Mould element structural avoid-hole automatic generation system and method

A technology for automatically generating and avoiding holes, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as the inability to automatically generate avoiding holes, and achieve fast speed, good applicability, and high accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

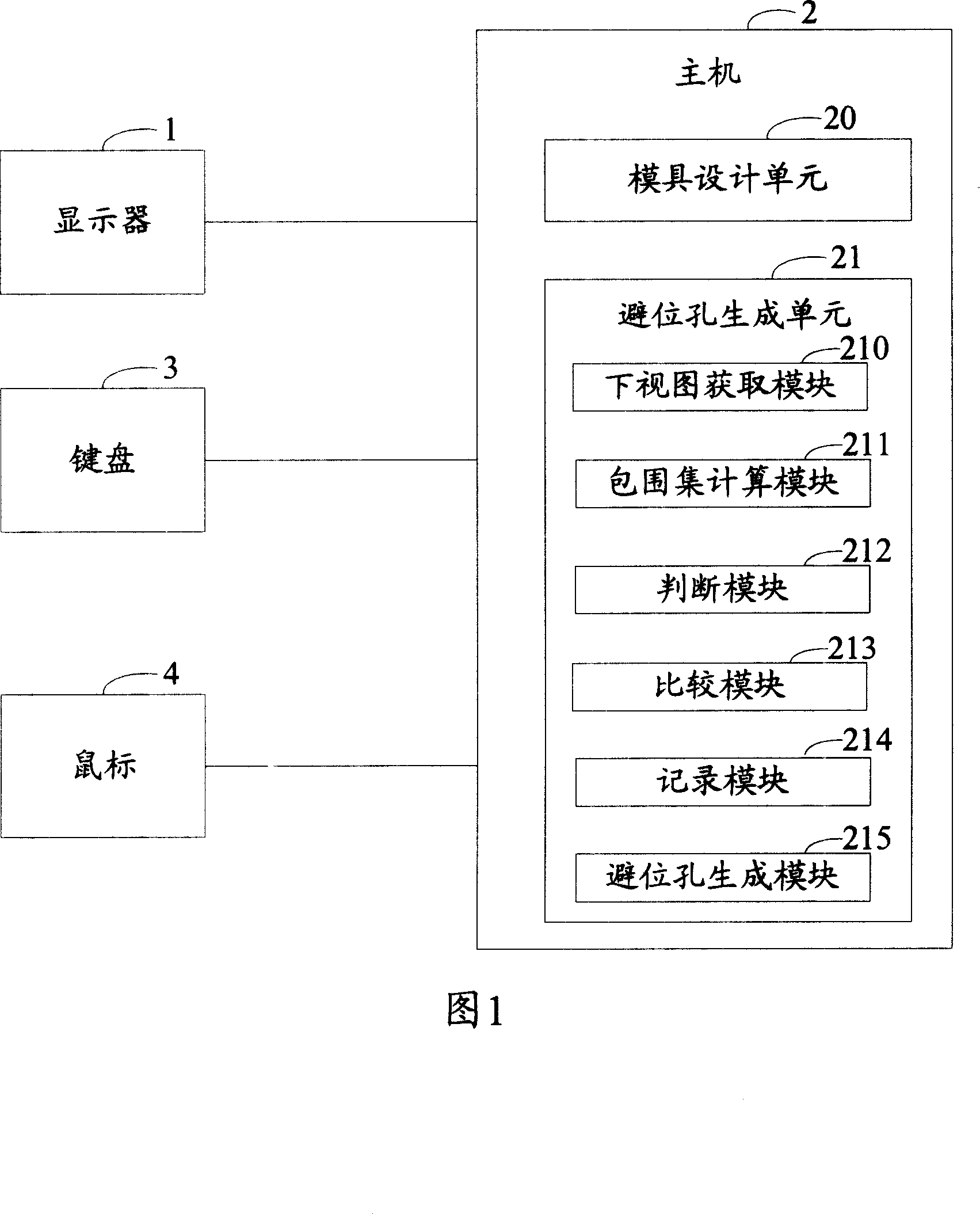

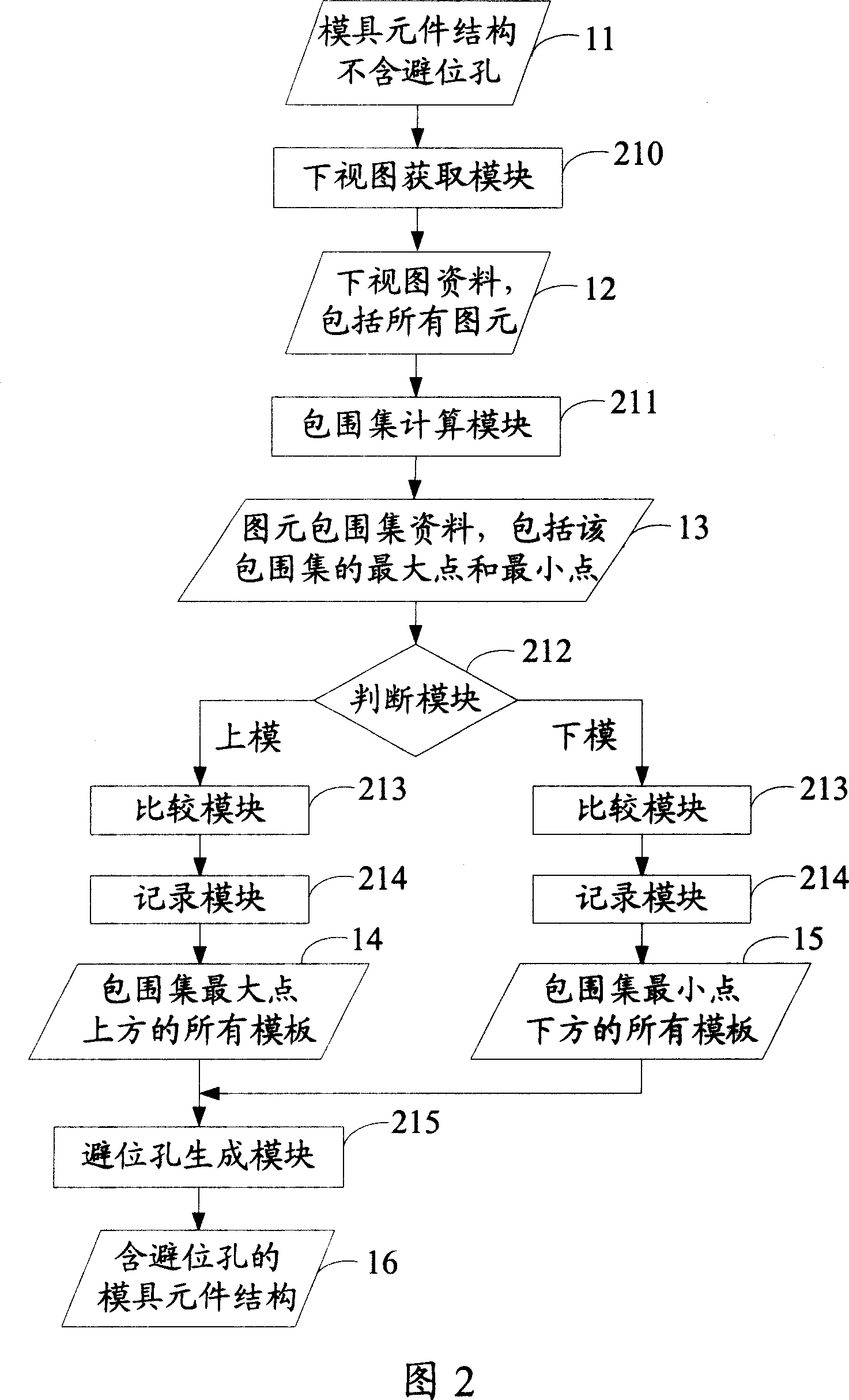

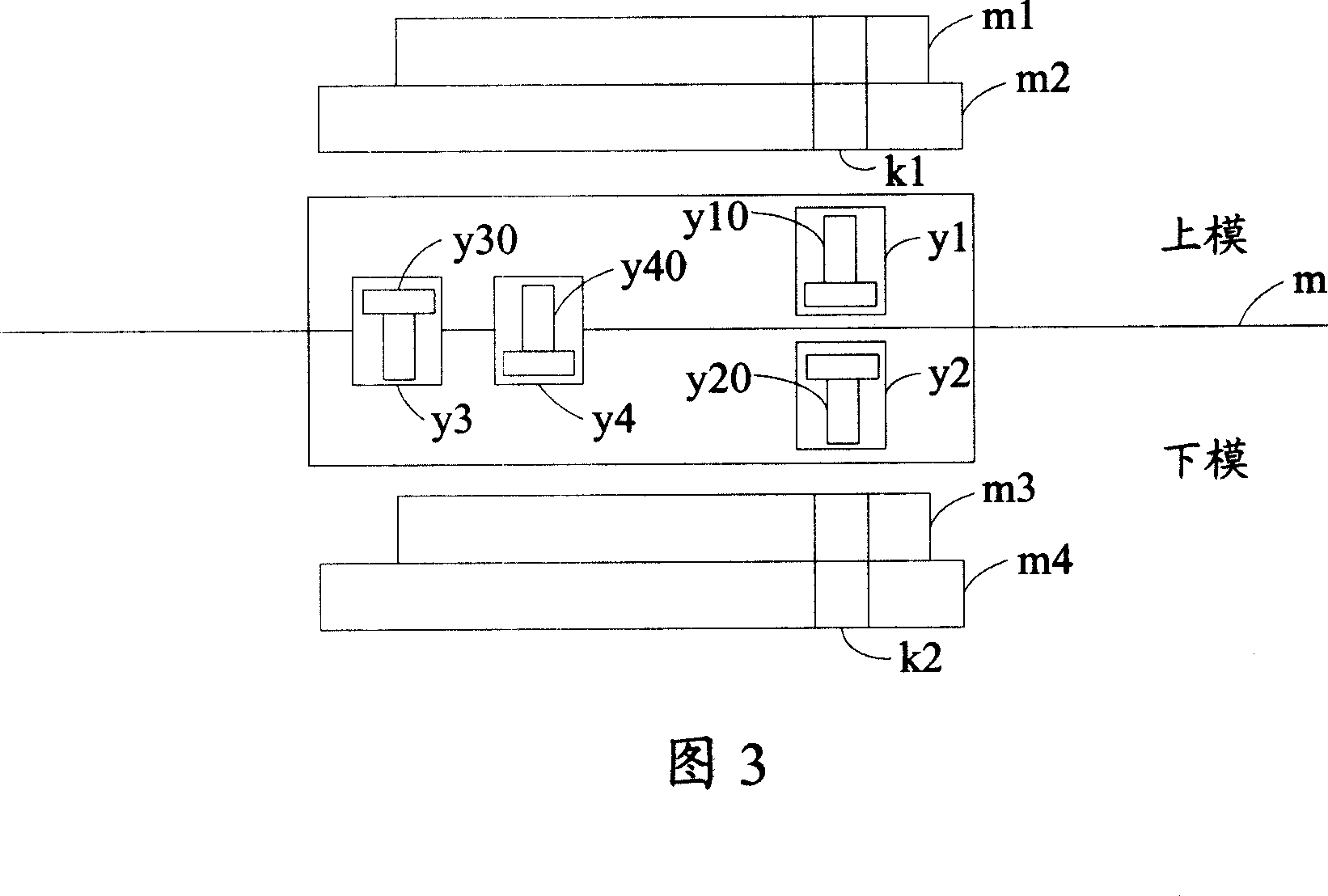

[0014] As shown in FIG. 1 , it is a system architecture diagram of a preferred embodiment of the system for automatically generating avoidance holes for mold component structures according to the present invention. The system mainly includes a monitor 1 , a host 2 , a keyboard 3 and a mouse 4 , and the host 2 includes a mold design unit 20 and an avoidance hole generation unit 21 . Wherein, the mold design unit 20 is used to generate the mold element structure, and the escape hole generation unit 21 is used to generate the escape hole of the mold element structure according to the mold element structure generated by the mold design unit 20 .

[0015] The host 2 is connected with a display 1 for displaying the mold element structure generated by the mold design unit 20 and the escape hole of the mold element structure generated by the escape hole generation unit 21 . The keyboard 3 and mouse 4 are used to input data when generating the mold element structure.

[0016] The avoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com