TETRA LAVAL HLDG & FINANCE SA

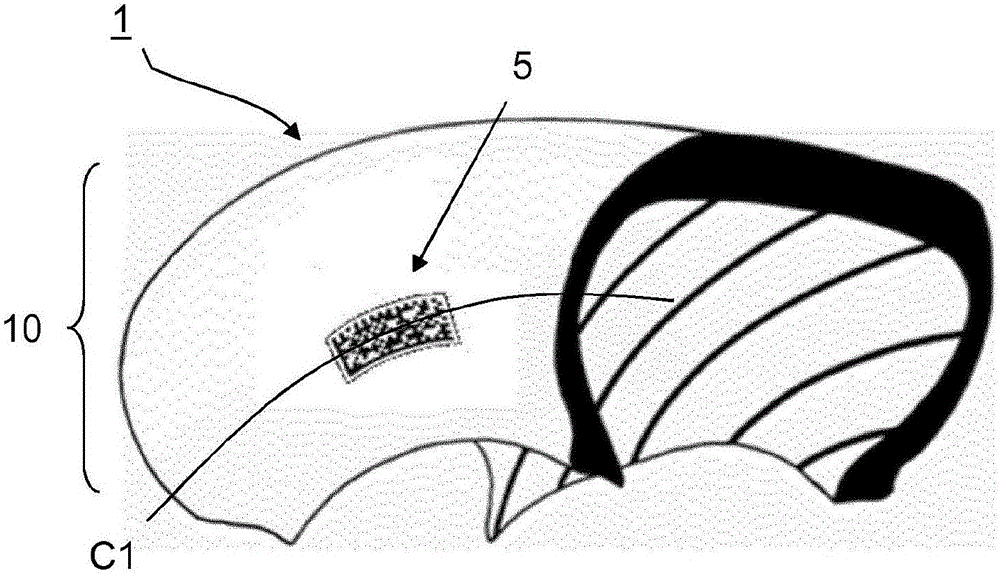

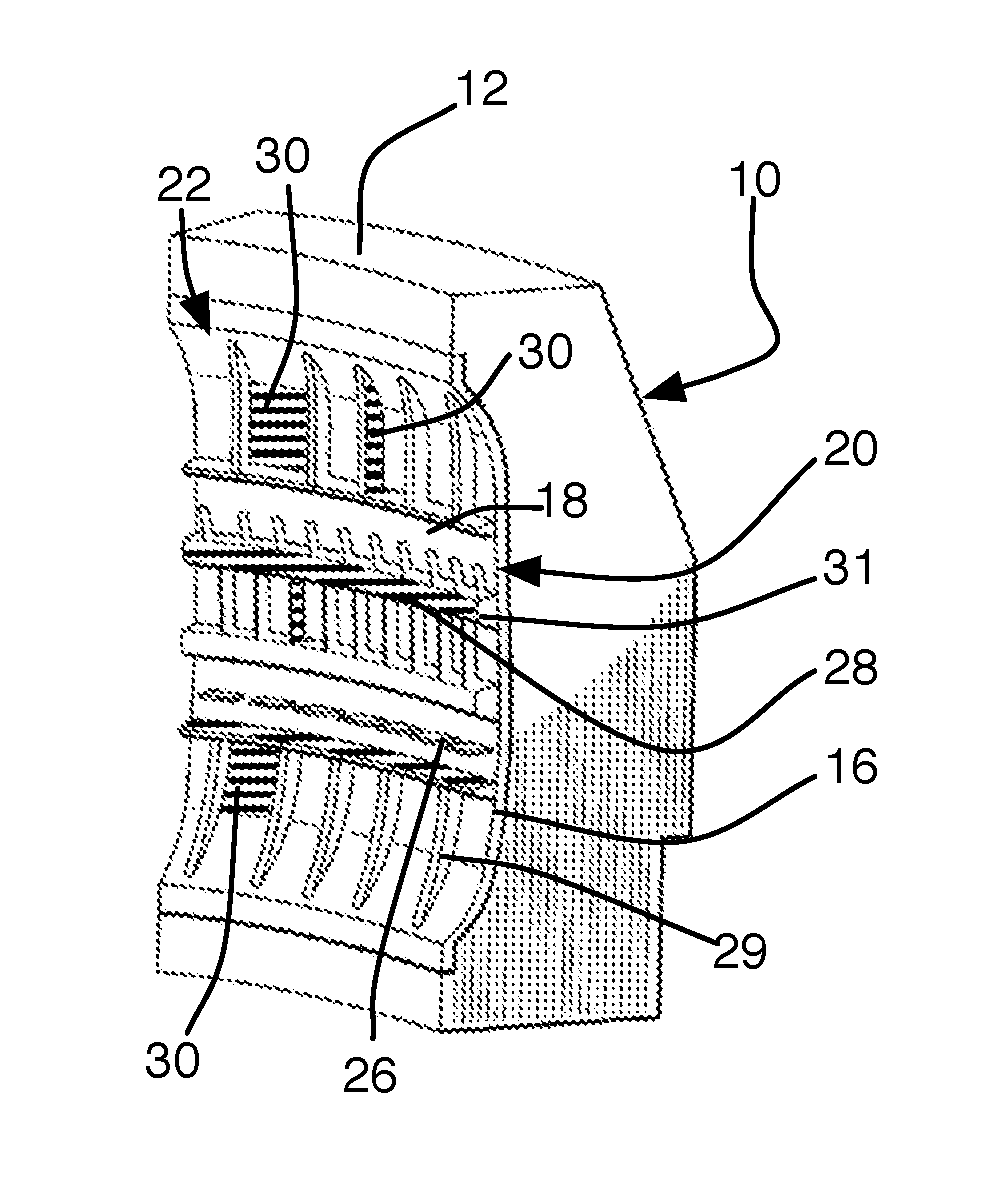

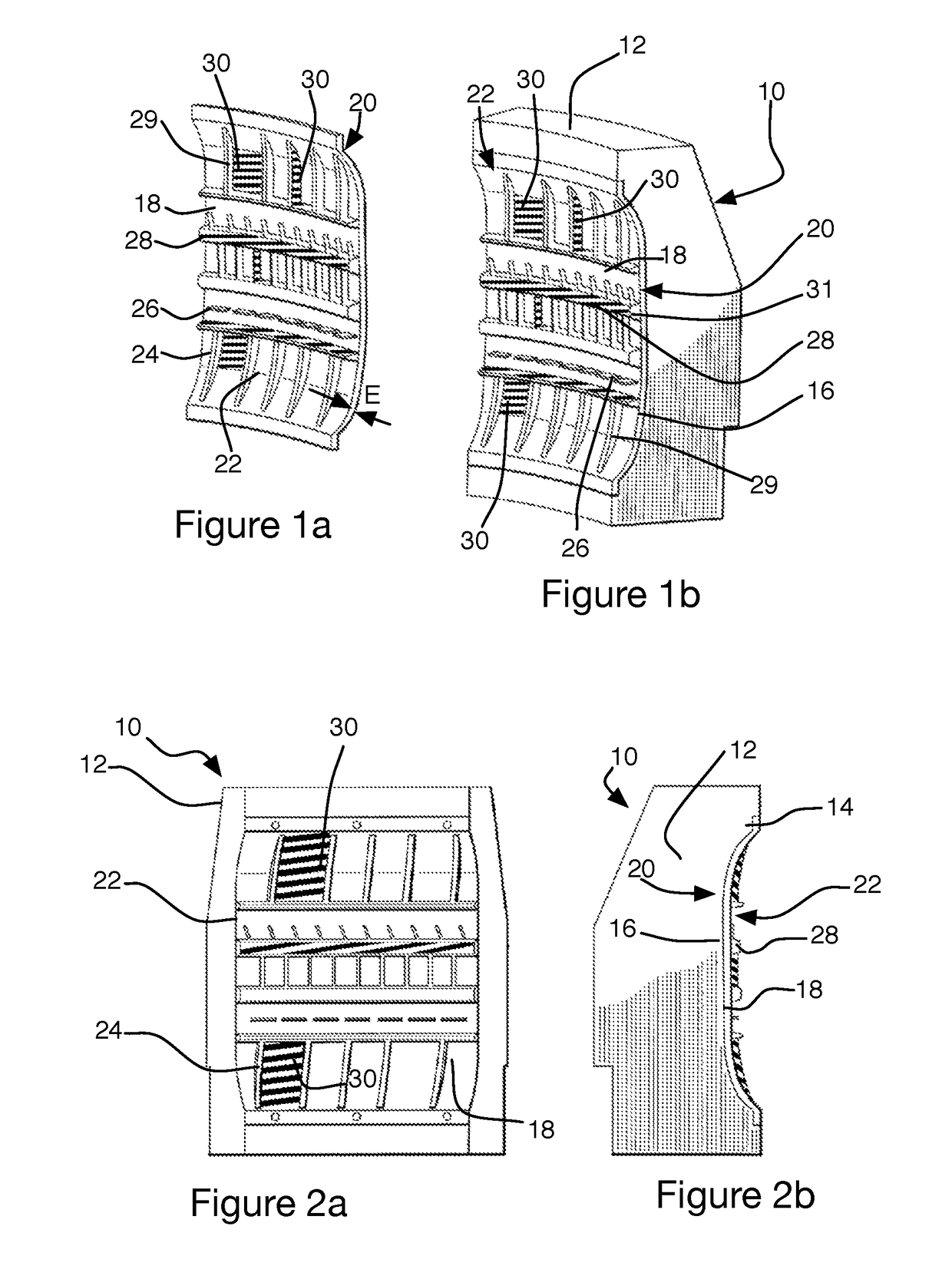

Mould Element Comprising A High-Contrast Texture

A mould element (18) intended to be attached in a mould (10) for vulcanizing tires, the mould element (18) having the form of a skin with a thickness (E) comprised between 0.25 and 6 mm and comprising a bearing surface (20) with, on the opposite side, a moulding surface (22) intended to form all or part of the external surface of the tire. The mould element comprises a pattern (30) comprising a plurality of recessed (19, 21, 112) or protruding (106, 107) elements, formed as integral parts of the mould element (18).

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

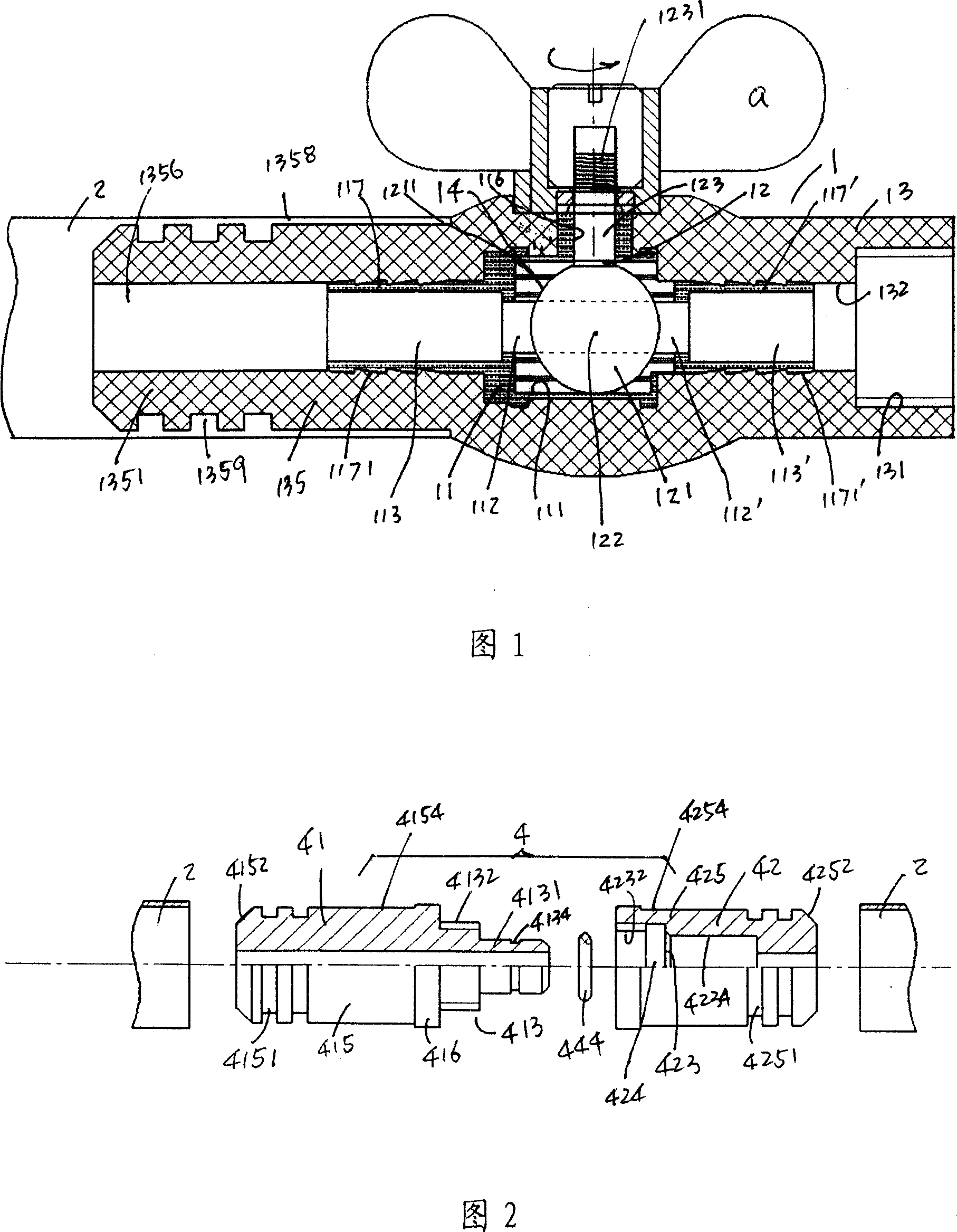

Water flow controller for water sprinkler and its tool handle

The invention relates to a water flow controller used ejector and relative tool handle rod, wherein said handle rod comprises tool rod, tool head connector and water flow controller connected to the tool rod; the ball valve of water flow controller is in the mould element to form the main body of ball valve; therefore, water valve is sealed in the mould element; the main body of ball valve and corn element can confirm success flow; the tool rod connector is formed by sub-main screw buckles, while its mounting end has rectangle screw buckle; the tool head connector, tool rod connector and mould element have glue container and glue groove, to realize reliable connection.

