Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

960results about "Multicore optical fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

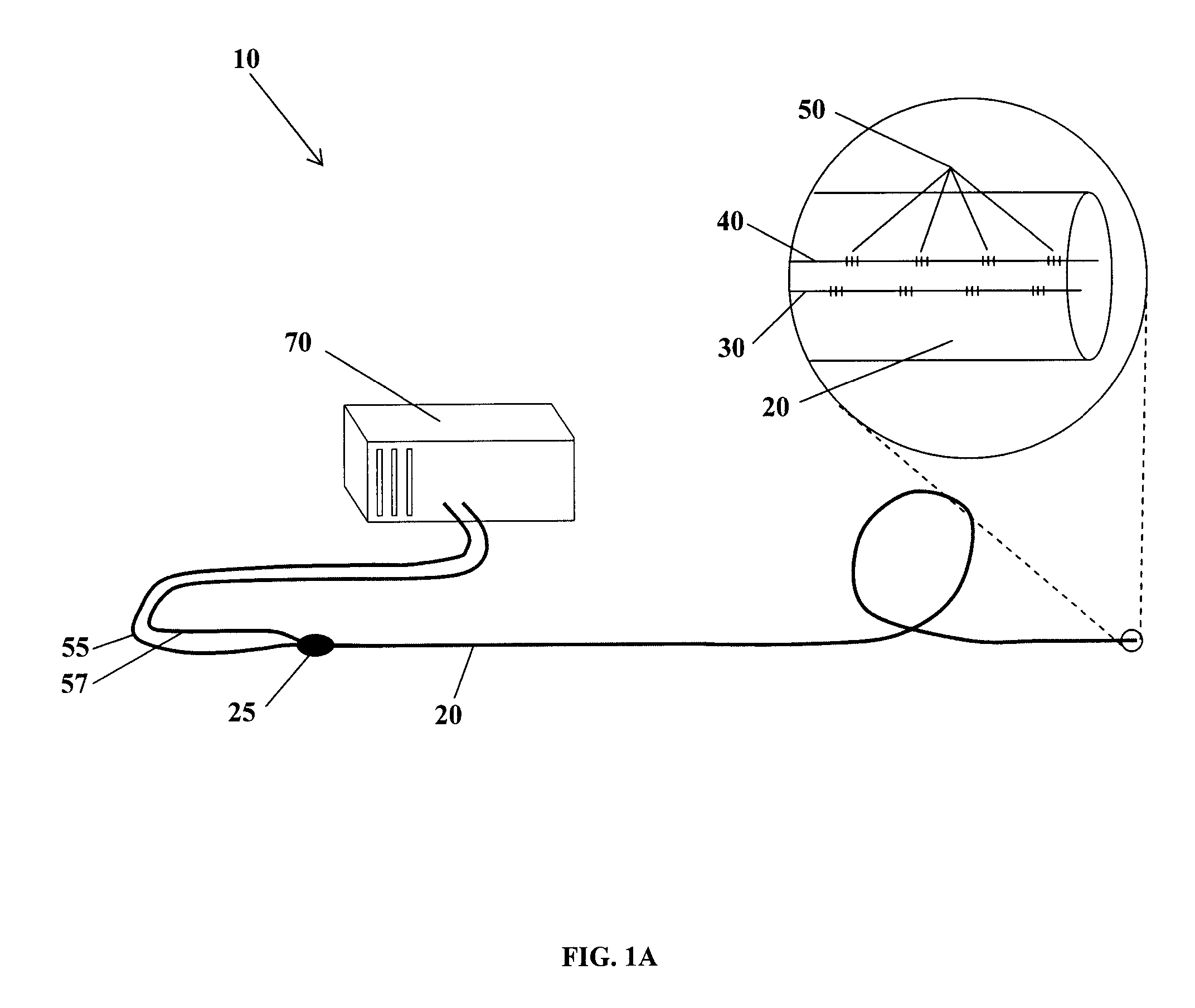

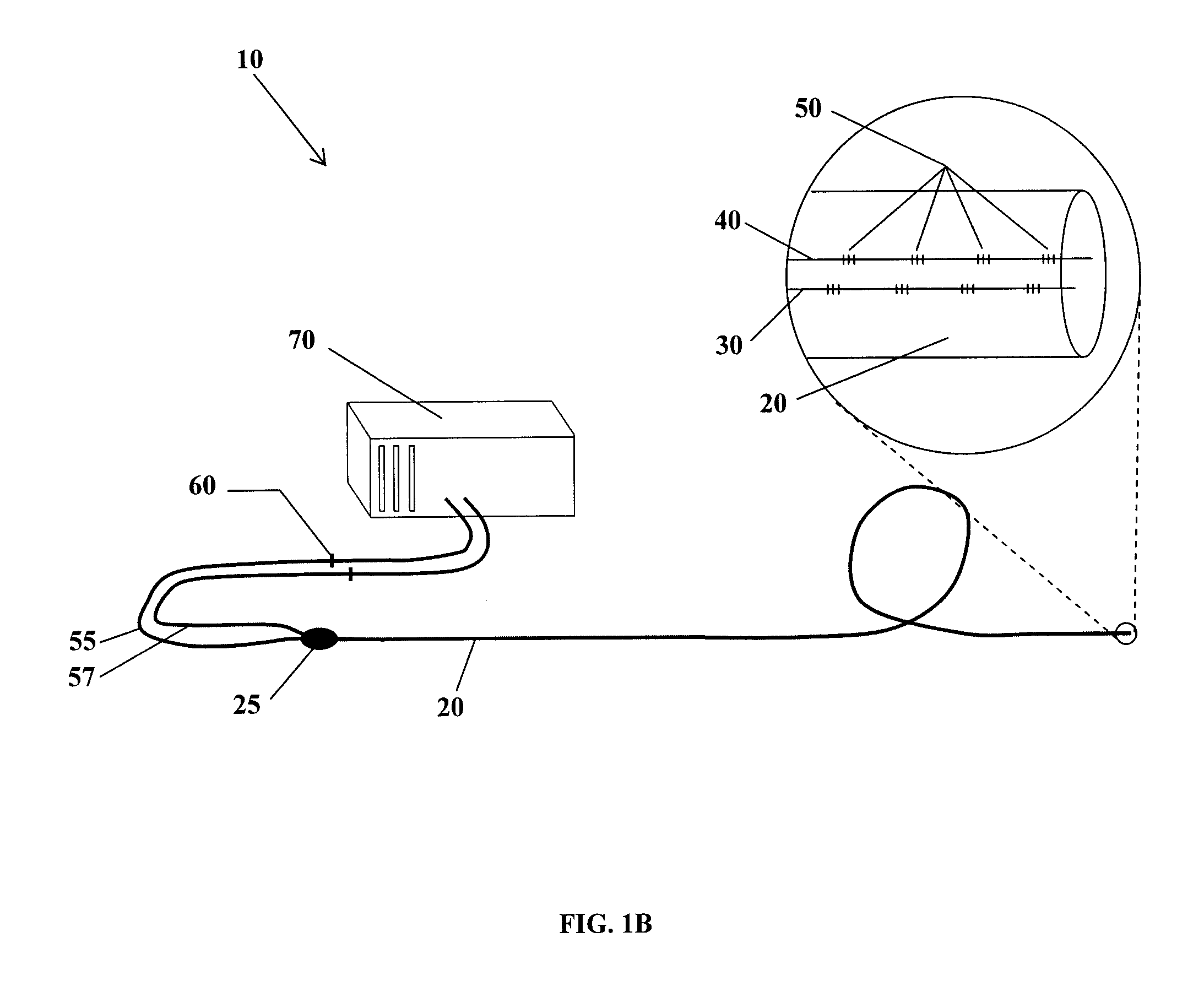

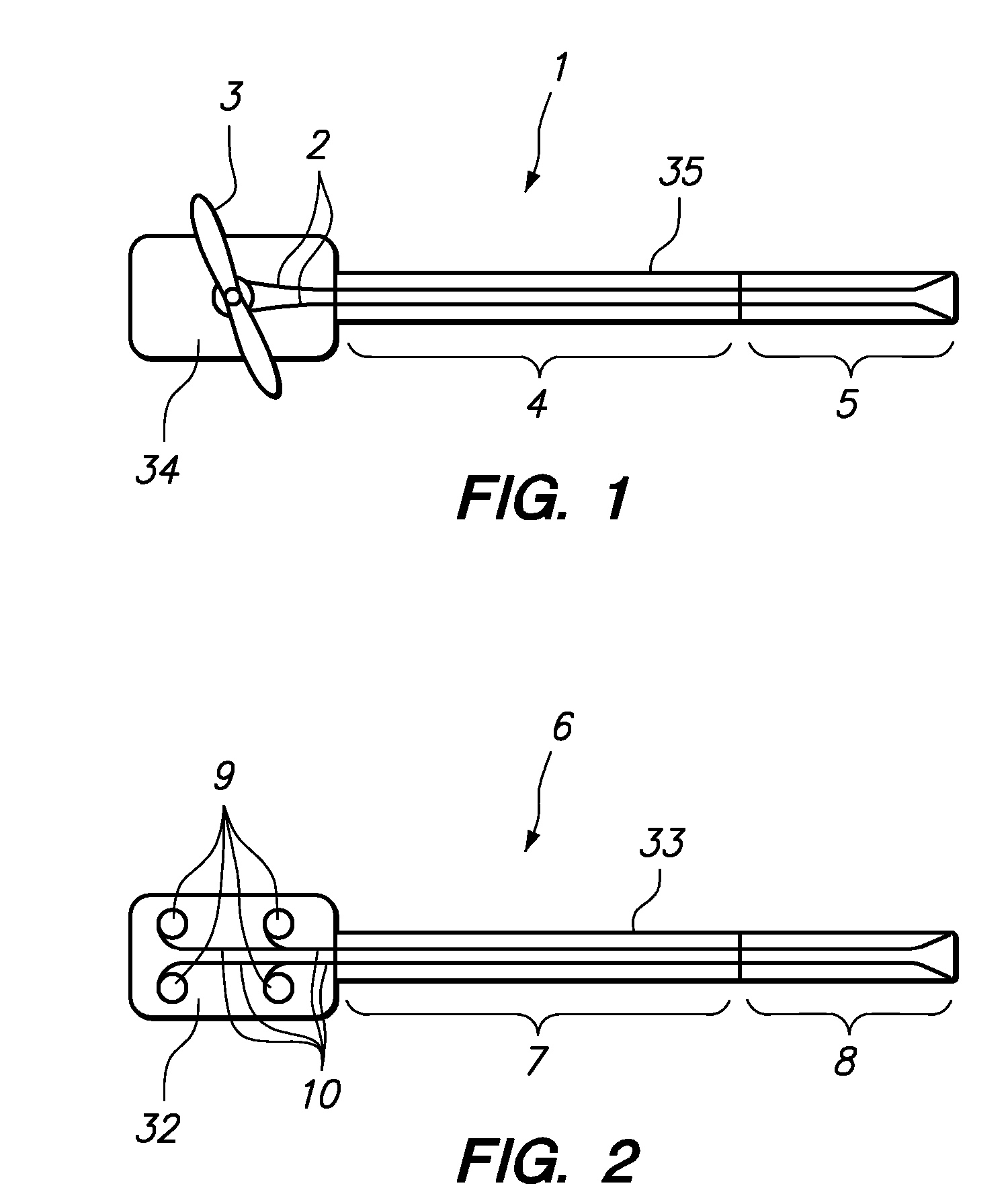

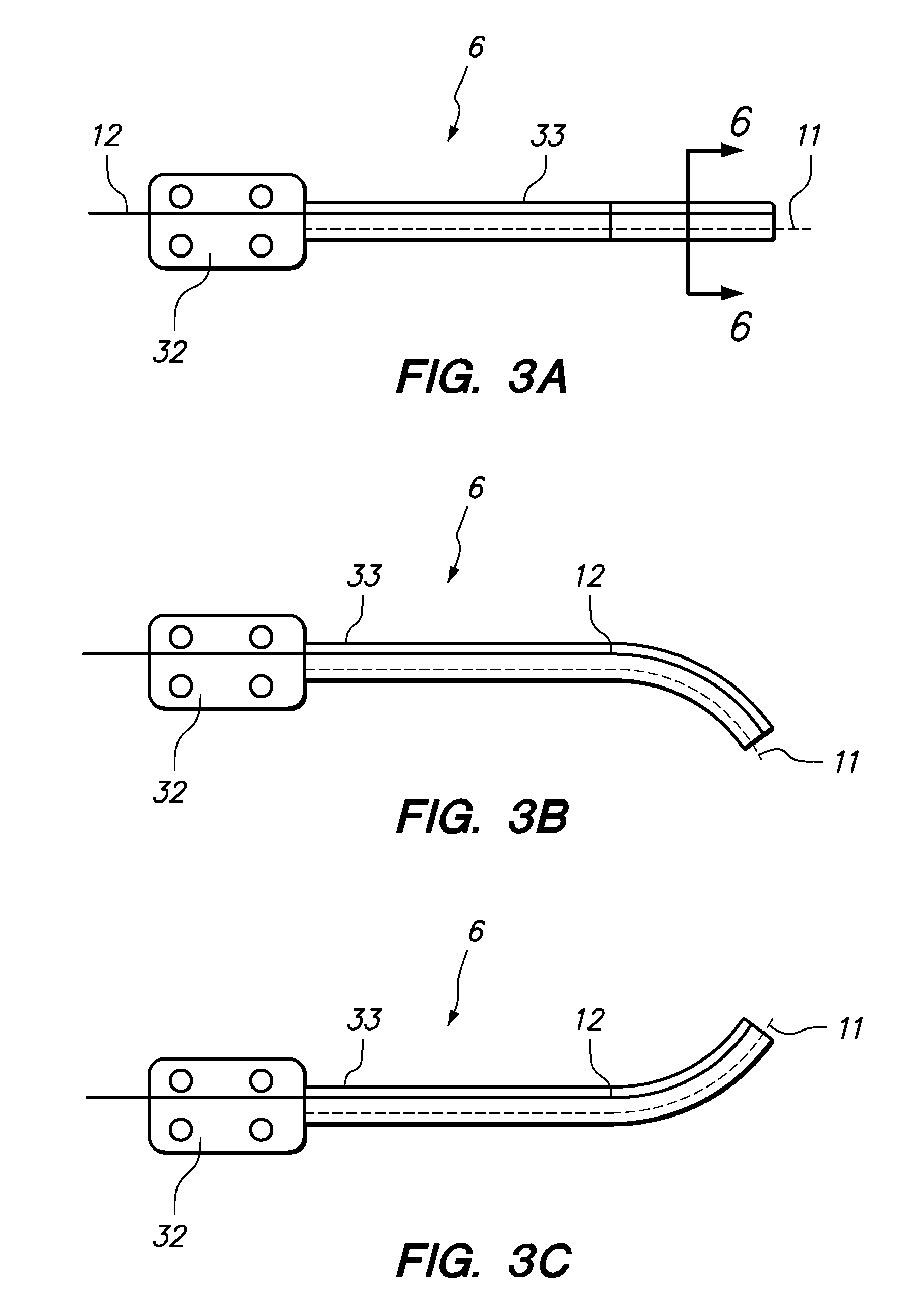

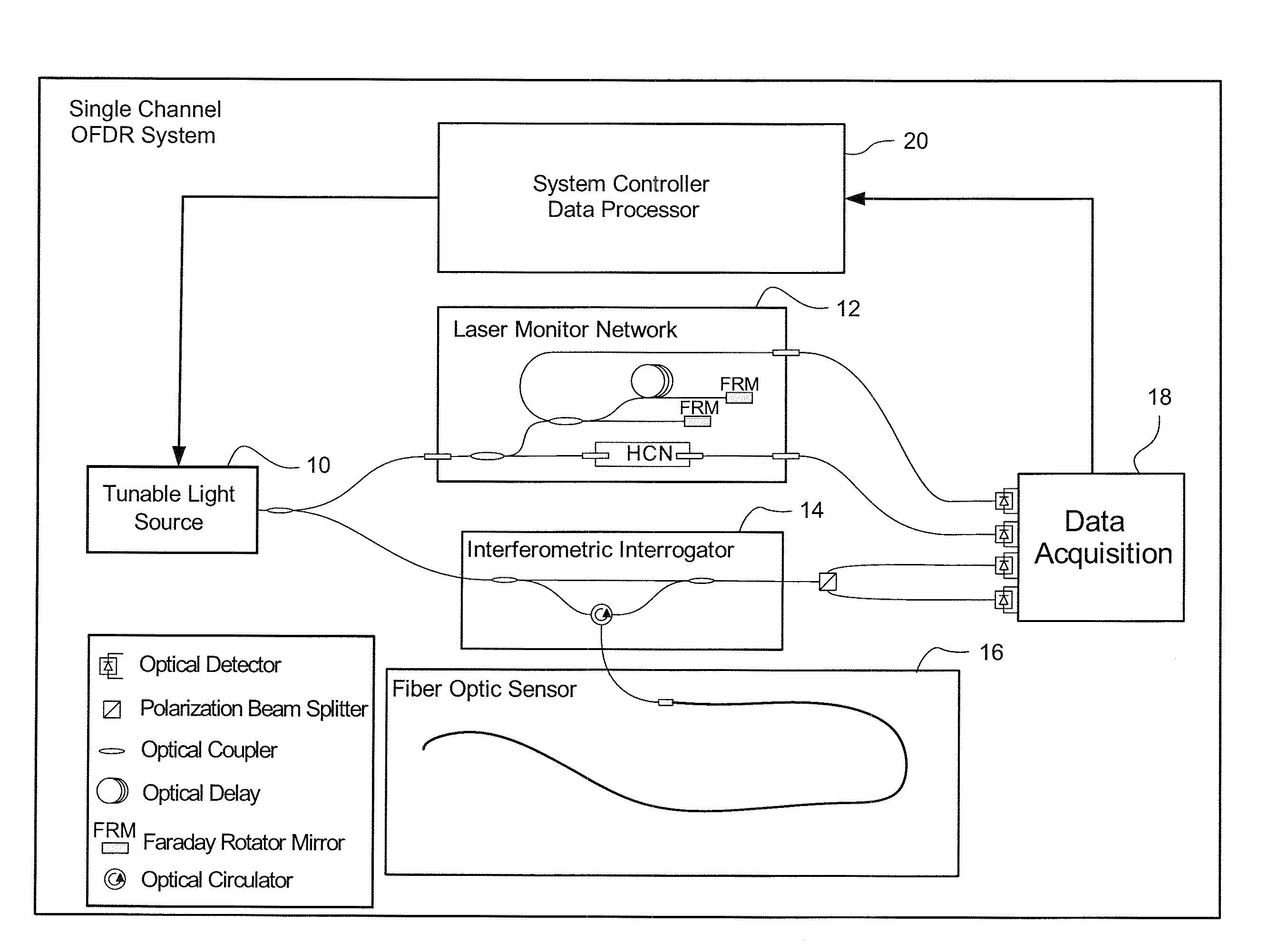

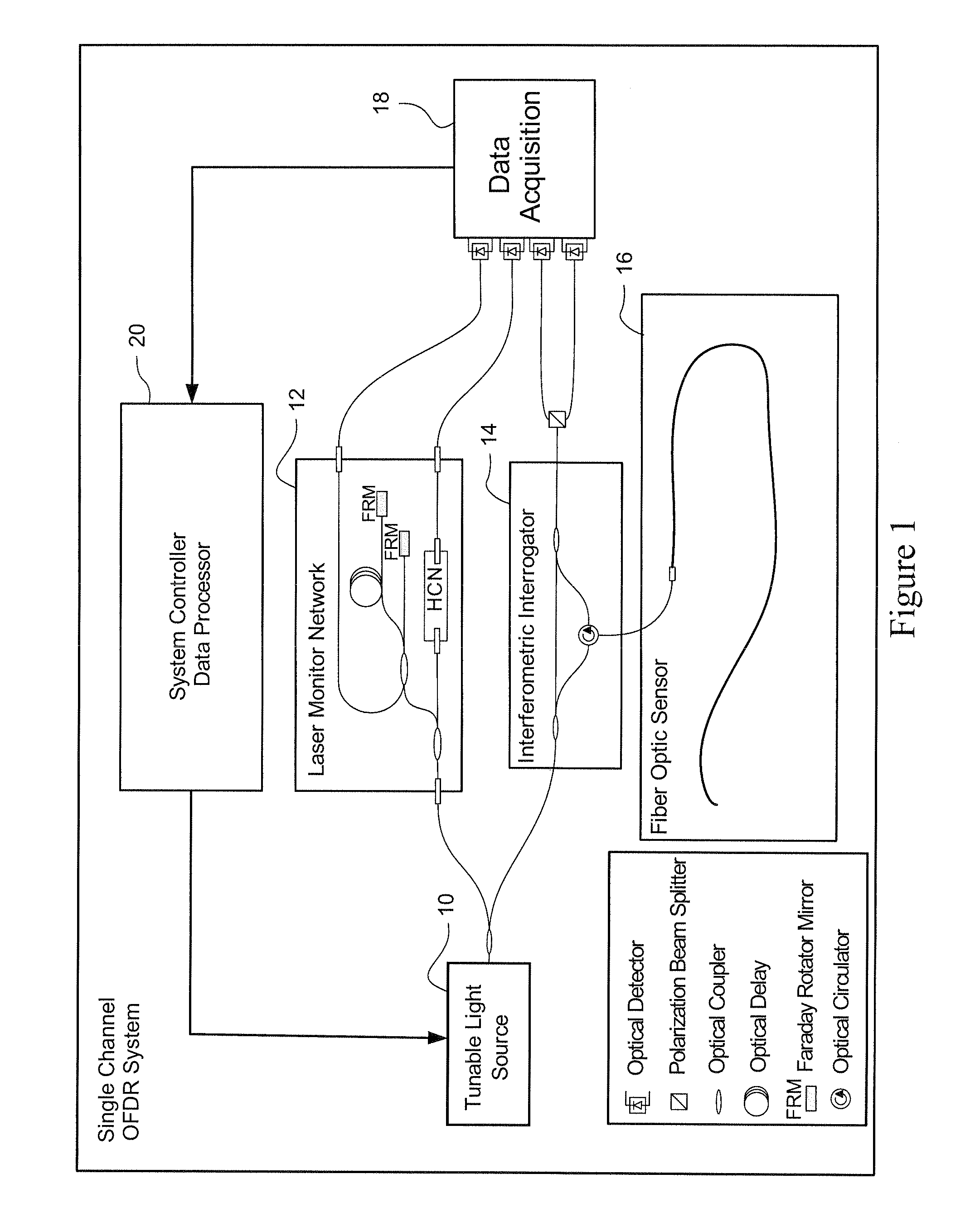

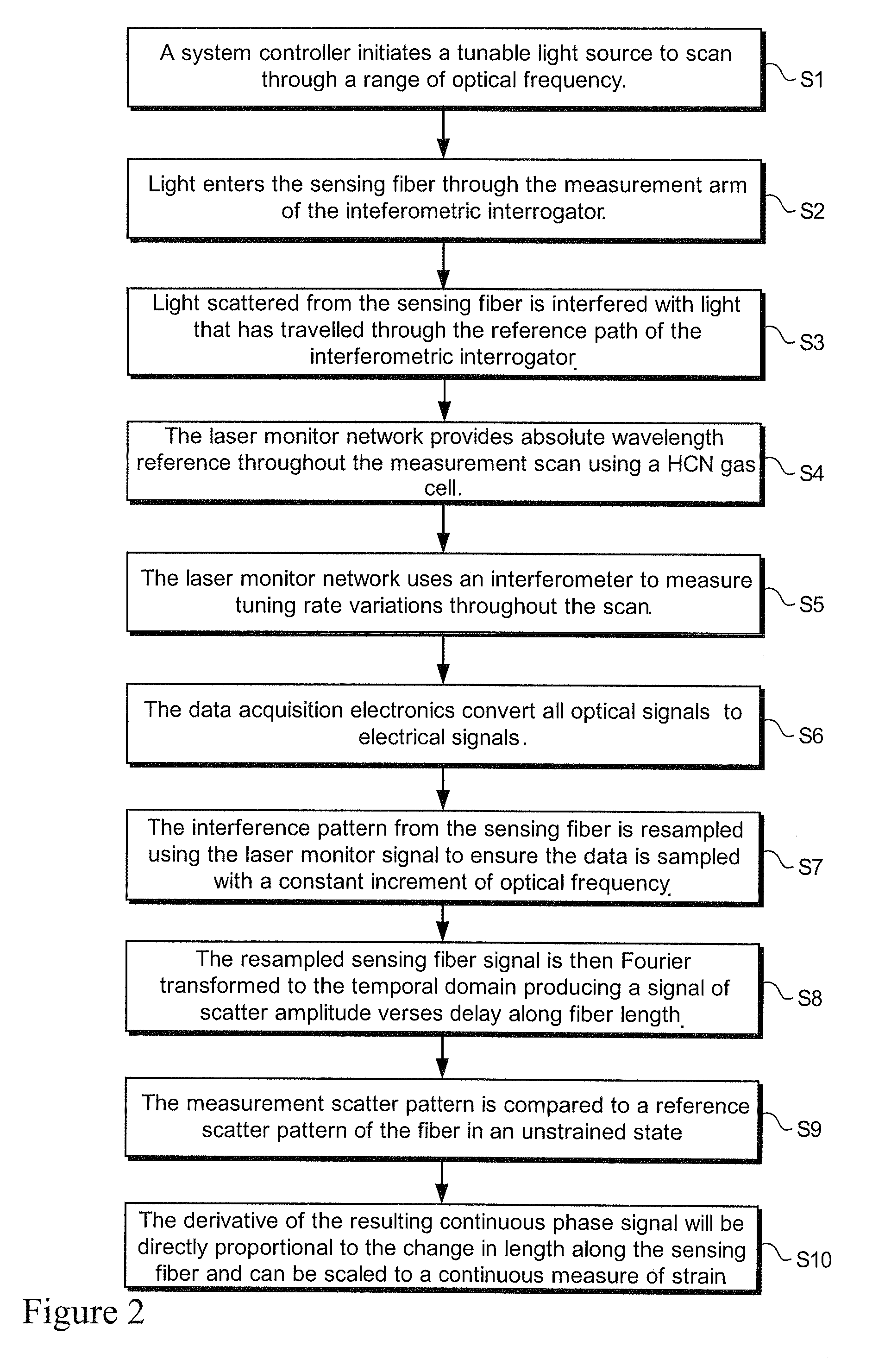

Fiber optic position and shape sensing device and method relating thereto

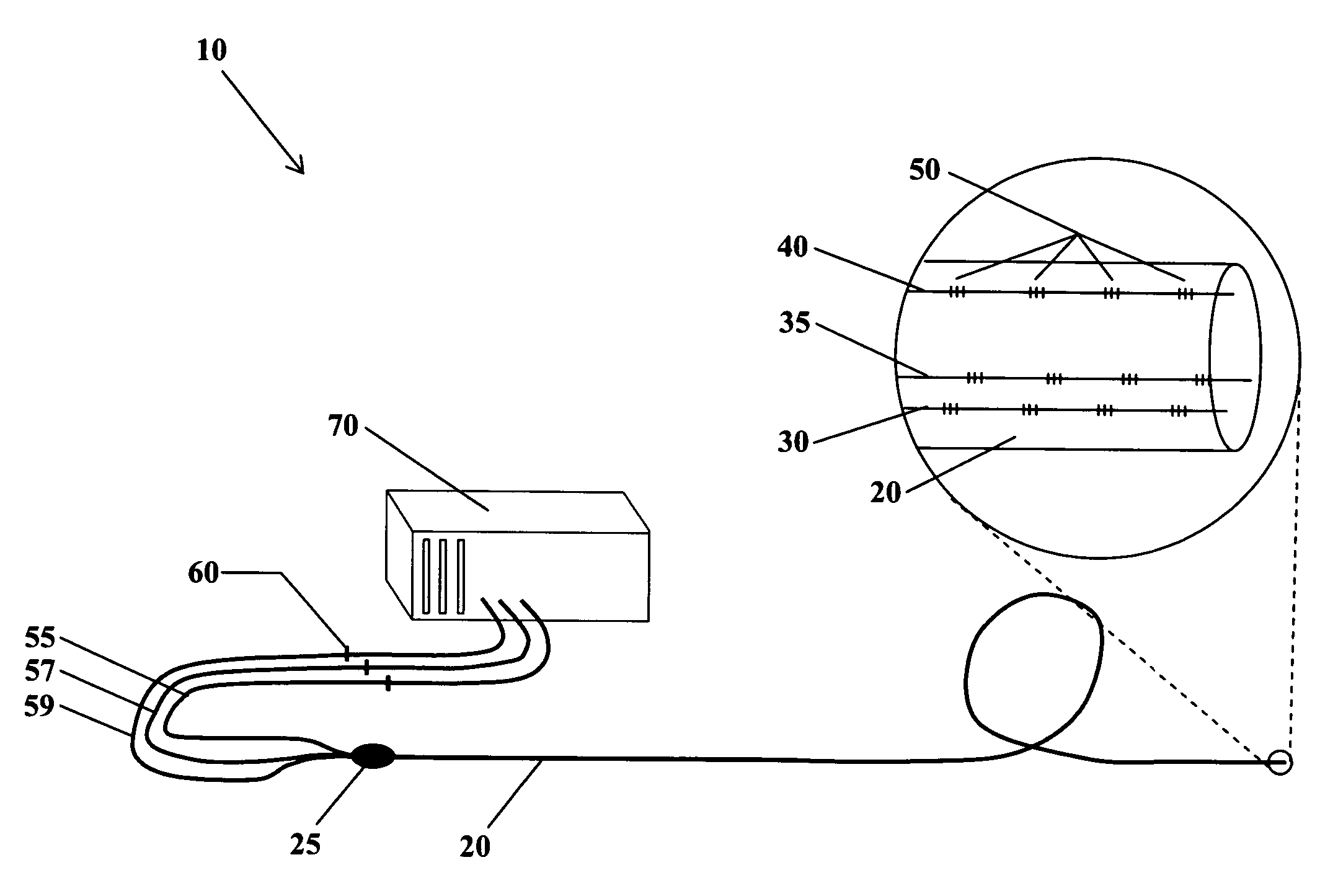

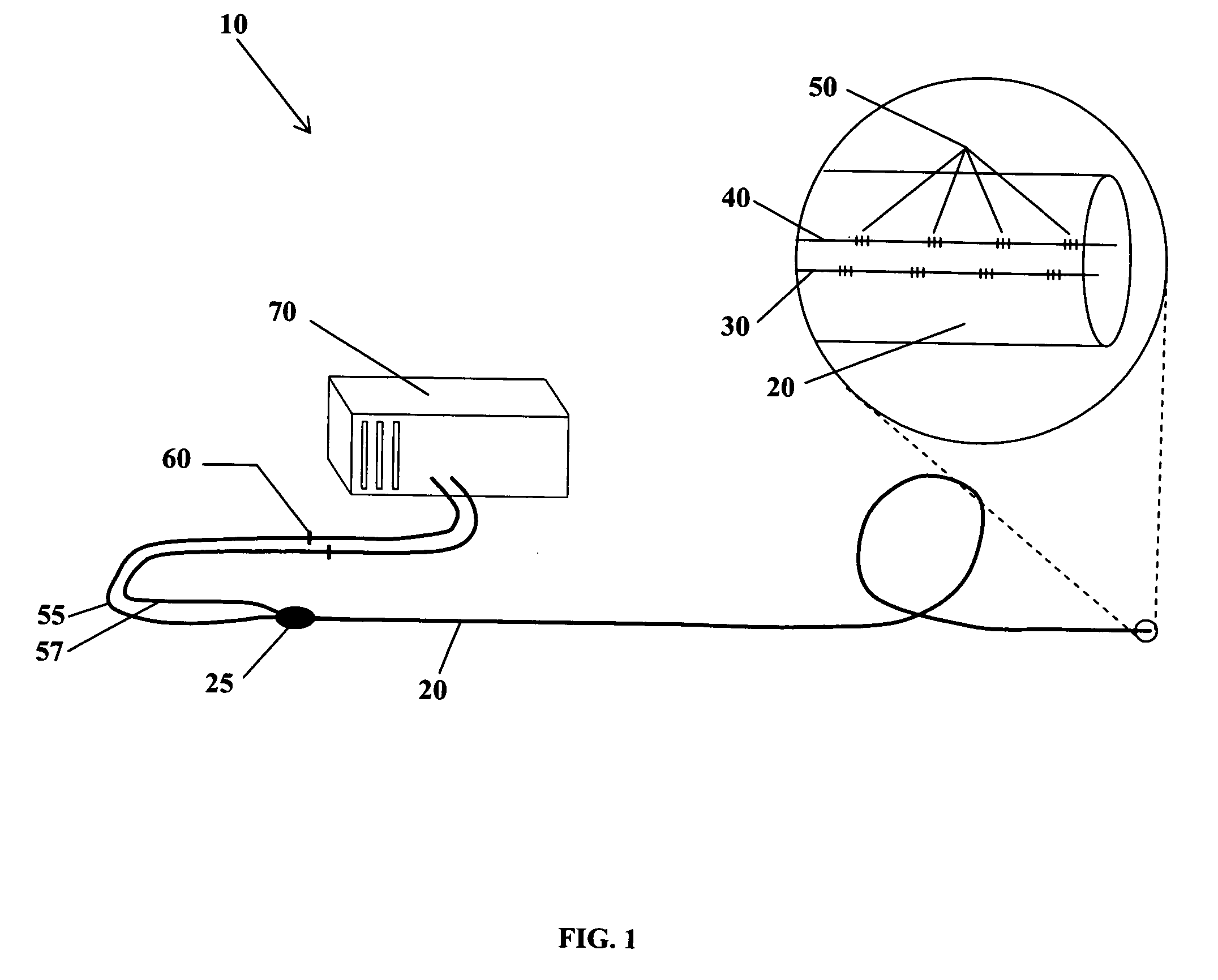

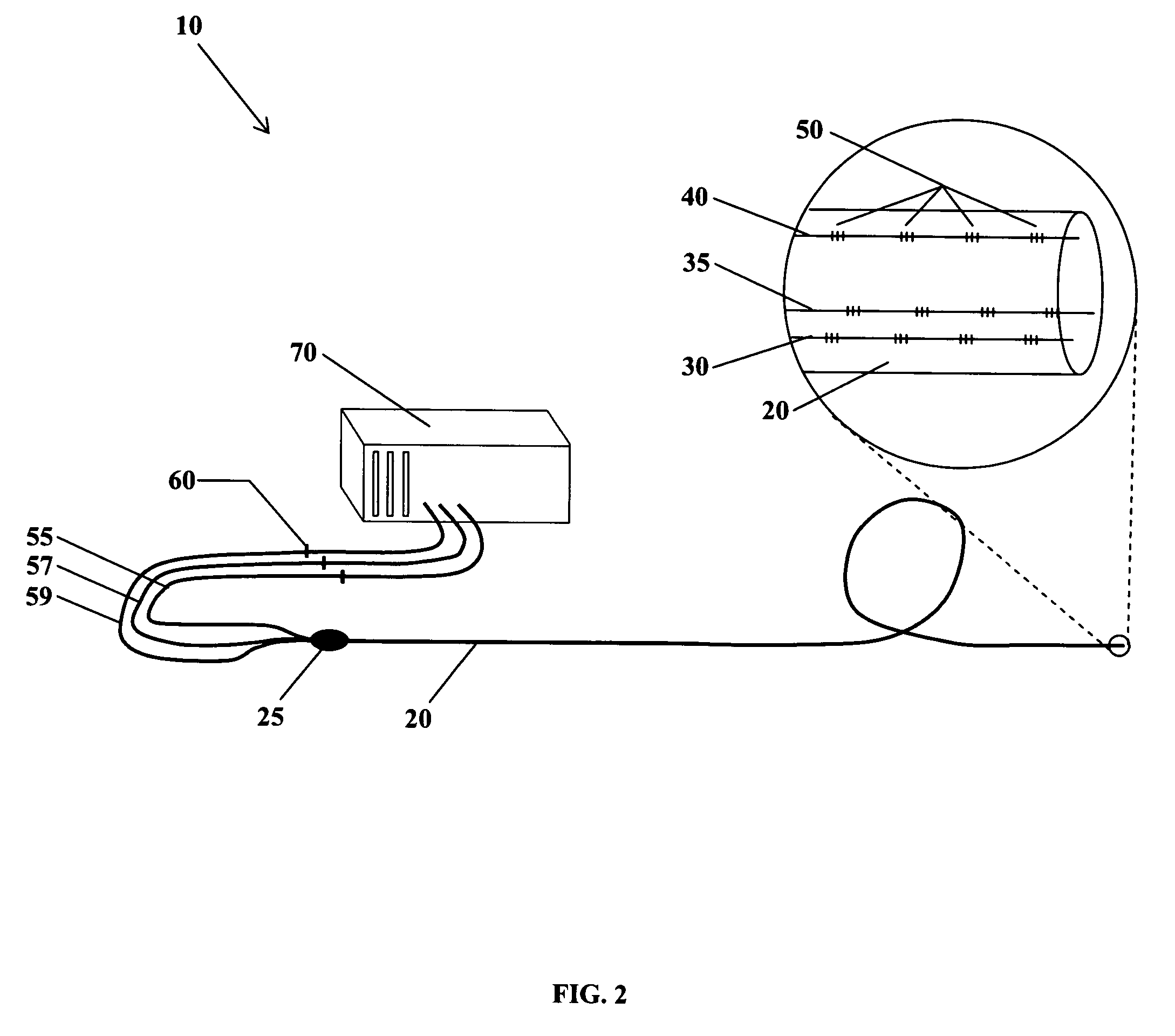

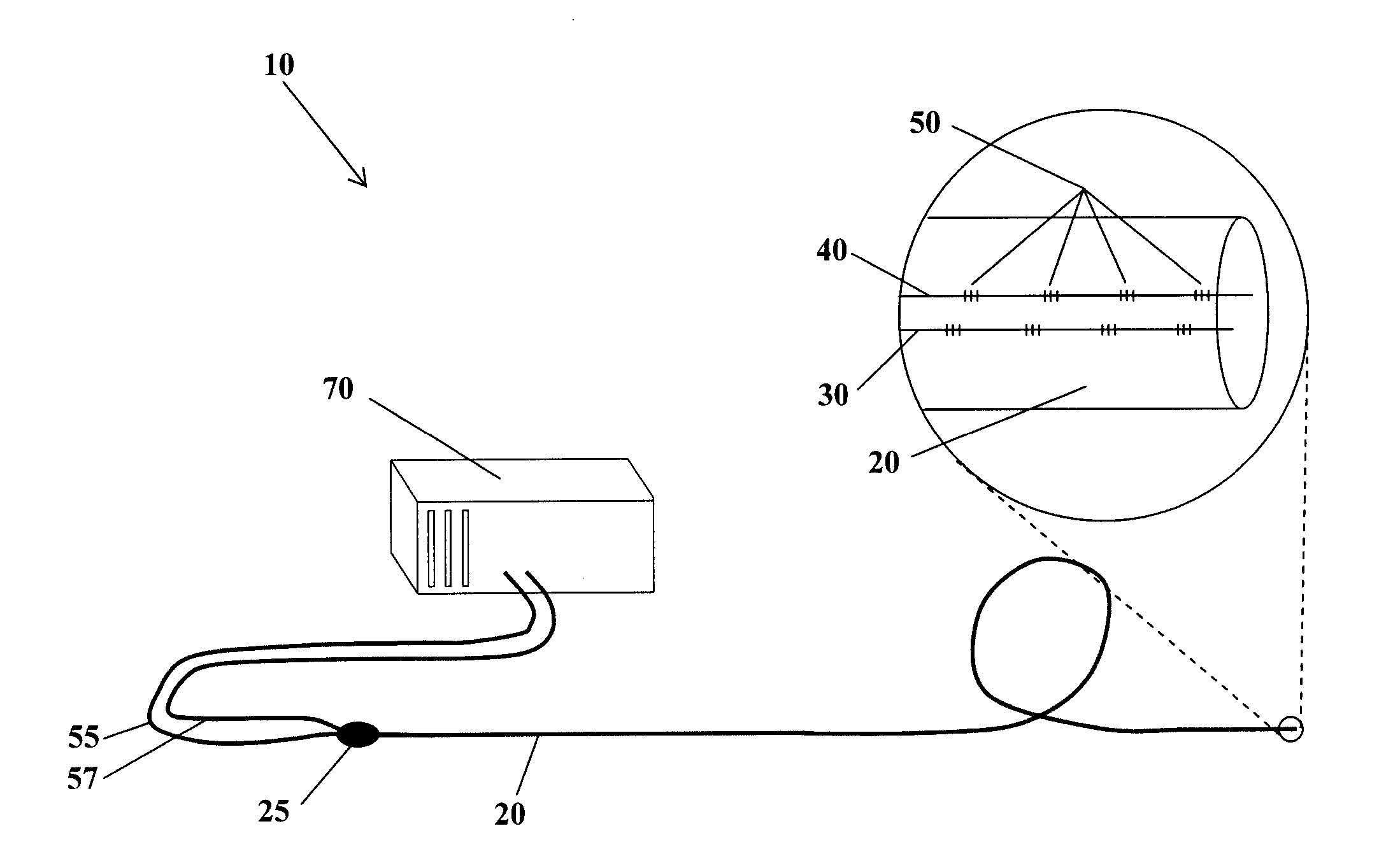

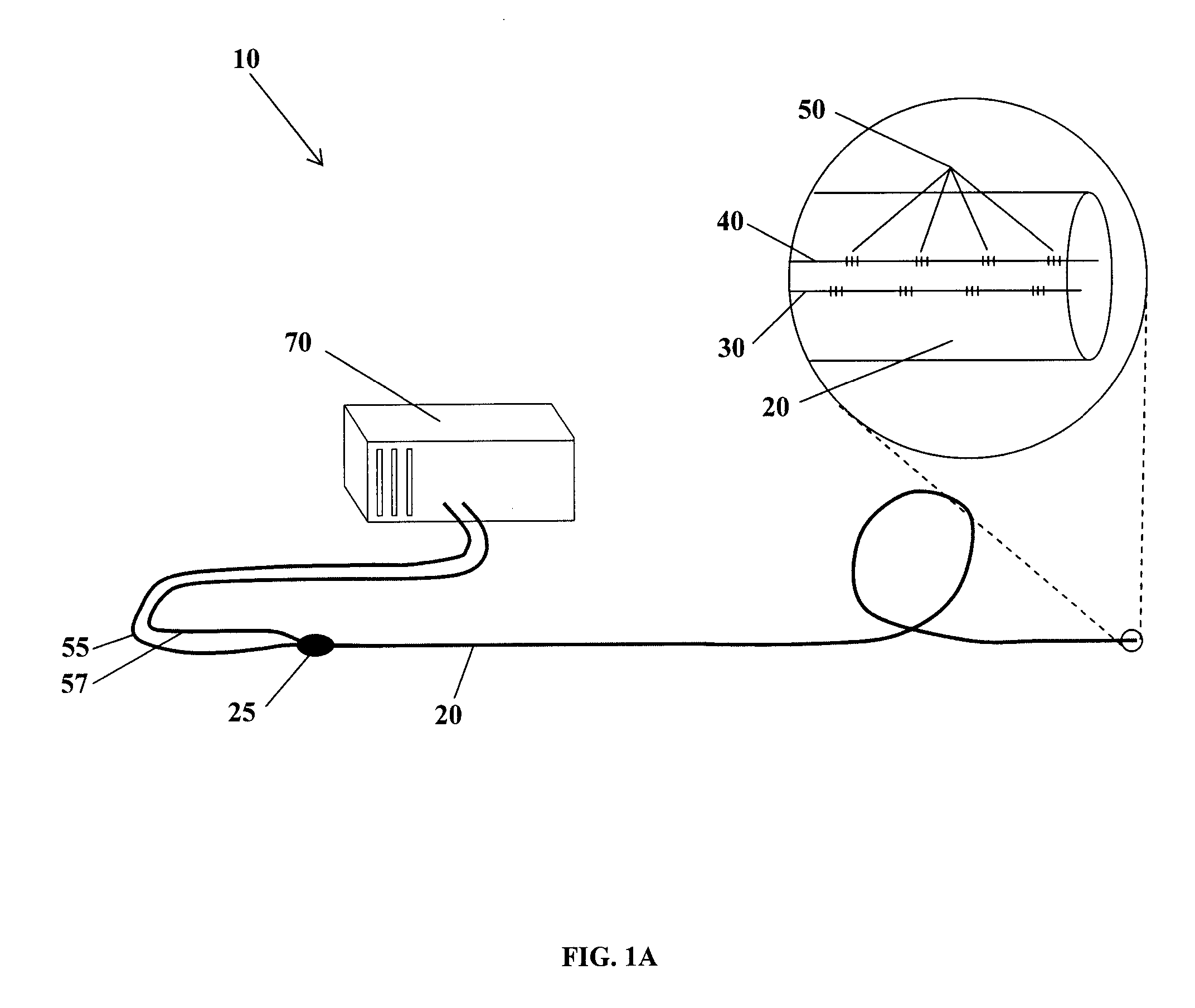

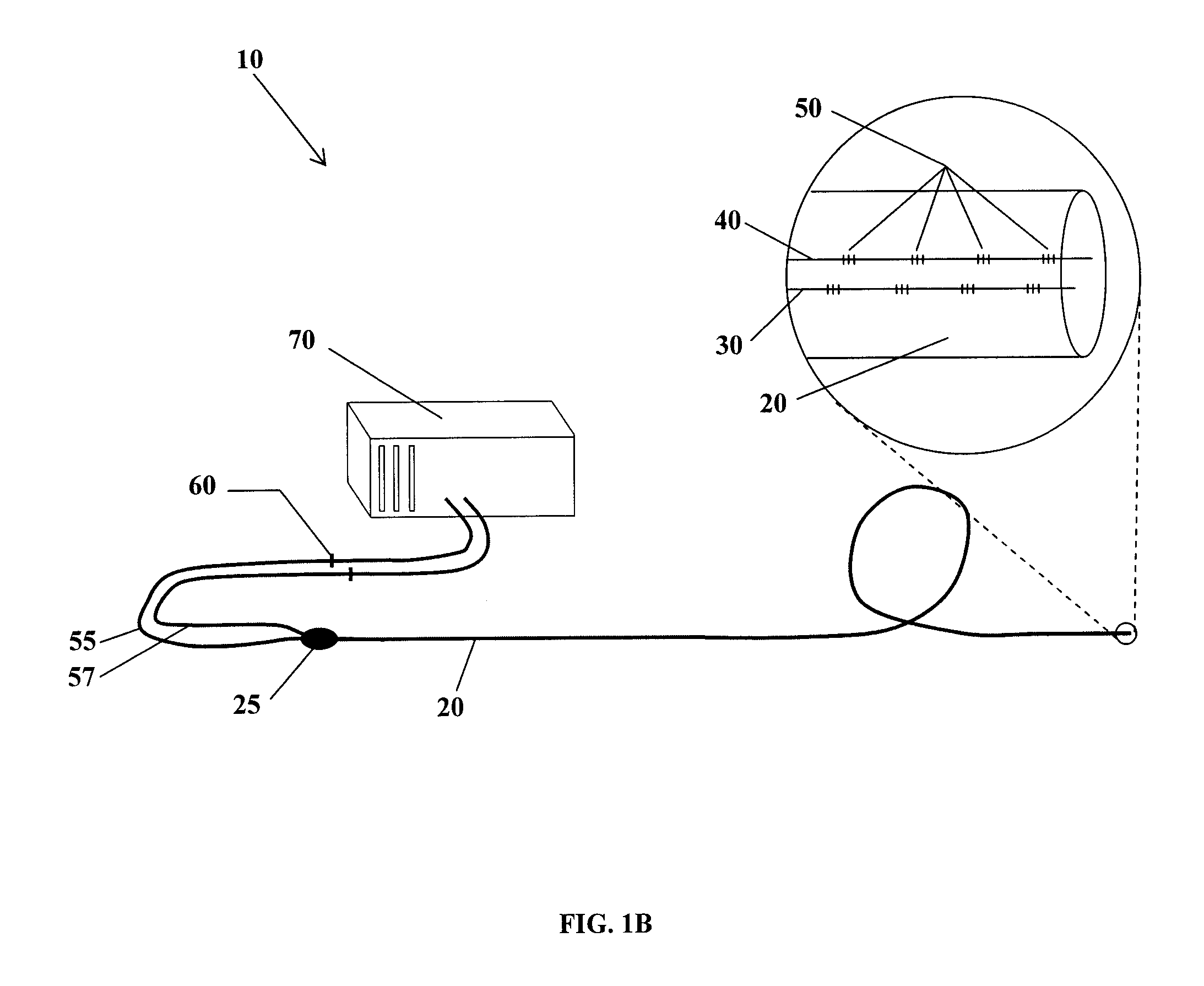

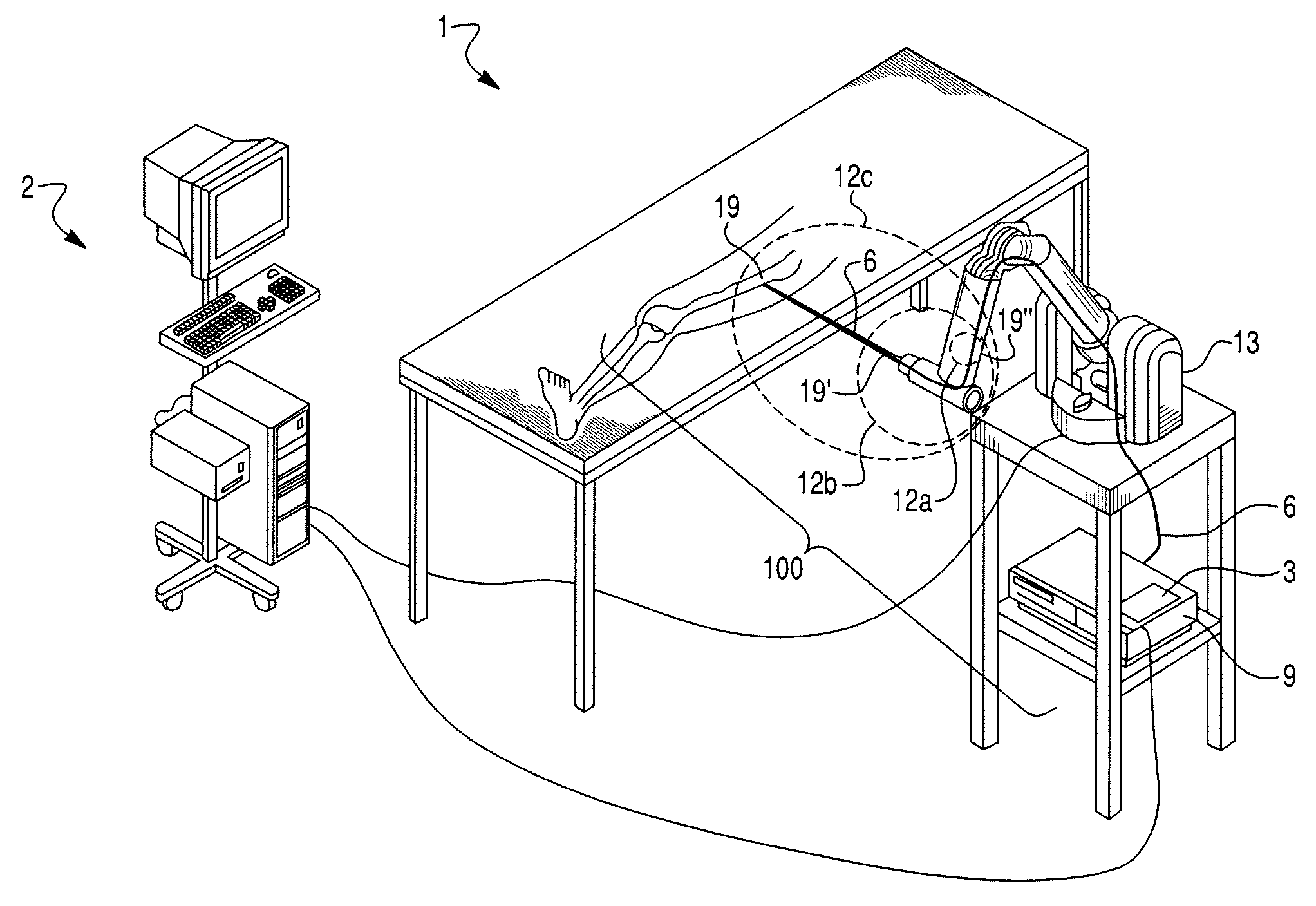

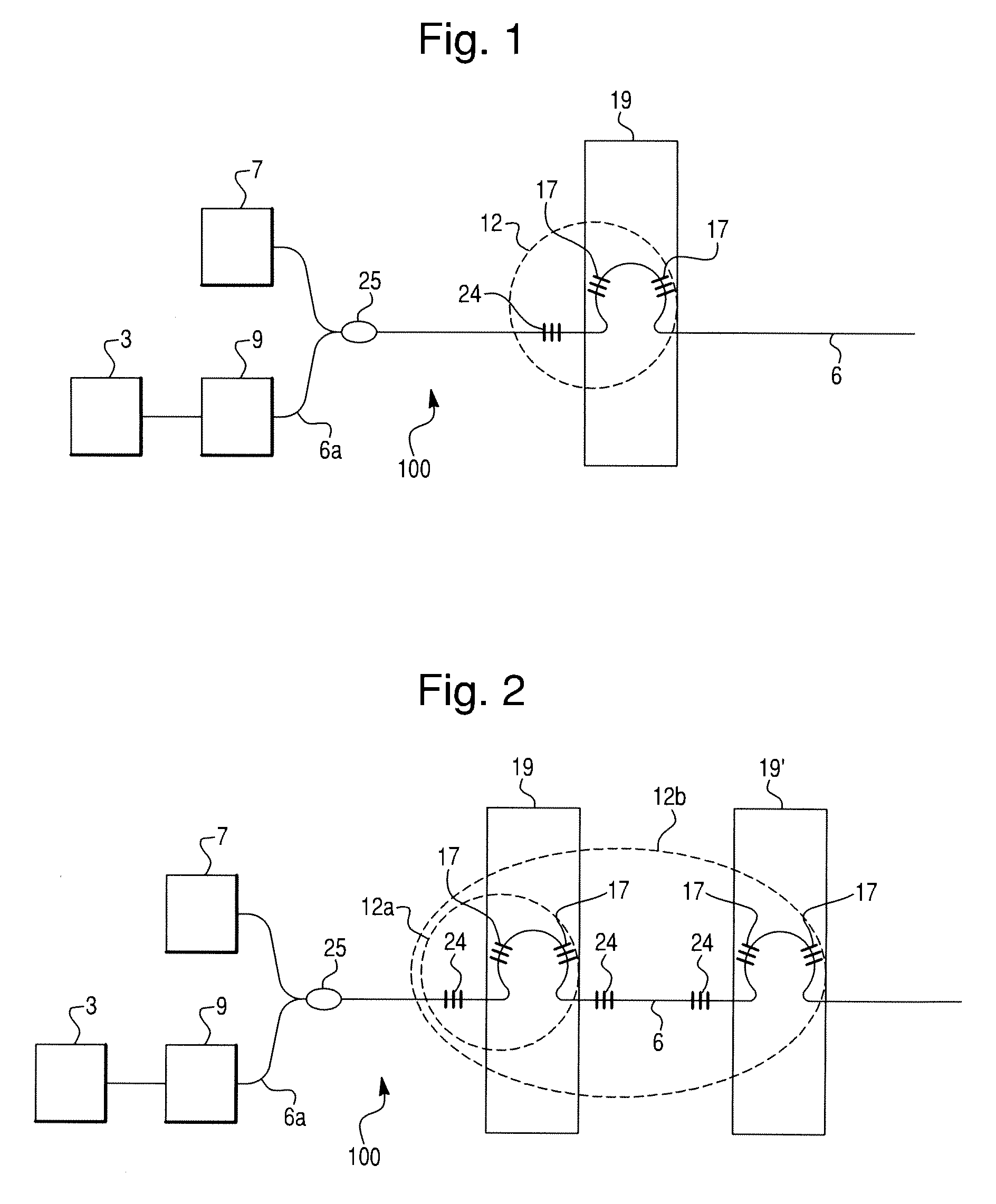

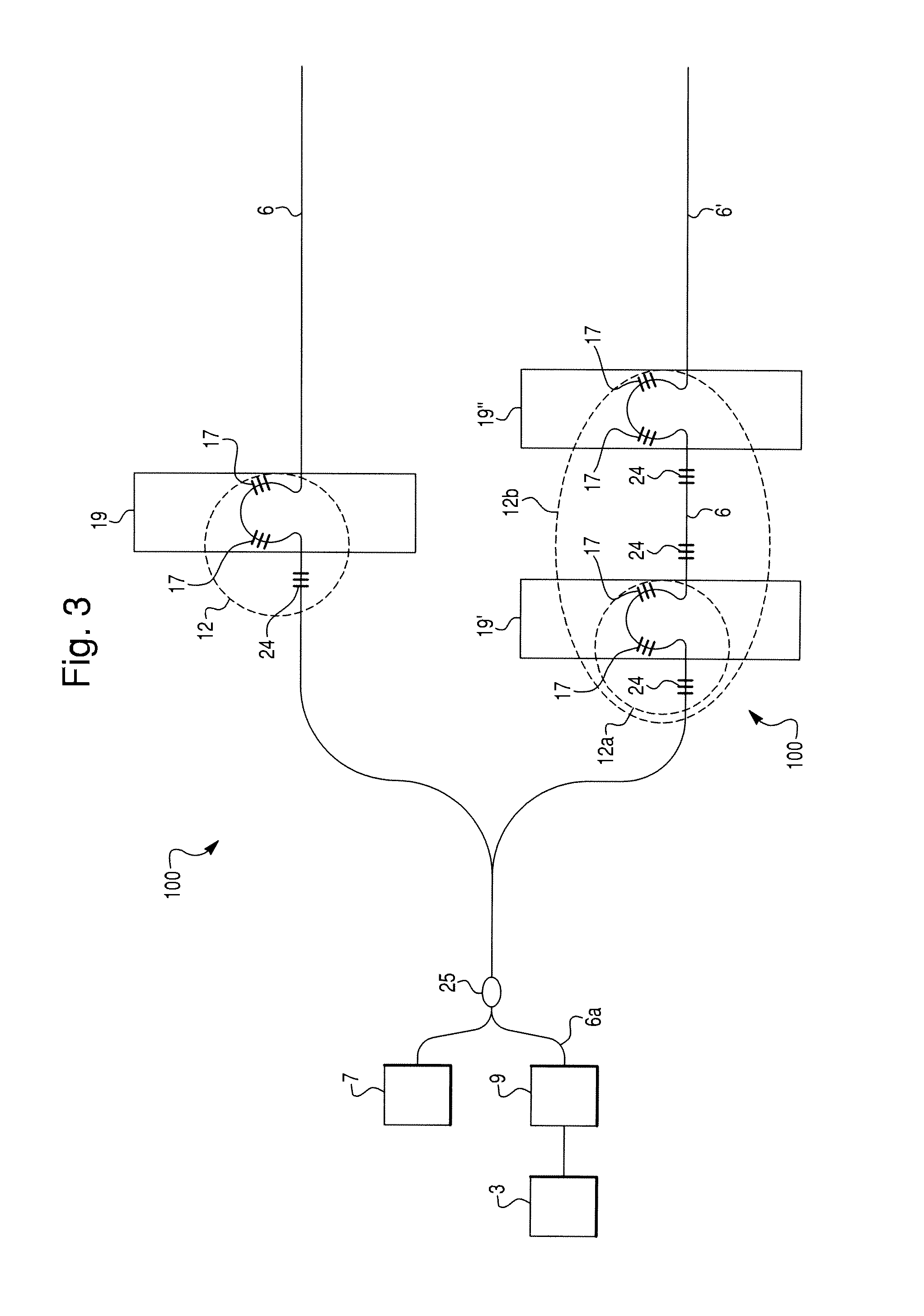

The present invention is directed toward a fiber optic position and shape sensing device and the method of use. The device comprises an optical fiber means. The optical fiber means comprises either at least two single core optical fibers or a multicore optical fiber having at least two fiber cores. In either case, the fiber cores are spaced apart such that mode coupling between the fiber cores is minimized. An array of fiber Bragg gratings are disposed within each fiber core. A broadband reference reflector is positioned in an operable relationship to each fiber Bragg grating wherein an optical path length is established for each reflector / grating relationship. A frequency domain reflectometer is positioned in an operable relationship to the optical fiber means. In use, the device is affixed to an object. Strain on the optical fiber is measured and the strain measurements correlated to local bend measurements. Local bend measurements are integrated to determine position or shape of the object.

