A folding device for forming corrugations in sheet metal

A folding device, metal plate technology, applied in applications, household appliances, hollow objects, etc., can solve the problems of reducing thickness, reducing service life, damaging plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

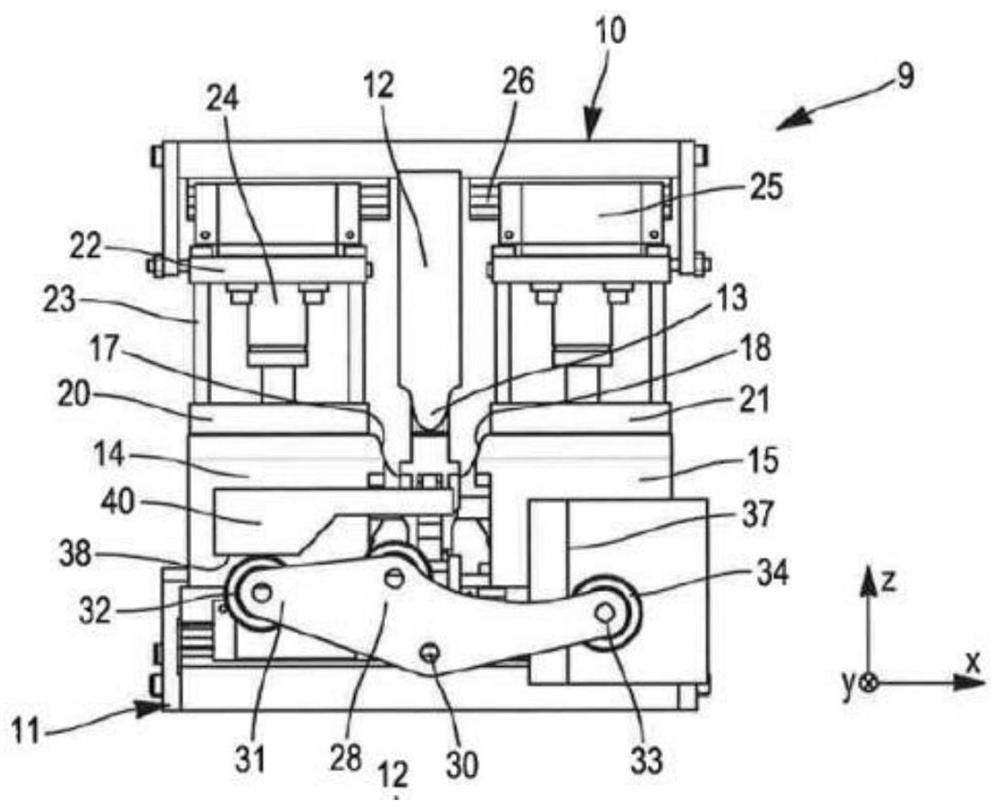

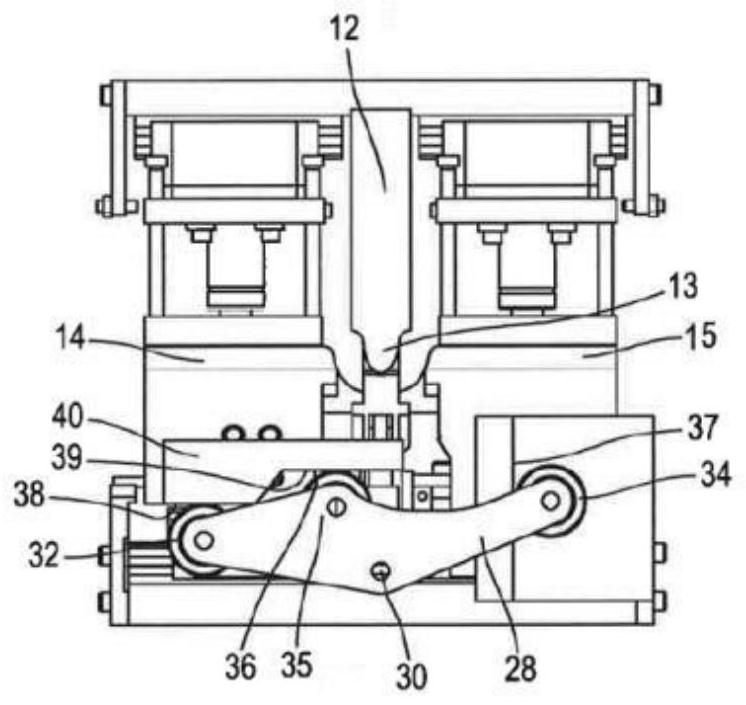

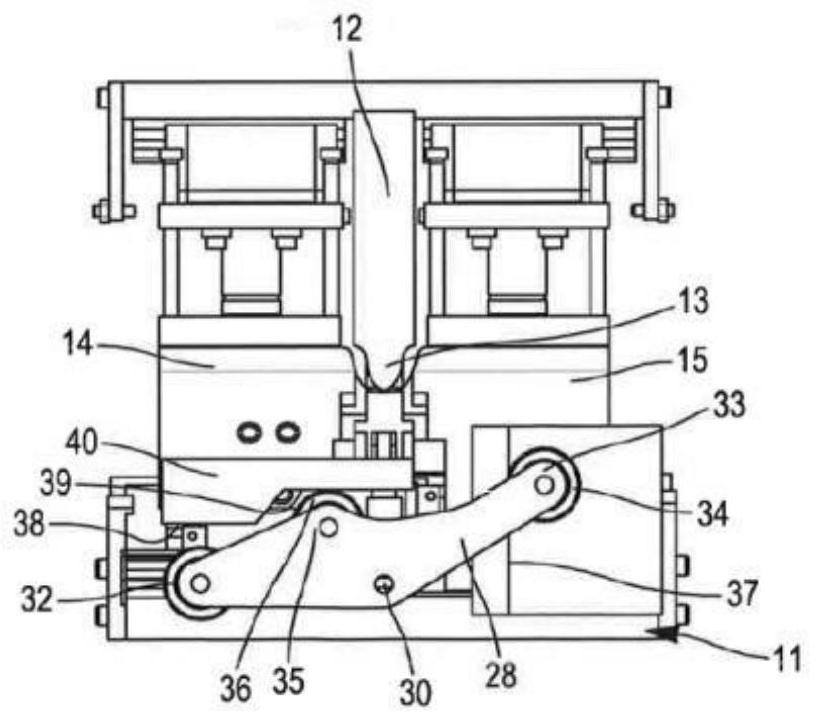

[0079] Conventionally, the "longitudinal" orientation of the folding device 9 is parallel to the axis y, ie parallel to the direction of the corrugations 2 to be formed, and the "transverse" orientation is parallel to the axis x, ie perpendicular to the direction of the corrugations 2 to be formed.

[0080] Figure 9 A corrugated metal sheet 1 is shown for forming a sealing membrane for storage tanks for cryogenic fluids, such as liquefied natural gas.

[0081] Rectangular metal plate 1 has a first series of parallel corrugations 2, called low corrugations, which extend from one edge of the plate to the other in the y direction, and a second series of parallel corrugations 3, called high corrugations, high corrugations along x The direction extends from one edge of the metal plate 1 to the other. The directions x and y of the series of corrugations are vertical. The corrugations 2, 3 protrude, for example, from the inner surface of the metal plate 1 and are designed to come ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com