Owner:TIANJIN JINMAO GROUP

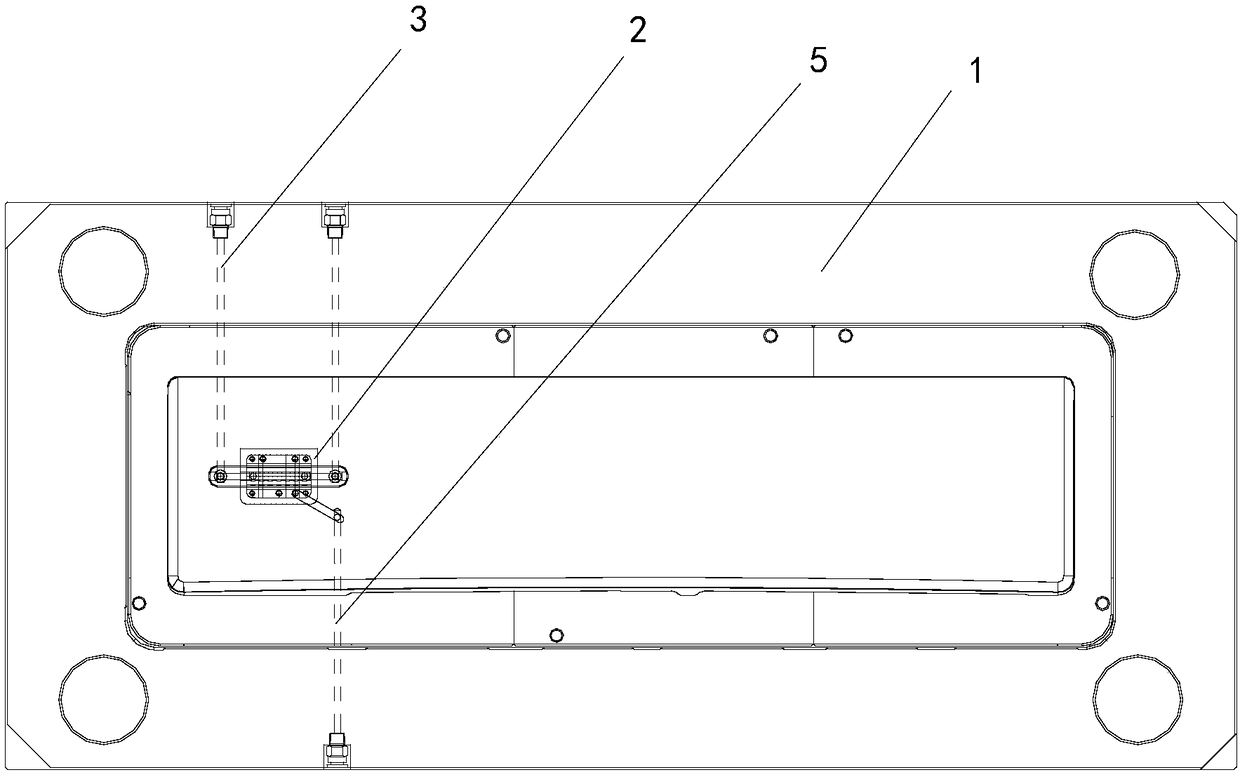

Injection mould and Injection molding method

The invention provides an injection mould and an injection molding method. The injection mould comprises a moving template and at least moving mould insert arranged on the moving template according toa predetermined position. According to the invention, on the basis of cooperation of the moving mould insert, a waterway, and a gas circuit, air in a mould cavity can flow out, so that mould exhausting is enhanced; the temperature of the moving mould insert during the injection molding process is ensured; because the mould is heated before injection and pressure maintaining, a phenomenon that mobility of the material flow is affected because of too low material flow temperature caused by heat losses of the material flow due to heat transferring and thus a hungry joint problem of an injectionmolding part is avoided. Besides, after injection and pressure maintaining, the mould is cooled by the heat exchange with the waterway, so that the cooling speed and the thermal insulation effect of the mould are controlled; and the material flow temperature is controlled and the material flow flowing efficiency is increased, so that the moulding quality of the thin wall region of a to-be-mouldedelement and the yield of the to-be-moulded element are improved effectively.