Owner:LUNA INNOVATIONS

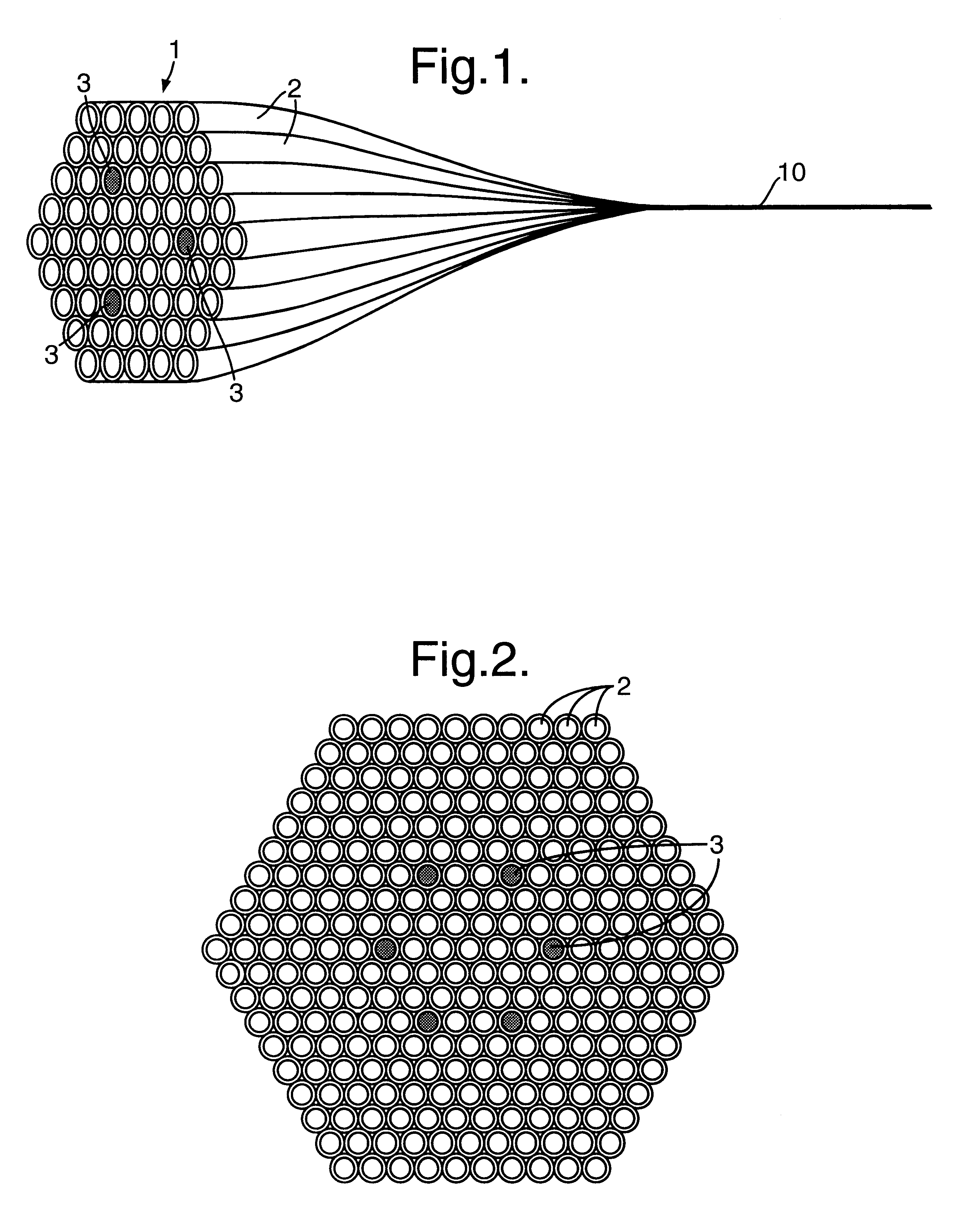

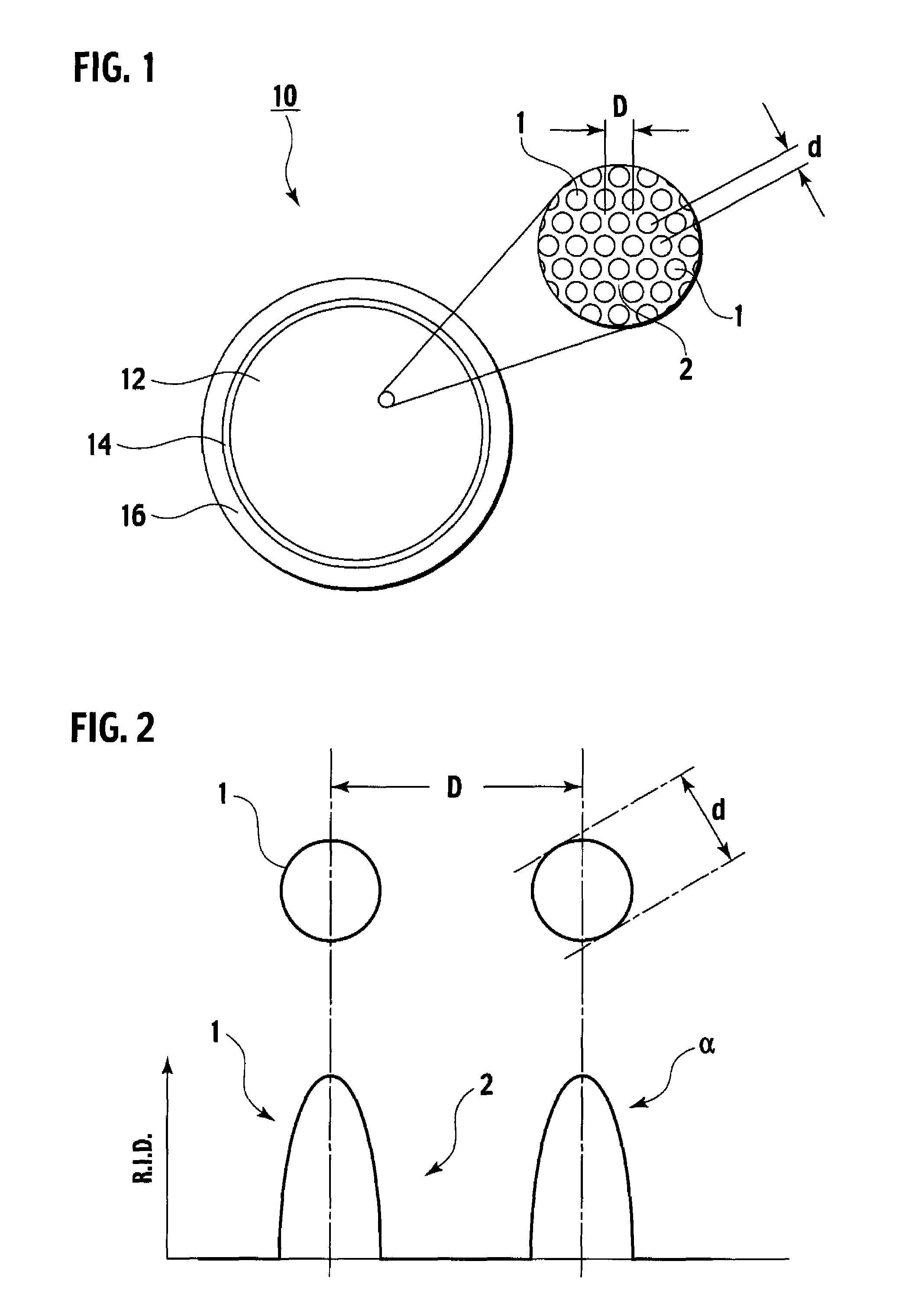

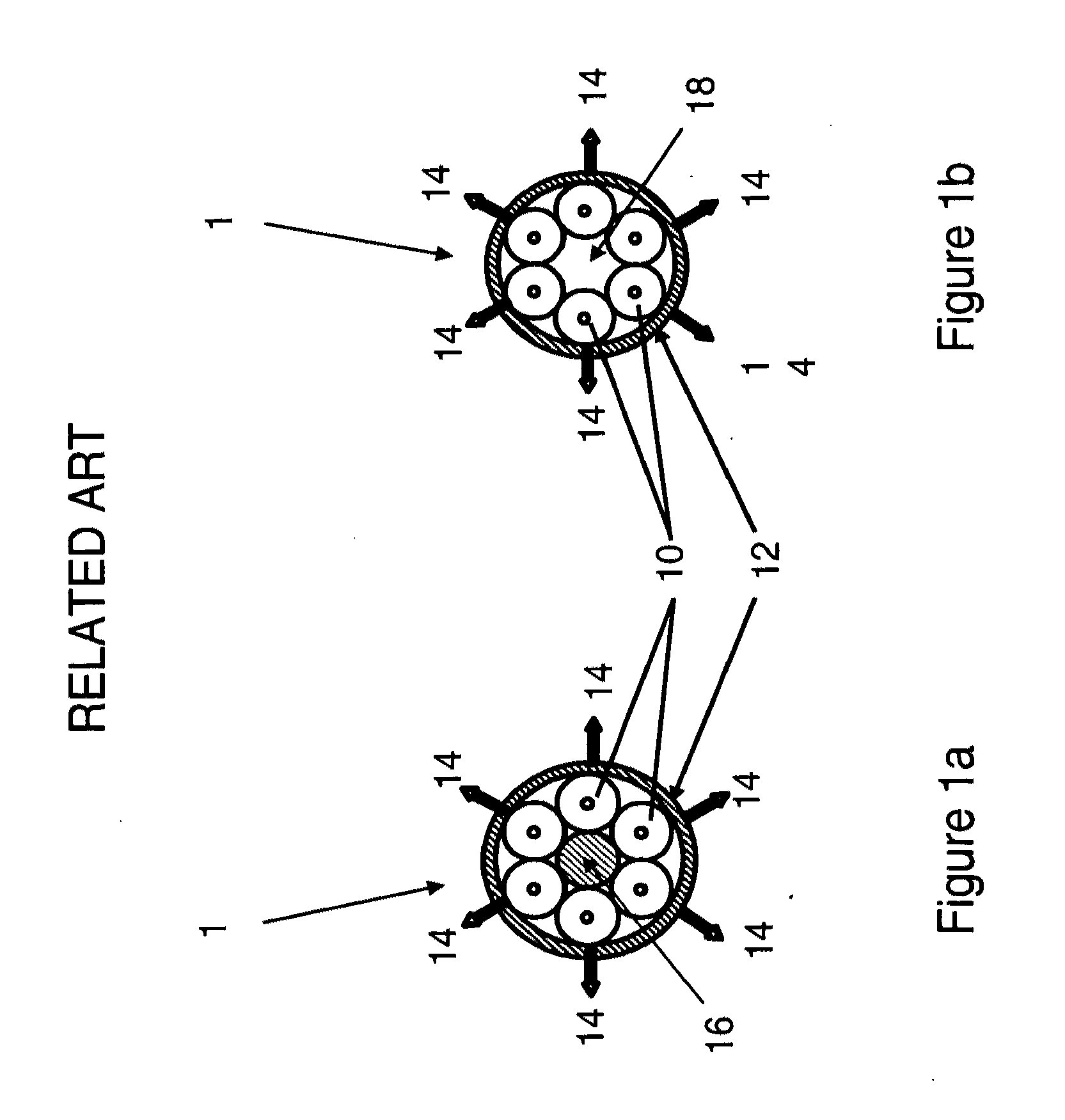

Multicore optical fibre

InactiveUS6301420B1Glass making apparatusOptical fibre with multilayer core/claddingFiberRefractive index

An optical fiber for transmitting radiation comprising two or more core regions, two or more core regions, each core region comprising a substantially transparent core material and having a core refractive index, a core length, and a core diameter, wherein said core regions are arranged within a cladding region, said cladding region comprising a length of first substantially transparent cladding material, having a first refractive index, wherein said first substantially transparent cladding material has an array of lengths of a second cladding material embedded along its length, wherein the second cladding material has a second refractive index which is less than said first refractive index, such that radiation input to said fiber propagates along at least one of said core regions. The cladding region and the core regions may be arranged such that radiation input to said optical fiber propagates along one or more said lengths of said core regions in a single mode of propagation. The optical fiber may be used as a bend sensor, a spectral filter or a directional coupler. The invention also relates to a method of manufacturing a multicore optical fiber.

Owner:NKT RES & INNOVATION

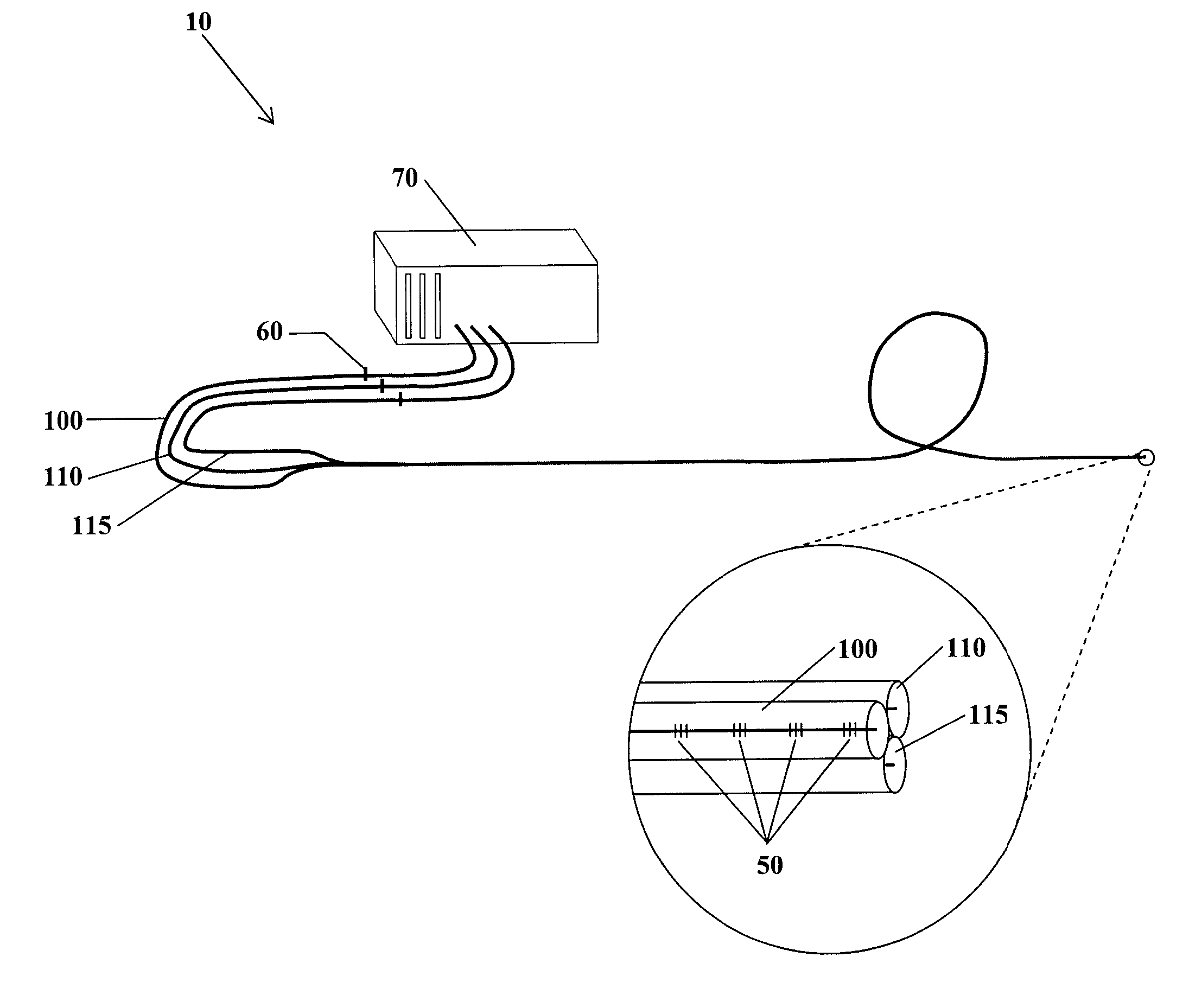

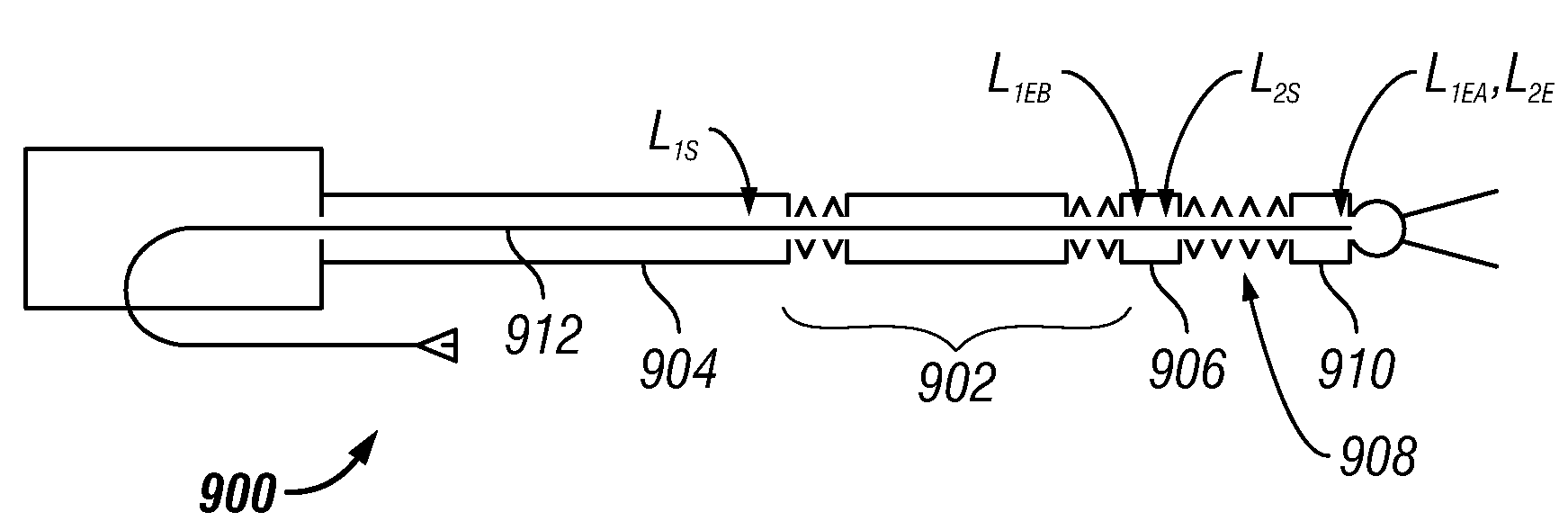

Fiber optic position and shape sensing device and method relating thereto

The present invention is directed toward a fiber optic position and shape sensing device and the method of use. The device comprises an optical fiber means. The optical fiber means comprises either at least two single core optical fibers or a multicore optical fiber having at least two fiber cores. In either case, the fiber cores are spaced apart such that mode coupling between the fiber cores is minimized. An array of fiber Bragg gratings are disposed within each fiber core and a frequency domain reflectometer is positioned in an operable relationship to the optical fiber means. In use, the device is affixed to an object. Strain on the optical fiber is measured and the strain measurements correlated to local bend measurements. Local bend measurements are integrated to determine position and / or shape of the object.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Fiber Optic Position and Shape Sensing Device and Method Relating Thereto

ActiveUS20070065077A1Improve spatial resolutionImprove accuracyRadiation pyrometryEndoscopesFiberGrating

The present invention is directed toward a fiber optic position and shape sensing device and the method of use. The device comprises an optical fiber means. The optical fiber means comprises either at least two single core optical fibers or a multicore optical fiber having at least two fiber cores. In either case, the fiber cores are spaced apart such that mode coupling between the fiber cores is minimized. An array of fiber Bragg gratings are disposed within each fiber core and a frequency domain reflectometer is positioned in an operable relationship to the optical fiber means. In use, the device is affixed to an object. Strain on the optical fiber is measured and the strain measurements correlated to local bend measurements. Local bend measurements are integrated to determine position and / or shape of the object.

Owner:INTUITIVE SURGICAL OPERATIONS INC

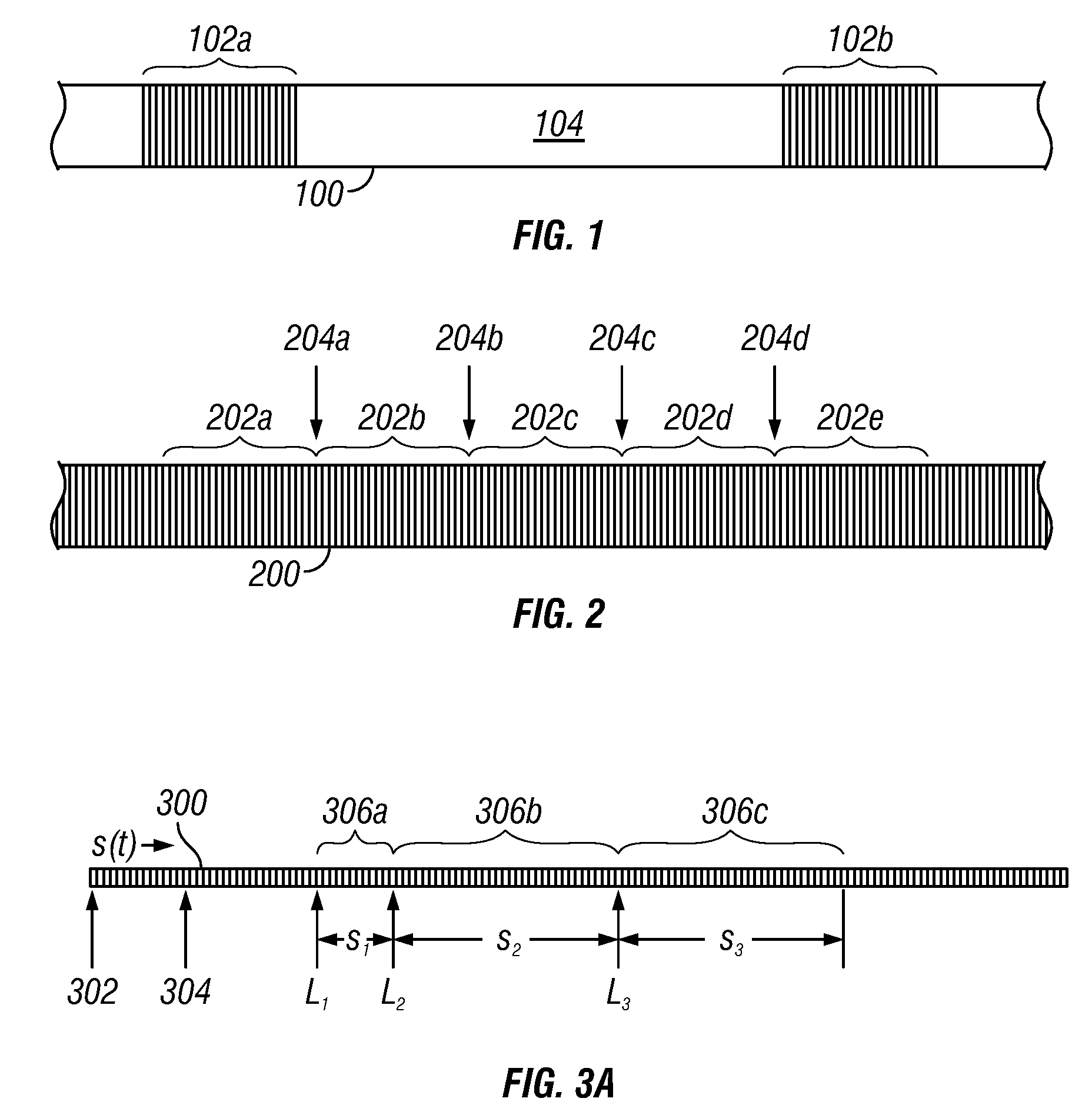

Fiber optic shape sensor

A shape sensing system to determine the position and orientation of one link with respect to another link in a kinematic chain. An optical fiber is coupled to two or more links in a kinematic chain. A shape sensing segment is defined to start at a proximal link and to end at a distal link, crossing one or more joints. A reference frame is defined at the start of the shape sensing segment. As the joints move, an interrogator senses strain in the shape sensing segment. The sensed strain is used to output a Cartesian position and orientation of the end of the shape sensing segment with respect to the reference frame defined at the start of the shape sensing segment. The pose of the kinematic chain is determined from the Cartesian positions and orientations of one or more shape sensing segments defined for the kinematic chain and from an a priori model and constraints of the kinematic chain.

Owner:INTUITIVE SURGICAL OPERATIONS INC

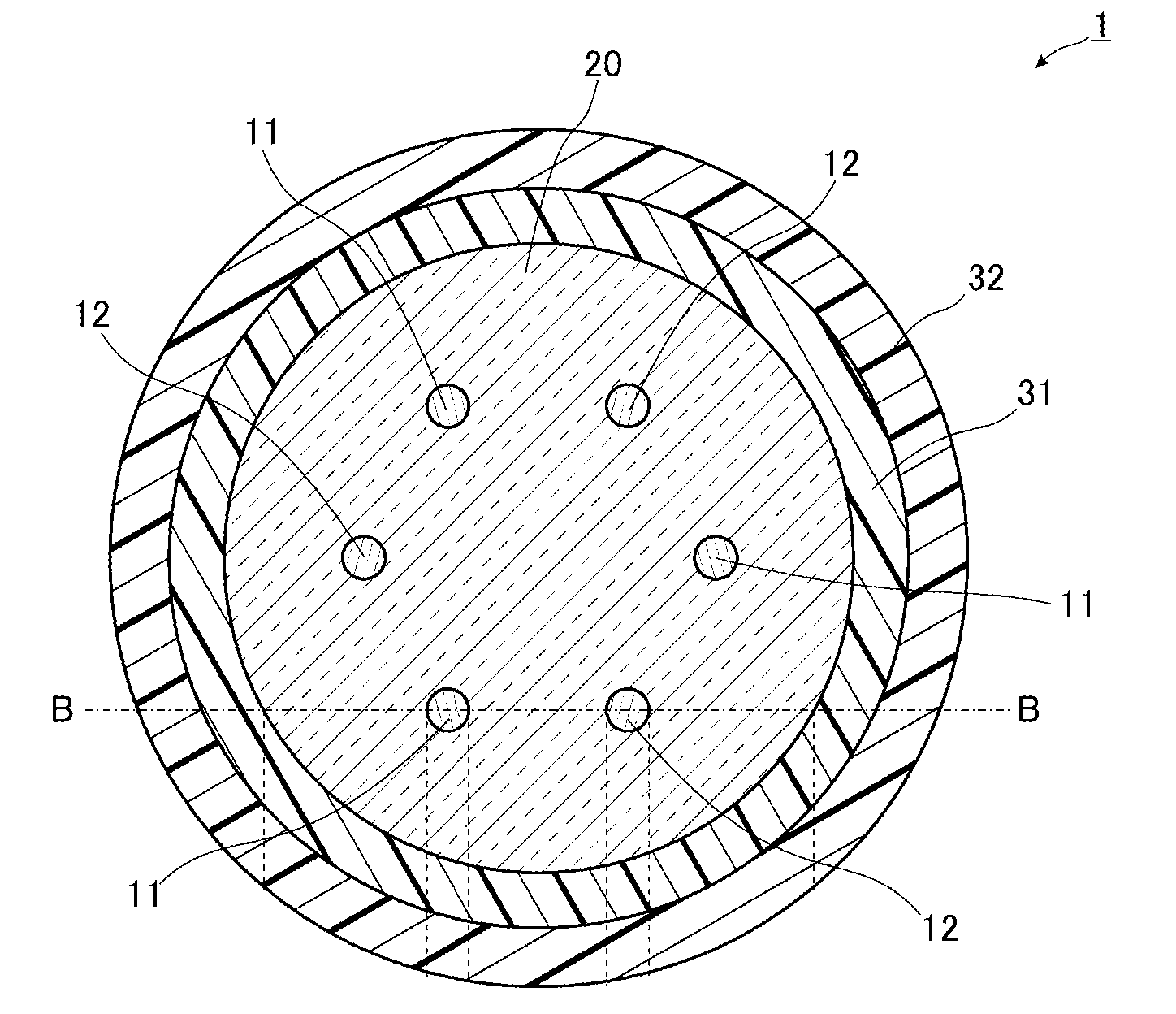

Polarization maintaining multi-core optical fiber

InactiveUS20130108206A1High densityField distribution is reducedOptical fibre with polarisationMulticore optical fibreLong axisOptical polarization

In a polarization maintaining multi-core optical fiber according to the present invention, structural birefringence is generated since an elliptic core is applied. In addition, each core is arranged so that a direction of a line connecting between centers of the nearest cores and a long axis direction of a field distribution in each core may be different from each other, and thereby, overlap of field distributions between the nearest cores is reduced. As a result, a crosstalk among cores is reduced.

