Mould element for a tyre mould comprising a mark

A technology of molds and components, applied in tires, household appliances, and other household appliances, can solve the problems of unrecognizable coding matrix symbols, complex and expensive laser etching production lines, etc., and achieve an easy-to-read effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In the ensuing description, substantially the same or similar elements will be denoted by the same reference numerals.

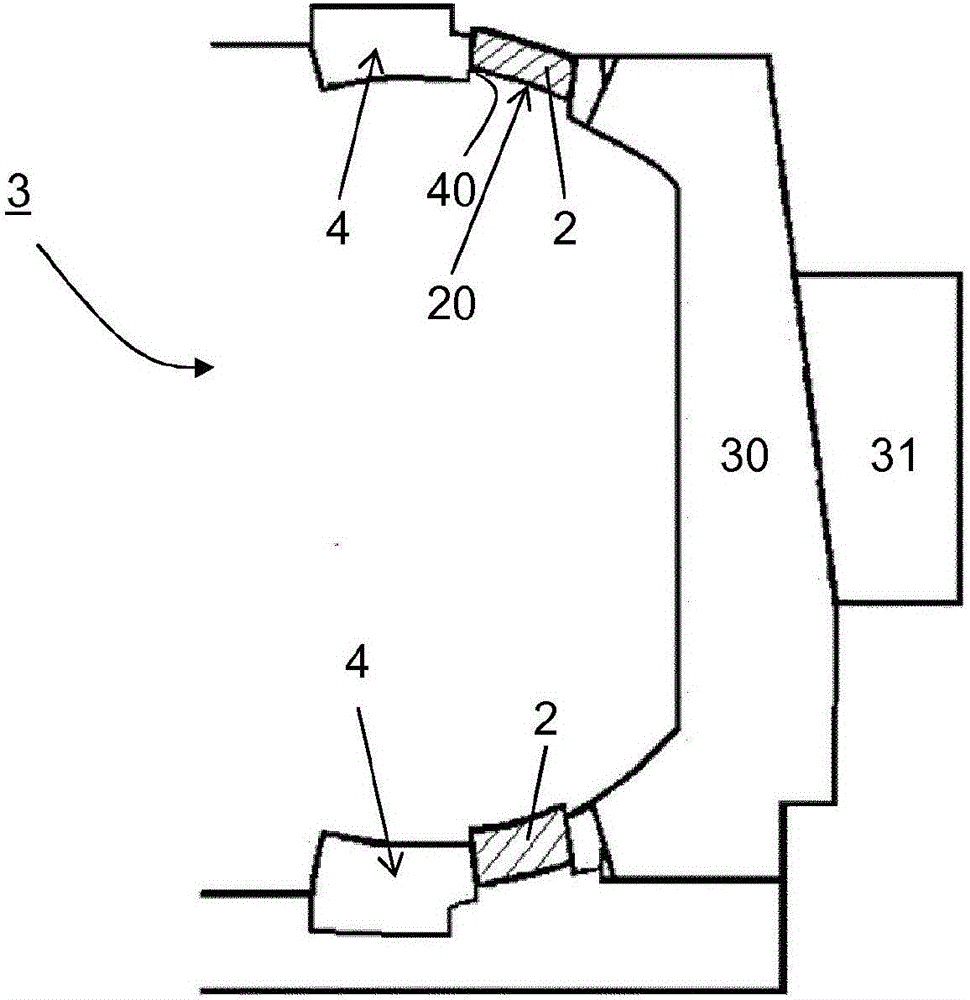

[0068] figure 1 A mold 3 is shown comprising:

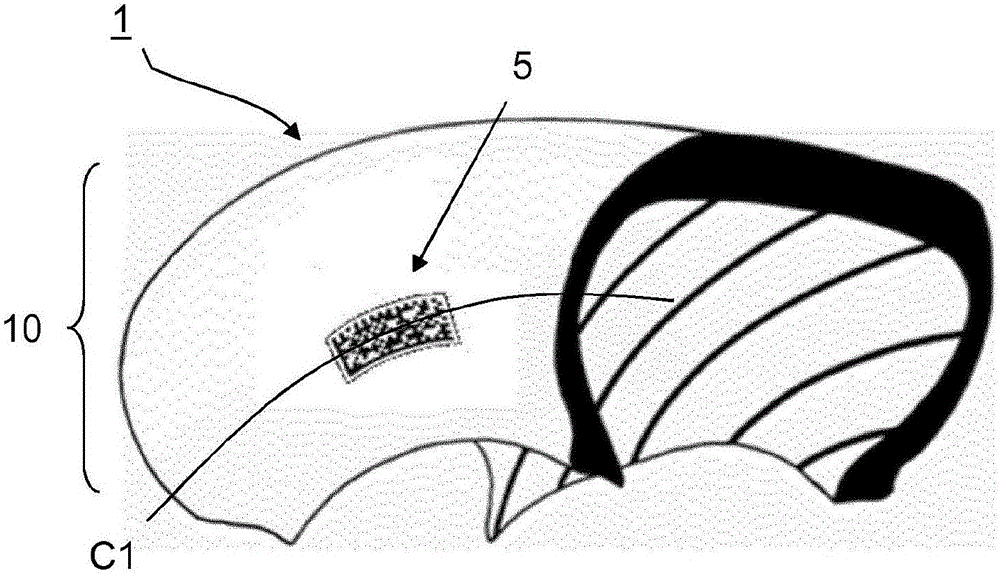

[0069] - a housing 4 intended for molding the sidewall 10 of the tire 1 , said housing comprising a housing 40 in which the mold element 2 is installed;

[0070] - the closed section 30 is held (clamped) by the conically thinned strip 31 ;

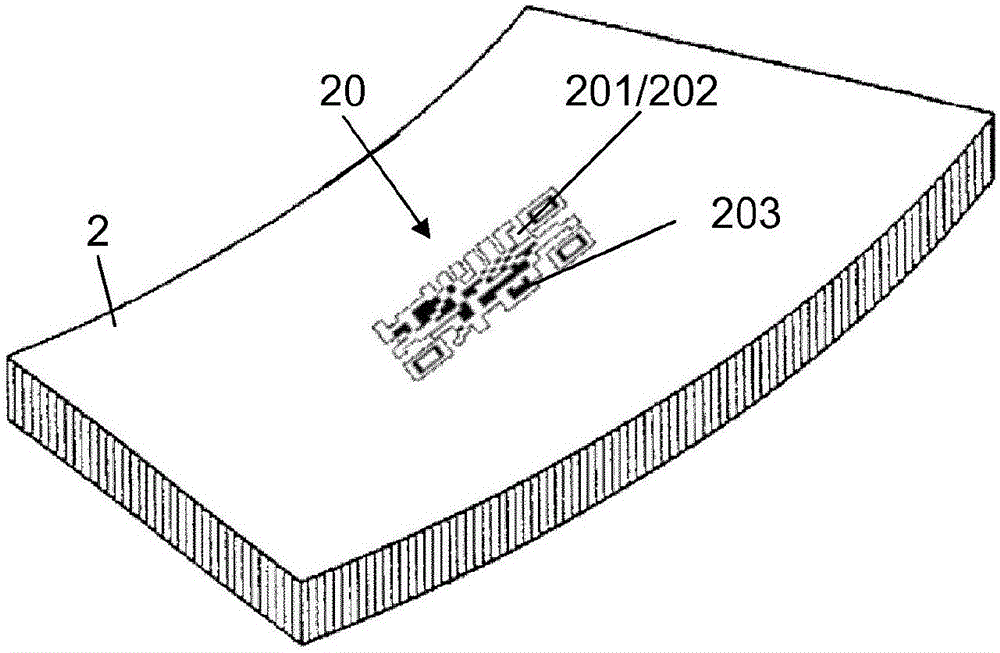

[0071] - Mold element 2 comprising markings 20 .

[0072] The mold element 2 is a removable insert intended to be mounted in the housing 40 of the housing 4 . In a non-limiting embodiment, said insert 2 is made of aluminum. This makes it possible to have a plastically removable insert and thus makes it easier to create markings in the insert 2 . The markings 20 are intended to be molded on the tire with coded matrix symbols 5 in contrast to the sidewall of the tire. The indicia 20 thus correspond to the inverse shape of the coding matrix symbols 5 to be imprint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com