Large ceramic shell choking method for allowance-free precision casting

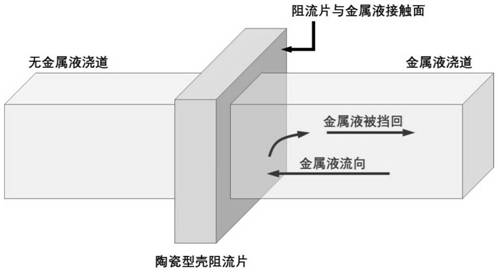

A large-scale ceramic and precision casting technology, applied in casting molding equipment, casting molds, casting mold components, etc., can solve problems such as high risk of high temperature creep deformation, out-of-tolerance casting surface size, shell expansion, etc. The effect of production qualification rate, accurate metal liquid flow direction, and reduction of master alloy dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

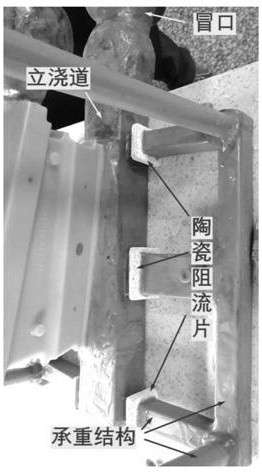

[0029] This embodiment is an example of installing a spoiler in the ceramic shell used for investment casting of super-large blades of a gas turbine turbine, and specifically includes the following steps:

[0030] Step S1: Design the casting system of the wax mold with baffles: it is necessary to add baffles between the vertical sprue and the load-bearing structure. Here, the cross-sectional dimensions of the wax mold are 30mm×20mm and 40mm×30mm, so design the baffles The size is 40mm×30mm and 50mm×40mm, and the thickness is about 10mm.

[0031] Step S2: Fabrication of the baffle: the baffle adopts the manufacturing method of the ceramic shell in the traditional investment precision casting, and the shell is made of a plate-shaped wax mold of 220mm×160mm×10mm. According to the thickness of the spoiler required, the number of shell layers is selected as 10 layers. The first layer is the surface layer, the 2nd, 3rd, and 4th layers are the transition layer, the 5th to 9th layers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com