Owner:ZHUHAI GREE PRECISION MOLD CO LTD

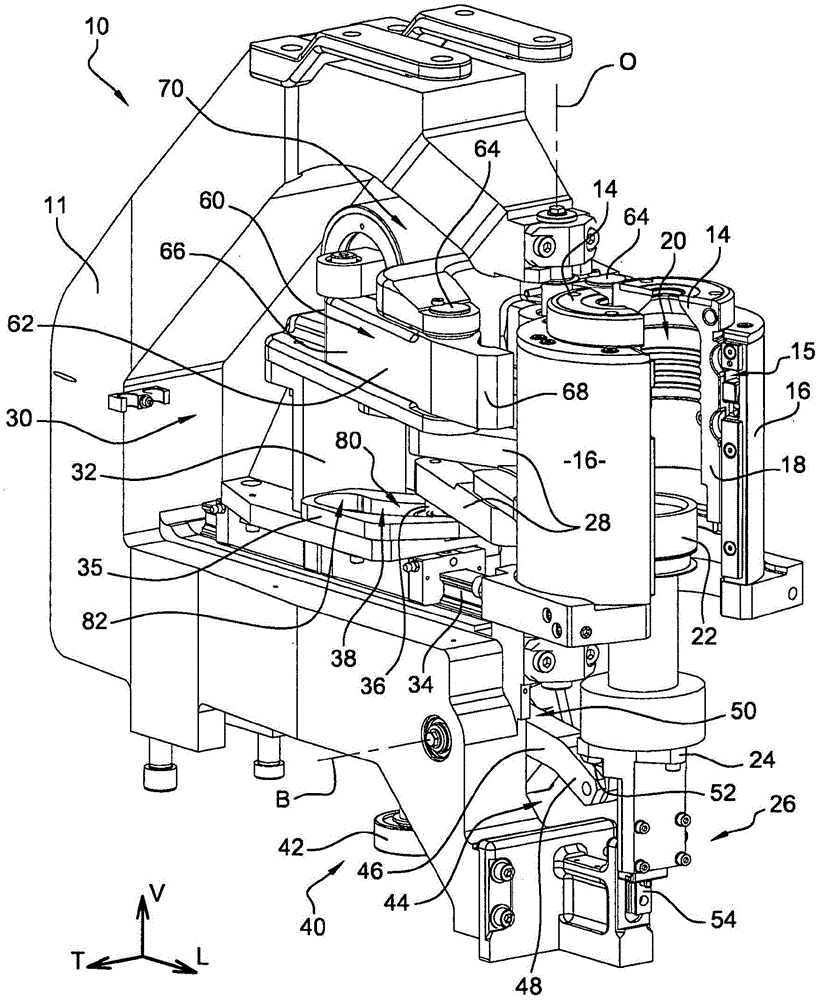

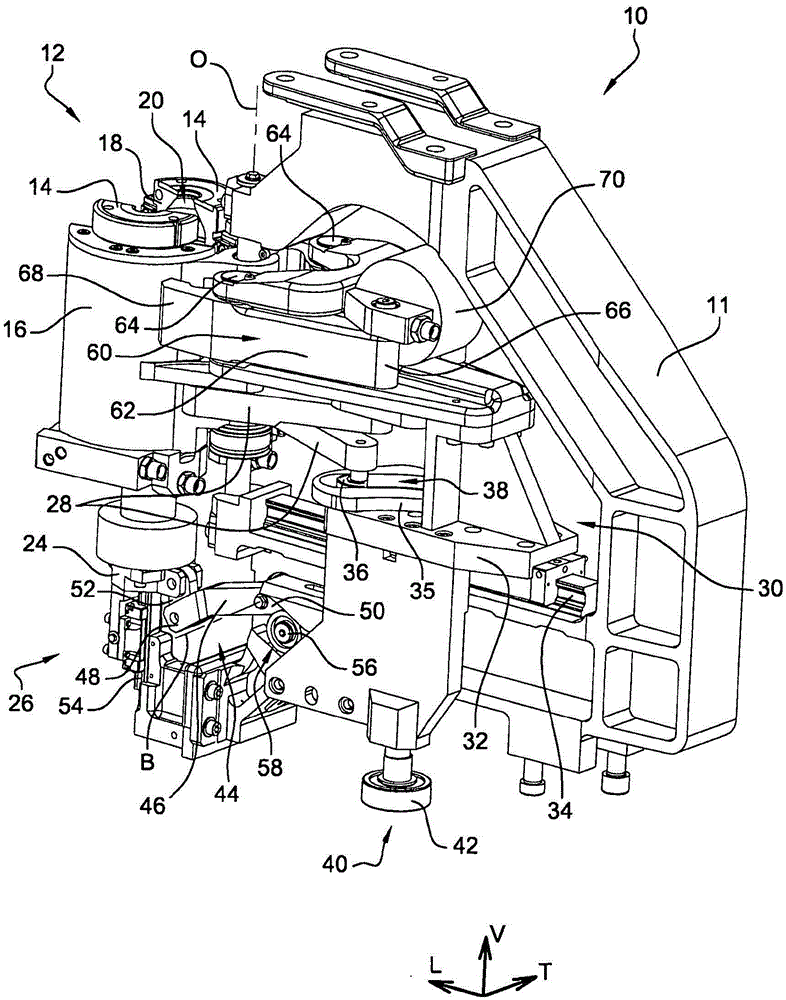

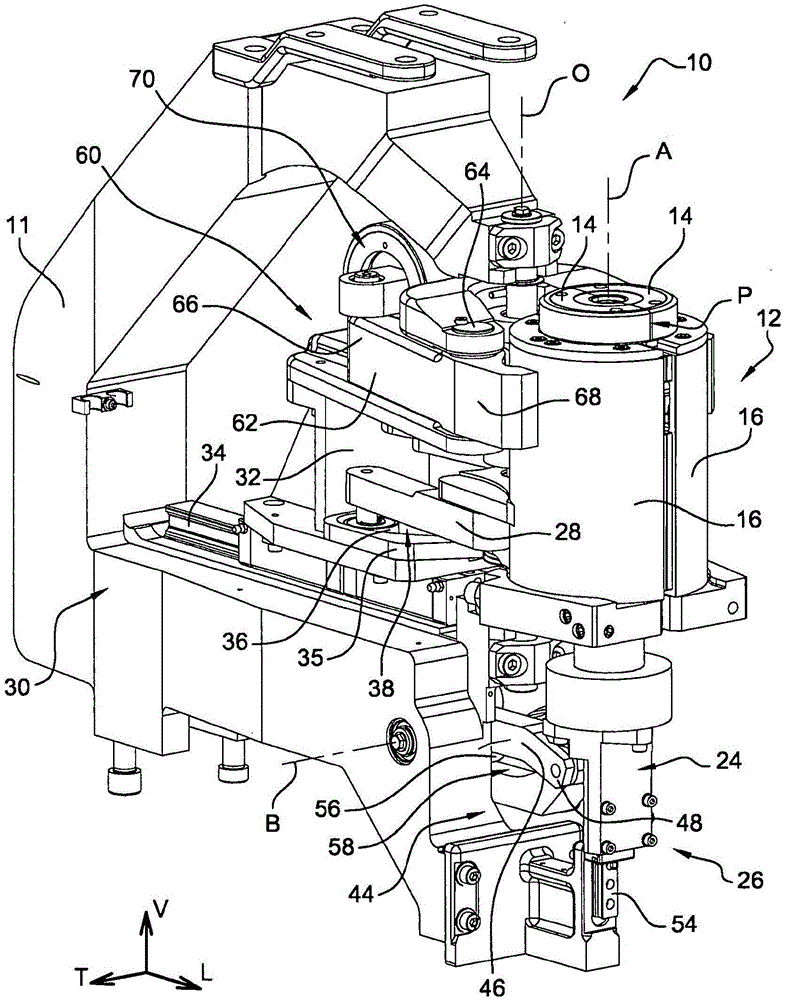

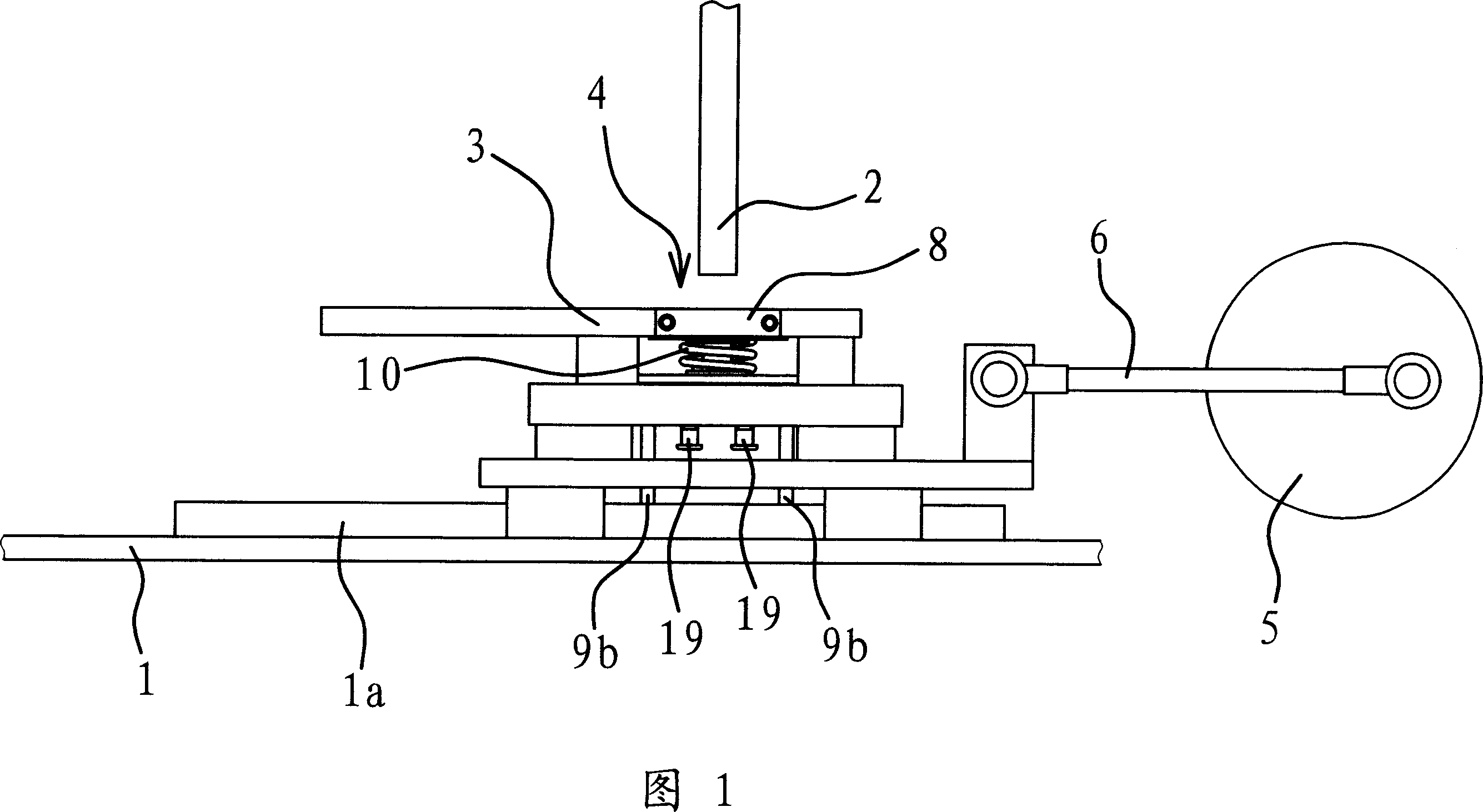

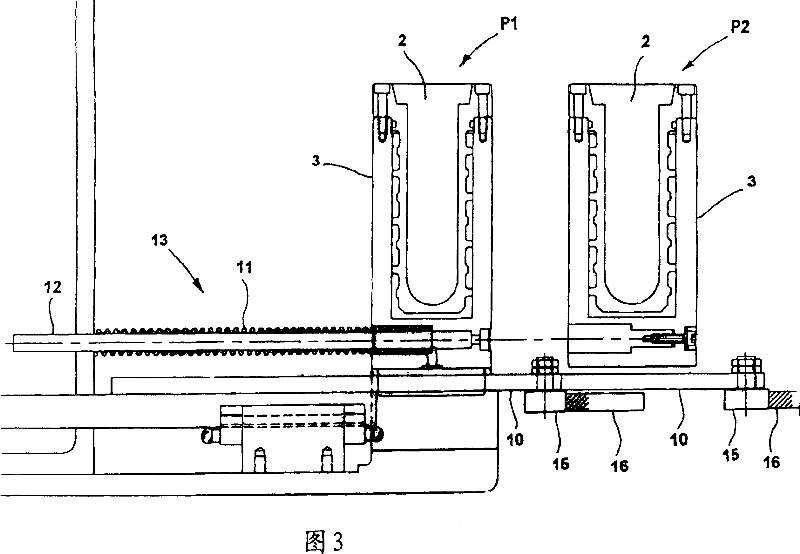

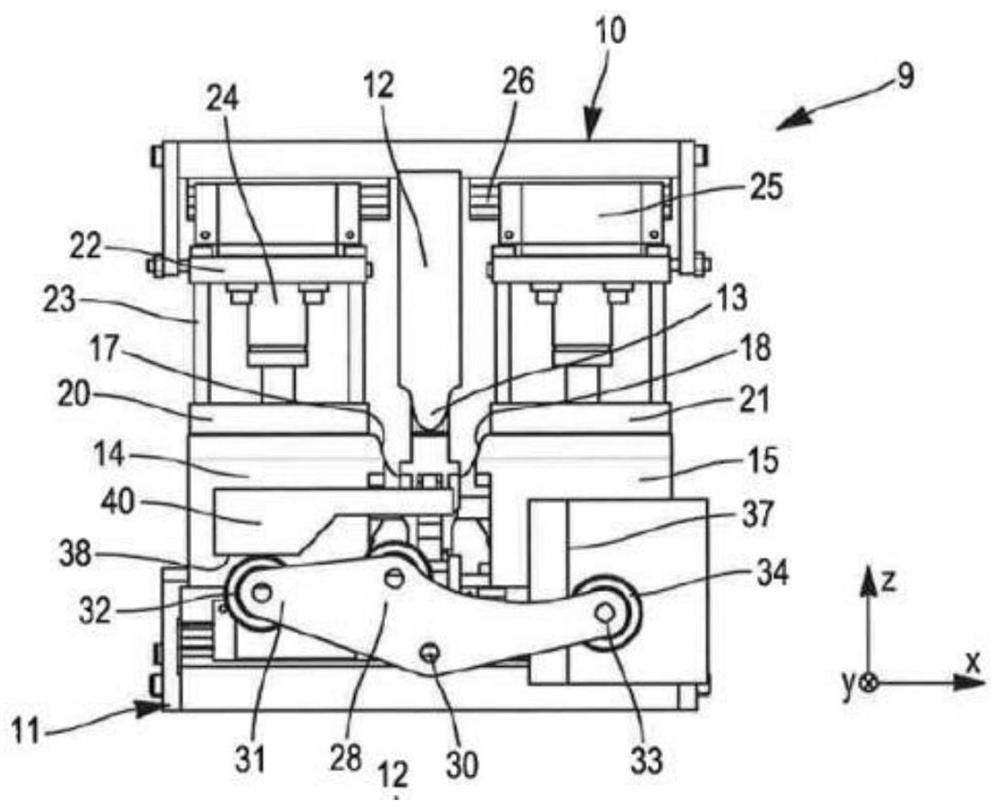

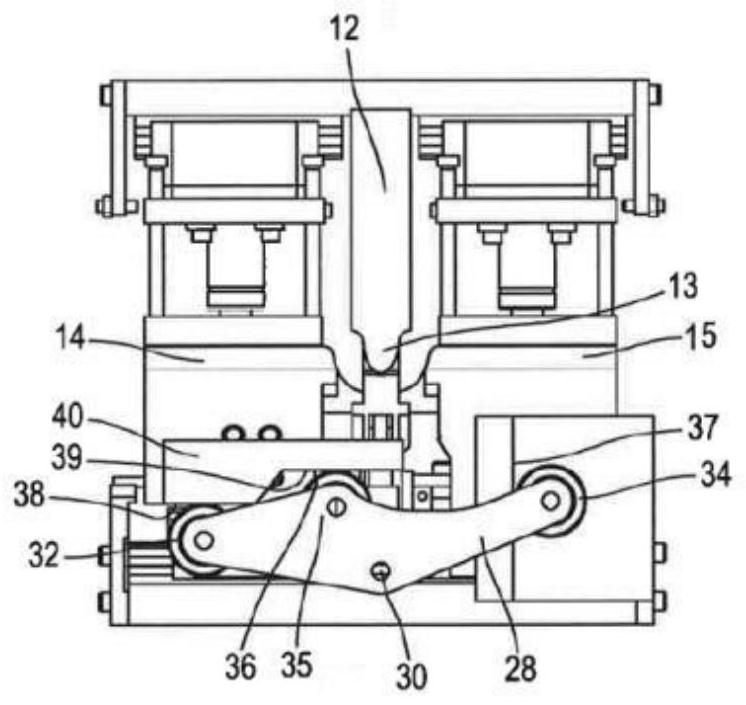

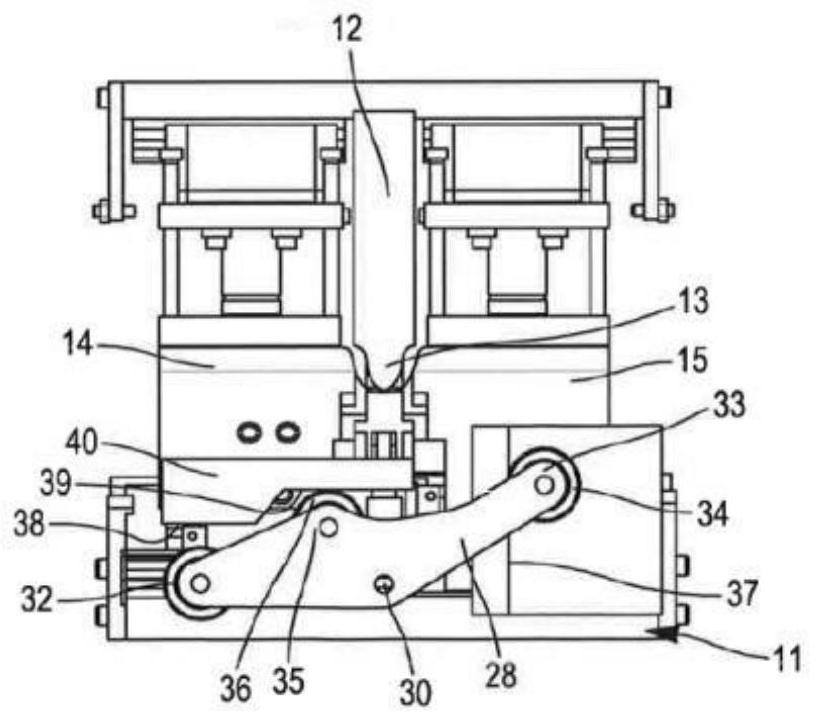

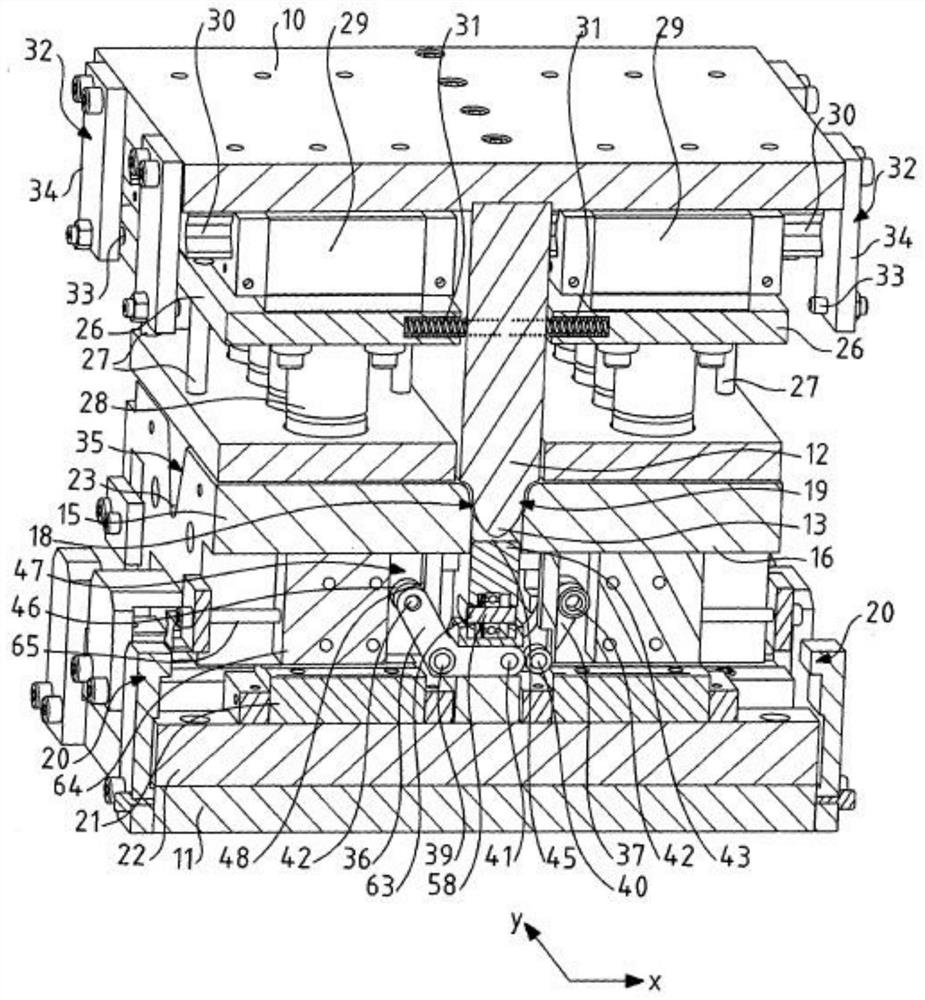

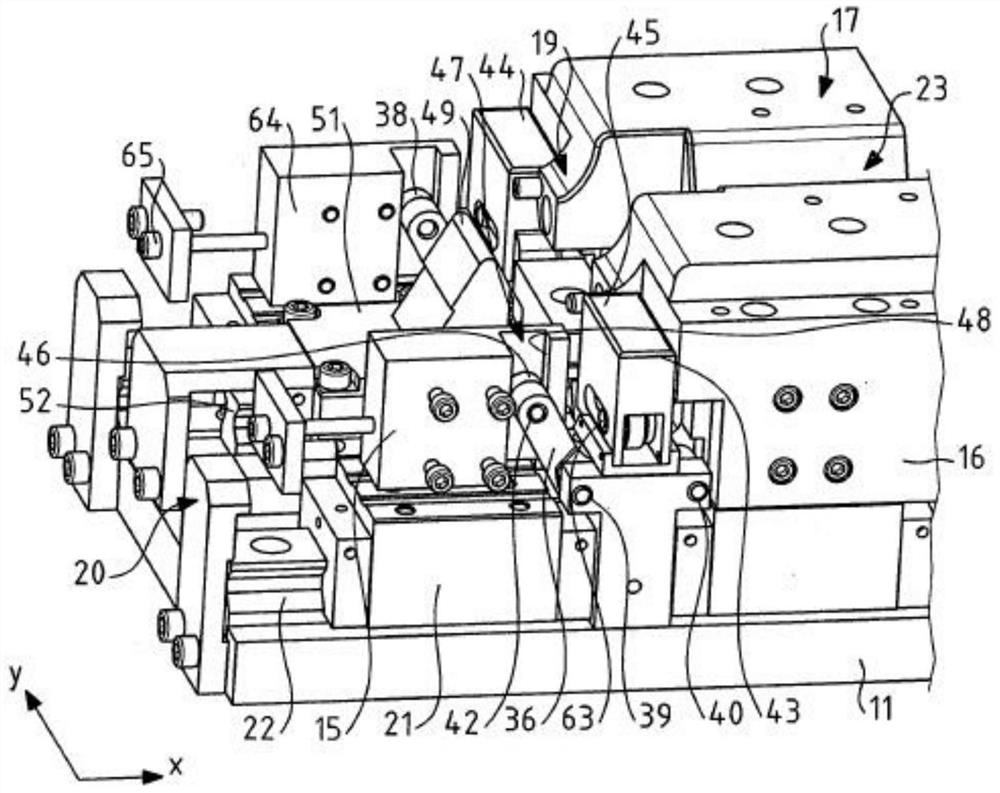

Moulding unit for the manufacture of containers comprising compensation gripper

ActiveCN105658409AImprove energy efficiencyGuaranteed uptimeDomestic articlesShell moldingEngineering

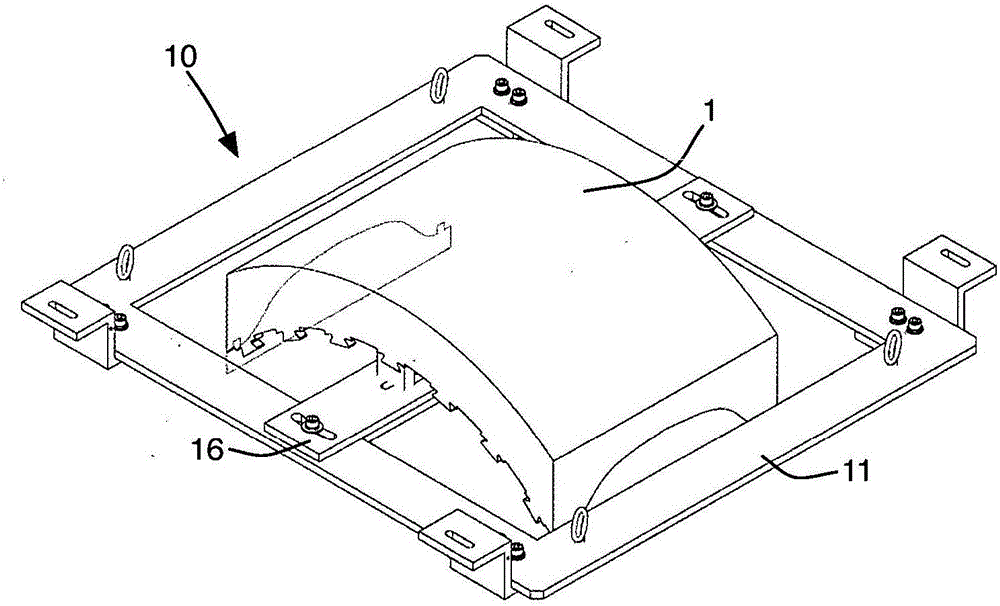

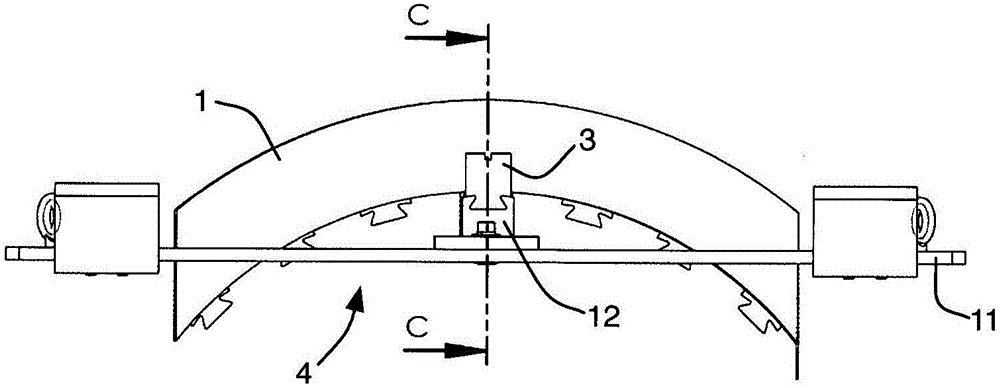

The present invention relates to a moulding unit (10) for the manufacture of containers from preforms made of thermoplastic, said moulding unit (10) being characterized in that it comprises compensating means which are formed of at least one gripper (60) which acts on mould carriers (16) that carry the mould (12) of the unit (10) in order to clamp them against one another when the moulding unit (10) is in the closed position and to apply a compensating force that tends to clamp together moulding elements (14) of the mould (12) at said parting line (P) and opposes the forces that a pressurised fluid applies to the moulding elements (14) when a container is being moulded from a preform.