Owner:SUMITOMO ELECTRIC IND LTD

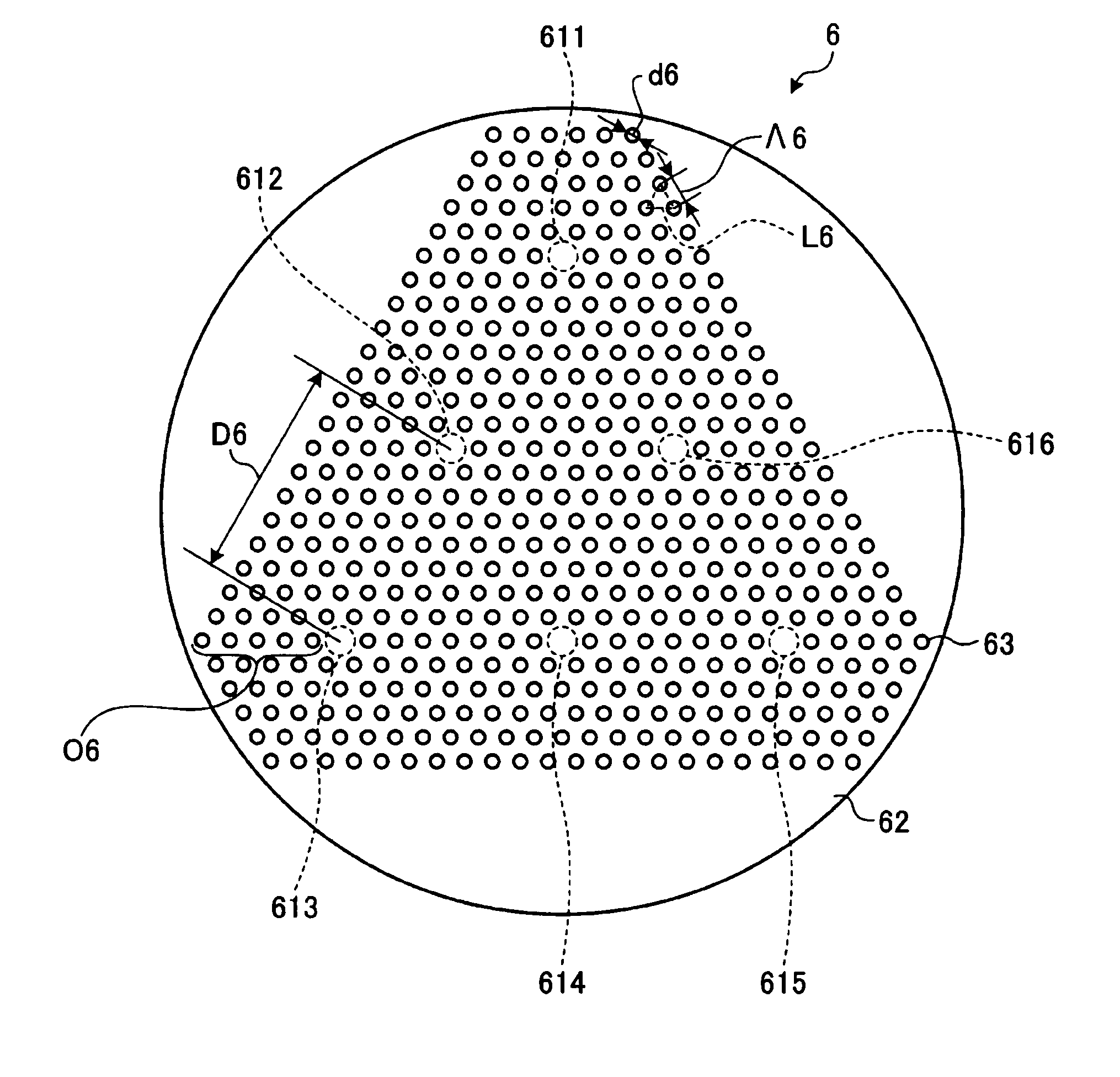

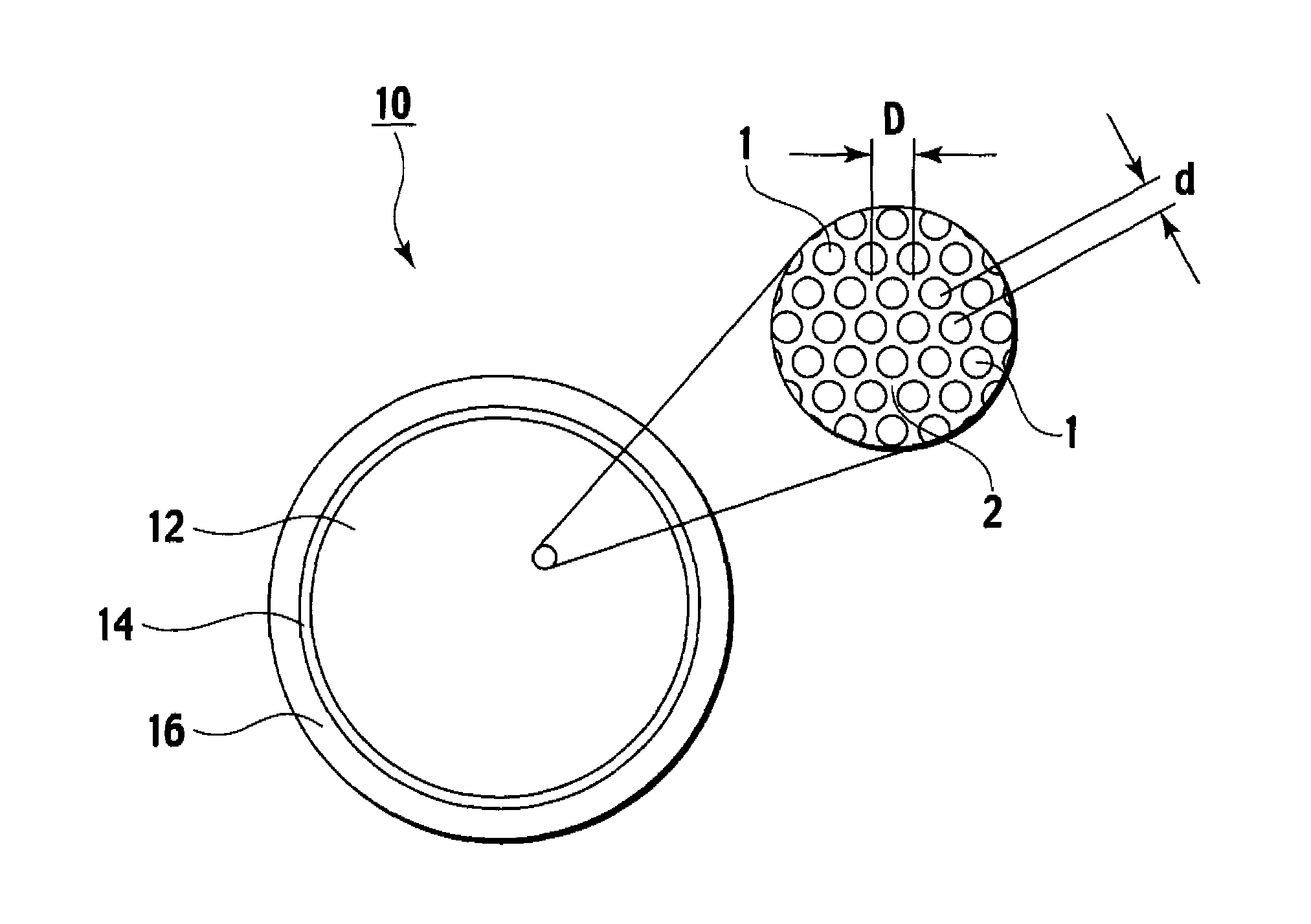

Multi-core holey fiber and optical transmission system

A multi-core holey fiber with suppression of crosstalk deterioration among transmitted optical signals in a plurality of cores, and an optical transmission system using the fiber are disclosed. The multi-core holey fiber comprises a plurality of cores arranged separately from each other, and a cladding surrounding the plurality of cores wherein the cladding has plurality of holes arranged in a triangular lattice shape to create hole layers around the plurality of cores. Additionally, d / Λ is not more than 0.5, where Λ [μm] is lattice constant of the triangular lattice, d [μm] is diameter of each of the holes; a distance between adjacent cores is equivalent to not less than six hole layers; the cores arranged farthest from the center of the multi-core holey fiber is surrounded by not less three hole layers; and the sum of the coupling coefficients between the adjacent cores is not more than 1.6×10−5 / m.

Owner:FURUKAWA ELECTRIC CO LTD

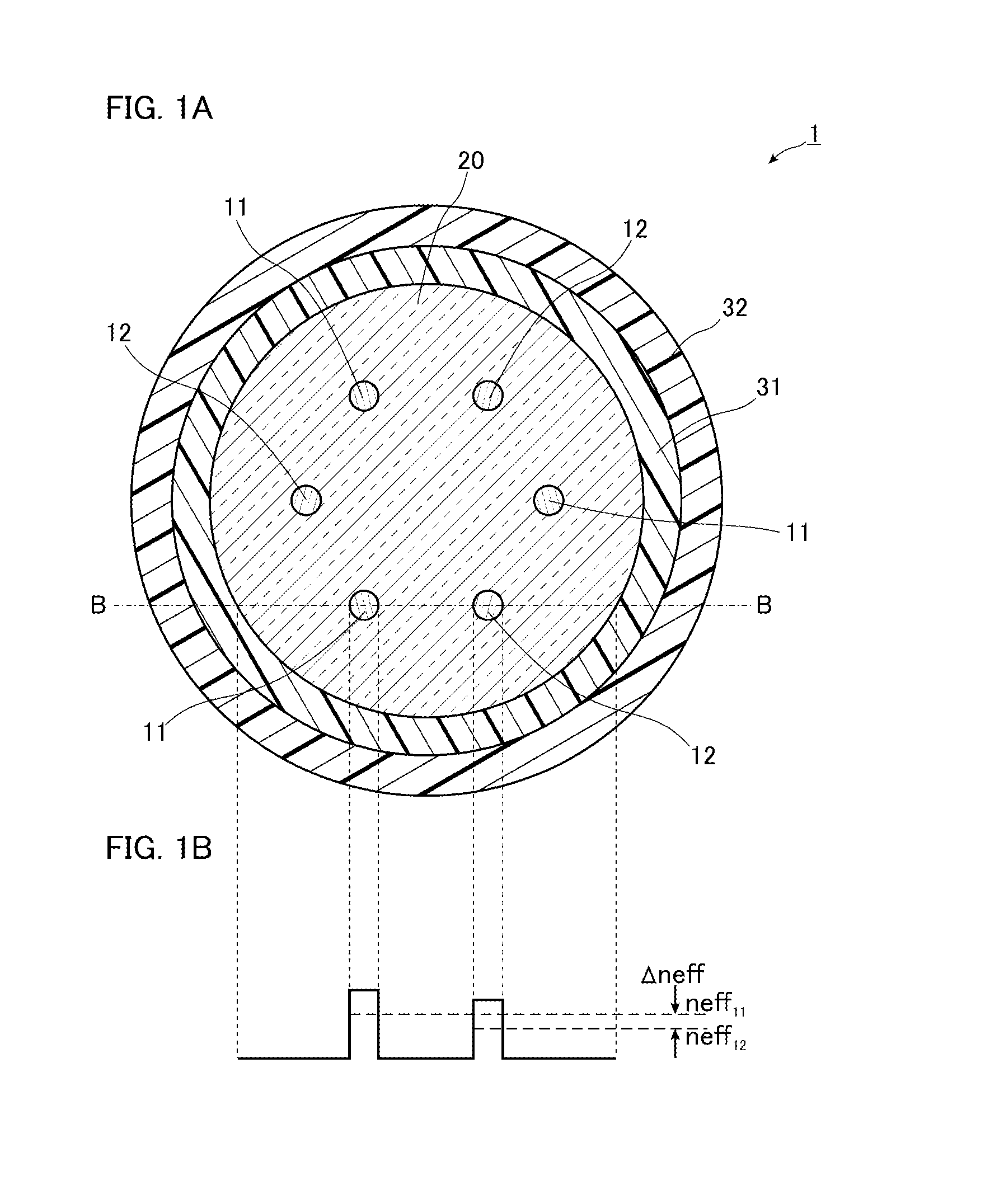

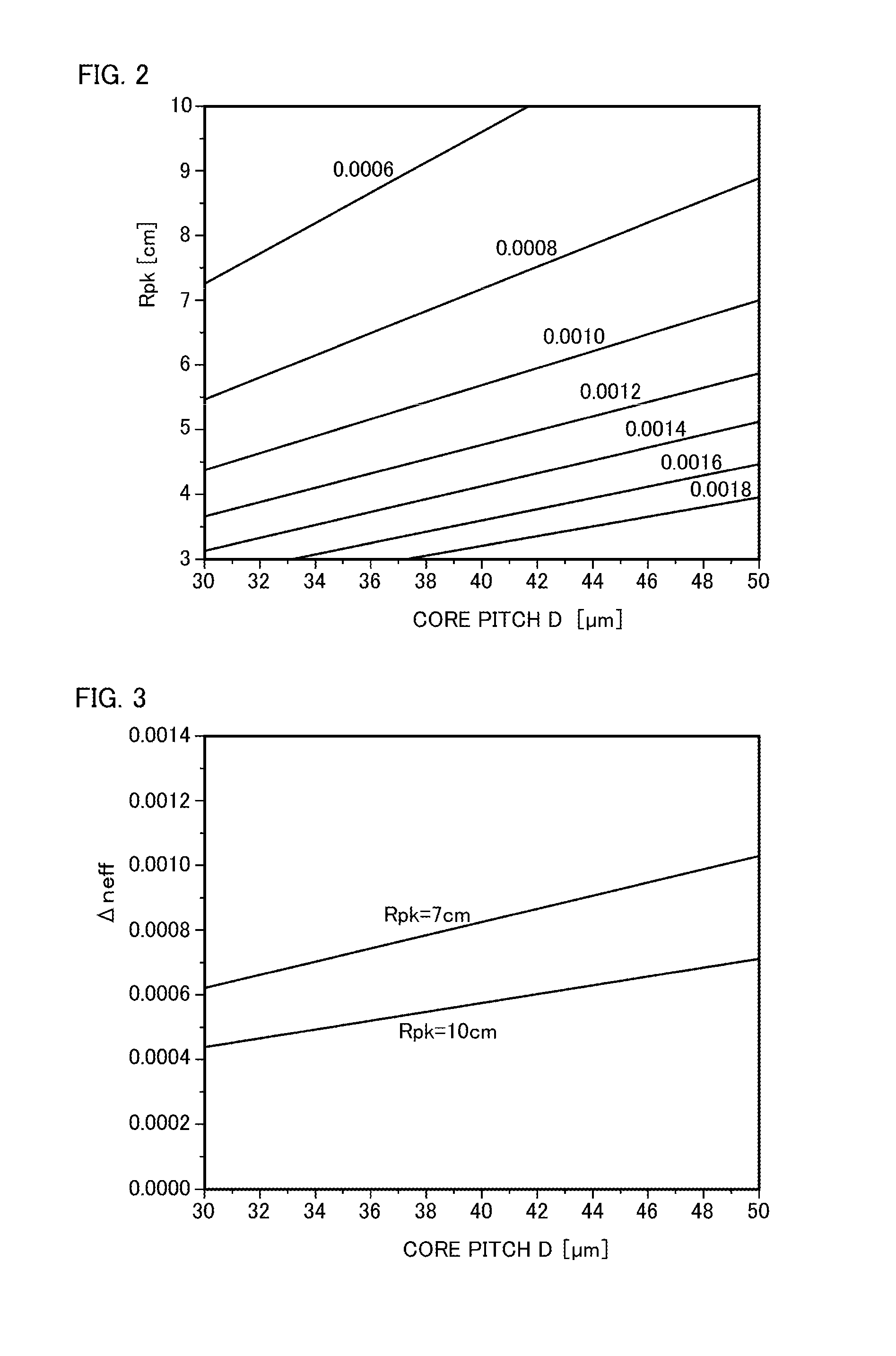

Multi-core fiber

ActiveUS20140334789A1Suppressing splicing lossOptical fibre with multilayer core/claddingMulticore optical fibreMode field diameterEffective refractive index

A multi-core fiber includes an even number of six or more of cores and a clad that surrounds the outer circumferential surfaces of the cores. The cores are formed of two types of cores and in which an effective refractive index difference in a fundamental mode is 0.002 or less in a predetermined range or more that the effective refractive index difference in the fundamental mode is varied according to a core pitch. Two types of the cores are alternately and annularly disposed at regular spacings. A difference in the mode field diameter of light propagating through the cores is 1 μm or less.

Owner:THE FUJIKURA CABLE WORKS LTD +1

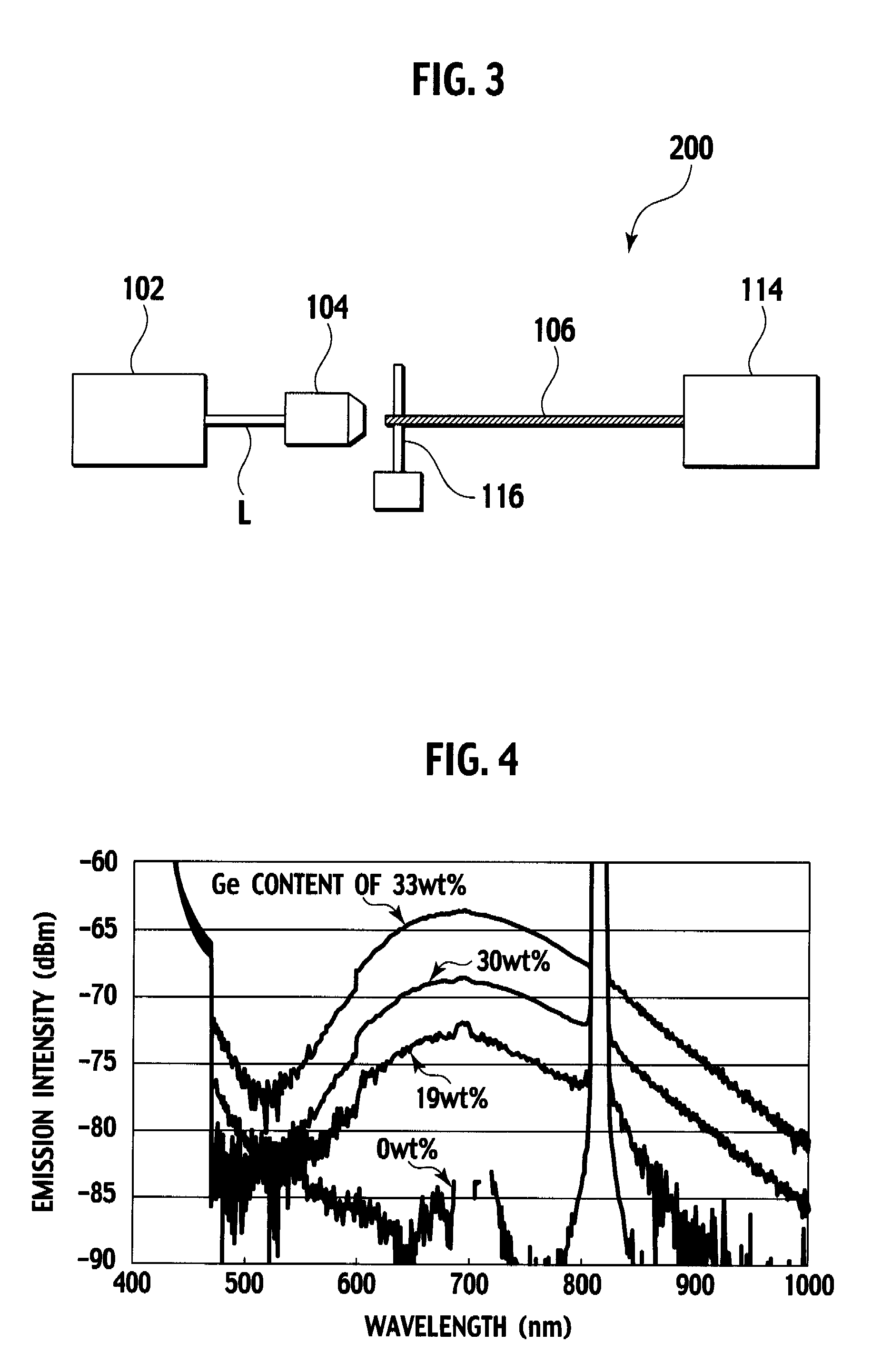

Multi-core fiber

ActiveUS7418178B2Optical fibre with multilayer core/claddingBundled fibre light guideQuartzNumerical aperture

A multi-core optical fiber apparatus is disclosed. The multi-core optical fiber apparatus includes a cladding comprising quartz and a plurality of cores embedded in the cladding. Each of the cores has a diameter (D) ranging from 1.3 μm to 2.0 μm, a numerical aperture (NA) from 0.35 to 0.45 and a refractive index profile factor (α) from 2.0 to 4.0. A center of each of the cores has a germanium content of 20 wt % to 30 wt %. An interval between adjacent cores is 3.0 μm or more.

Owner:THE FUJIKURA CABLE WORKS LTD

Fiber optic shape sensor

A shape sensing system to determine the position and orientation of one link with respect to another link in a kinematic chain. An optical fiber is coupled to two or more links in a kinematic chain. A shape sensing segment is defined to start at a proximal link and to end at a distal link, crossing one or more joints. A reference frame is defined at the start of the shape sensing segment. As the joints move, an interrogator senses strain in the shape sensing segment. The sensed strain is used to output a Cartesian position and orientation of the end of the shape sensing segment with respect to the reference frame defined at the start of the shape sensing segment. The pose of the kinematic chain is determined from the Cartesian positions and orientations of one or more shape sensing segments defined for the kinematic chain and from an a priori model and constraints of the kinematic chain.

Owner:INTUITIVE SURGICAL OPERATIONS INC

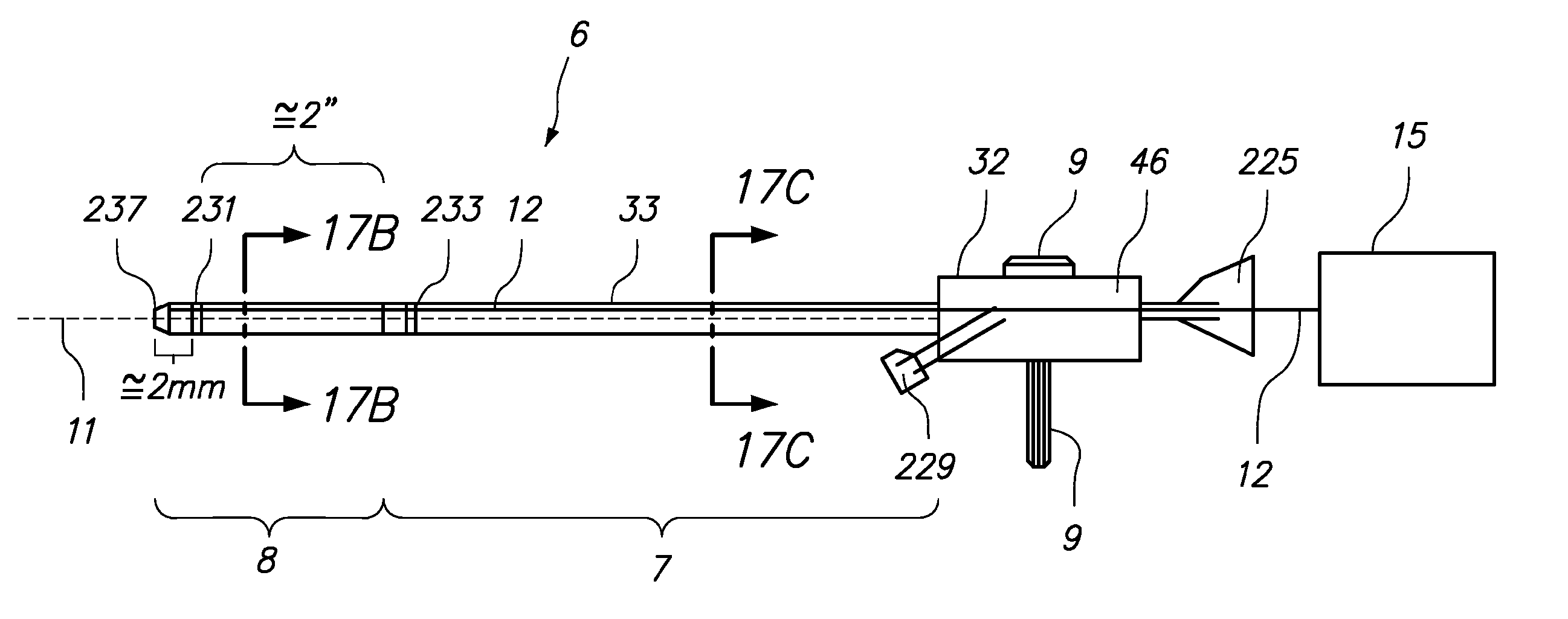

Fiber optic instrument sensing system

A medical instrument system comprises an elongate instrument body; an optical fiber coupled in a constrained manner to the elongate instrument body, the optical fiber including one or more Bragg gratings; a detector operably coupled to a proximal end of the optical fiber and configured to detect respective light signals reflected by the one or more Bragg gratings; and a controller operatively coupled to the detector, wherein the controller is configured to determine a geometric configuration of at least a portion of the elongate instrument body based on a spectral analysis of the detected reflected portions of the light signals.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

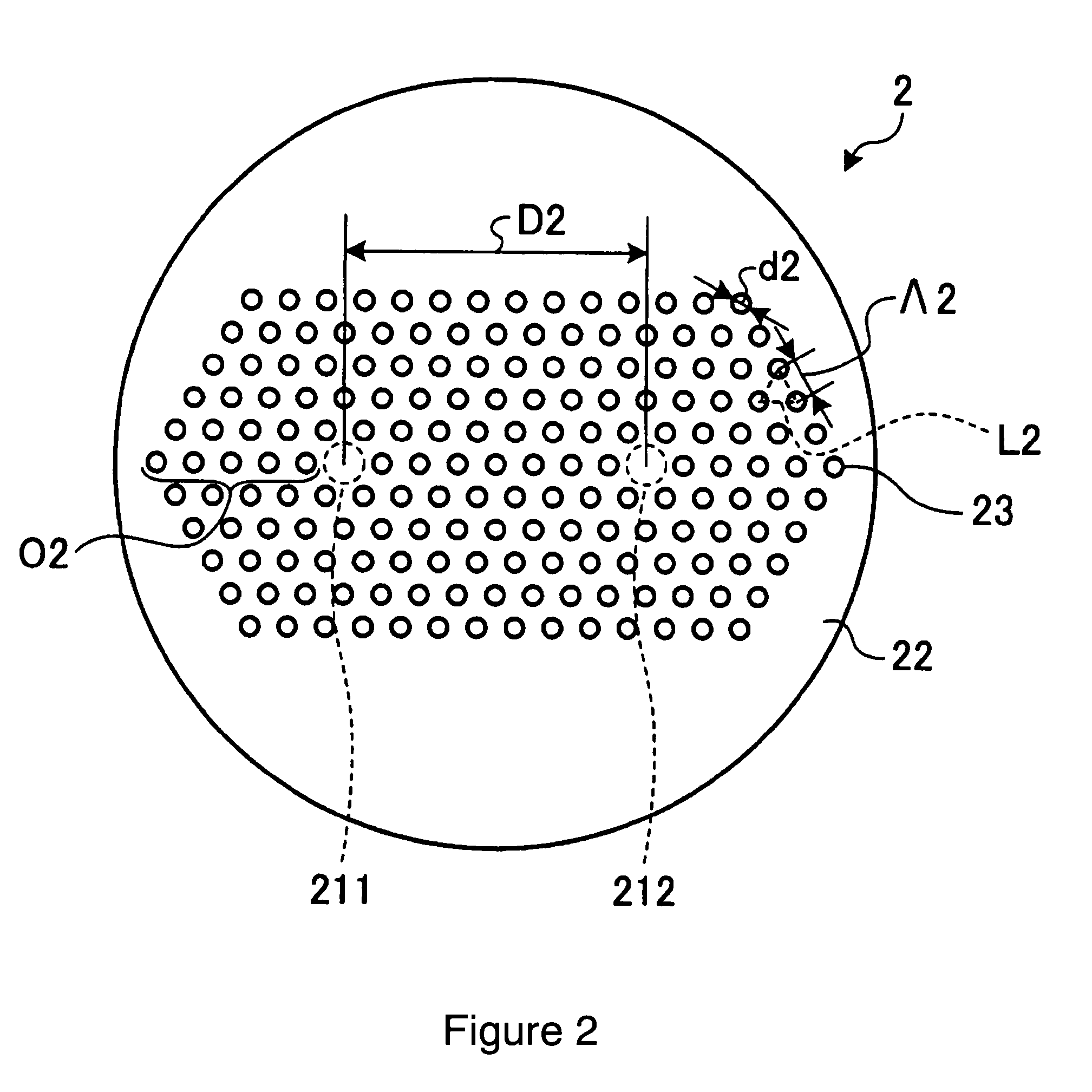

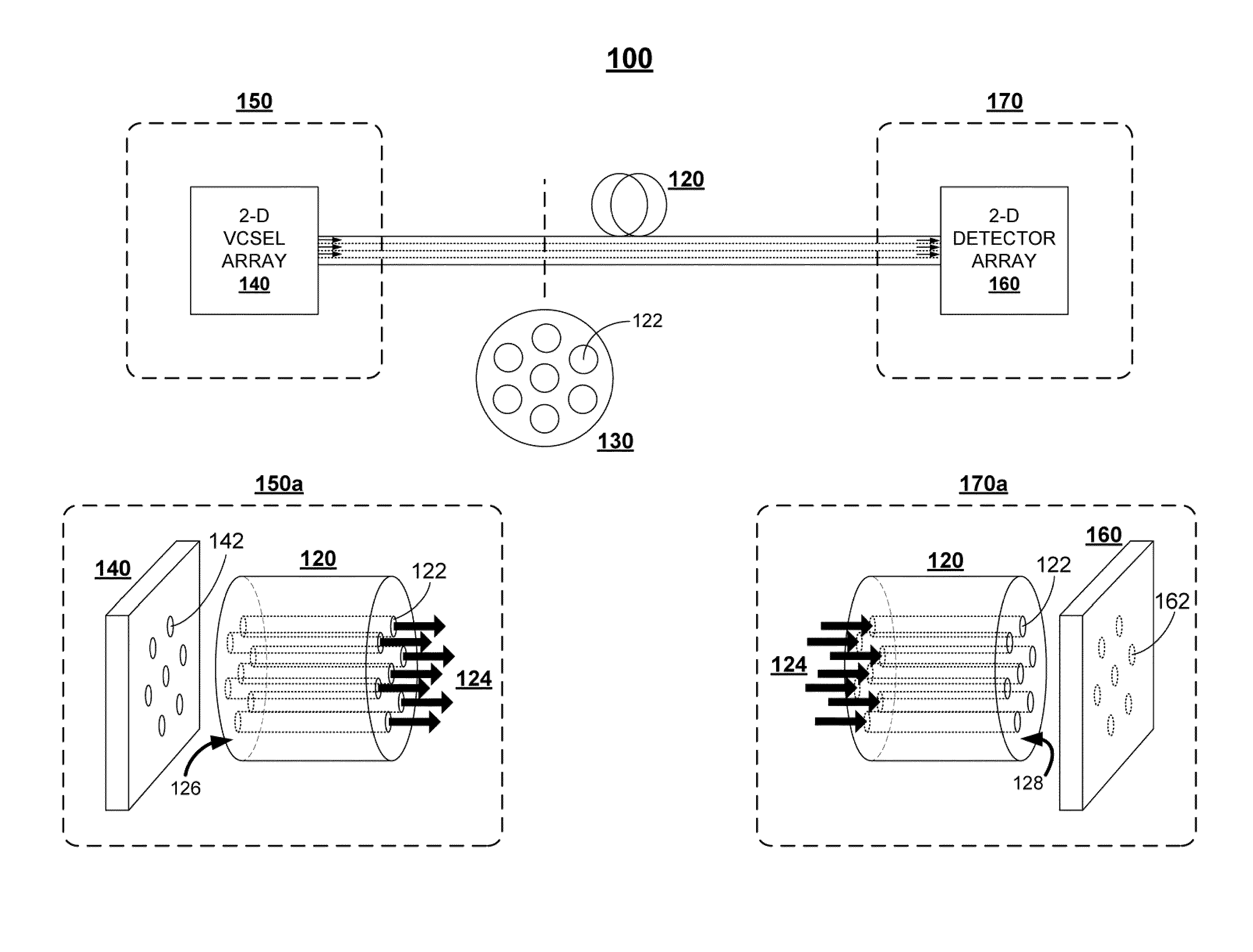

Multicore fiber transmission systems and methods

ActiveUS20110274435A1Wavelength-division multiplex systemsOptical mode multiplex systemsAccess networkTransmission channel

An optical data link includes first and second pluralities of transmission devices, at least one of which is configured as an array. A multichannel transmission link has a first end connected to the first plurality of transmission devices and a second end connected to the second plurality of transmission devices so as to form a plurality of parallel transmission channels therebetween. The multichannel transmission link includes a multicore fiber with a plurality of individual cores having a configuration matching the array configuration of the at least one plurality of transmission devices. The multicore fiber has an endface connected directly to the at least one plurality of transmission devices, with the individual cores of the multicore fiber aligned with respective devices in the at least one plurality of transmission devices. Further described are access networks and core networks incorporating a transmission link comprising at least one span of a multicore fiber.

