Process for the realization of counter- mould elements for the containment of welding bead of plastic profiled elements

一种塑料成型、实现方法的技术,应用在家用元件、应用、家里用具等方向,能够解决成型元件外表面轮廓变化大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

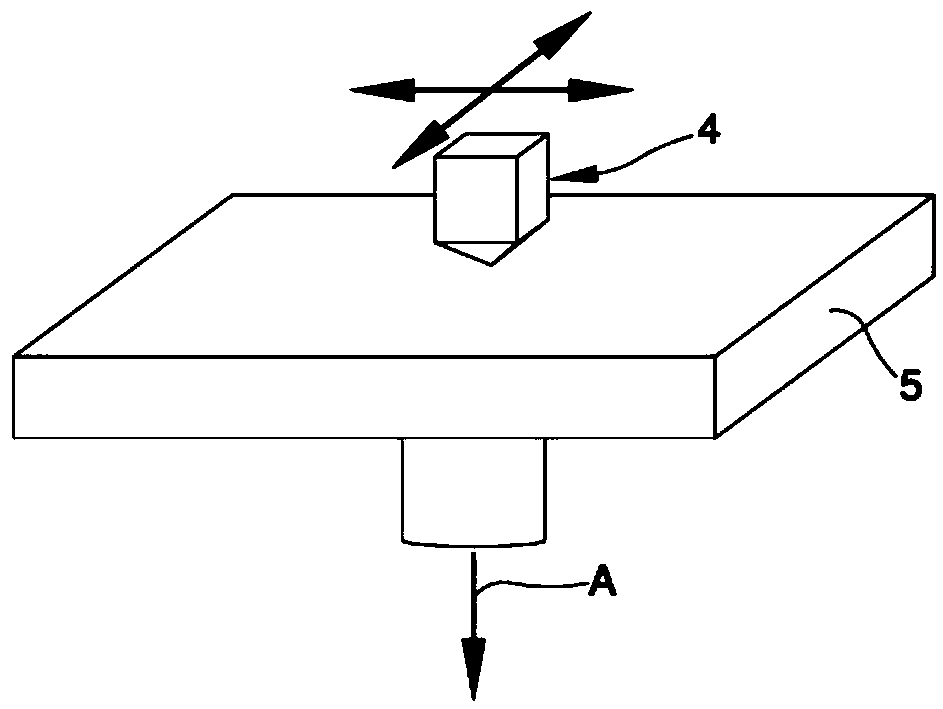

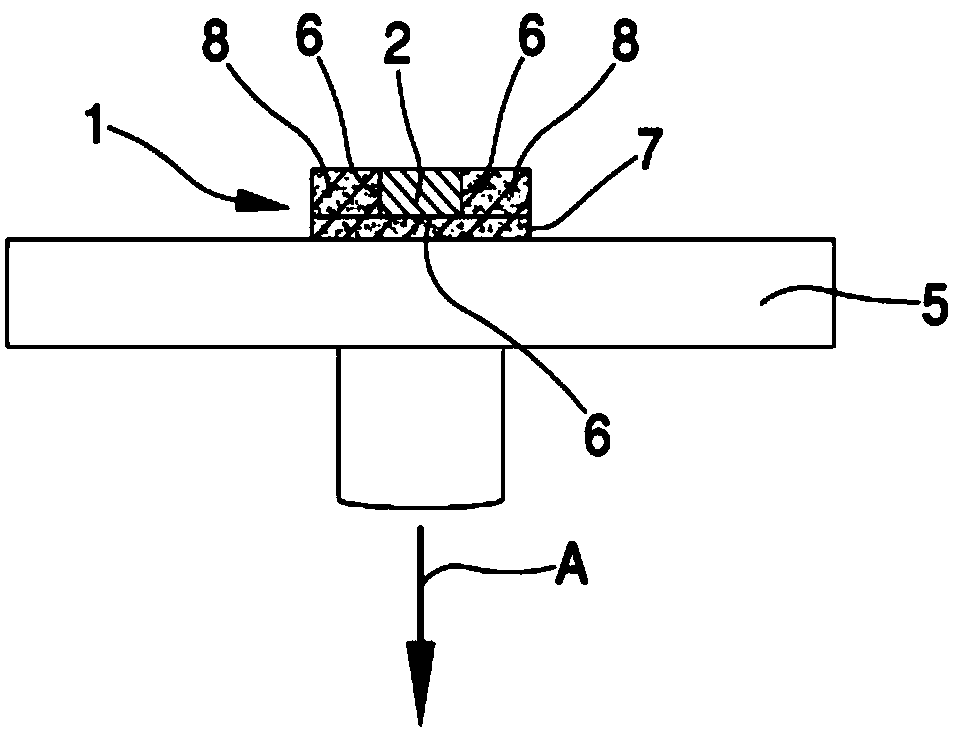

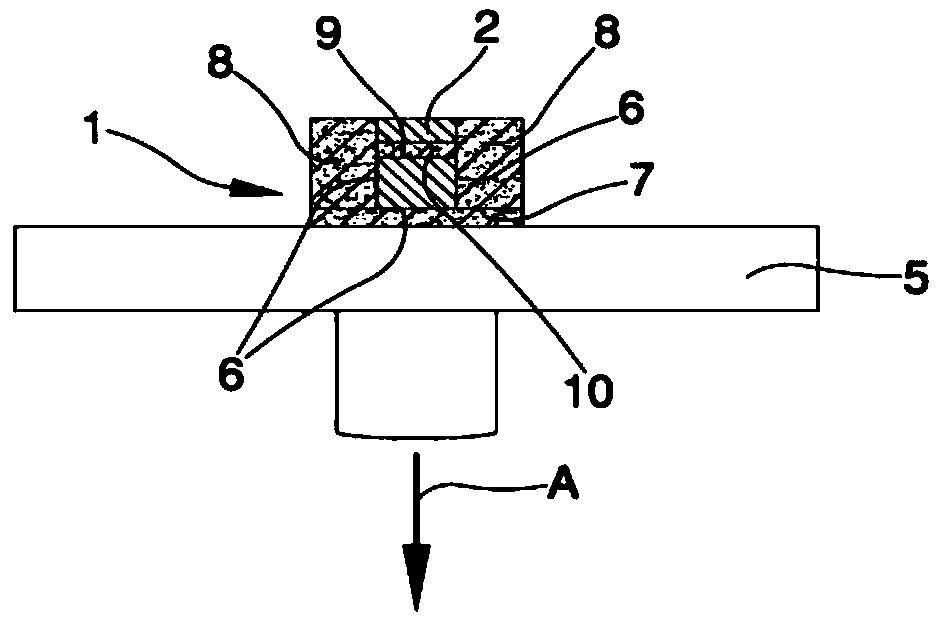

[0043] The invention relates to the realization of a counter-molding element for receiving a welding bead of a plastic molding element formed during the melting of two molding elements.

[0044] In the preferred embodiment shown in the figures, the counter-mould element 1 has at least one body 2 adapted to receive at a seat at least one pair of profiled elements of plastic material welded together to obtain a door and window frame.

[0045] Each profiled element includes a weld surface weldable to a welded surface of another profiled element in a welded configuration in which the lateral faces of the profiled elements substantially adjoin one another and define locating surfaces.

[0046] In this case, the welding surfaces can be welded together by interposing, for example, a hot plate welding device which can be placed between the welding surfaces of the profiled elements.

[0047] Specifically, the method includes:

[0048] - a stage of obtaining the contour of at least a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com