Owner:SIDEL PARTICIPATIONS SAS

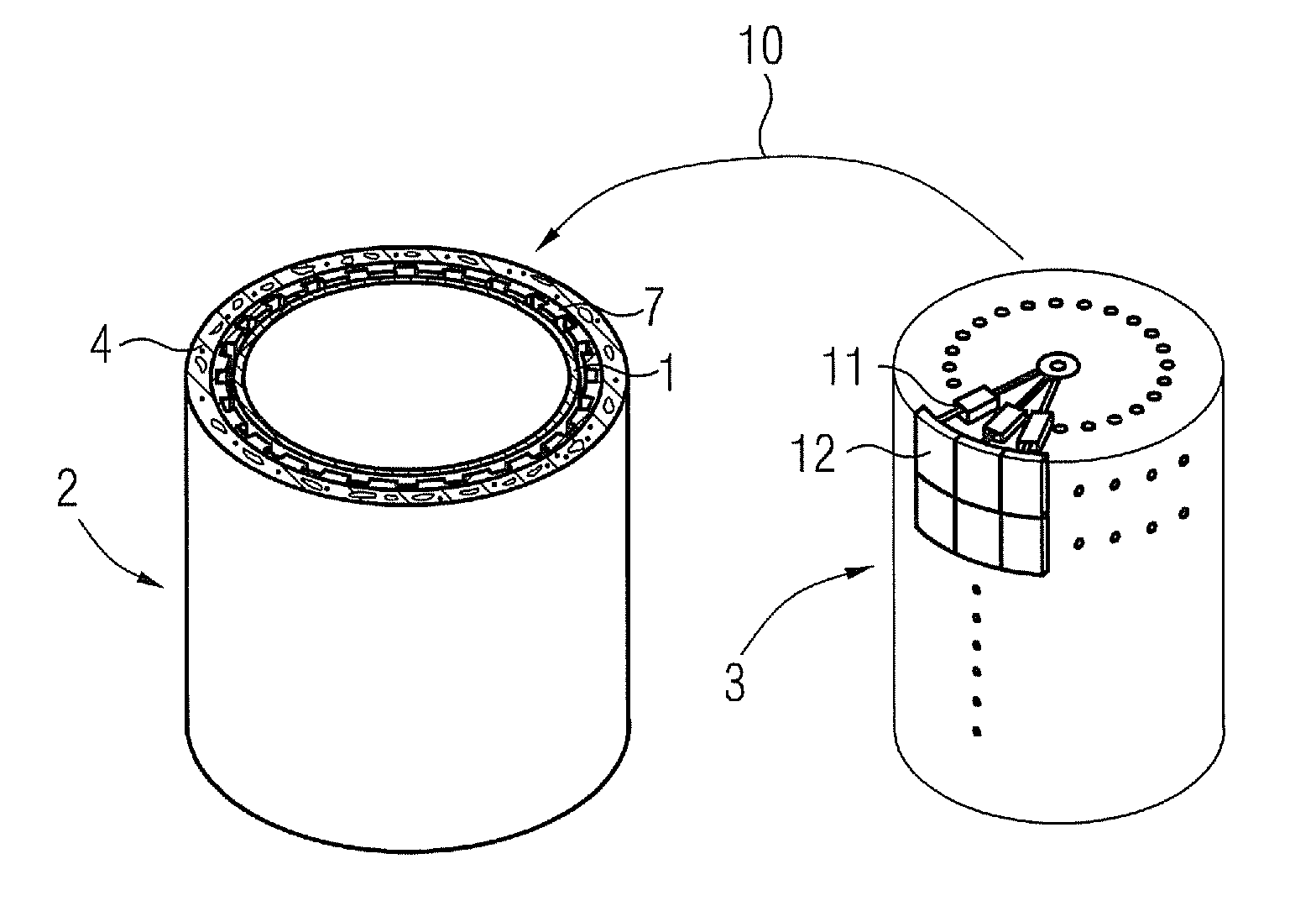

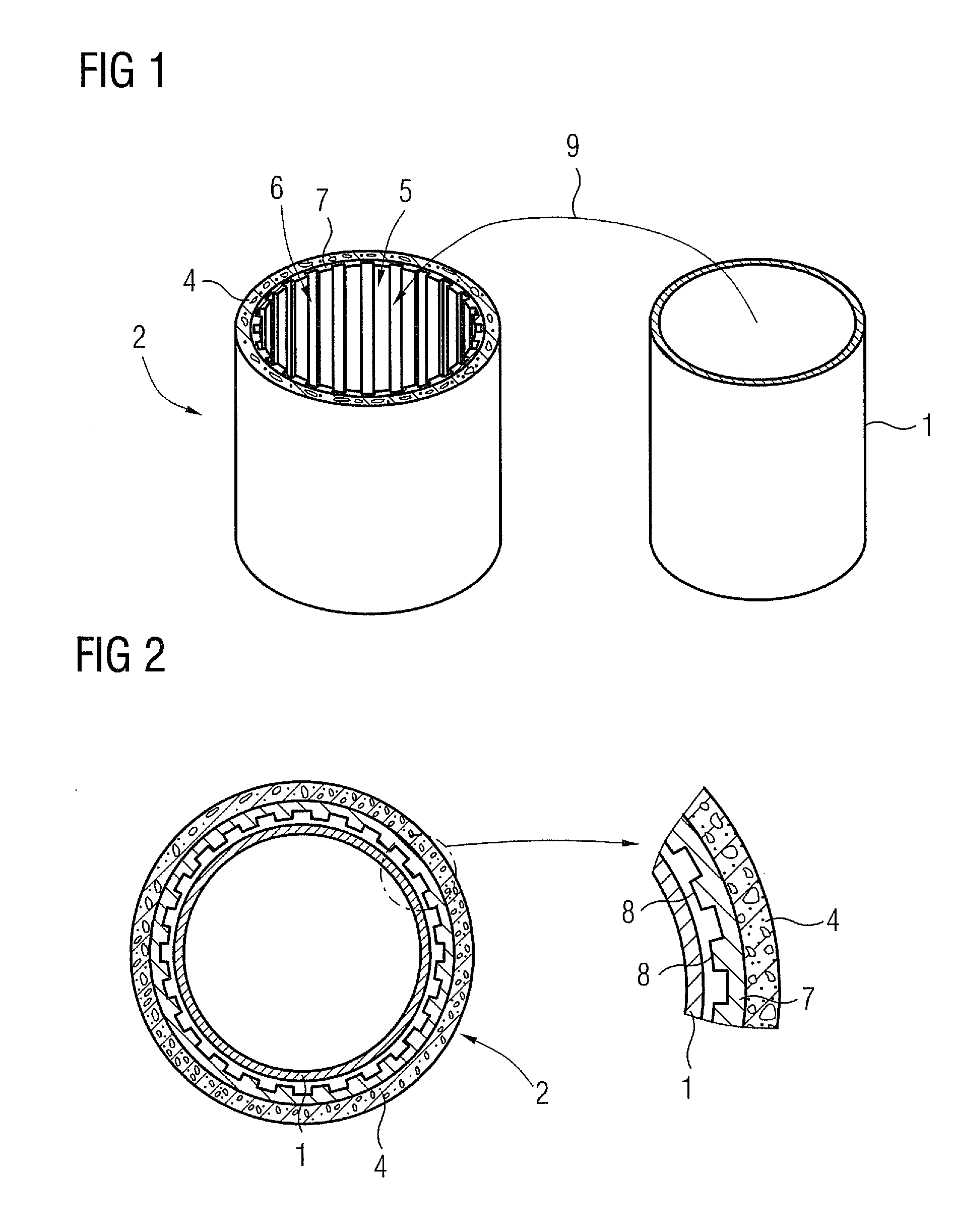

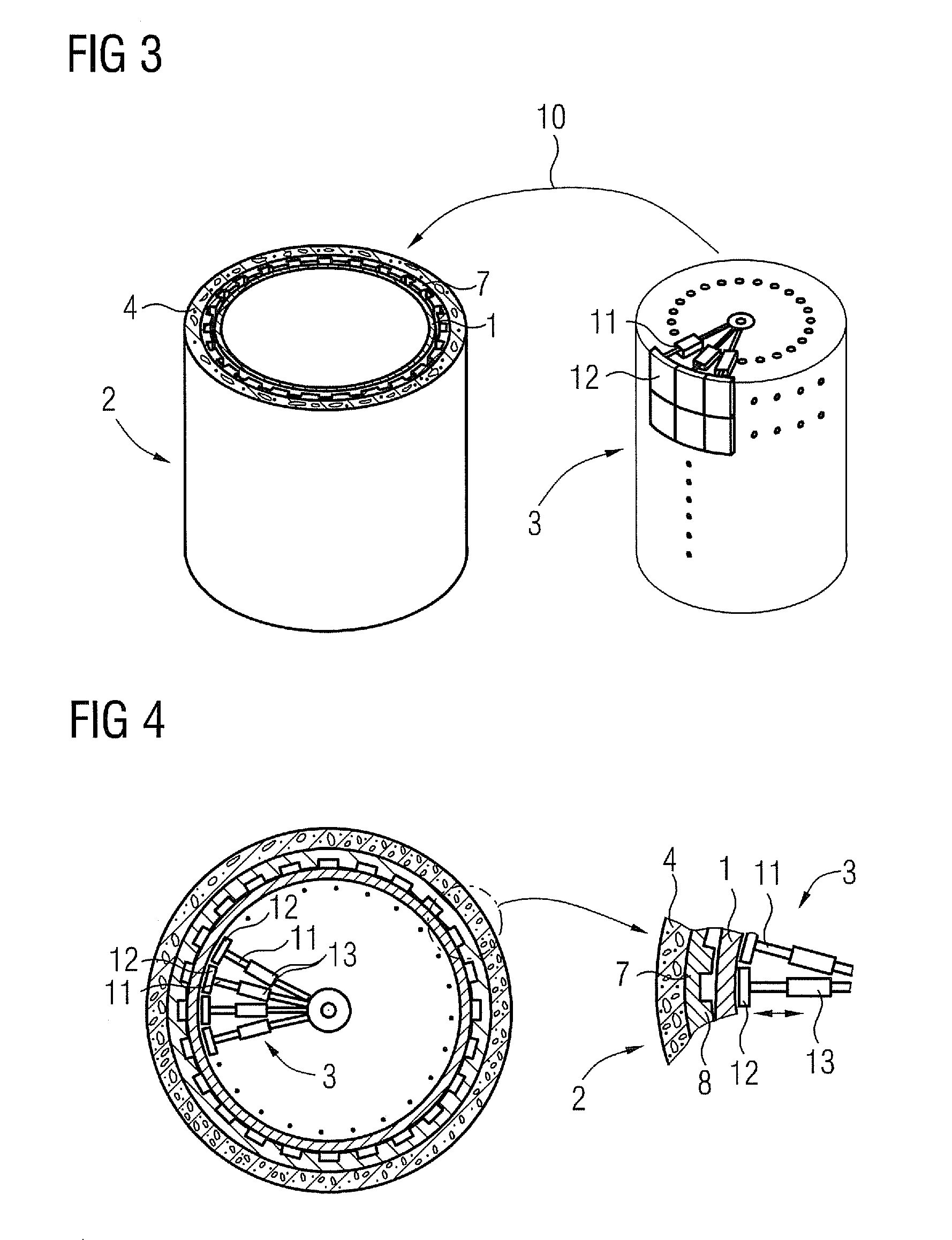

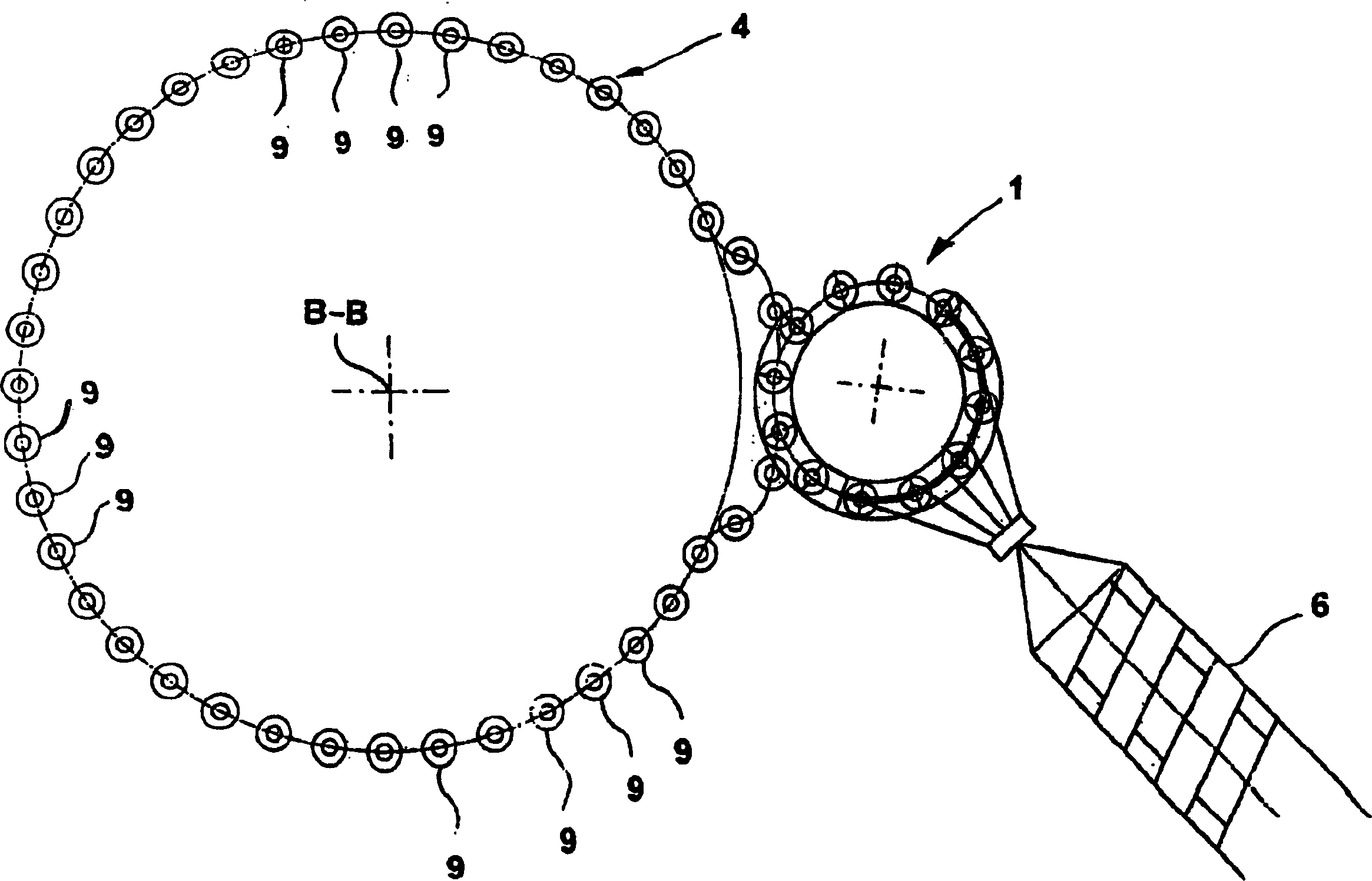

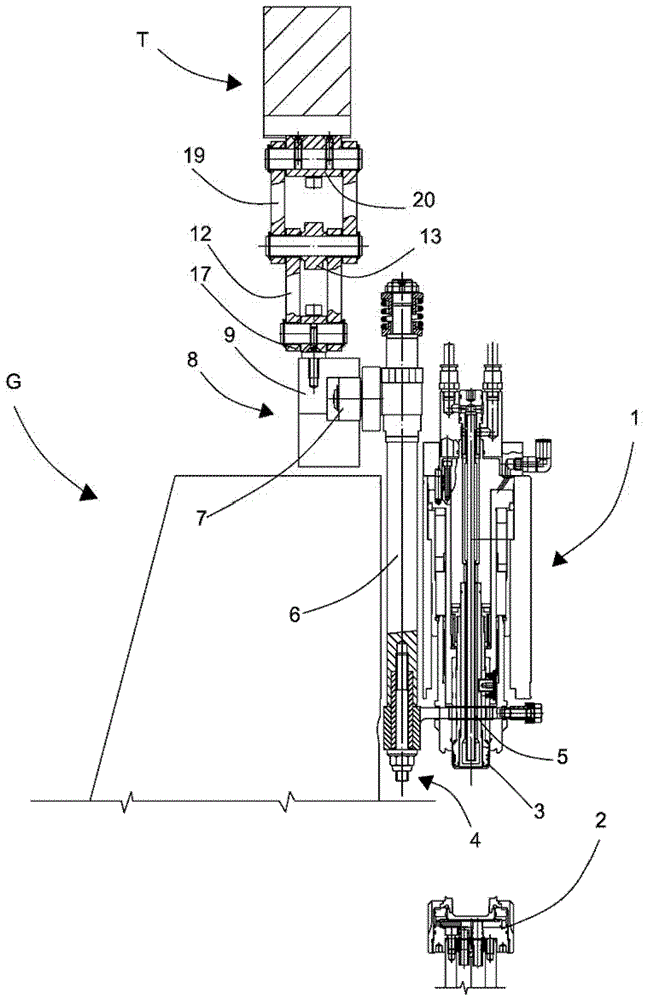

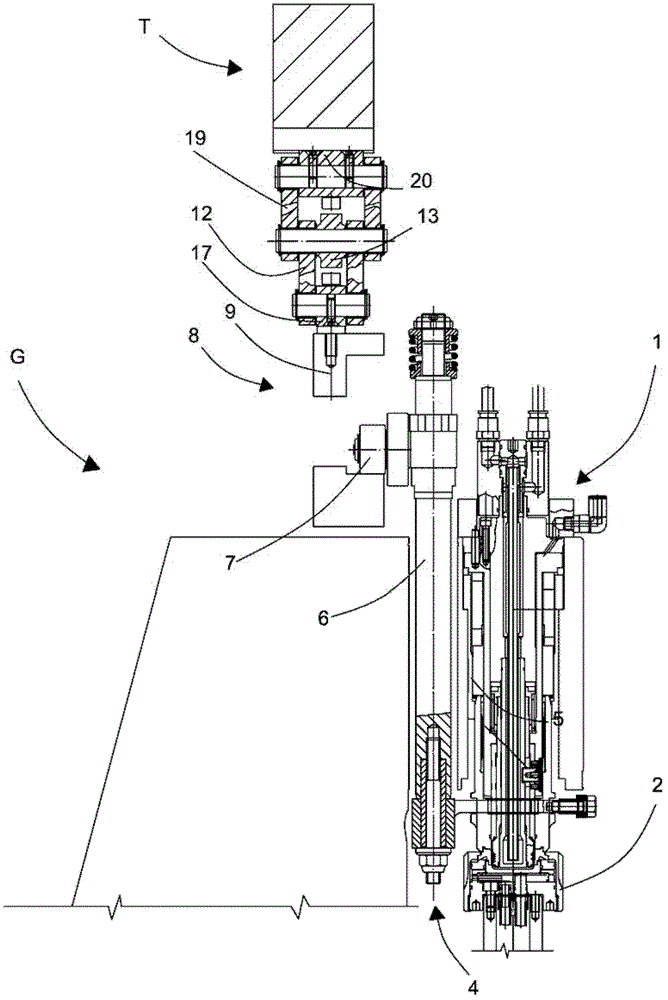

Method and apparatus for manufacturing a rotor

A method and apparatus for manufacturing a rotor are provided. The rotor is particular a rotor yoke for a wind turbine generator. A hollow rolled metal cylinder is provided and plastically deformed permanently to a predetermined shape and a predetermined size. The apparatus includes a pressing unit and a mould element.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Device and method for compression moulding of plastic articles