Owner:OFS FITEL LLC

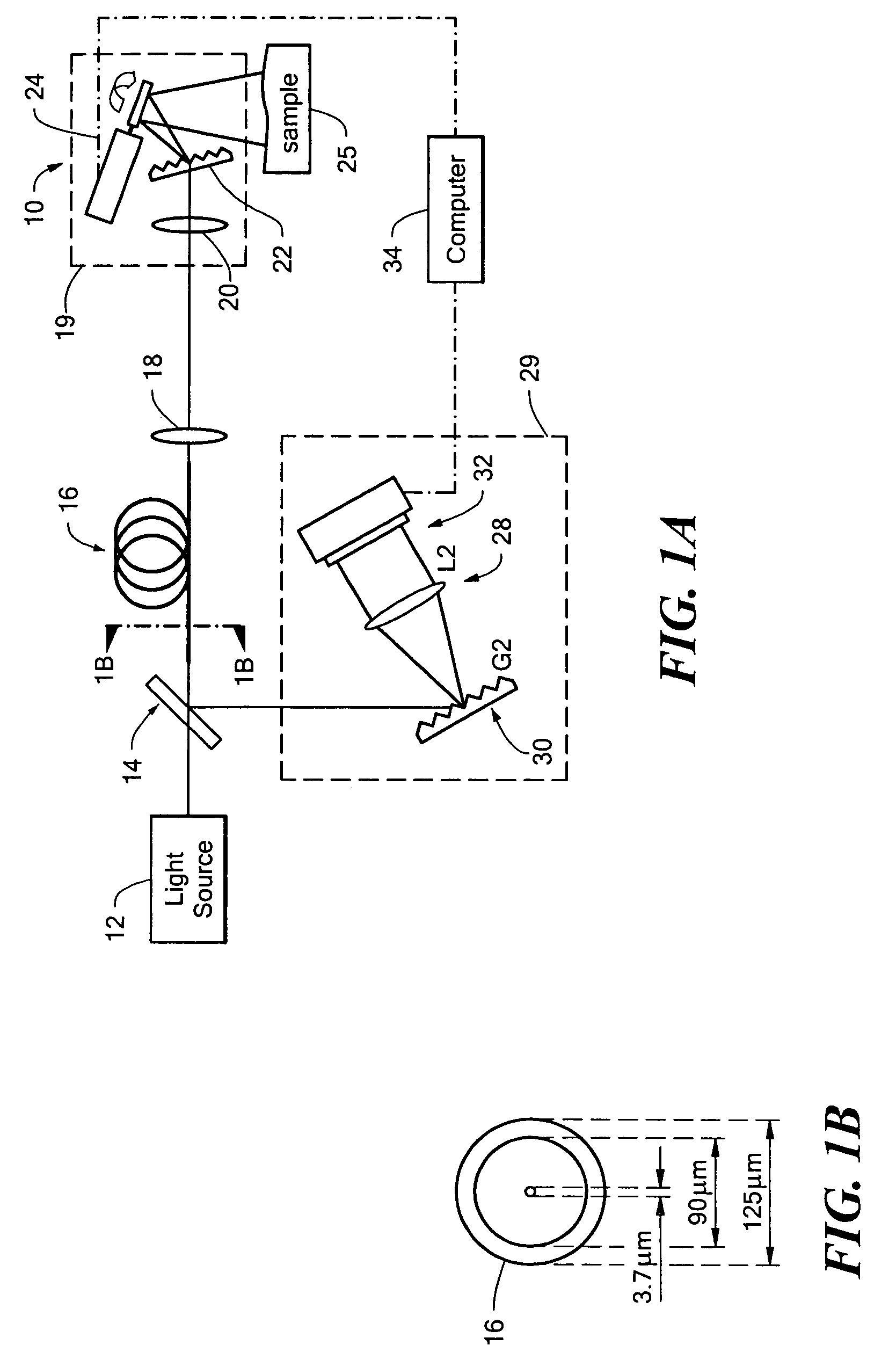

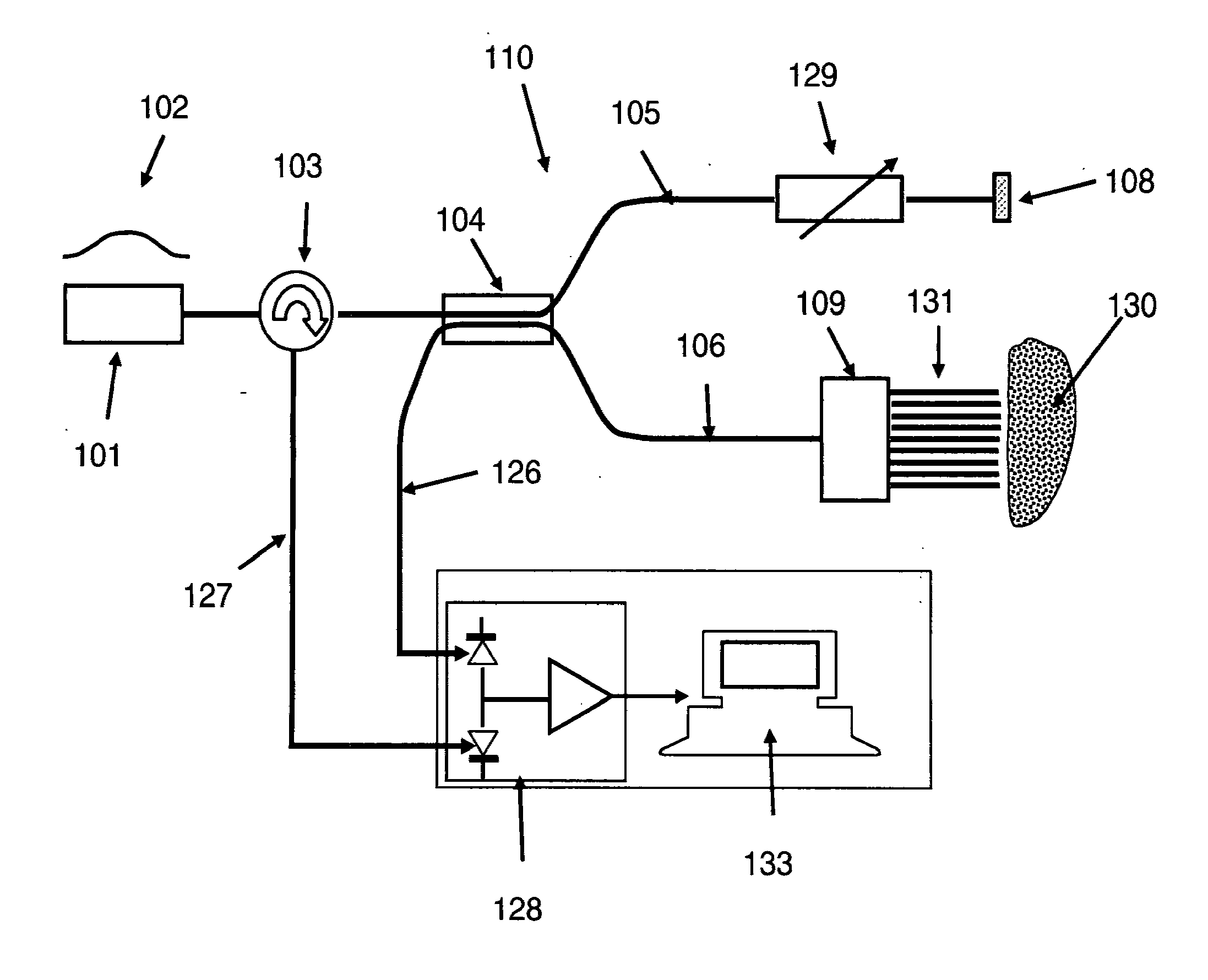

Imaging system and related techniques

ActiveUS7447408B2Reduces image speckleAdd depthRadiation pyrometrySpectrum investigationDouble-clad fiberComputer science

Owner:THE GENERAL HOSPITAL CORP

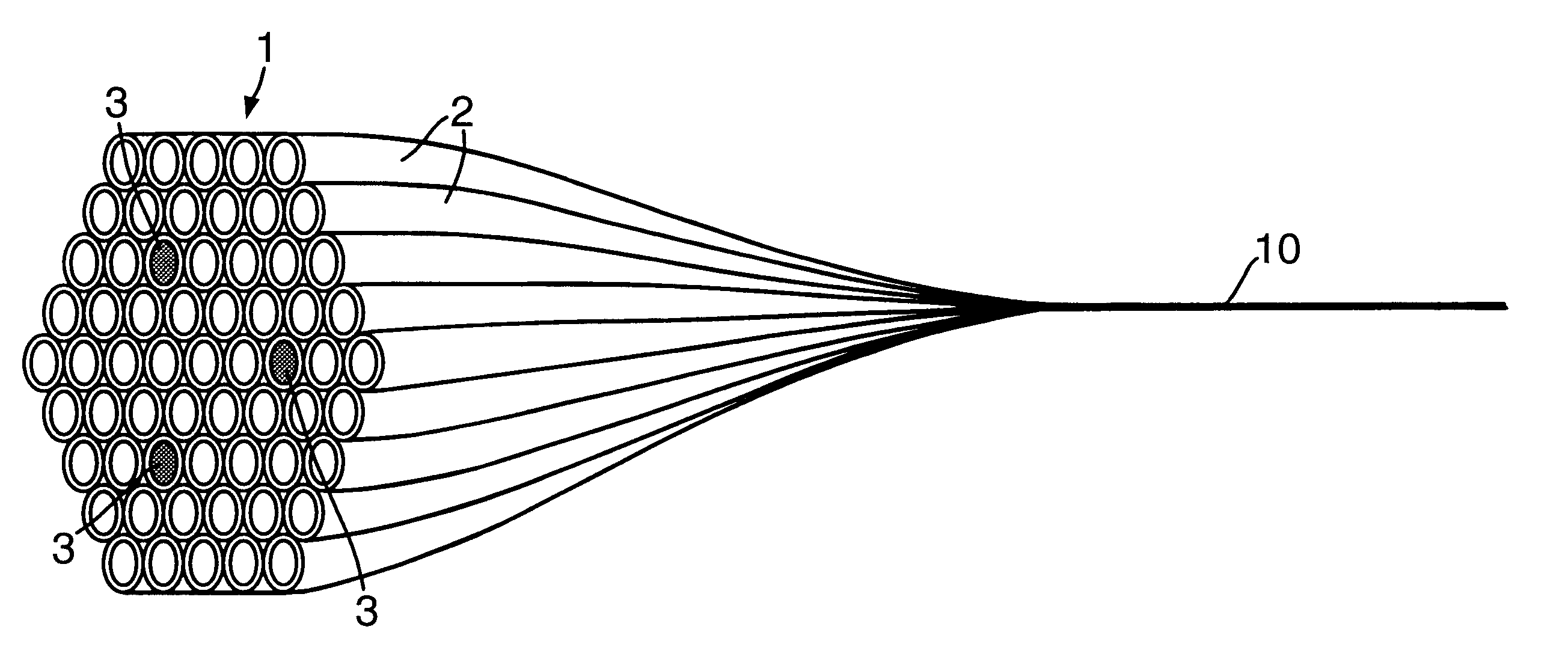

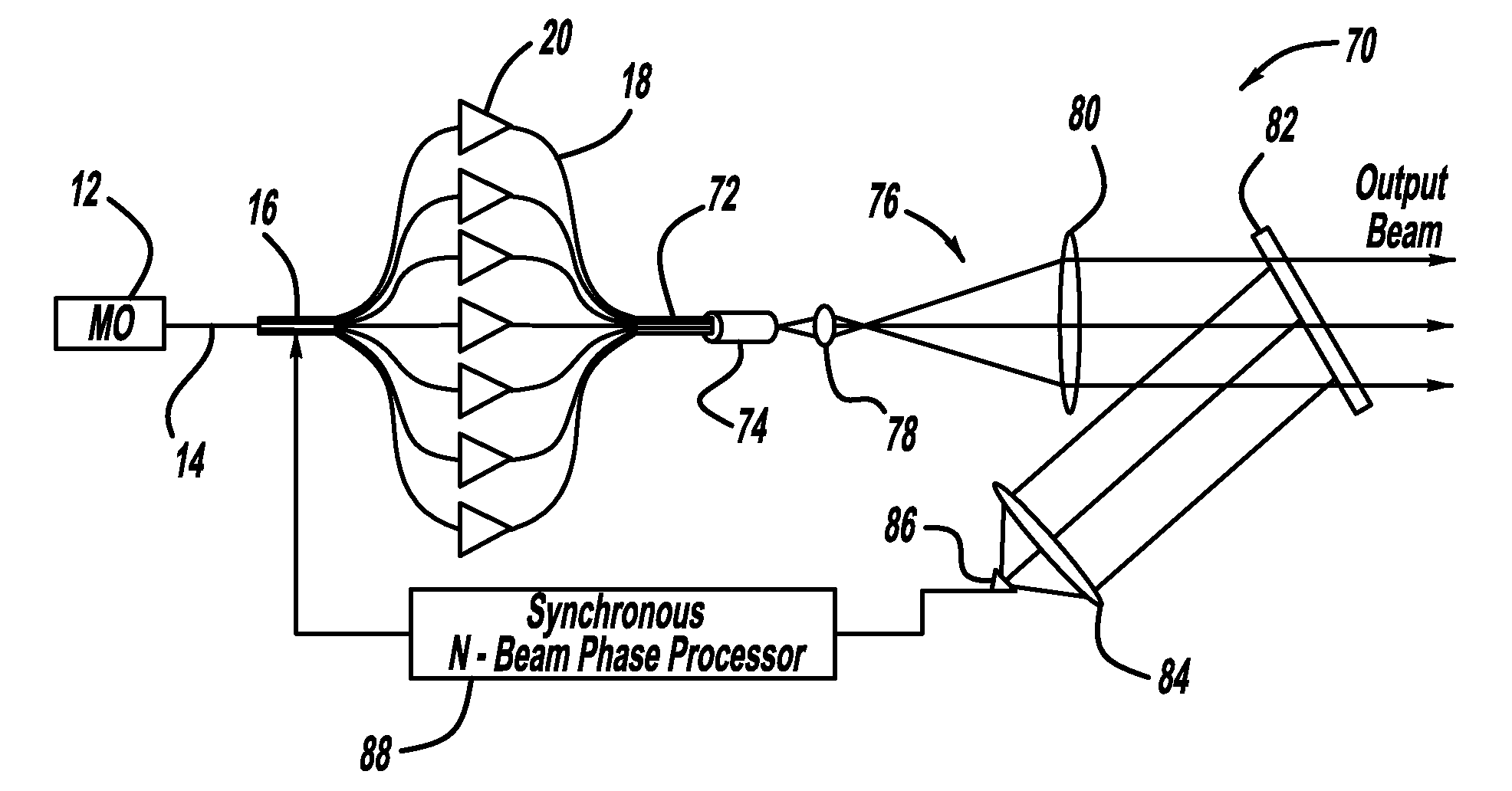

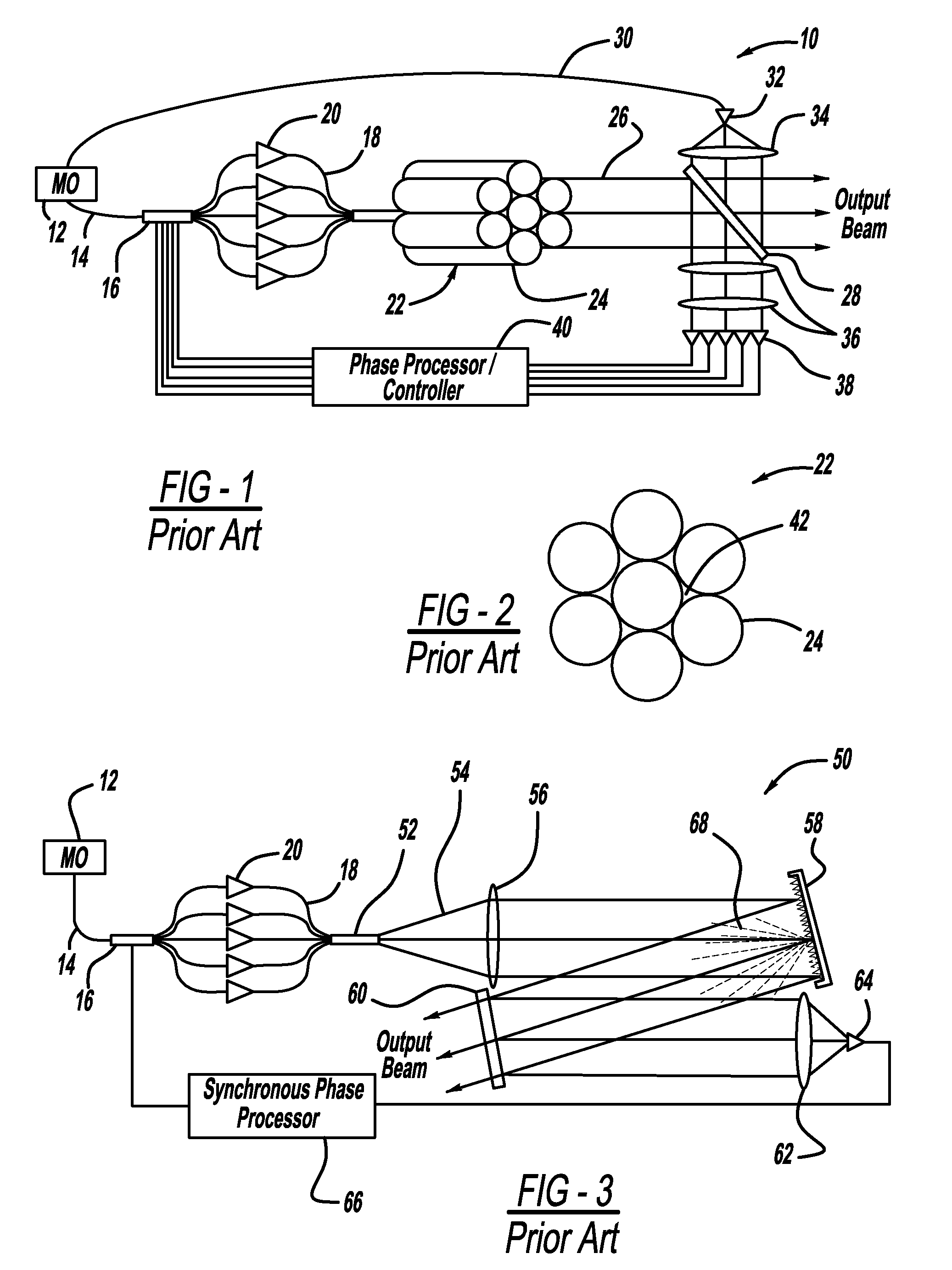

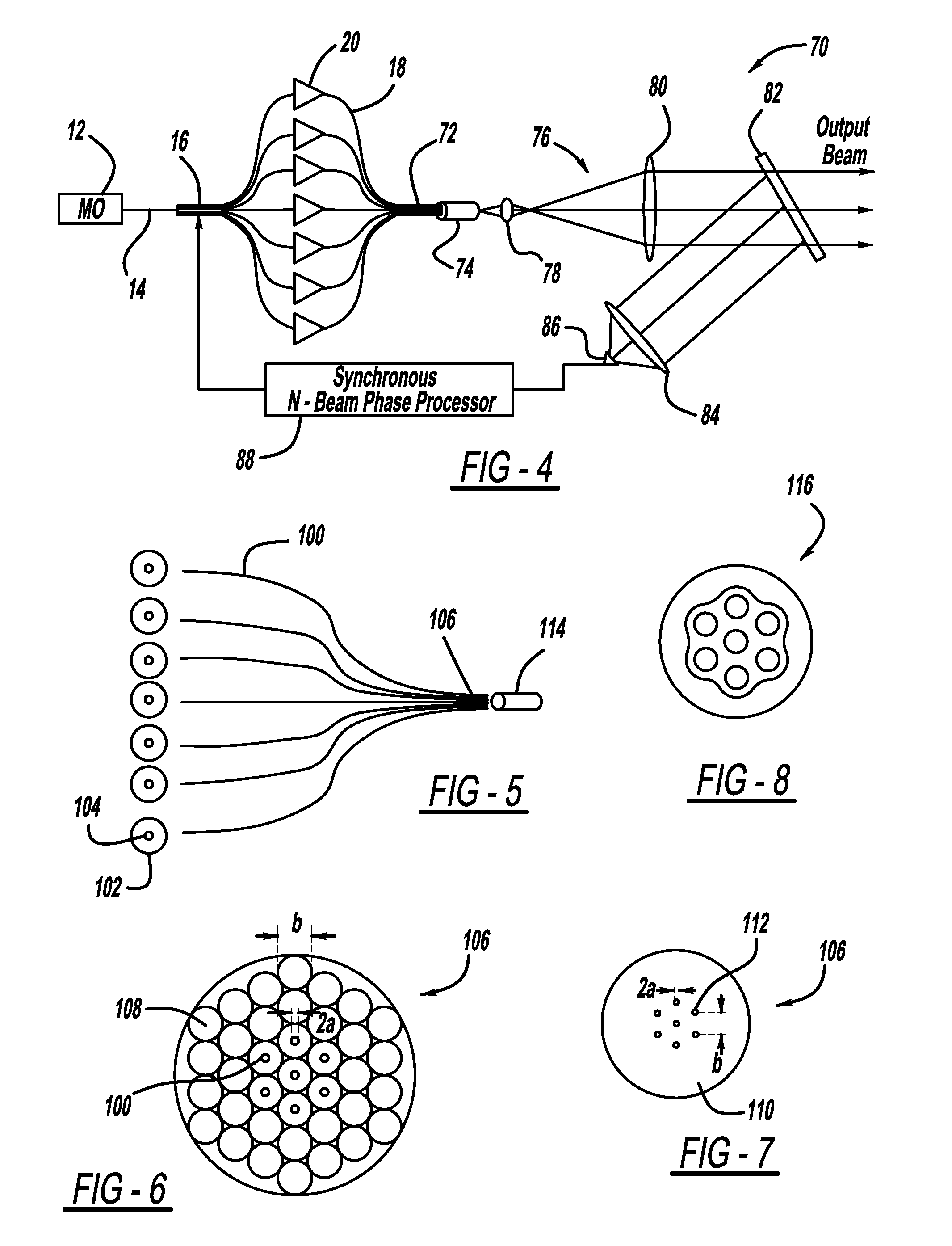

All-fiber integrated high power coherent beam combination

A fiber laser amplifier system including a master oscillator that generates a signal beam. A splitter splits the signal beam into a plurality of fiber beams where a separate fiber beam is sent to a fiber amplifier for amplifying the fiber beam. A tapered fiber bundle couples all of the output ends of all of the fiber amplifiers into a combined fiber providing a combined output beam. An end cap is optically coupled to an output end of the tapered fiber bundle to expand the output beam.

