Safety device for punches in a compression moulding apparatus

A technology for safety devices and objects, applied in the direction of household components, applications, household appliances, etc., can solve problems such as damage to mold components or removal mechanisms, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

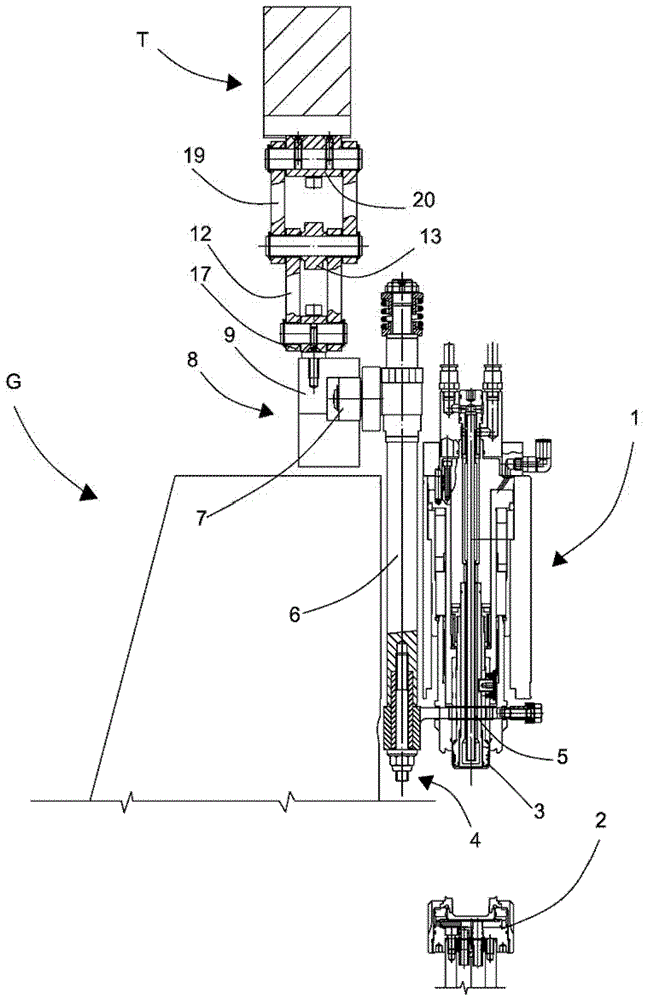

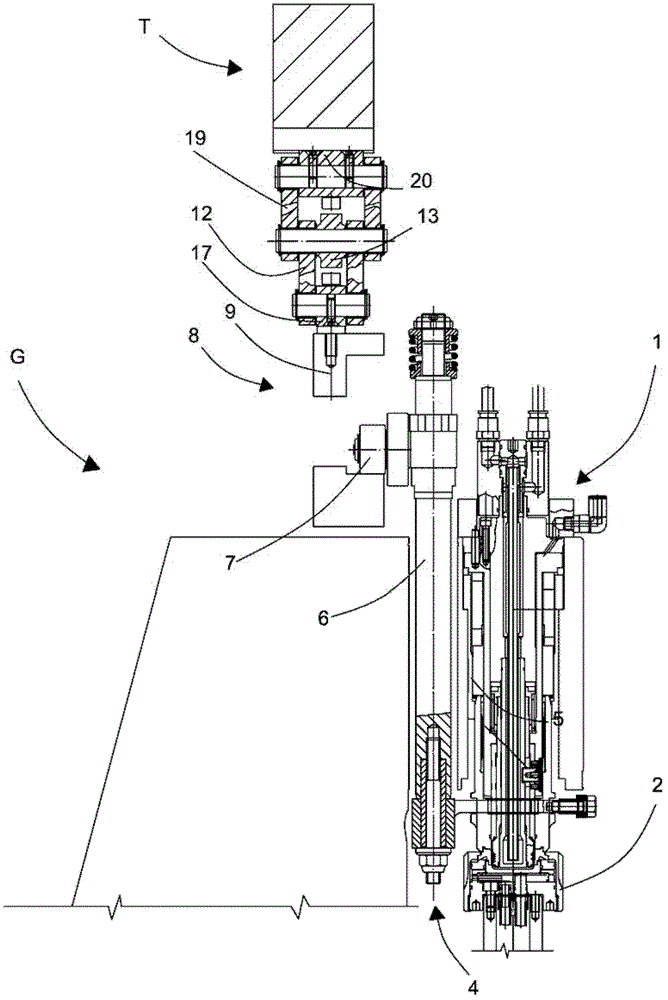

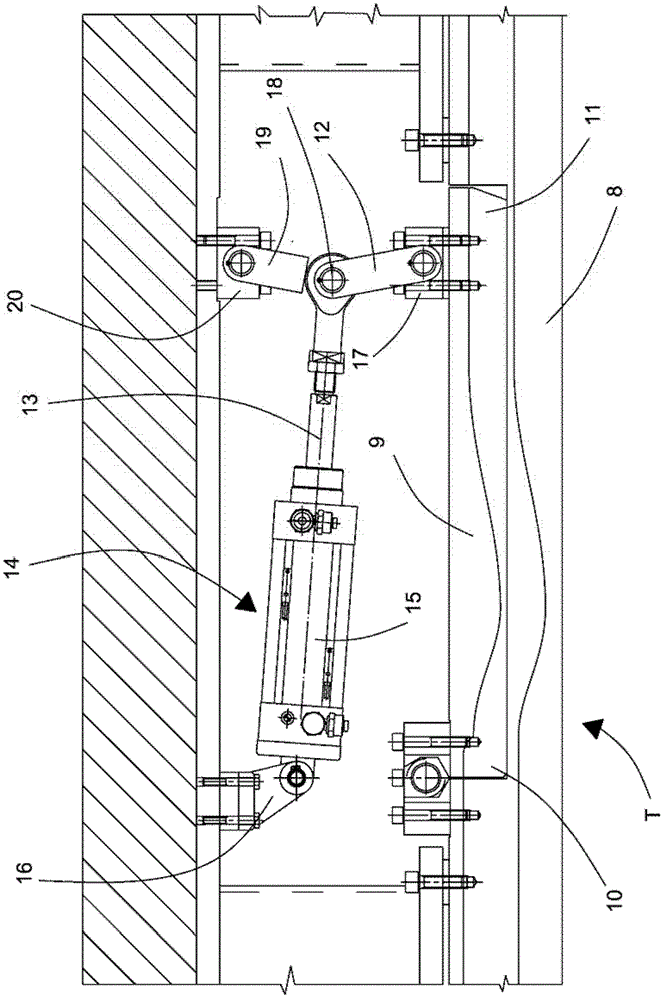

[0017] exist figure 1 In , the punches 1 and the corresponding mold elements of the conveyor belt G for molding caps are shown in the open position after molding an object 3 (such as a cap) and before the removal mechanism 4 removes the object 3 from the punch 1 2.

[0018] The molding conveyor belt G comprises a plurality of die elements 2 and a plurality of punches 1 arranged at a constant angular pitch along the periphery of the conveyor belt. The punch 1 is arranged in a fixed position, while the die element 2 can be figure 1 shown in the first lower position and figure 2 Vertical movement is shown between a second upper position, in which the die element 2 is clear of the punch 1 , and in a second upper position, in which the die element 2 interacts with the punch to mold the object 3 .

[0019] After the object 3 has been molded, the mold element 2 is lowered again to the first lower position, detached from the punch 1 , while the manufactured object 3 is still adher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com