A device for compression moulding of plastic objects, comprising a plurality of compression-moulding units (9), each of which comprises a core mould element and a moulding cavity (2) filled by dropping into it a dose of plastic material; each moulding unit (9) is designed to carry out a moulding sequence comprising an operation of opening of the mould, an operation of filling of the moulding cavity, and an operation of closing of the mould. The device further comprises cam mechanisms for taking the moulding cavity outside of the vertical axes of the positive-mould element between the operation of opening of the mould and the operation of filling of the moulding cavity.

Owner:S.I.P.A.工业设计自动化股份公司

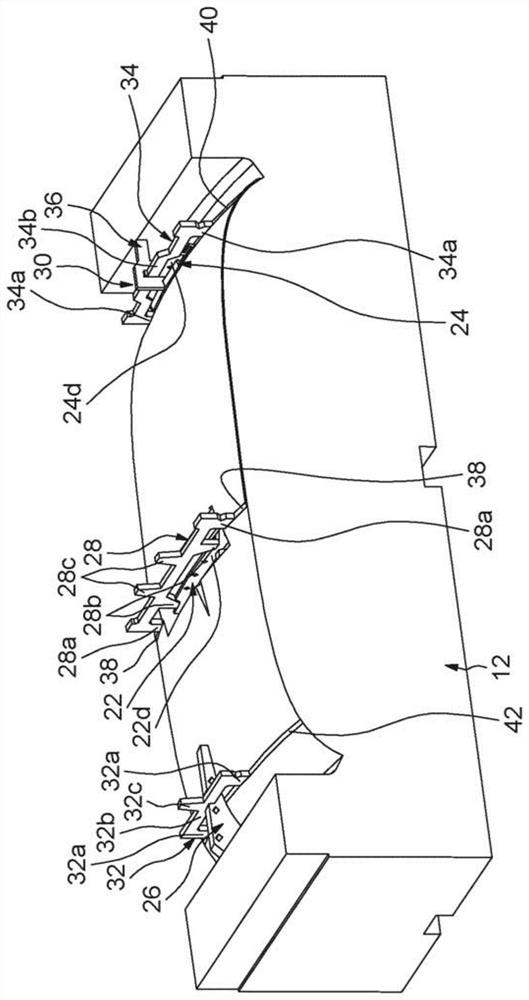

Method for cutting sectors for tyre moulds and semi-finished element for supplying sectors of a mould for moulding tyres

ActiveCN105793024APrecise positioningReduce consumptionTyresPositioning apparatusEngineeringMould Element

A cutting method for a semi-finished mould element (1) intended to supply sectors (2) of a mould for moulding and vulcanising tyres, said mould element (1) comprising at least one pair of male fastening members (3) on each side of a moulding face (4) designed to form the patterns of the tread of the tyre to be moulded, said method comprising the following steps: aligning and indexing the semi-finished mould element (1) on a fastening support (10) provided with indexing markings (14, 15) and female fastening members (12) corresponding to those of the mould element; fastening the indexed semi-finished mould element (1) to the fastening support (10) using the male fastening members (3) and female fastening members (12); cutting the sectors (2).

Owner:OCIETE DE TECH MICHELIN

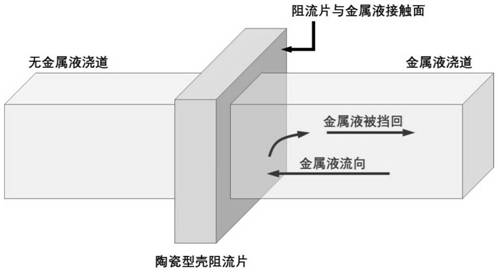

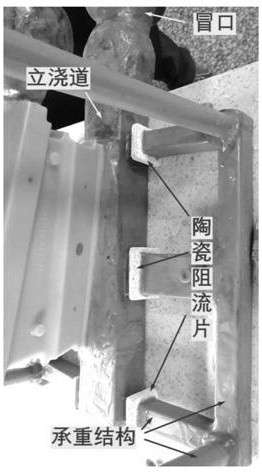

Large ceramic shell choking method for allowance-free precision casting

InactiveCN112475232AGuarantee the stability of the inner cavity profileControl flowFoundry mouldsFoundry coresInvestment castingAlloy

The invention discloses a large ceramic shell choking method for allowance-free precision casting, and belongs to the technical field of precision investment casting. The method comprises the following steps of designing a wax mould pouring system with spoilers, and adding the spoilers to the positions where the flow direction needs to be controlled and a bearing structure needs to be controlled;and the spoilers are made of a ceramic material. According to the combination of the wax mould pouring system with the spoilers, firstly, the prepared clean spoilers are connected with wax mould elements in the pouring system, and then the combination of the whole wax mould pouring system is carried out; and then shell making, dewaxing and sintering are carried out to obtain a final shell. The ceramic shell provided with the ceramic spoilers and designed by the invention is used for allowance-free precision casting and pouring of oversized blades, the flowing direction of molten metal is accurate, the usage amount of a mother alloy is remarkably reduced, and the production cost of precision castings is greatly reduced; and meanwhile, due to the fact that the usage amount of the mother alloy is greatly reduced, shell expansion of the ceramic shell is not generated any more, and the product percent of pass is also greatly increased. The method is reasonable in structural design, simple to operate and high in process stability.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Device and method for compression moulding of plastic articles

A device for compression moulding of plastic objects, comprising a plurality of compression-moulding units (9), each of which comprises a core mould element and a moulding cavity (2) filled by dropping into it a dose of plastic material; each moulding unit (9) is designed to carry out a moulding sequence comprising an operation of opening of the mould, an operation of filling of the moulding cavity, and an operation of closing of the mould. The device further comprises cam mechanisms for taking the moulding cavity outside of the vertical axes of the positive-mould element between the operation of opening of the mould and the operation of filling of the moulding cavity.

Owner:S.I.P.A.工业设计自动化股份公司

Method and device for manufacturing a multilayer compression moulded element

The invention relates to a method and a device for manufacturing a multi-layer compression molded element and to a compression molded element which is embodied as a multi-layer carbon brush and has at least a first and a second molding layer, in which, in order to carry out the method, a multi-component mould which comprises a molding element and a mould slide arrangement interacts with a molding die, and in which a mould which is defined by the selected configuration of the molding slide arrangement in the molding element is filled by filling molding segments which are formed one next to the other with molding material in chronological succession in a transverse direction with respect to the axis of the molding die, and by the compression molded element being subsequently formed by moving the molding die and molding slide arrangement relative to one another in the mould.

Owner:SCHUNK KOHLENSTEOFFTECHNIK GMBH

Blow mould

A blow mould includes at least first and second blow mould elements that inscribe a concavity; and at least one insert having an embossed surface to form a pattern onto a blow-moulded surface. The at least one insert is attached onto a surface of at least one of the first and / or second blow mould elements to form a part of the wall of the blow-moulded product. Such blow mould is an ISBM blow mould and the blow mould is such that the at least one insert is a plate having a wall thickness of between 0.2 mm and 2.0 mm and is attached onto at least one of the first and / or second blow mould elements by a reversible fixation mechanism selected from the group of adhesives, preferably a double-sided adhesive tape, a magnet and a geometric mechanism.