Owner:NORTHROP GRUMMAN SYST CORP

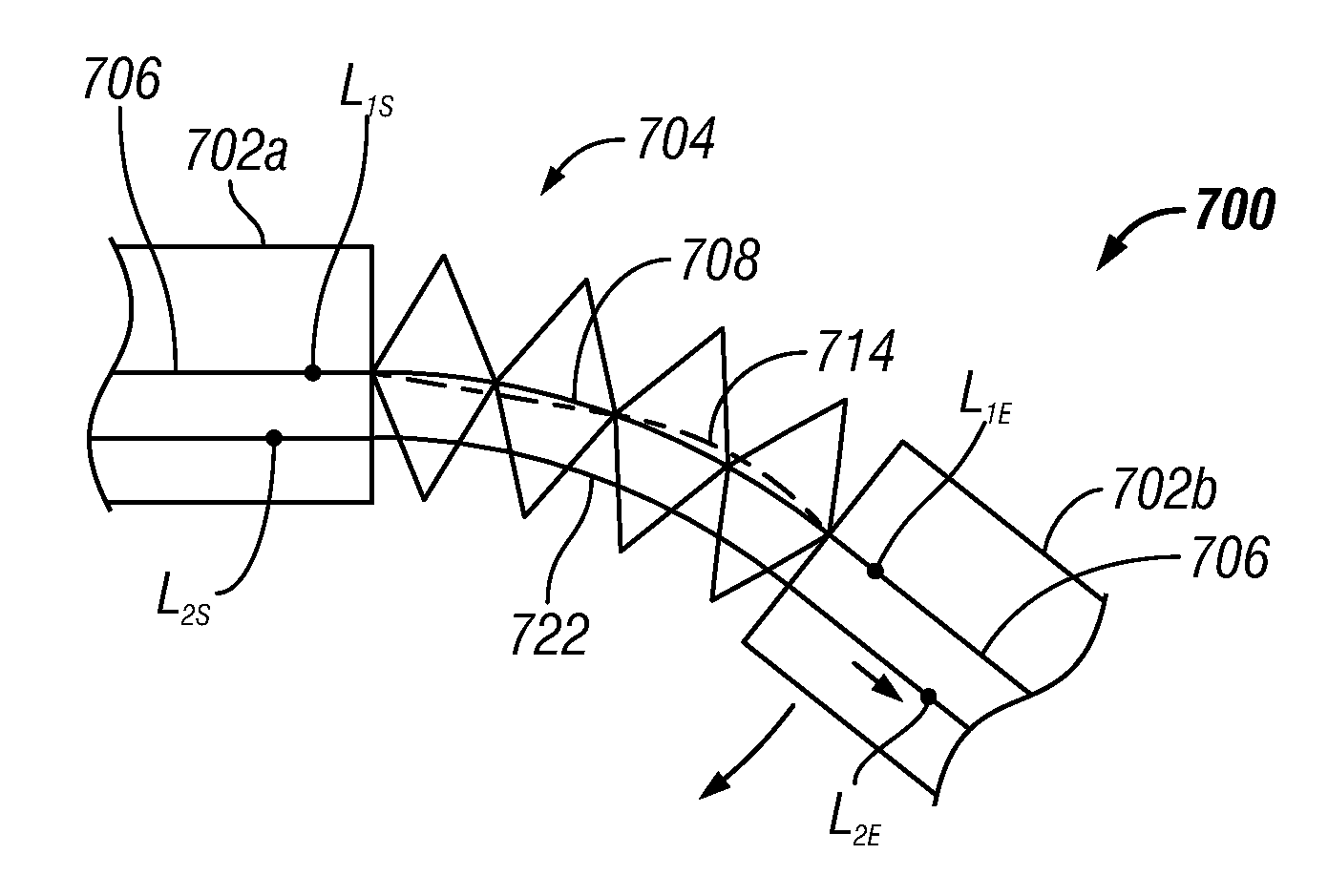

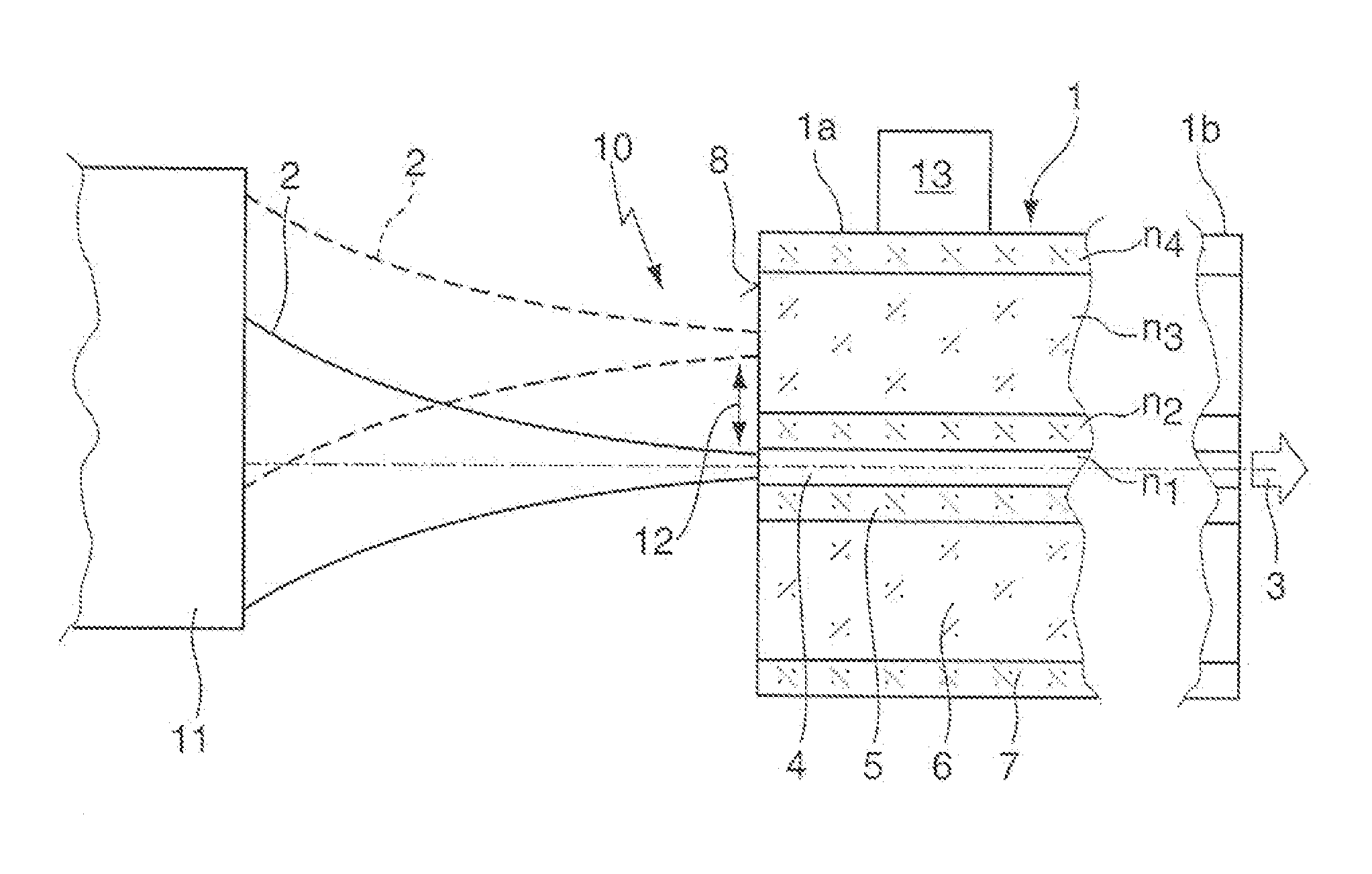

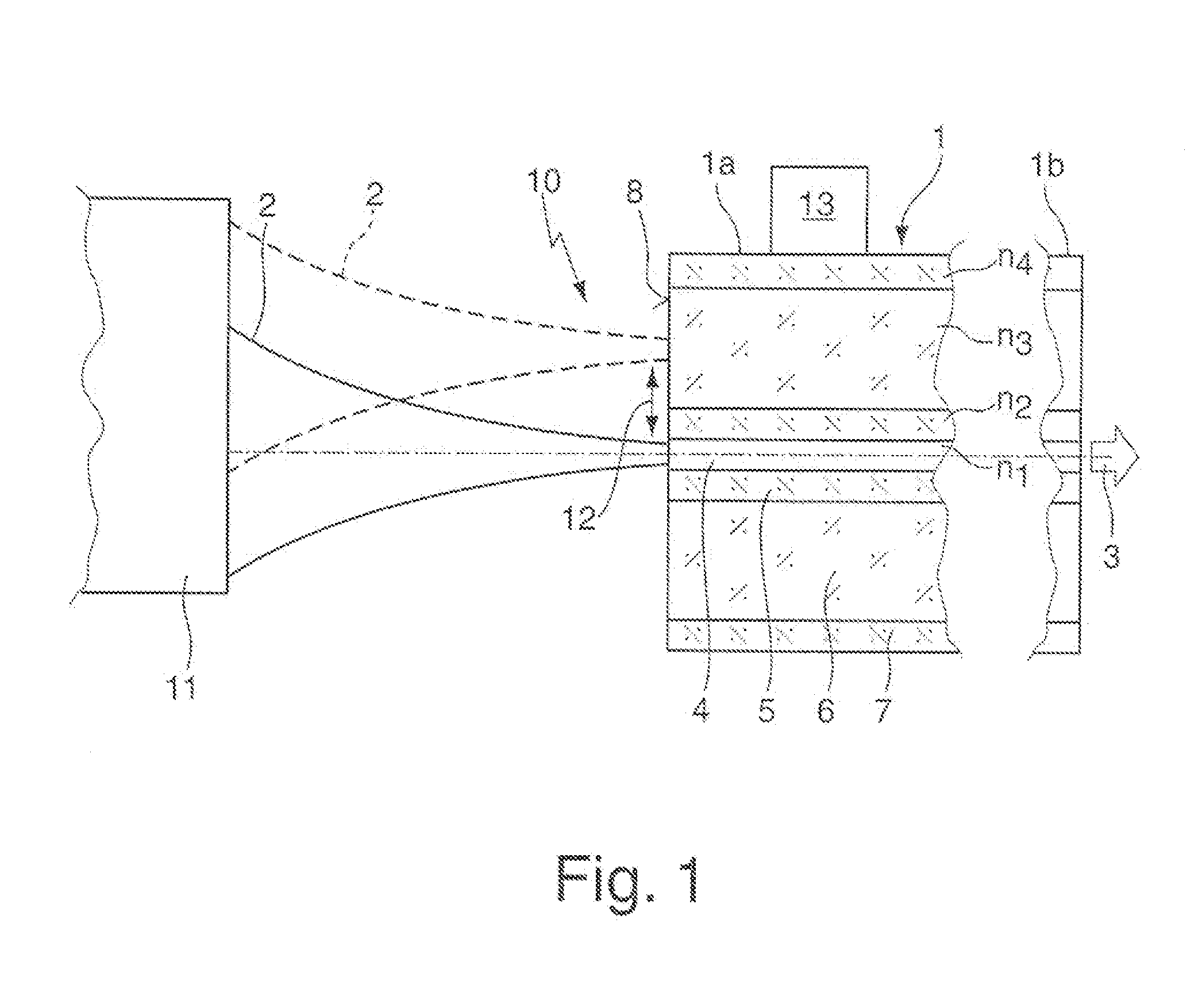

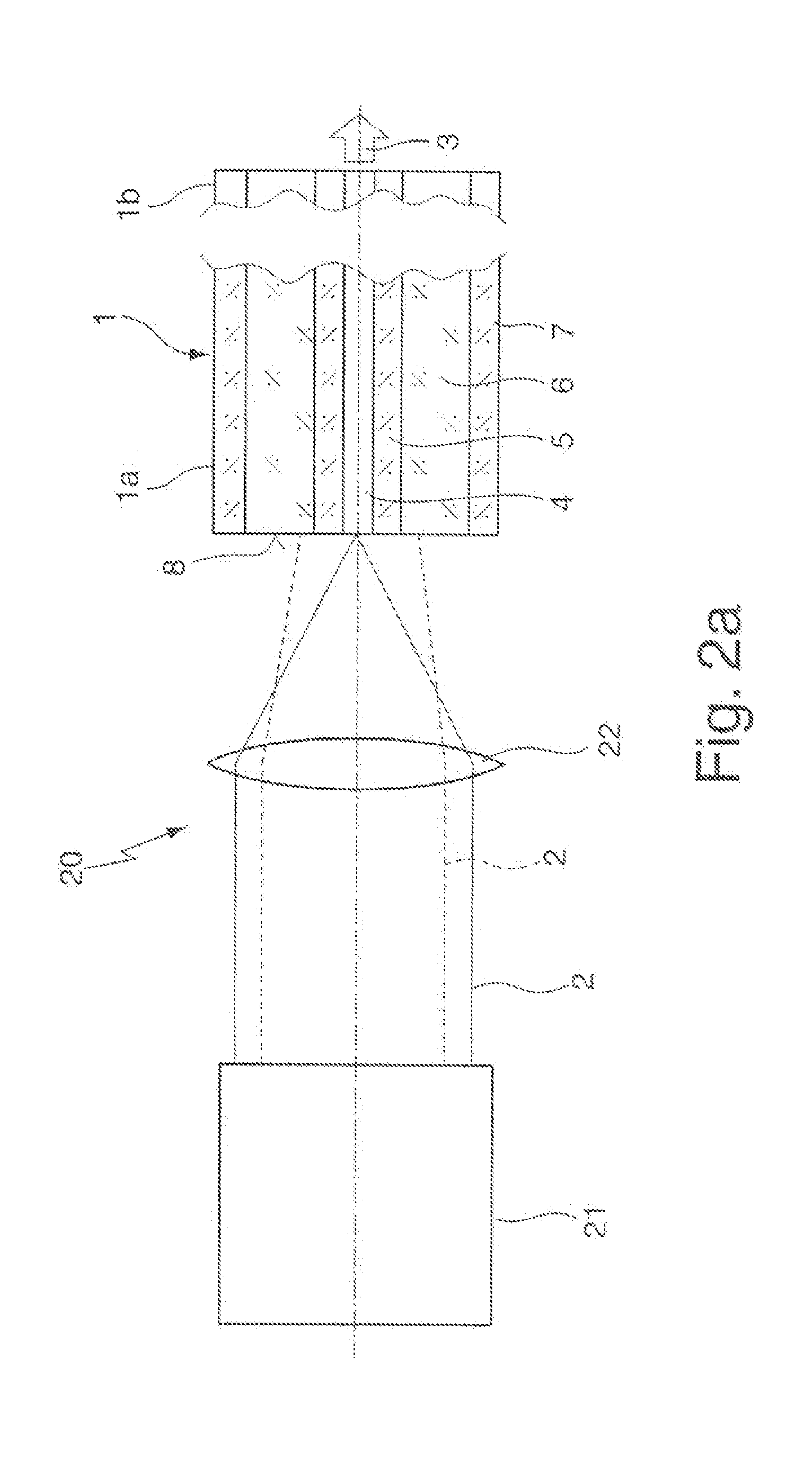

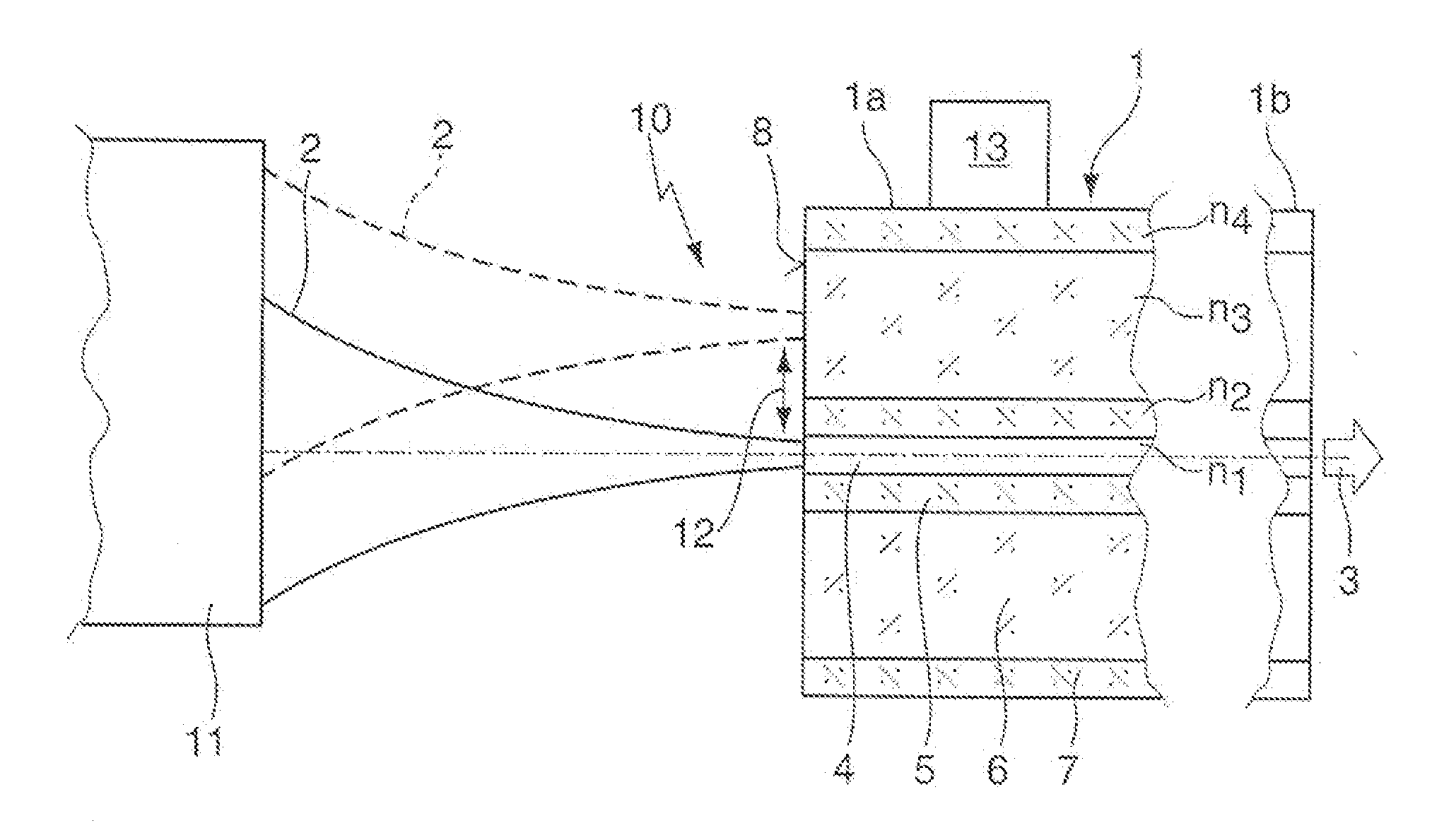

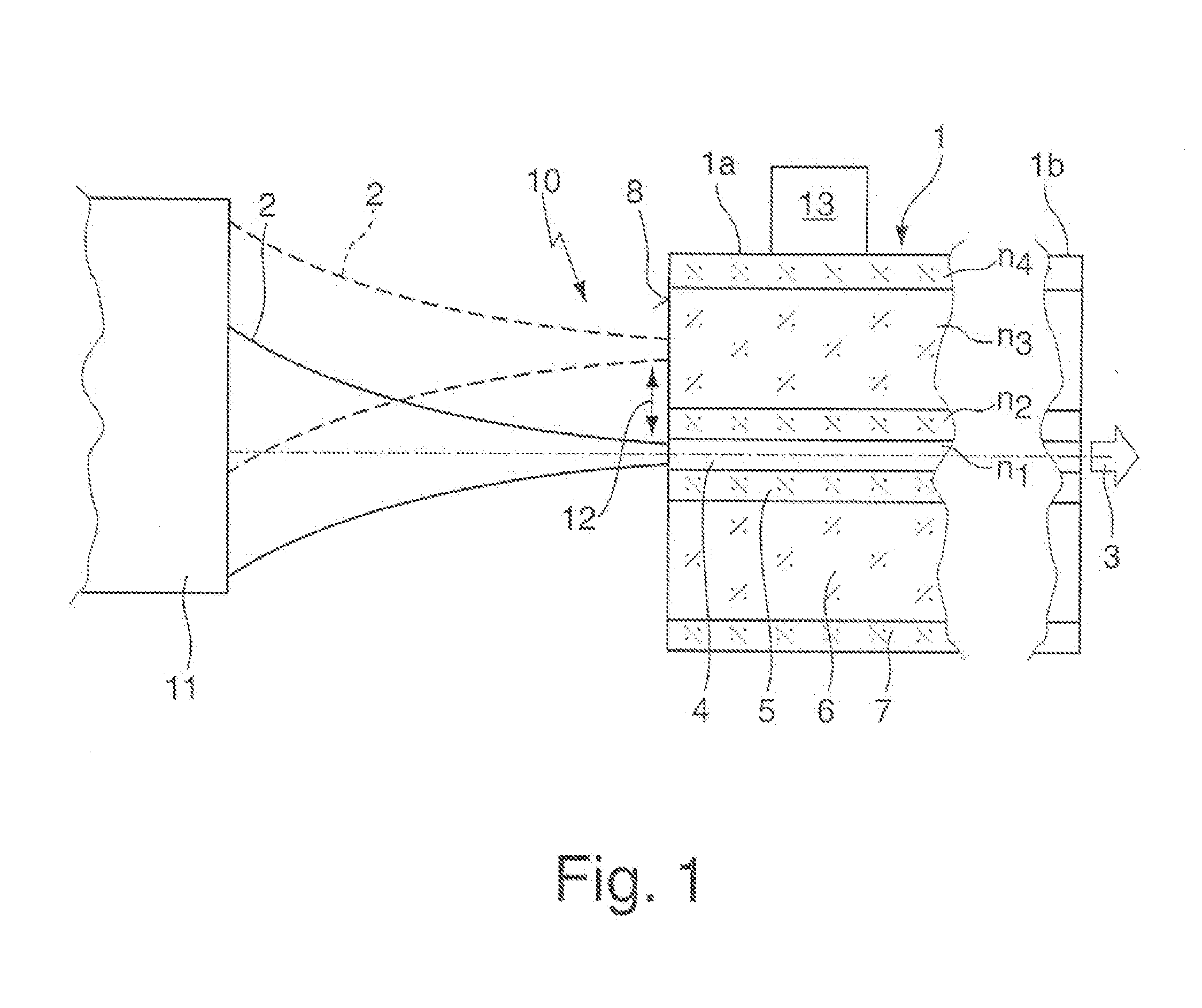

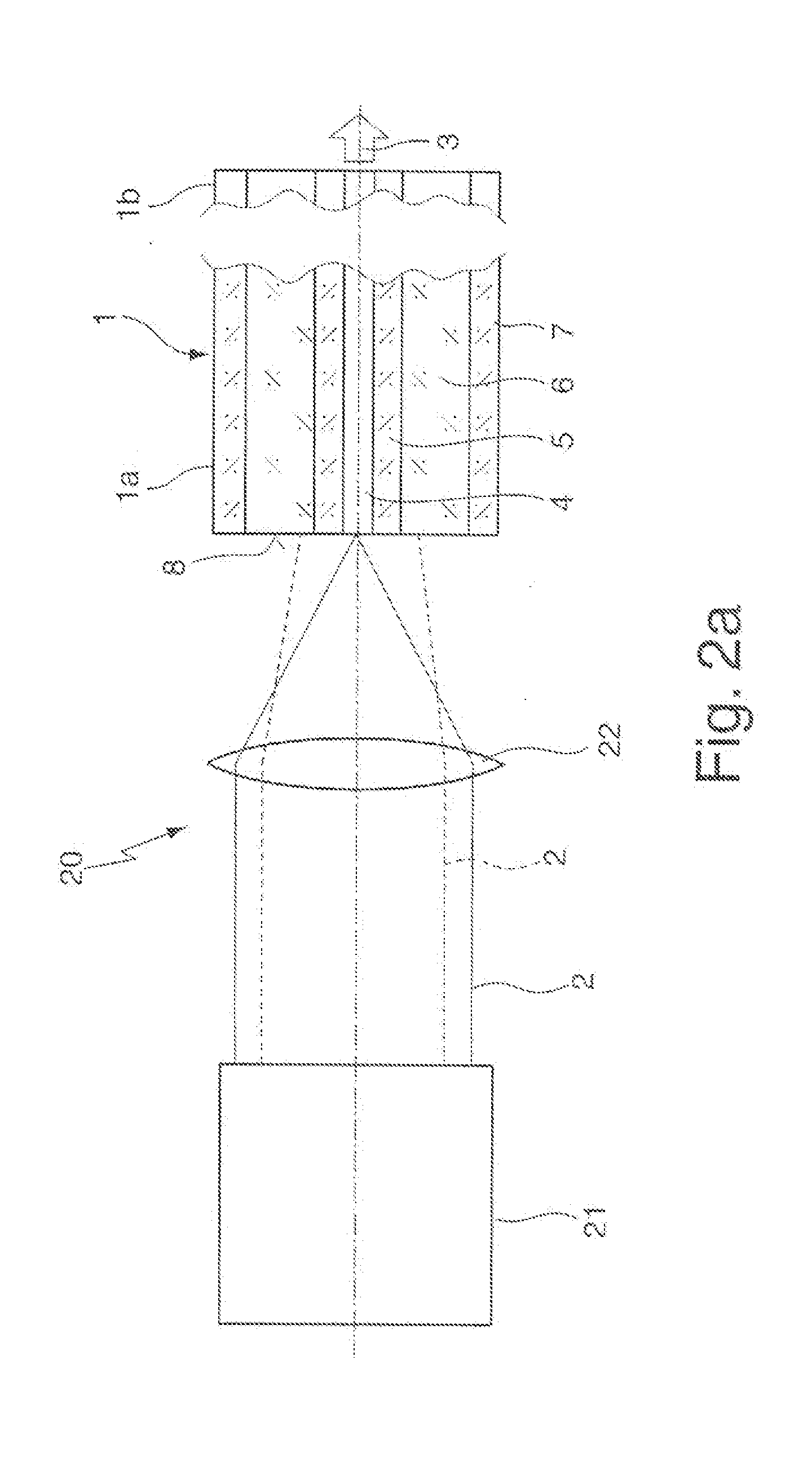

Method and arrangement for generating a laser beam having a differing beam profile characteristic by means of a multi-clad fiber

ActiveUS8781269B2Expand the range of adaptation potential of beam profile characteristicsReduce complexityLaser detailsOptical fibre with multilayer core/claddingFiberDouble-clad fiber

The invention concerns a method for generating a laser beam (3) with different beam profile characteristics, whereby a laser beam (2) is coupled into one fiber end (1a) of a multi-clad fiber (1), in particular a double-clad fiber, and emitted from the other fiber end (1b) of the multi-clad fiber (1) and whereby, to generate different beam profile characteristics of the output laser beam (3), the input laser beam (2) is electively coupled either at least into the inner fiber core (4) of the multi-clad fiber (1) or at least into at least one outer ring core (6) of the multi-clad fiber (1), as well as a corresponding arrangement (10).

