Punch components

A component and punch technology, which is applied to household components, household appliances, other household appliances, etc., can solve the problem of not providing detailed information on the structure of the second cooling circuit and the third cooling circuit, and achieve simple structure, easy assembly, The effect of simplified maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

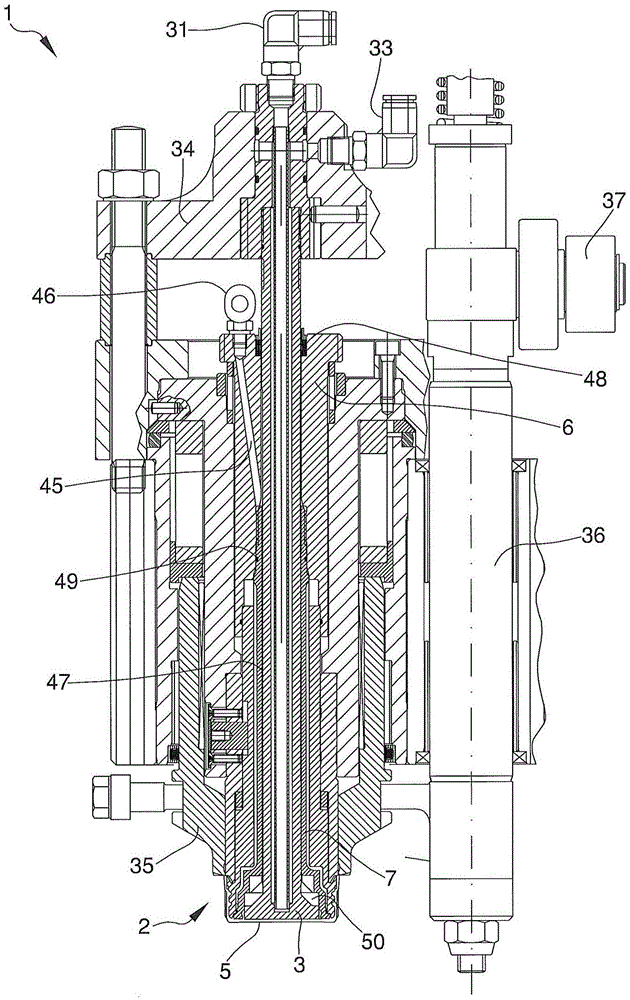

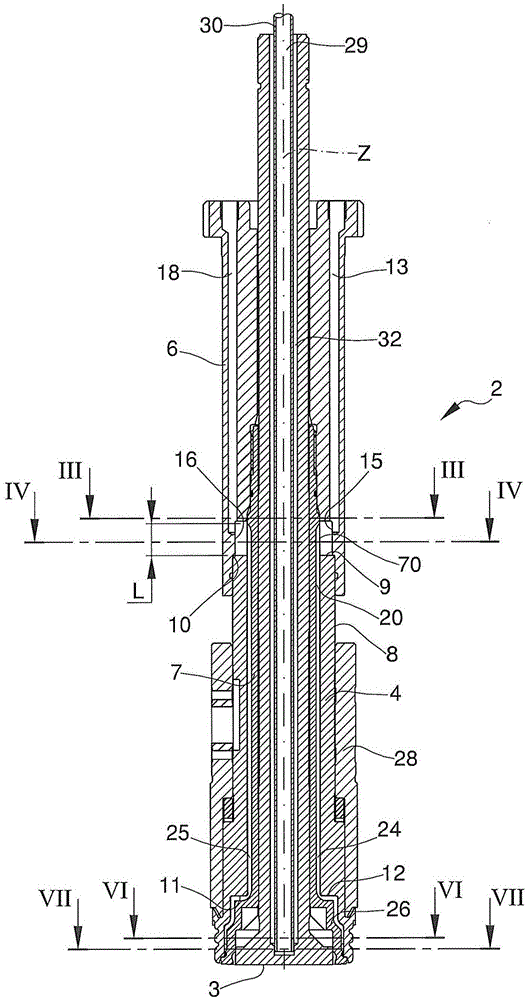

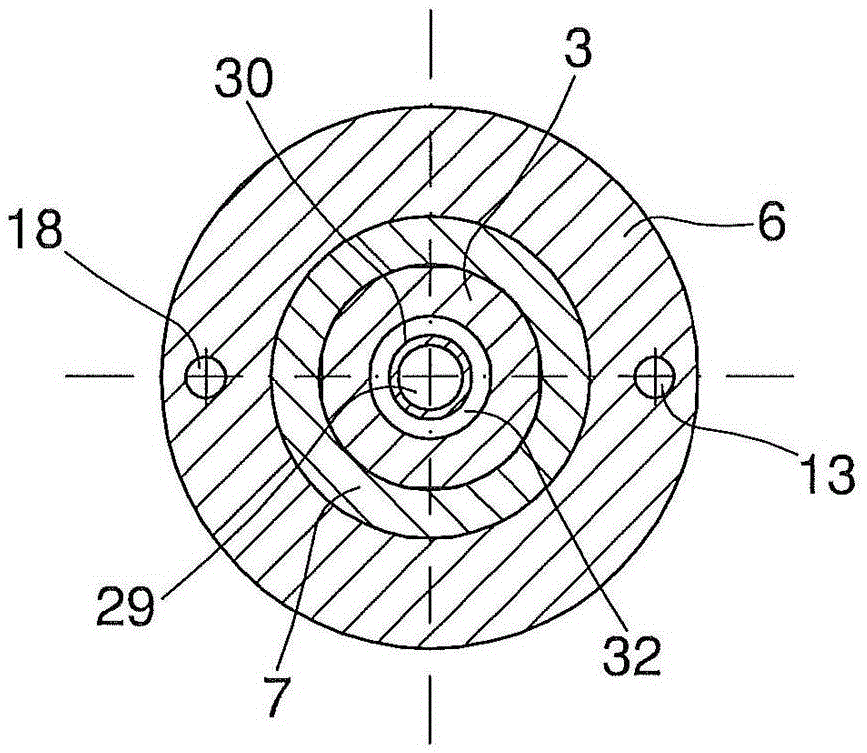

[0076] figure 1 Shown is a part of a molding unit 1 comprising a male mold element 2 which can also be found in figure 2 see in.

[0077] The male mold element 2 can be used to obtain an object 5 made of polymer material by injection molding or compression molding. The object 5 may be a hollow object such as, for example, a cap for a bottle, or more generally a cap for a container. In this case, the male mold element 2 cooperates with an unillustrated female mold (female mold) element included in the molding unit 1 .

[0078] Alternatively, the object 5 may be a substantially flat object, such as a seal for a bottle cap, or more generally a container cap. The seal can be molded directly inside the previously formed cap by means of the male mold element 2 . In this case, the molding unit 1 comprises, instead of the female molding element, a support element, not shown, for supporting the lid on its inner side on which the seal has to be formed.

[0079] The molding unit 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com