Owner:RESILUX NV

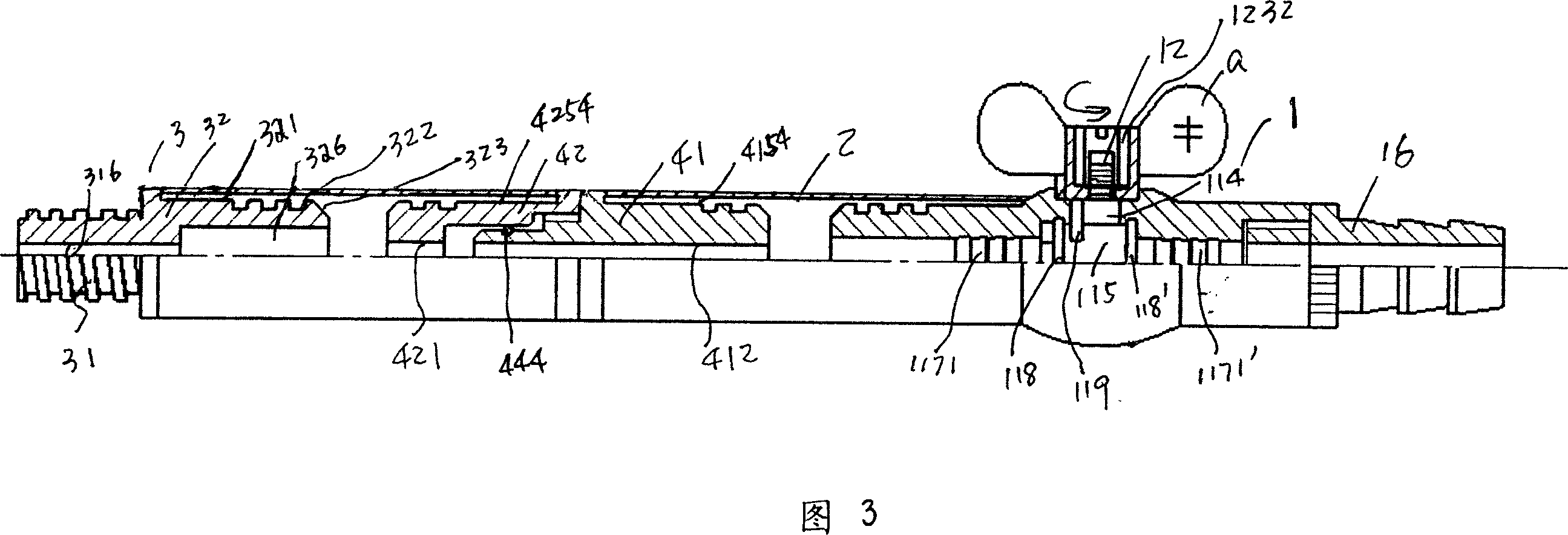

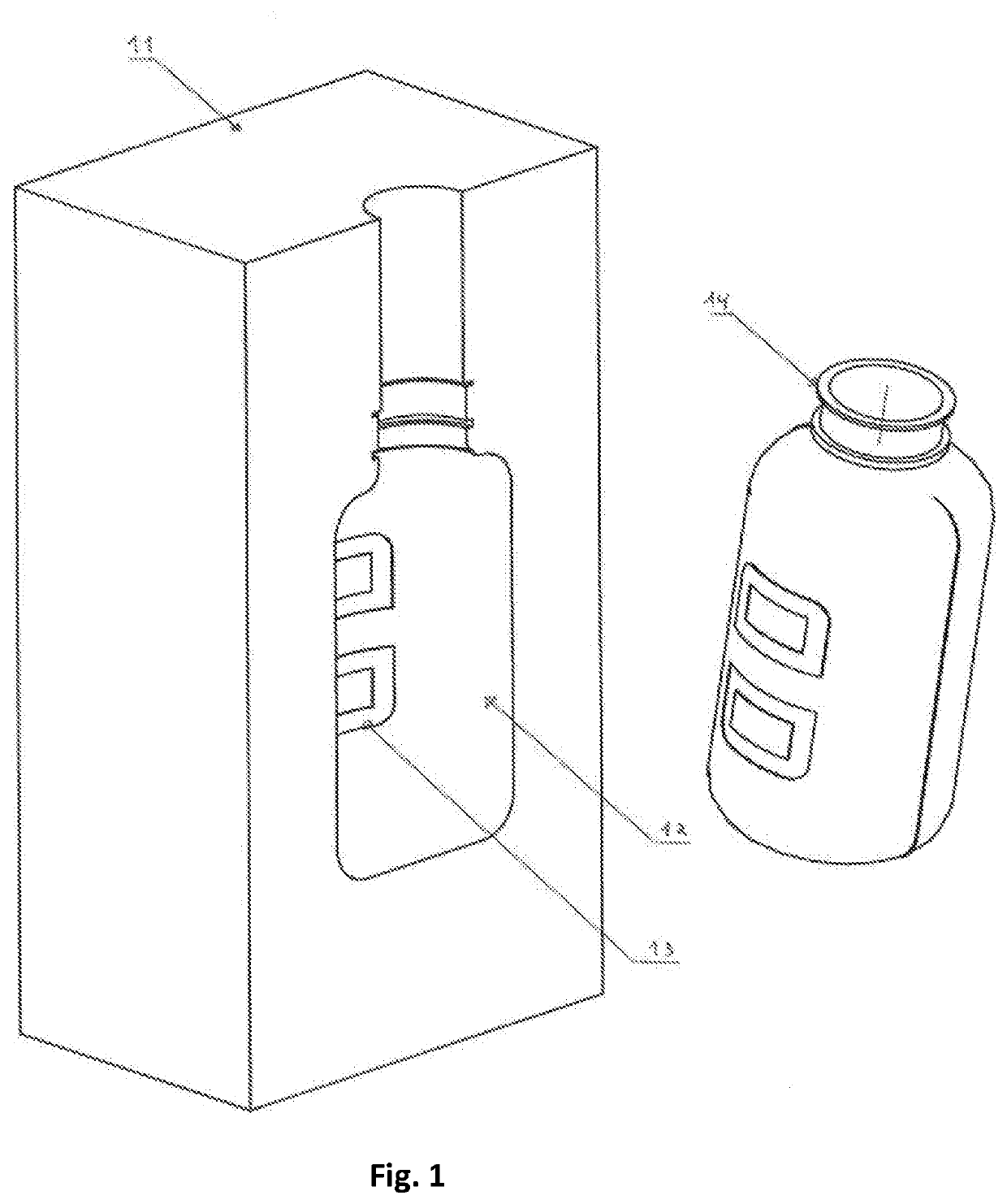

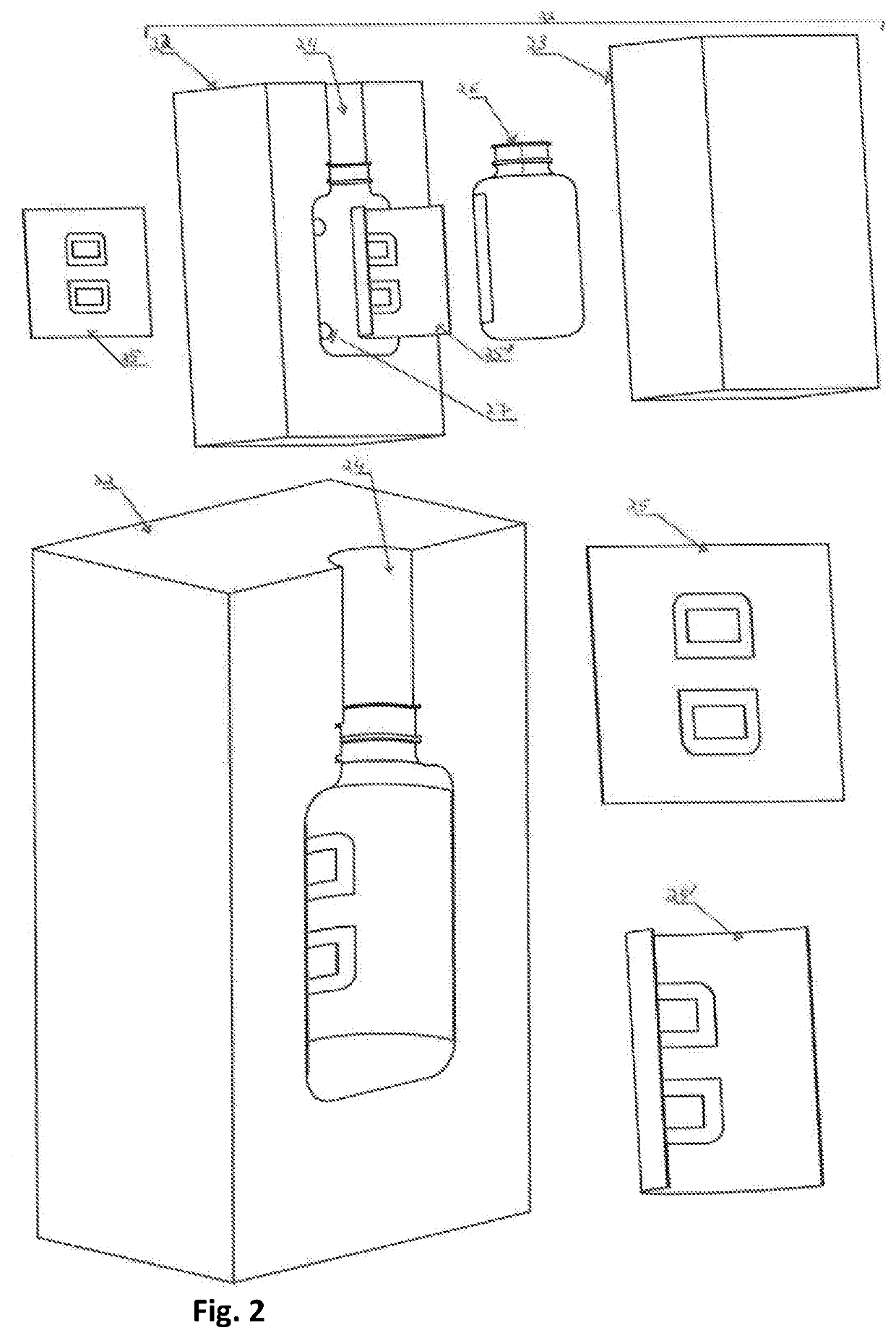

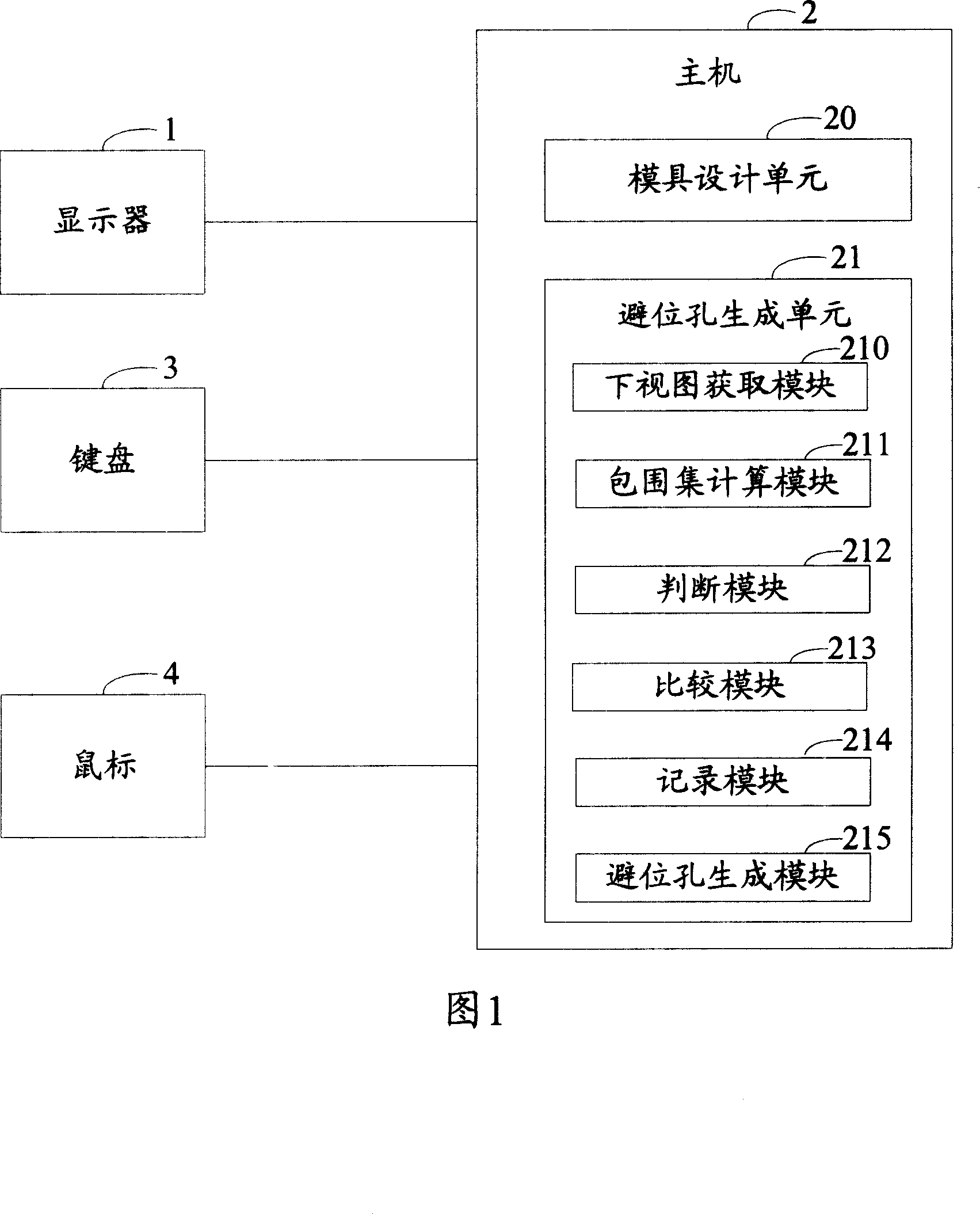

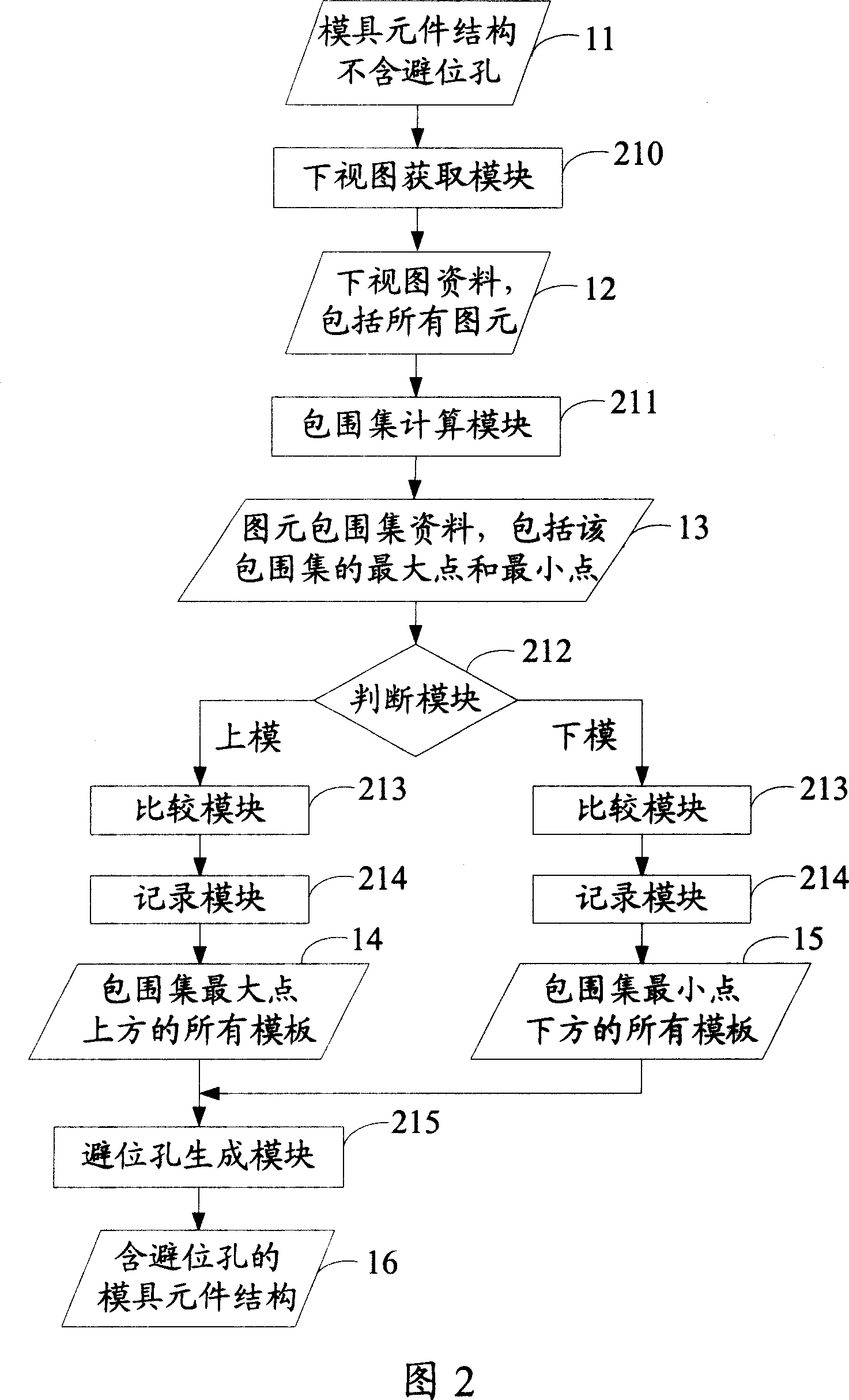

Mould element structural avoid-hole automatic generation system and method

InactiveCN101055603AAvoid cumbersomeAvoid mistakesSpecial data processing applicationsMould ElementEngineering

The invention provides a system and method for automatically generating a bit-preventing hole of mould element structure. The method includes the steps of: generating the mould element structure; extracting the planform of the mould element structure to acquire all metafiles of the planform; figuring out the enclosure of the metafiles; judging the position of the mould element structure; comparing the maximum point or the minimum point of the enclosure with all position parameters of moulding board in the mould; recording all moulding boards above the maximum point of the enclosure or all moulding boards under the minimum point of the enclosure; generating the bit-preventing hole of mould element structure on all moulding boards above the maximum point of the enclosure or on all moulding boards under the minimum point of the enclosure according to the size of parts in the mould element structure. The bit-preventing hole of mould element structure, using the invention, can be produced automatically and accurately after drawing each mould element structure, with the advantages of rapid speed, high accuracy and good applicability.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Method for manufacturing a wind turbine rotor blade

ActiveUS9422916B2Simple manufacturing methodEasy to operateEngine manufactureLaminationEngineeringMould Element

A method for forming a profile for a hollow component is provided. A first composite fiber layer is laid out on a first surface corresponding to a first profile section of the component. A second composite fiber layer is laid out in a second surface corresponding to a second profile section of the component. A collapsed bag is laid out in onto the first composite fiber layer. The bag and the first composite fiber layer are fixed to the first surface. First and second mould elements are coupled such that the first surface and the second surface correspond to the first and second profiles. The bag is inflated such that the first composite fiber layer is pressed to the first surface and the second composite fiber layer is pressed to the second surface so that the first and second layers are coupled to form the profile.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