Owner:TRUMPF LASERSYST FOR SEMICON MFG

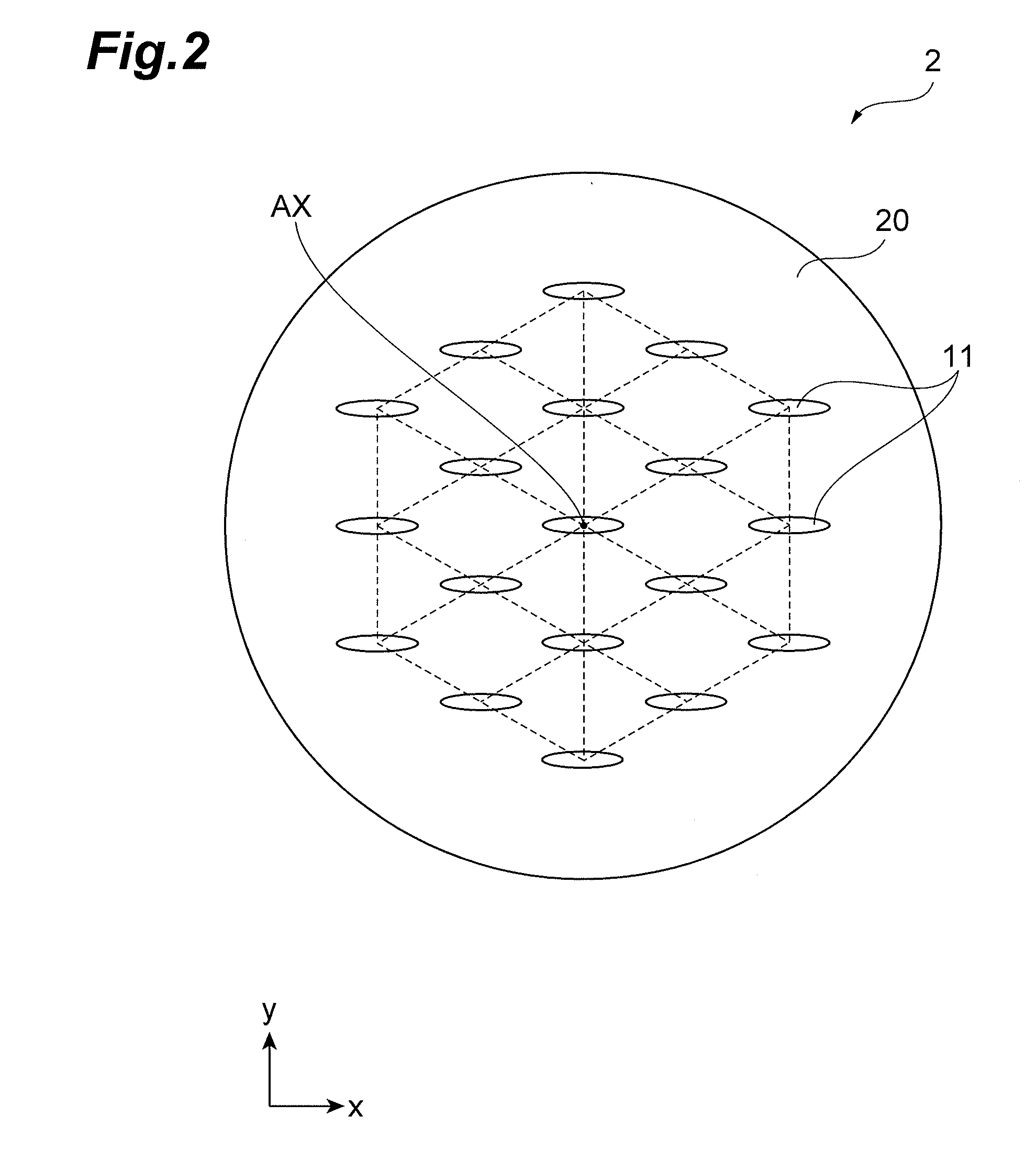

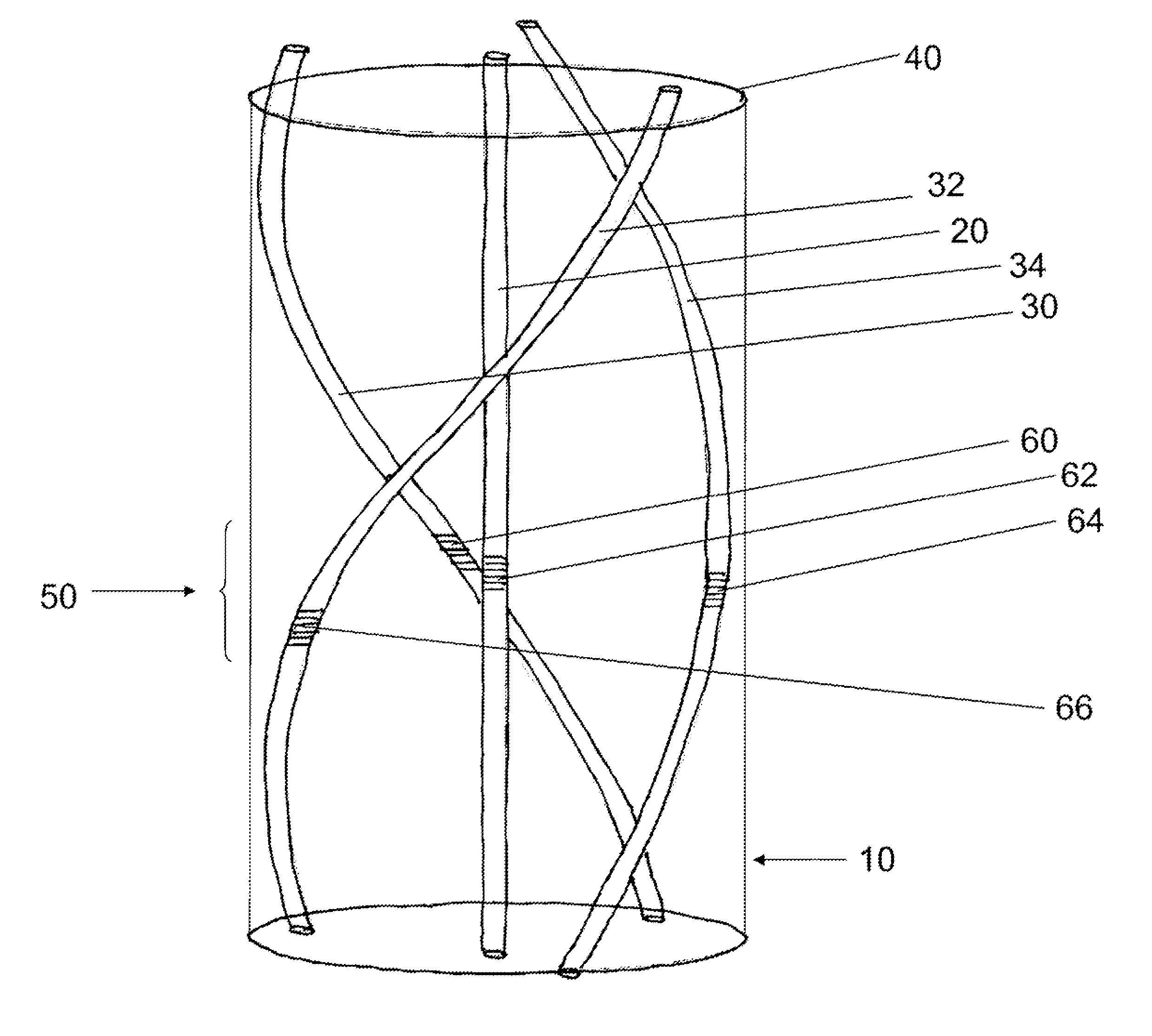

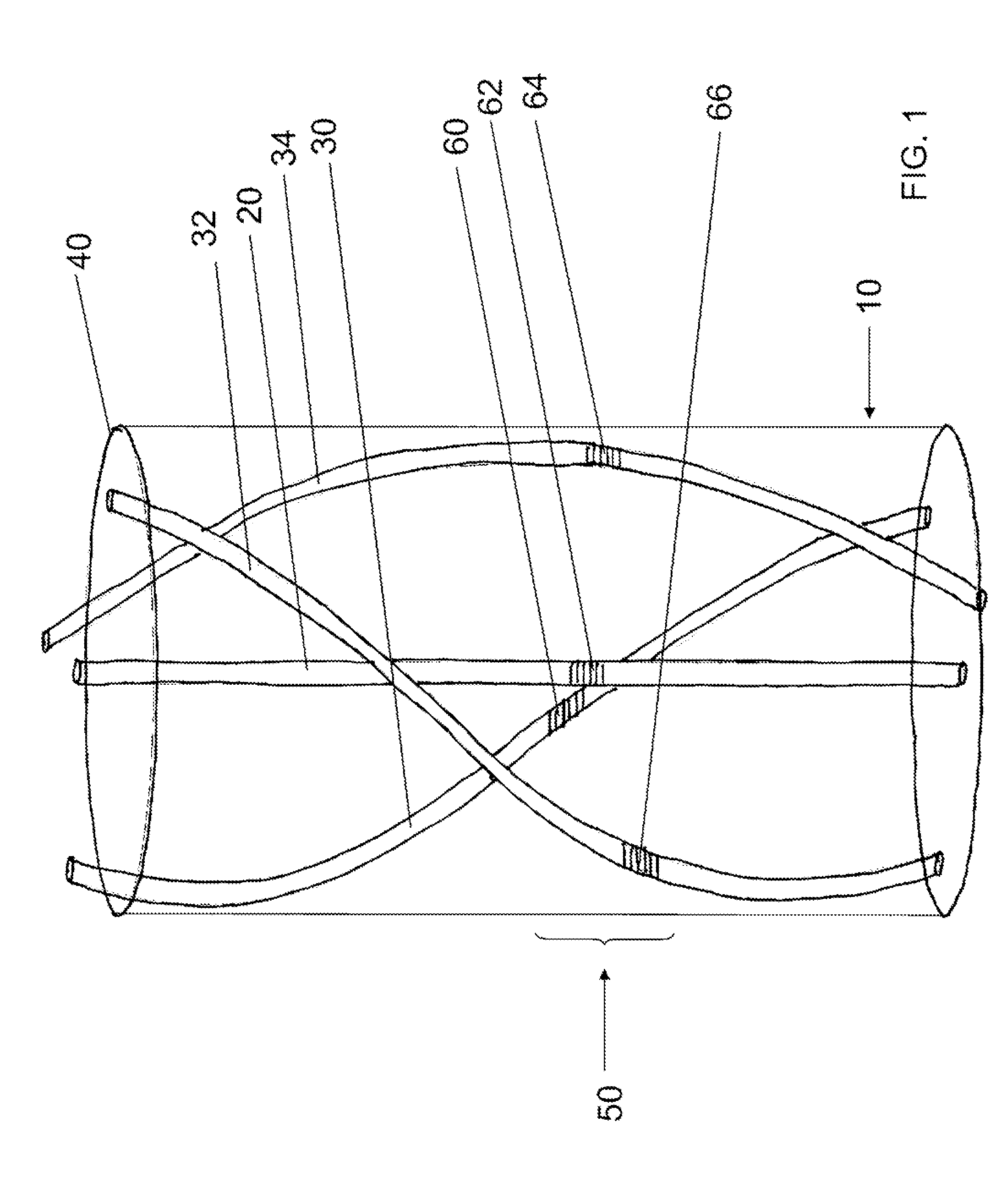

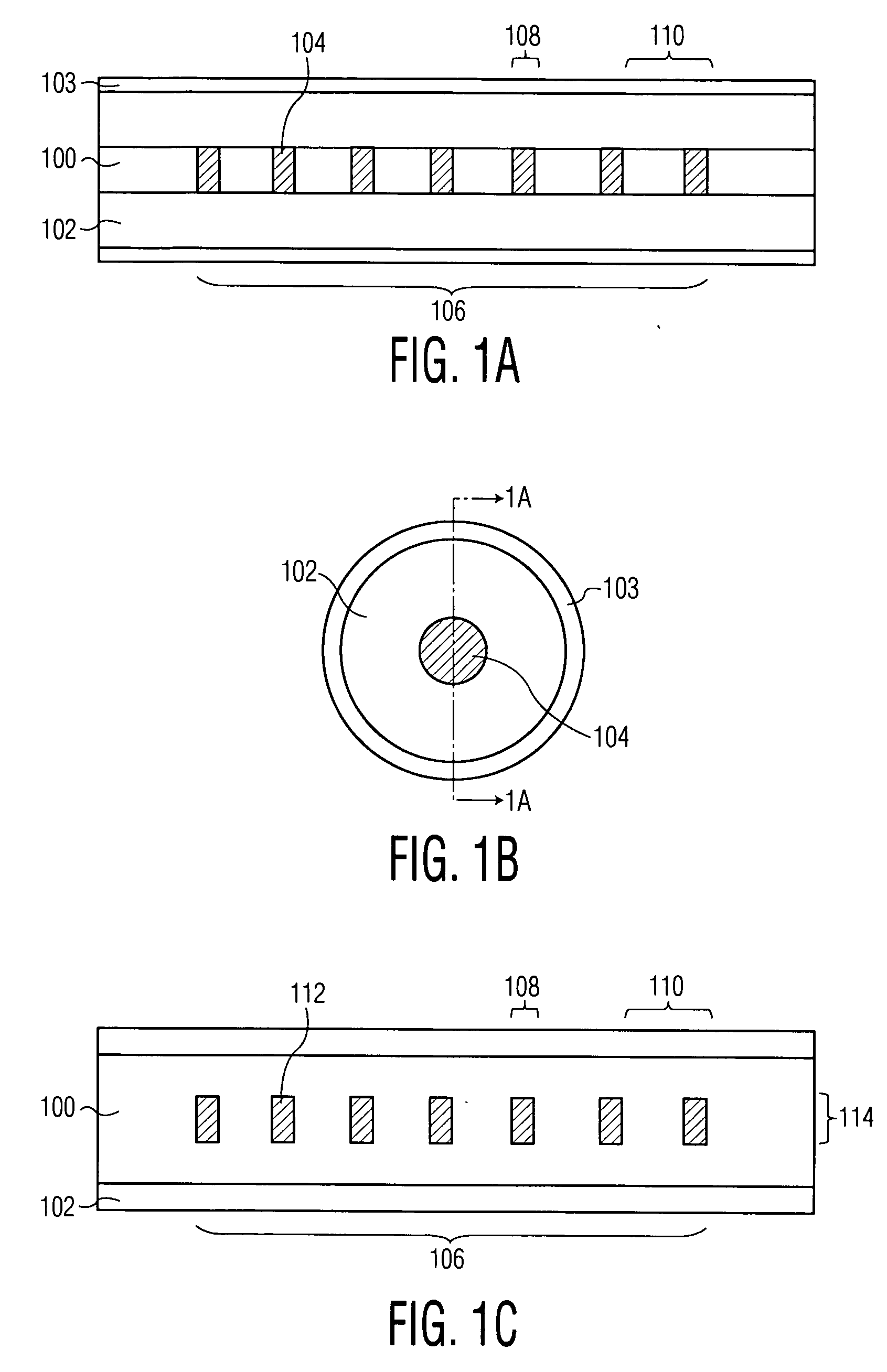

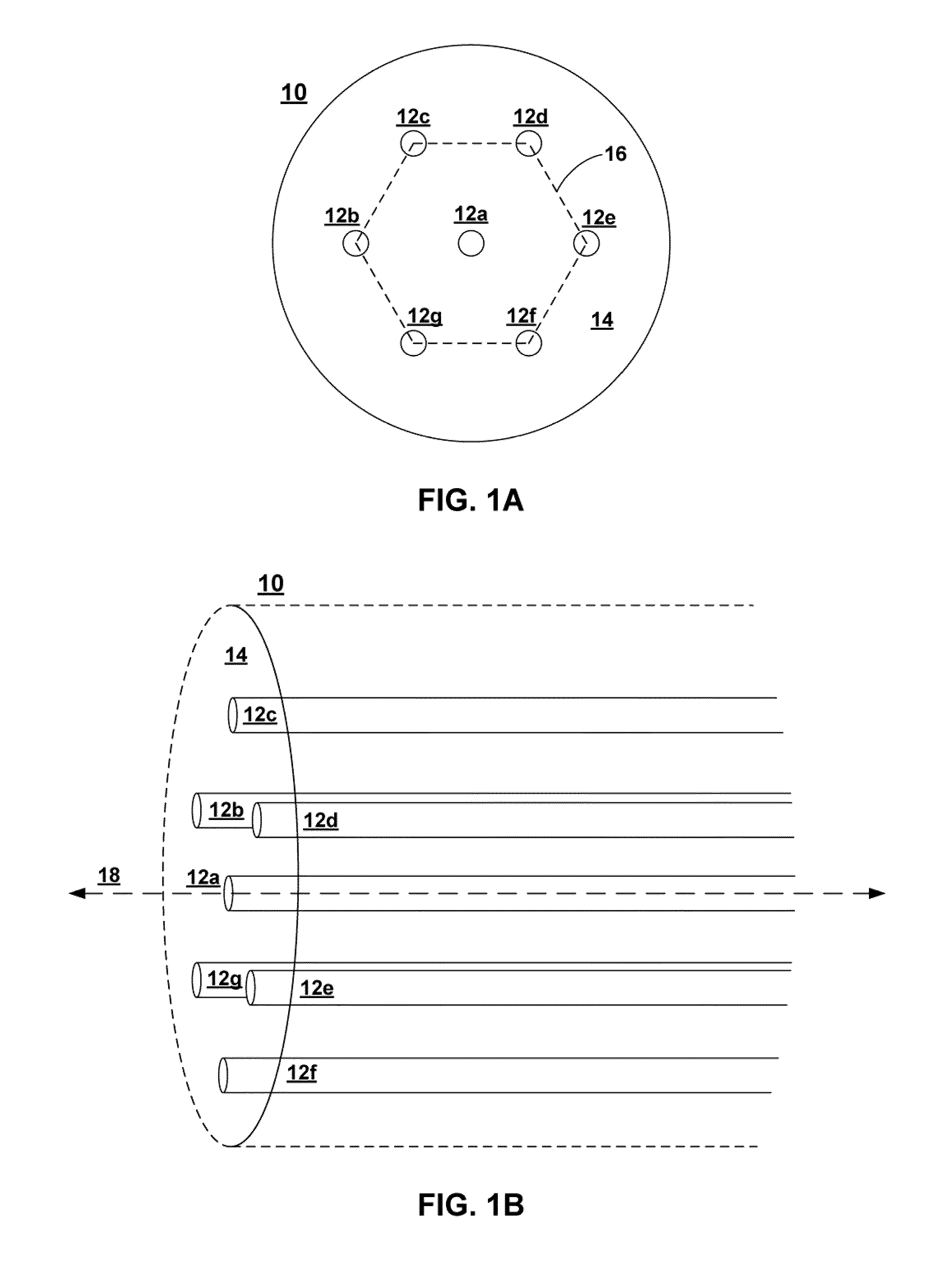

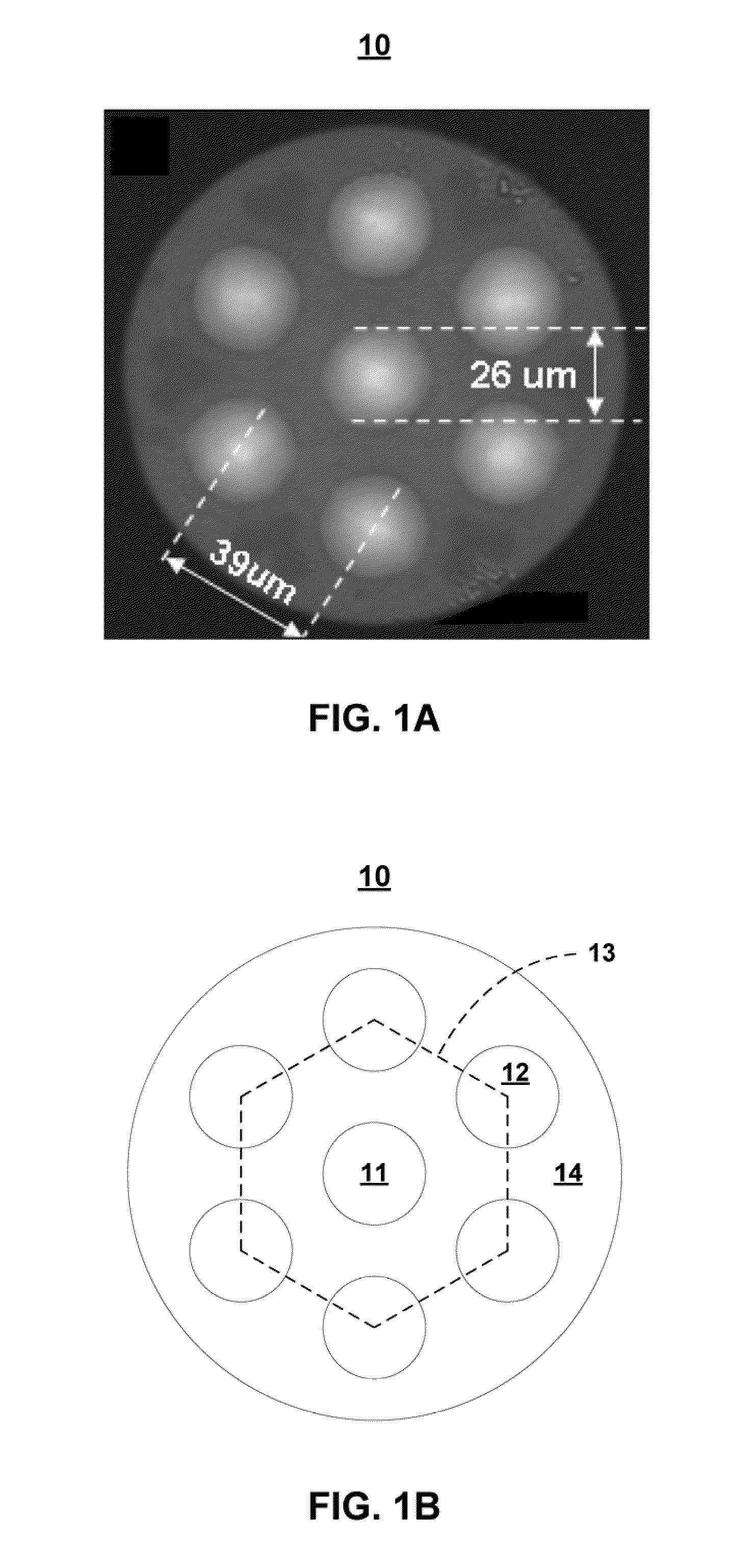

Multi-core optical fiber and method of making and using same

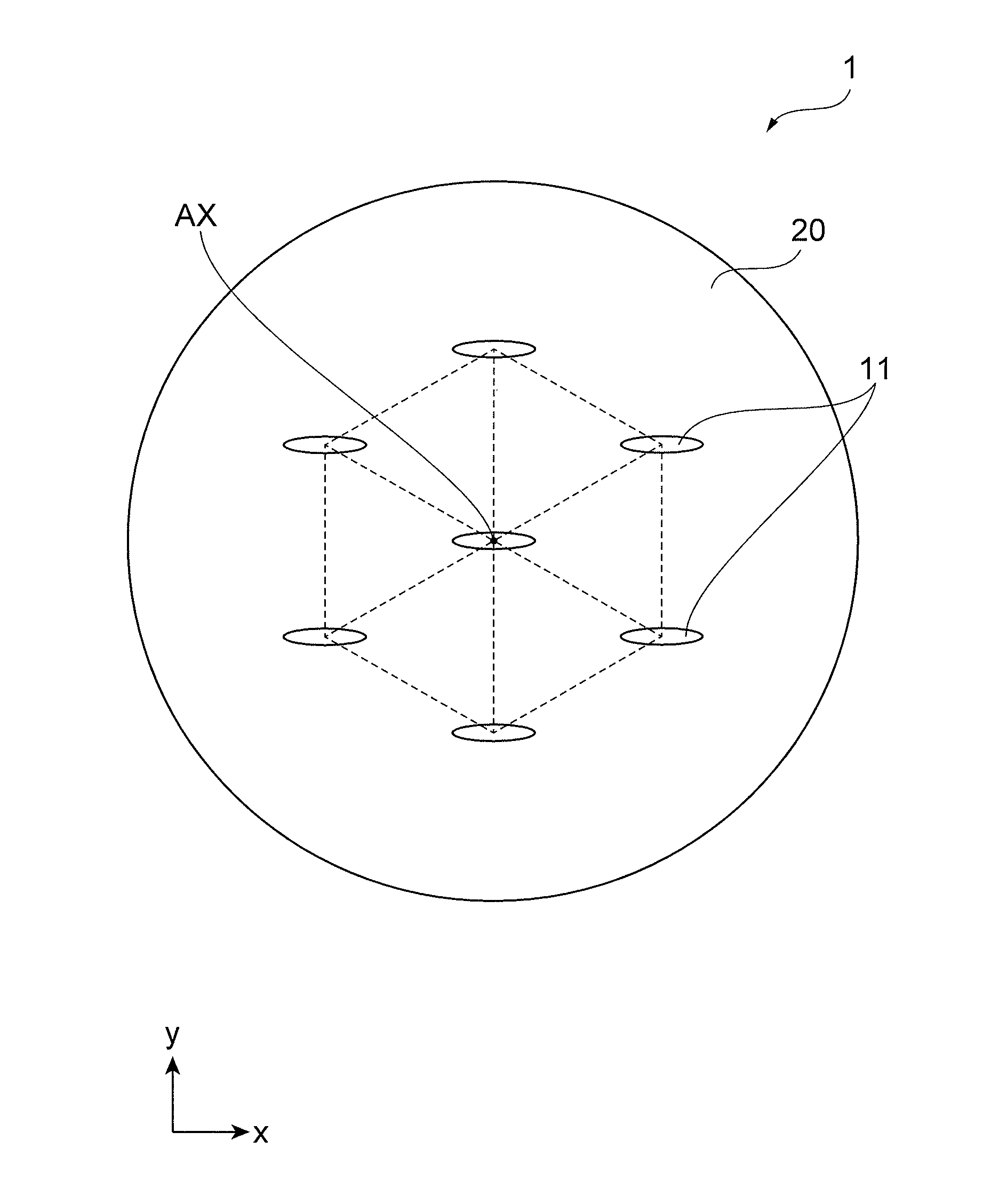

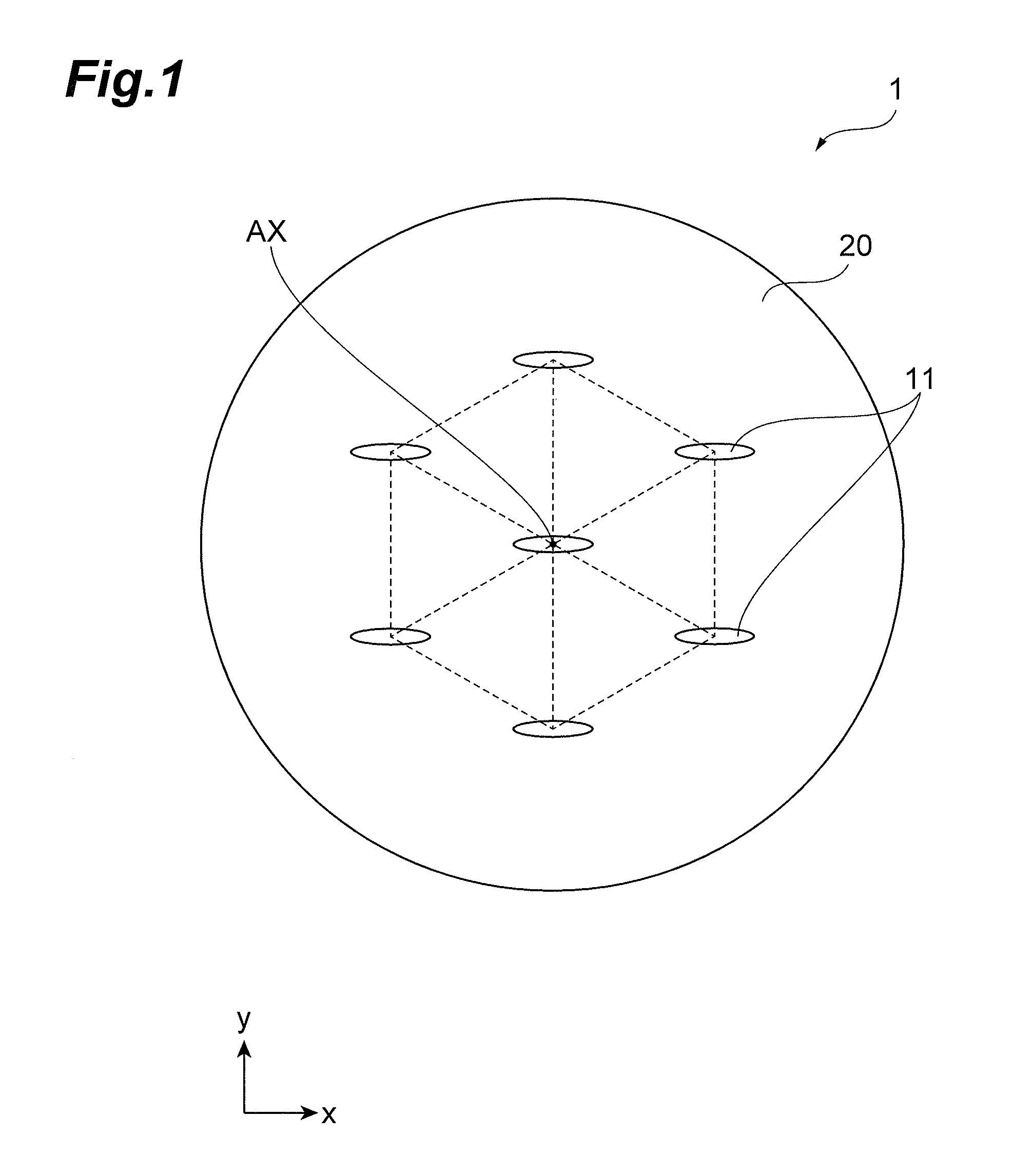

The apparatus includes a fiber comprising an axial center, a central single-mode waveguiding core and a plurality of peripheral single-mode waveguiding cores. The central core is located at a first distance from the axial center. The plurality of peripheral cores is located at respective second distances from the axial center. Each of the respective second distances is greater than the first distance, and each peripheral core of the plurality of peripheral cores follows a respective first helix about the axial center. The central core and the plurality of peripheral cores include an optical strain sensor rosette.

Owner:NAVY USA AS REPRESENTED BY THE SEC THE

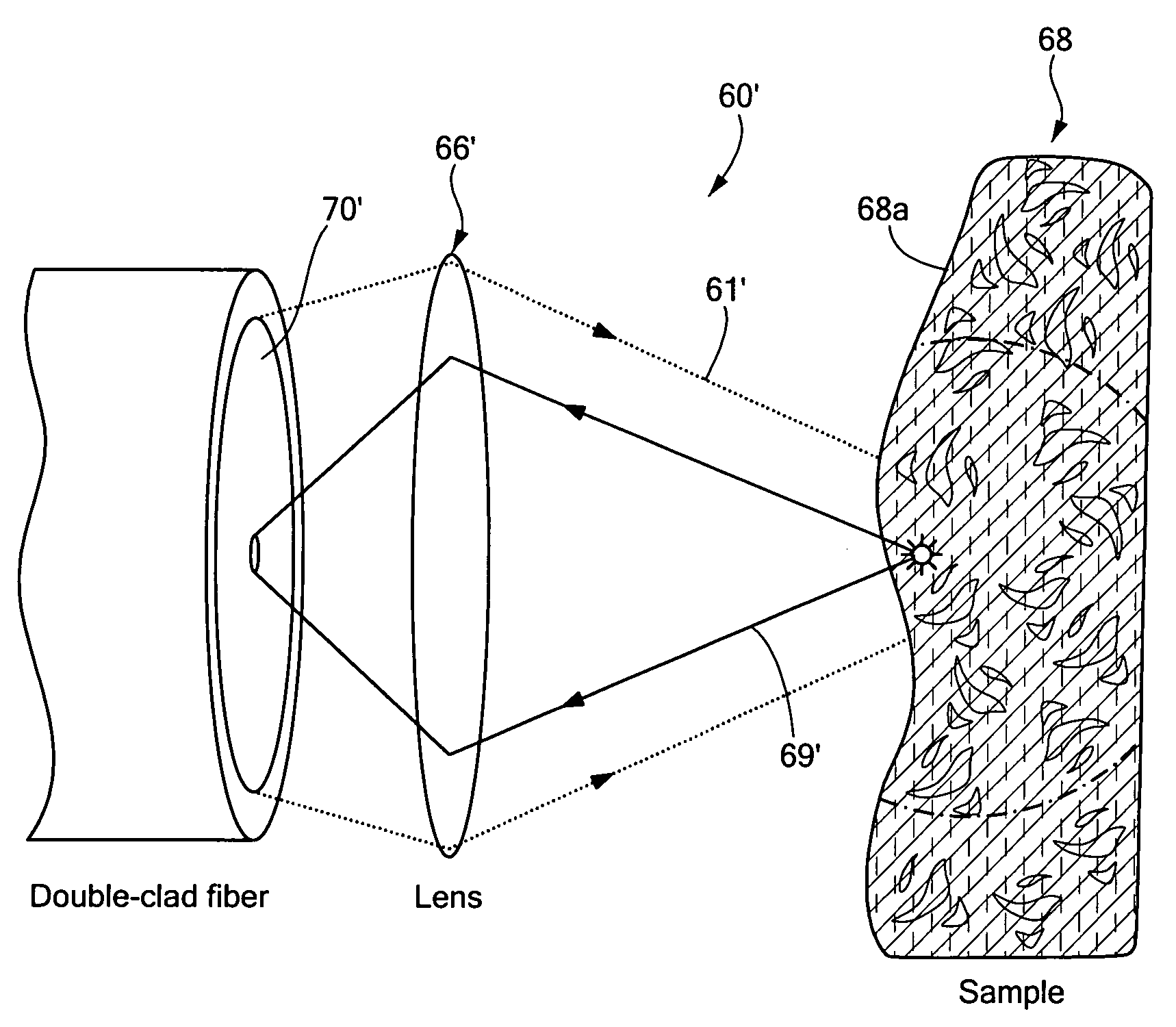

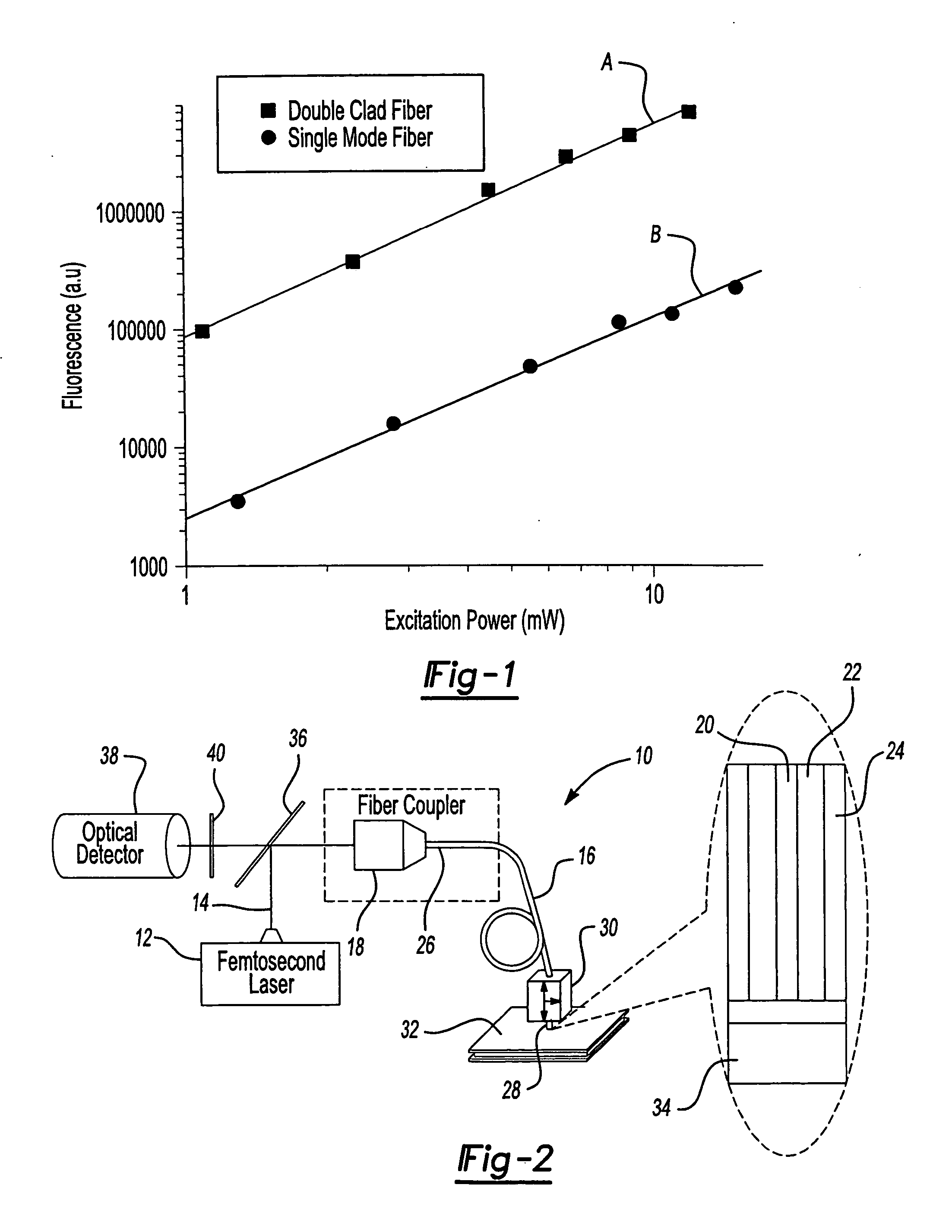

Double-clad fiber scanning microscope

ActiveUS20070002435A1High resolutionImprove detection efficiencyRaman scatteringMicroscopesFiberDouble-clad fiber

A scanning microscope having a laser outputting an excitation laser beam and a fiber member having a first core and a second core. The second core is generally disposed within the first core and is operable to receive the excitation laser beam from the laser and transmit the excitation laser beam to a sample to be tested. A moveable stage supports an end of the fiber member and / or a sample to be tested and is operable to move the end of the fiber member and the sample to be tested relative to each other.