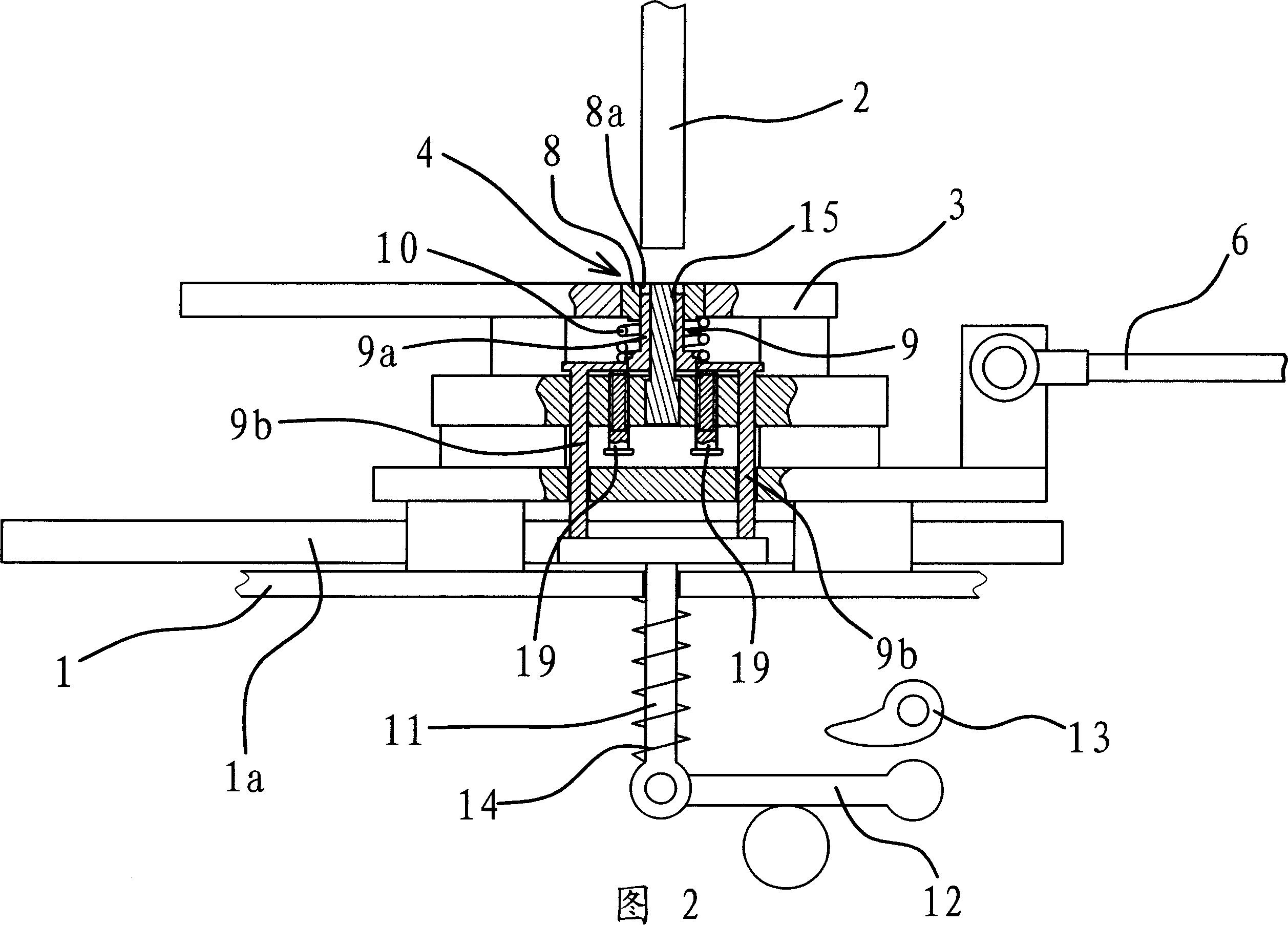

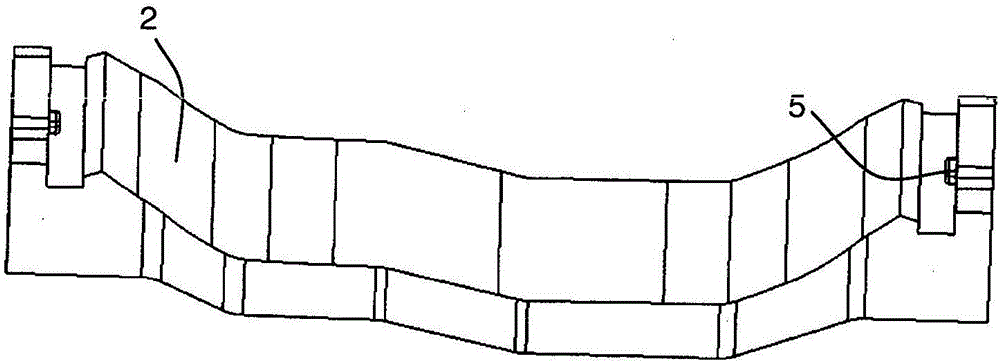

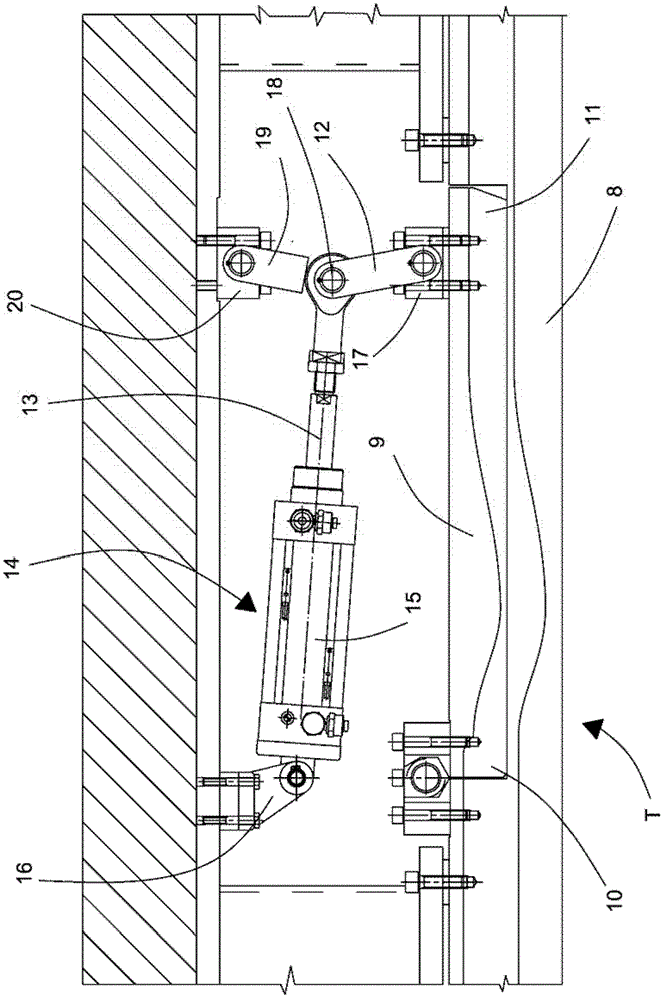

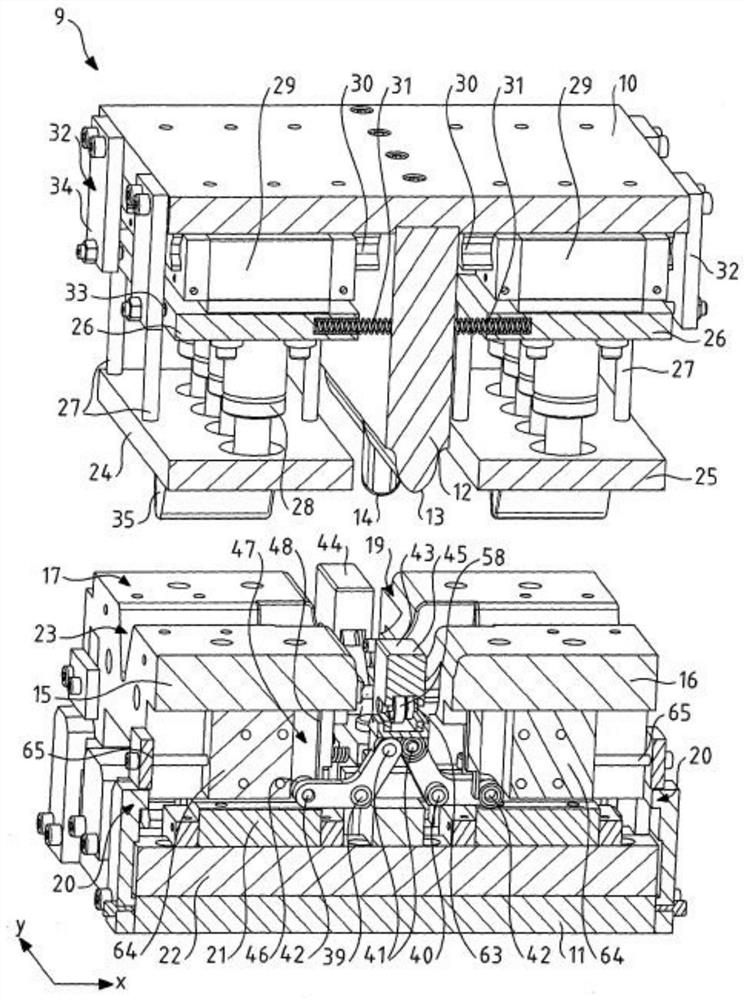

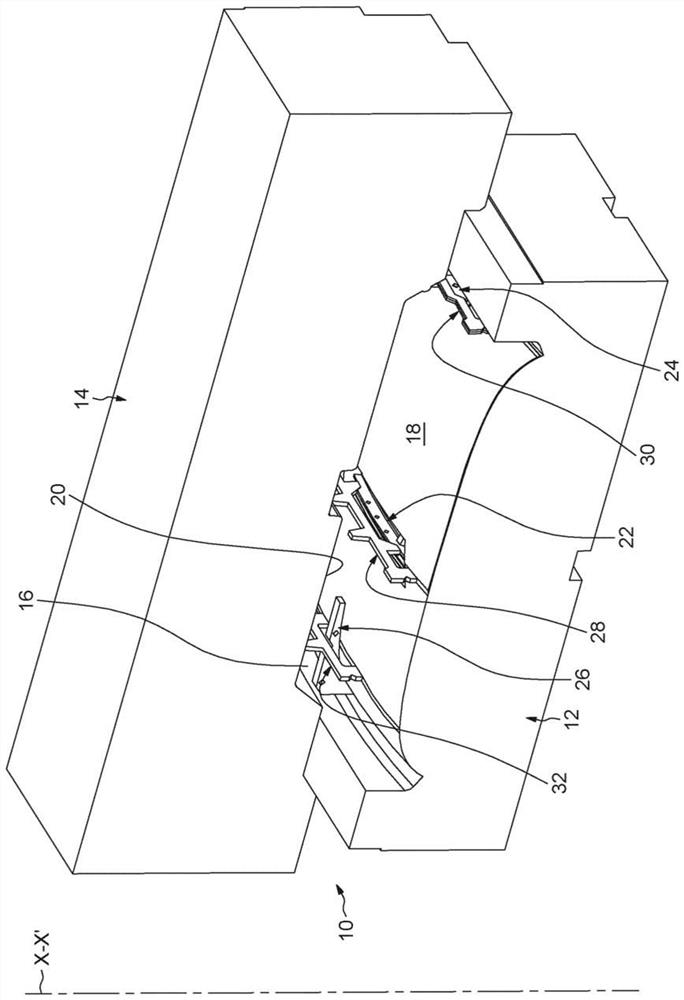

A folding device for forming corrugations in sheet metal

The invention relates to a folding device (9) for forming corrugations in a metal sheet for constructing a sealing membrane of a fluid storage tank, said folding device comprising: - an upper frame (10), - a lower frame (11), - a lower mold, with a first and a second mold element (14), the first and second mold elements are mounted slidingly on the lower frame (11) in the x direction, - an upper punch, - a first side clamps and a second side clamp (20), - an auxiliary device designed to assist at least one of the first and second die elements (14) in moving to the closed position, with the movement of the upper punch to the folded position Cooperating, wherein said auxiliary device is designed to move at least one of the first and second mold elements (14) according to a speed ratio that varies between the idling position and the folded position, the speed ratio being the mold element (14) at The ratio of the linear velocity in the x direction to the linear velocity of the upper punch (12) in the z direction.

Owner:GAZTRANSPORT & TECHNIGAZ SA

Process for the realization of counter- mould elements for the containment of welding bead of plastic profiled elements

ActiveCN109689343ASimple appearancePractical appearanceAdditive manufacturing with liquids3D object support structuresEngineeringAbutment

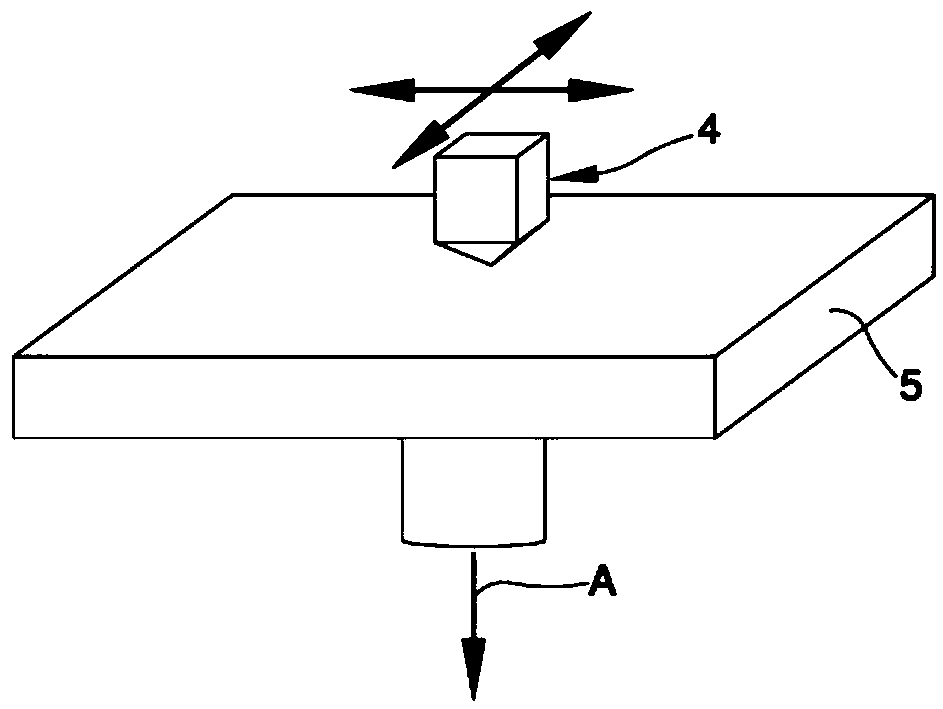

Process for the realization of counter-mould elements for the containment of welding bead of plastic profiled elements, in which counter-mould elements (1) have a main body (2) adapted to receive in abutment a pair of profiled elements of plastic material welded together to obtain a frame for windows / doors, each profiled element comprising a welding surface weldable to the welding surface of another profiled element in a welding configuration in which the lateral faces of profiled elements are substantially adjacent to one another and define a locator surface, wherein the process comprises: aphase of acquisition of the profile of a portion of the lateral faces; a phase of definition of the profile of a contact surface (3) of the main body (2) adapted to receive in abutment the locator surface, the profile of the contact surface (3) being substantially complementary to the profile of the locator surface; a phase of three-dimensional molding obtained by means of a three- dimensional molding device (4) to obtain the main body (2) starting from the profile of the contact surface (3) obtained in the phase of definition.

Owner:GRAF SYNERGY

Safety device for punches in a compression moulding apparatus

Owner:SACMI COOP MECCANICI IMOLA SOC COOP A R L

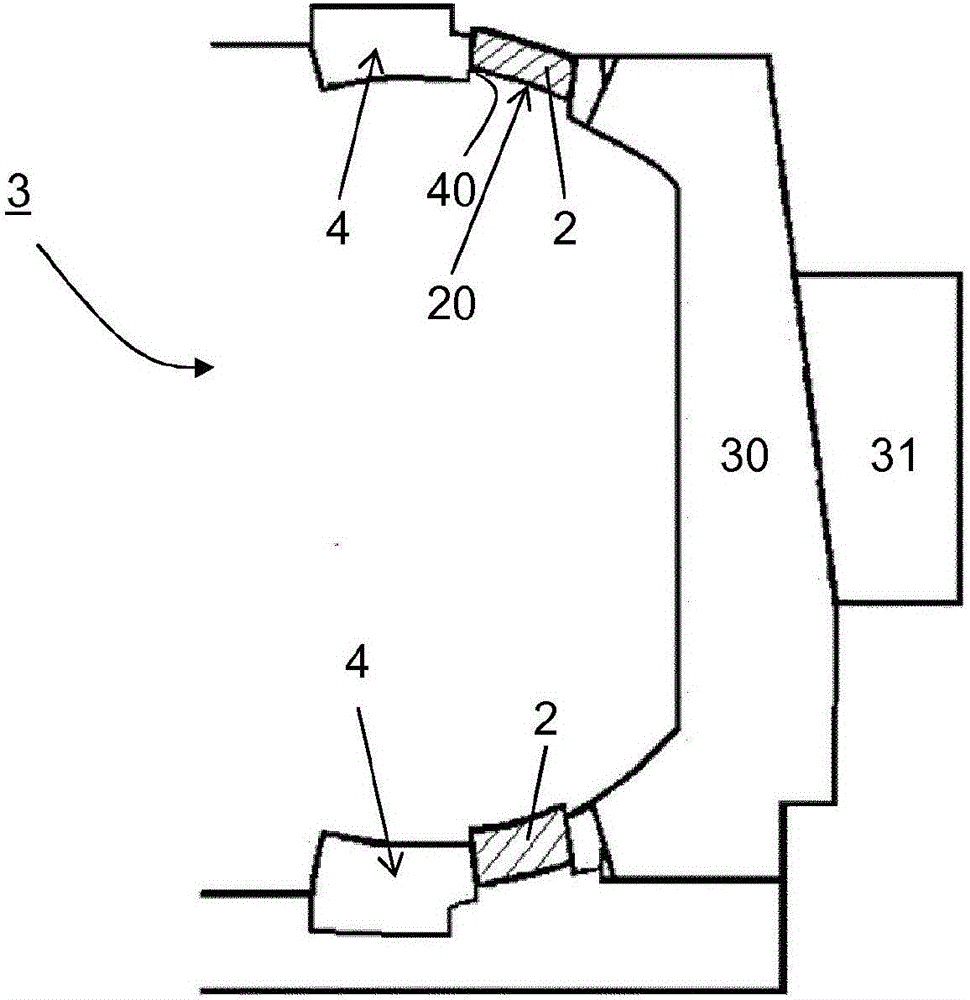

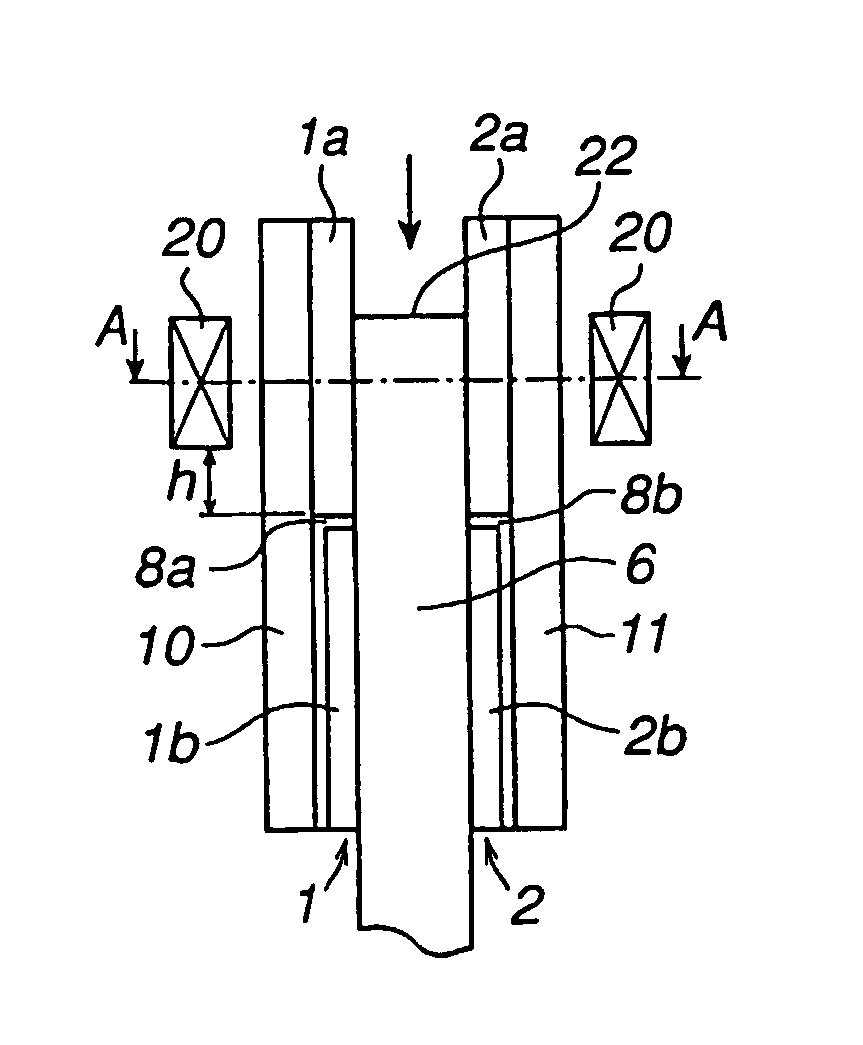

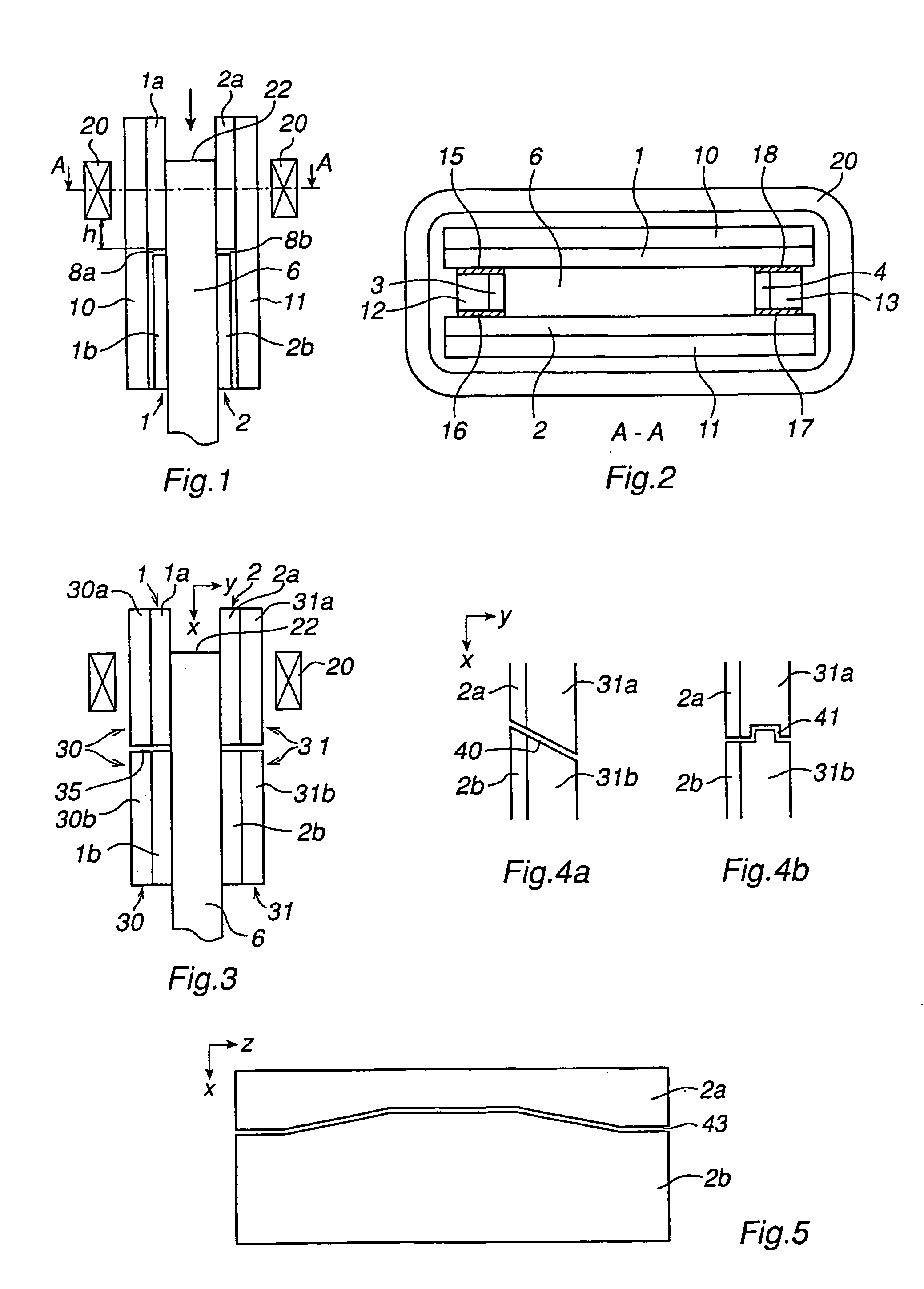

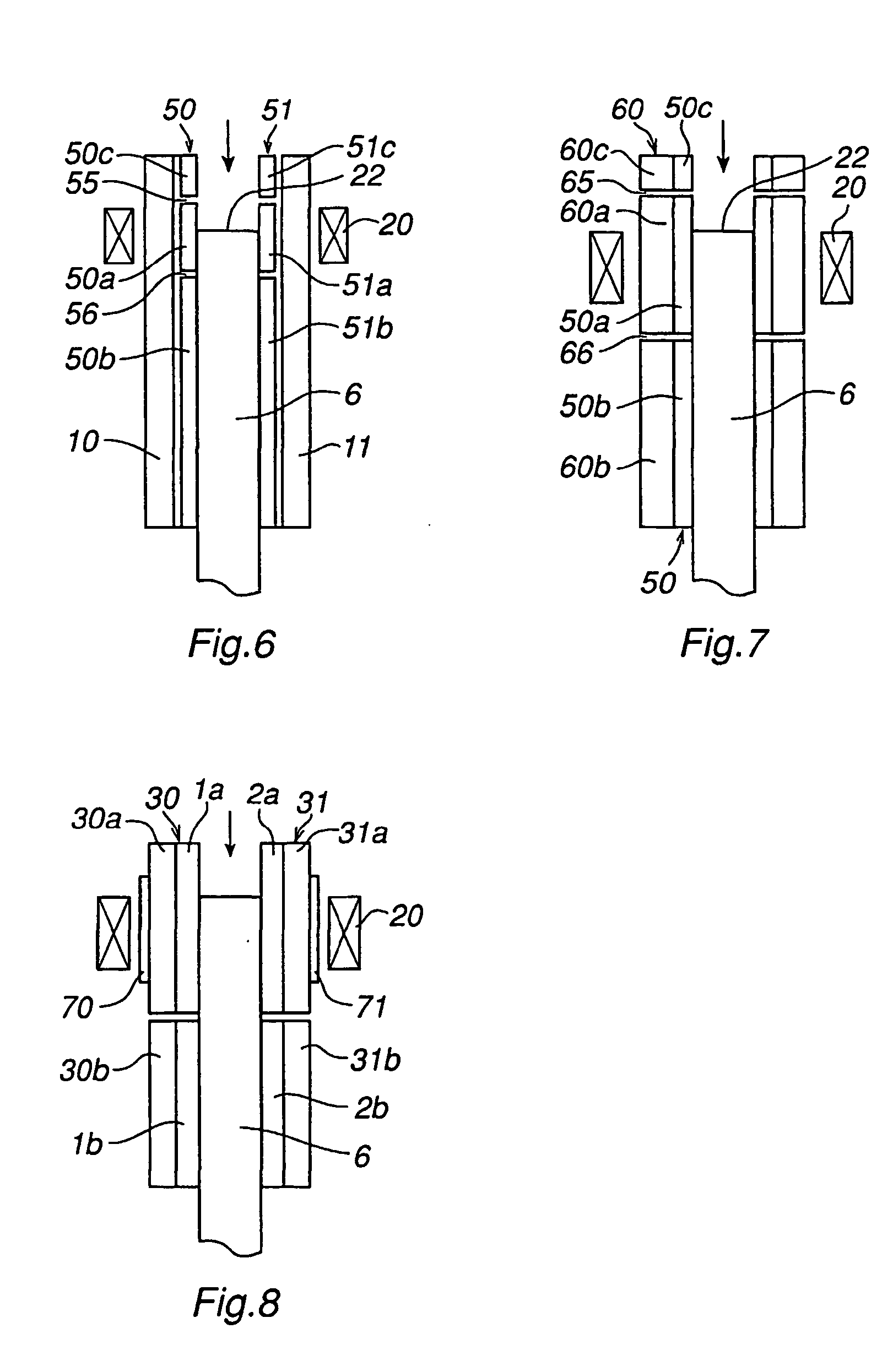

Device for casting of metal

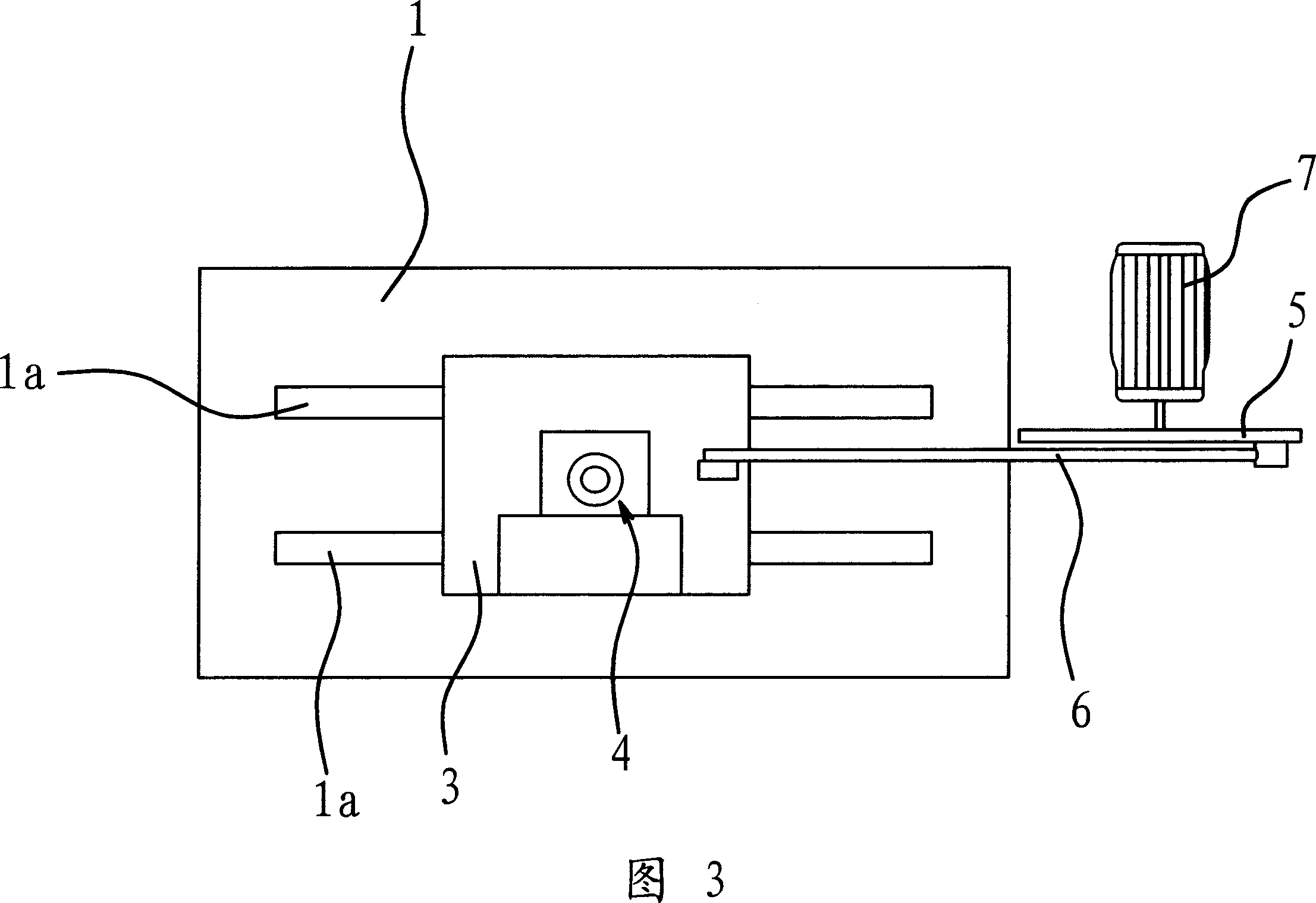

A device for continuous or semi-continuous casting of metal comprising a mould having a number of mould elements (1, 2) which together form a mould adapted for receiving a liquid metal (6), a mould supporting structure (30, 31) surrounding the mould and mechanically supporting it, and an induction coil (20) arranged close to the mould for reducing the contact pressure between the melt and the mould. At least one of the mould elements is divided into at least a first (1a, 2a) and a second (1b, 2b) part arranged so that they are electrically insulated from each other, the first mould element part being arranged before the second mould element part relative to the casting direction and said induction coil is arranged close to the first mould element part (1a, 2a).

Owner:ABB (SCHWEIZ) AG

Punch components

Owner:SACMI COOP MECCANICI IMOLA SOC COOP A R L

Bending machine for forming corrugations in sheet metal and method of use

The invention relates to a bending machine (9) for forming corrugations (2) in a metal sheet (1) for the construction of fluid-tight membranes for fluid storage tanks, said bending machine (9) comprising:- frame (11); - a lower mold comprising first and second mold elements (15, 16) mounted on said lower frame (11) to slide in the x-direction; - an upper punch (12); - first and second die pads (24, 25); - said bending machine (9) also includes auxiliary devices (36, 37), said auxiliary devices (36, 37) Adapted to assist movement of said first and second mold elements (15, 16) into an engaged position. The invention also discloses a method of using the machine.

Owner:GAZTRANSPORT & TECHNIGAZ SA

Method for manufacturing a mould element for a tyre mould

The method for manufacturing a mould element using a manufacturing device of the type comprising a die and a counter-mould defining a moulding cavity in the closed position, comprises the following steps: - opening the manufacturing device; - placing at least one insert (22), produced by laser sintering, against a moulding surface of the die; - mounting at least one wedge (28) on the die in abutment against said insert in order to immobilise it relative to said moulding surface; - closing the manufacturing device, the counter-mould pressing onto said wedge in order to keep said insert pressed against said moulding surface; - injecting aluminium into the moulding cavity of the manufacturing device; - opening the manufacturing device; - extracting from the manufacturing device the mould element provided with a moulding face at least formed by part of said insert and by the aluminium.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com