Owner:RGT UNIV OF MICHIGAN

Fiber optic instrument sensing system

A medical instrument system comprises an elongate instrument body; an optical fiber coupled in a constrained manner to the elongate instrument body, the optical fiber including one or more Bragg gratings; a detector operably coupled to a proximal end of the optical fiber and configured to detect respective light signals reflected by the one or more Bragg gratings; and a controller operatively coupled to the detector, wherein the controller is configured to determine a geometric configuration of at least a portion of the elongate instrument body based on a spectral analysis of the detected reflected portions of the light signals.

Owner:KONINK PHILIPS ELECTRONICS NV

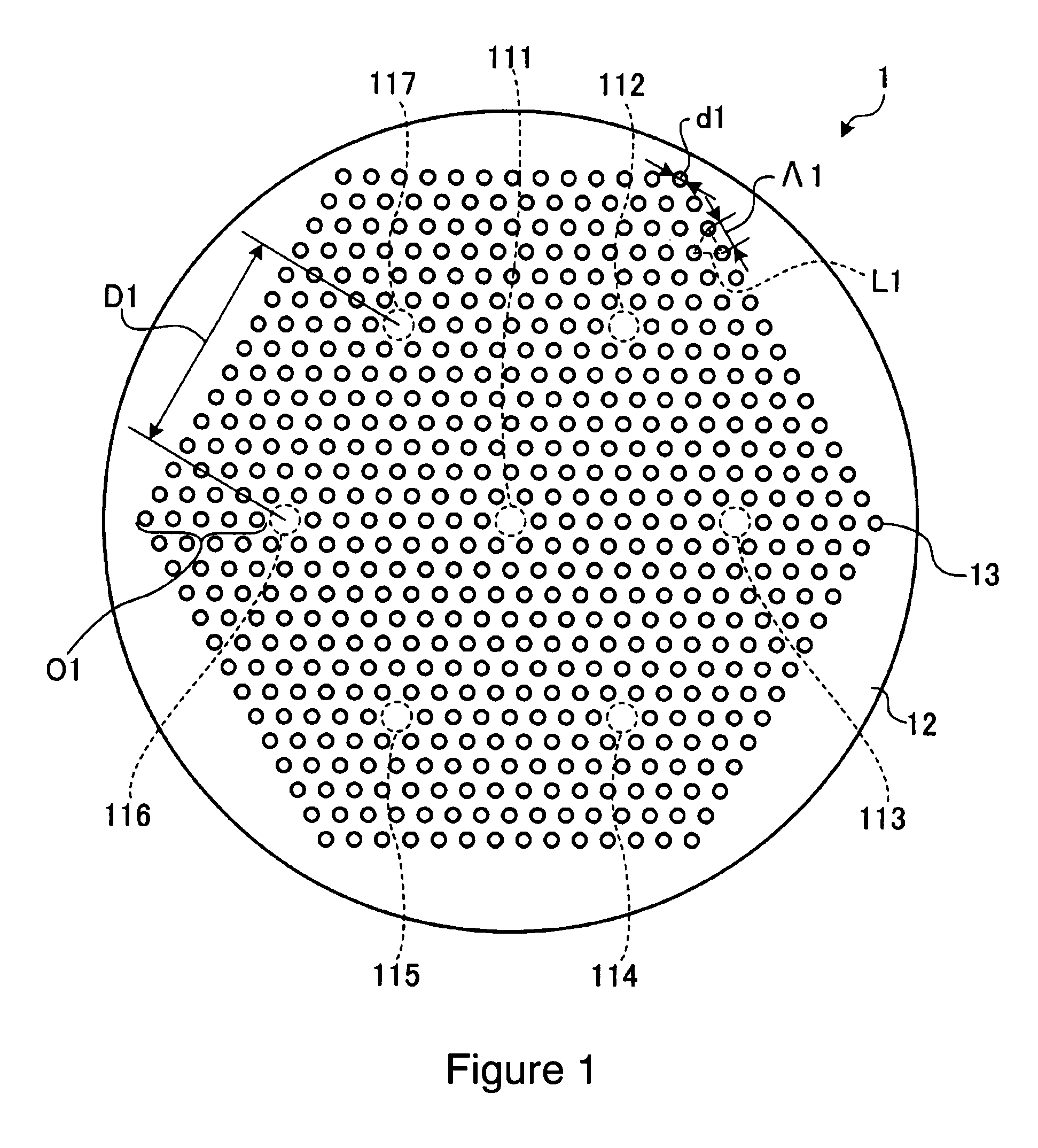

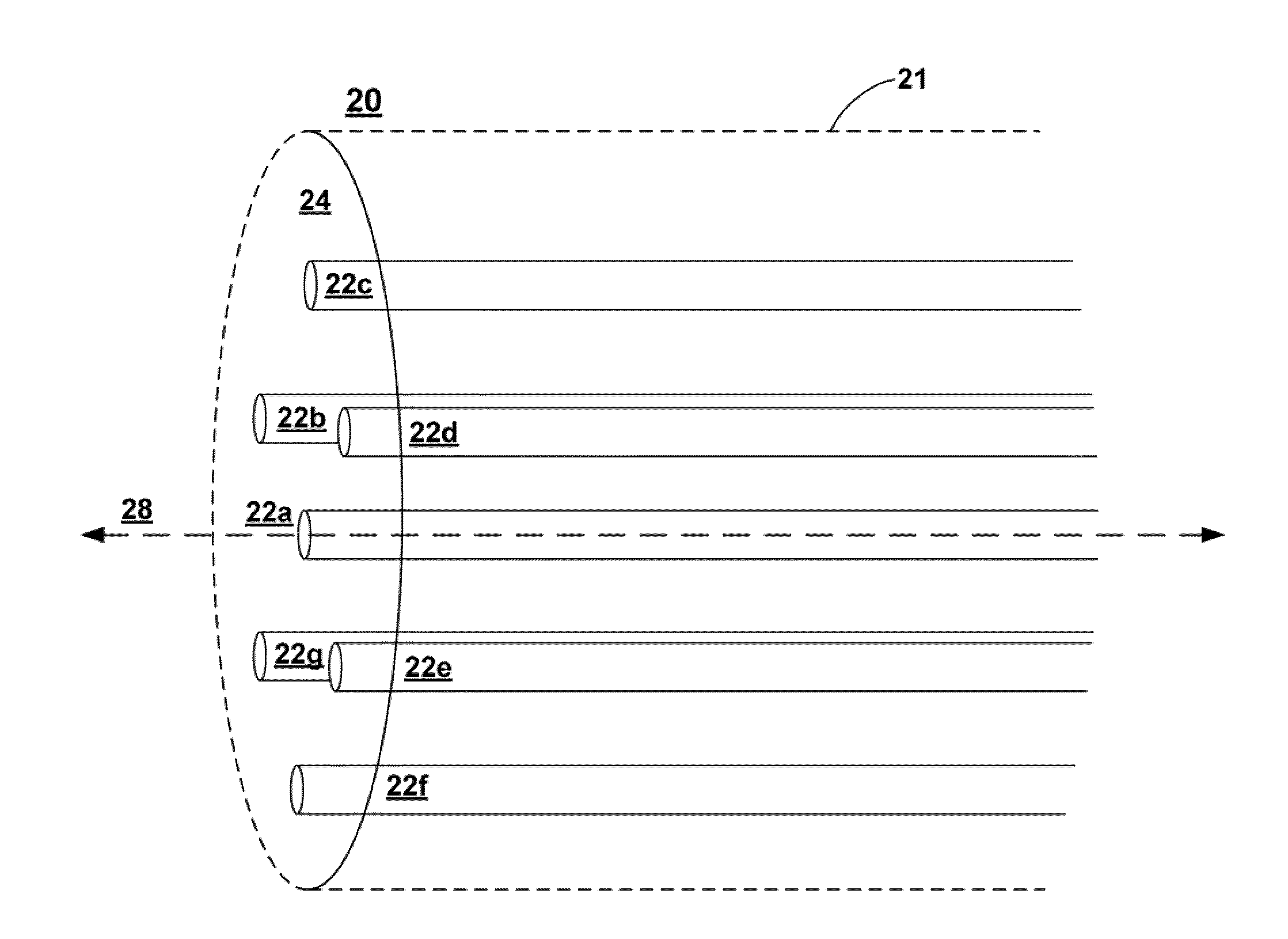

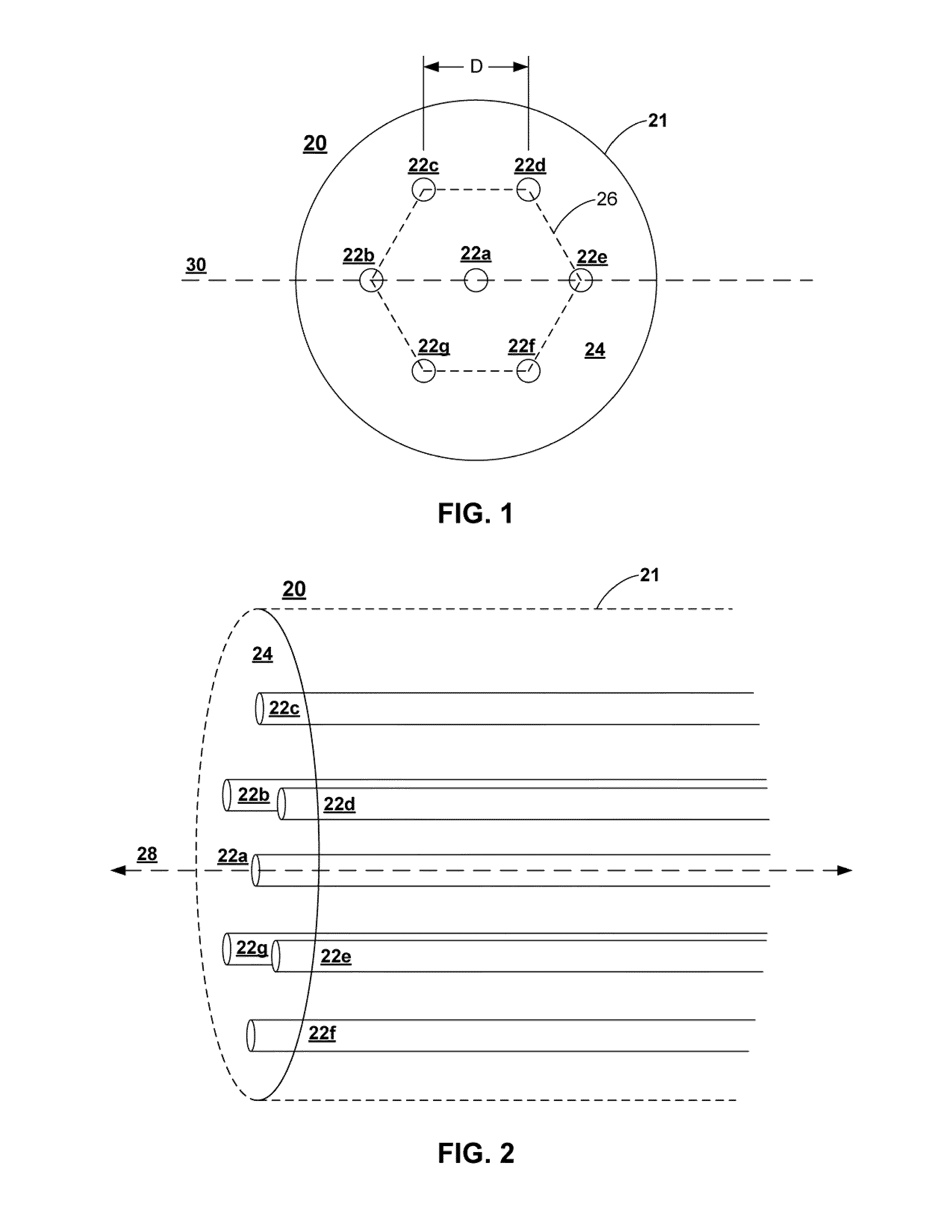

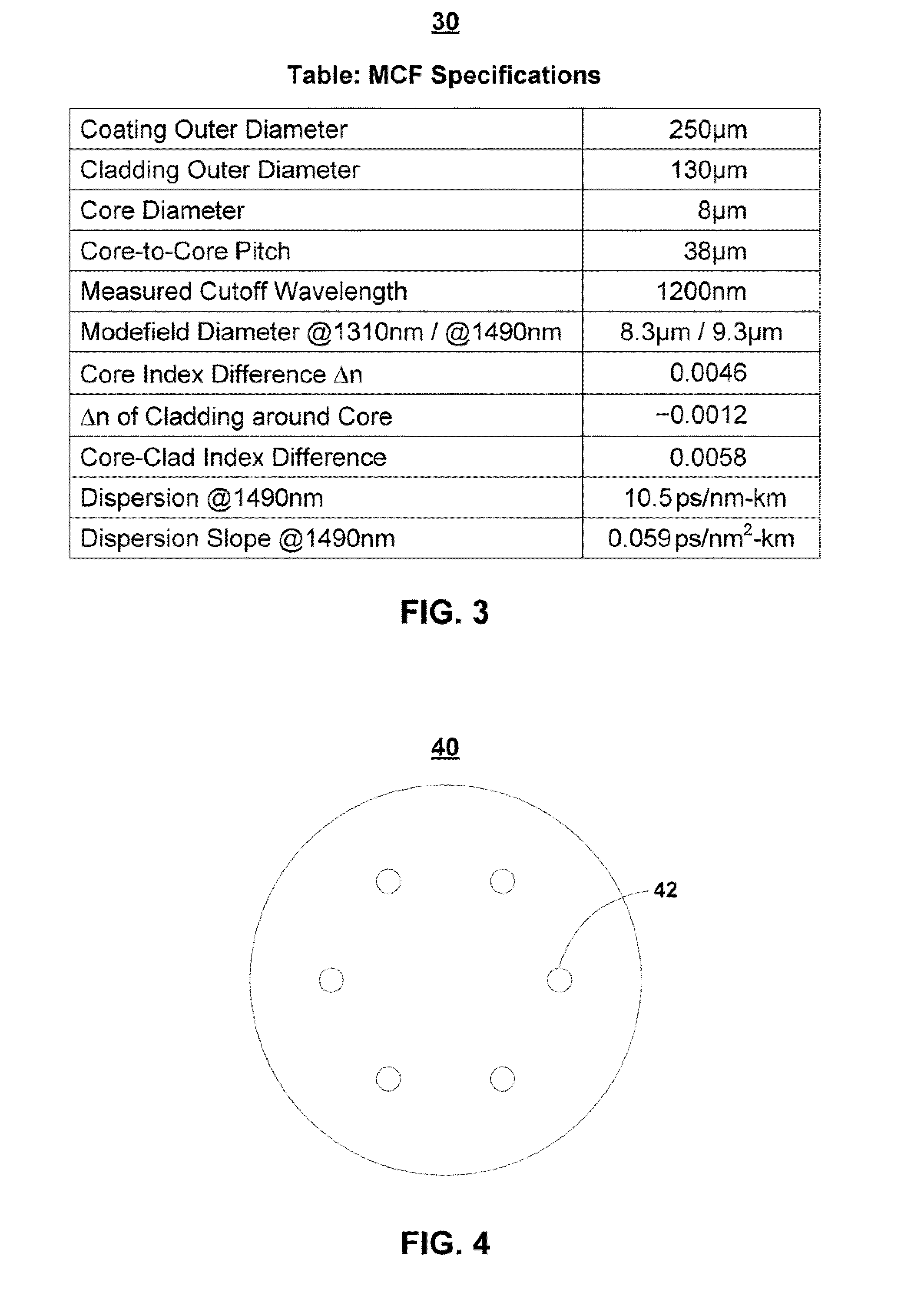

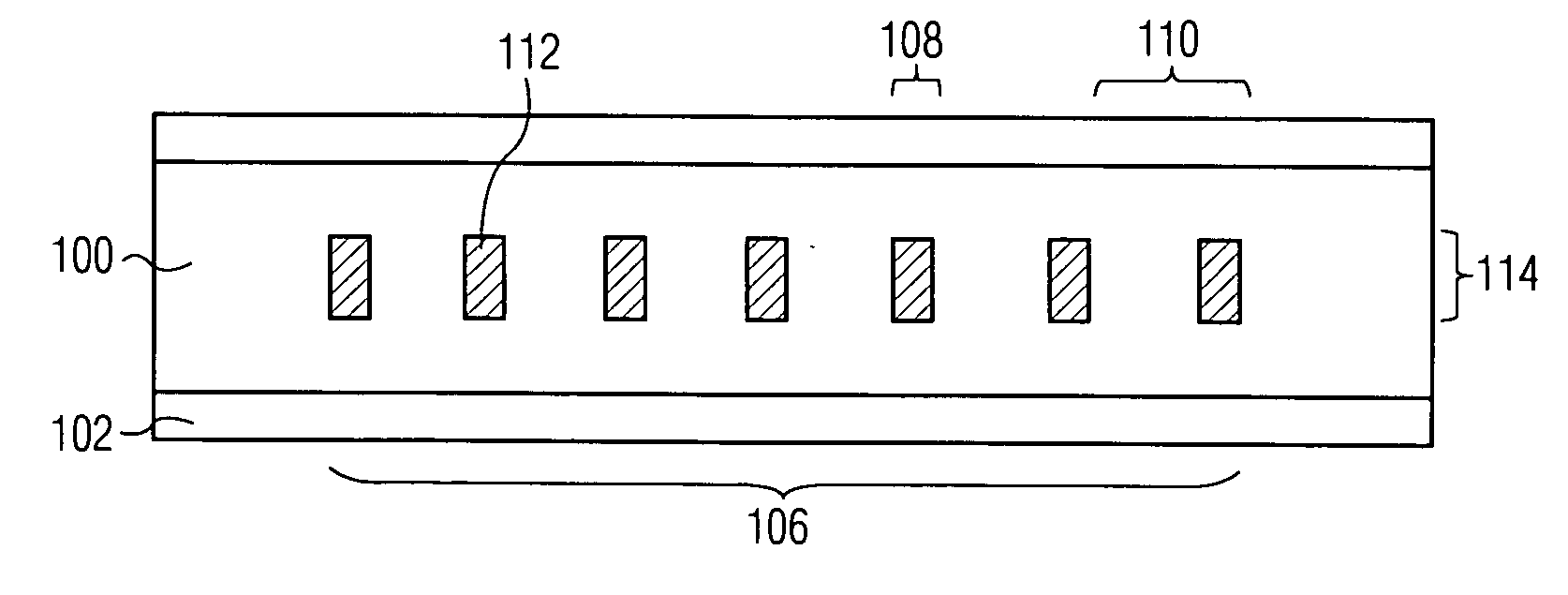

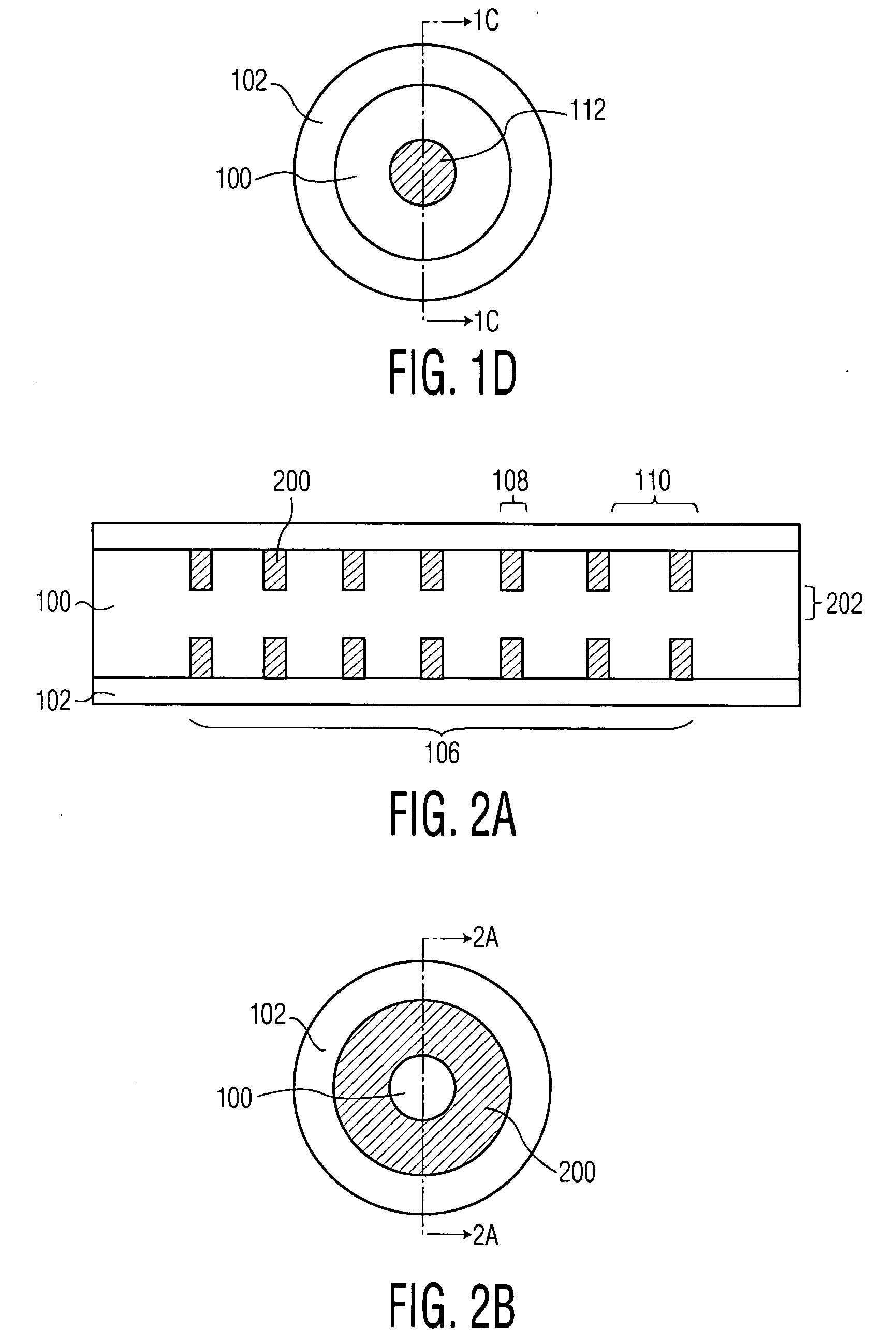

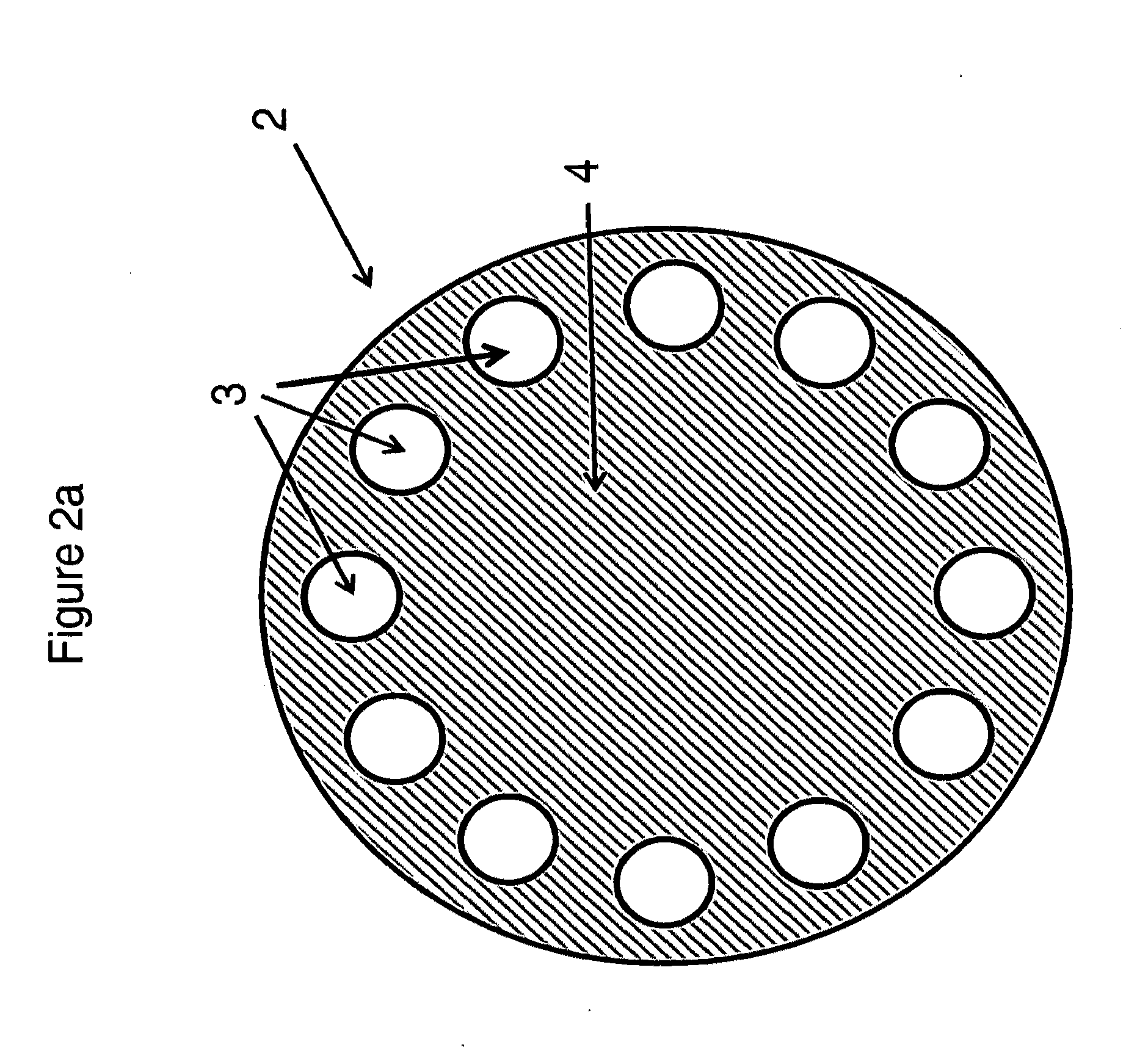

Multicore fibers and associated structures and techniques

ActiveUS20110274398A1Optical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingRefractive indexEngineering

A multicore fiber comprises a plurality of cores extending along the length of a fiber body. Each of the cores is surrounded by a cladding. The plurality of cores and surrounding cladding provide respective index variations, so as to form a respective plurality of waveguides for conducting parallel data transmissions from a first end of the fiber to a second end. The plurality of cores has a cross-sectional geometry in which the plurality of cores is configured in a polygonal array, in which at least some of the cores are positioned at the vertices of the array. The polygonal array is configured such that neighboring cores in the array are separated from each other by a distance that is sufficient to prevent crosstalk therebetween.

Owner:OFS FITEL LLC

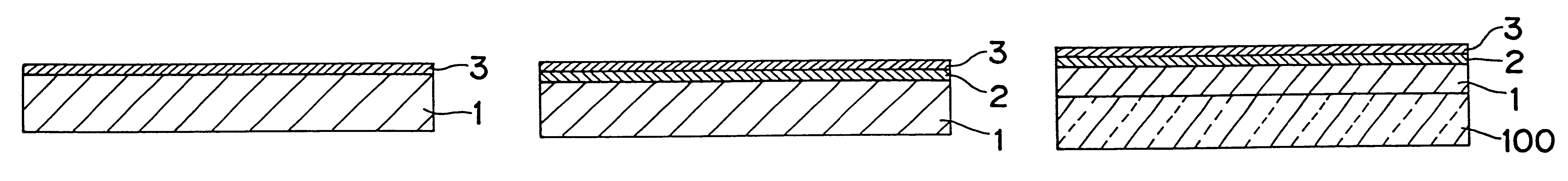

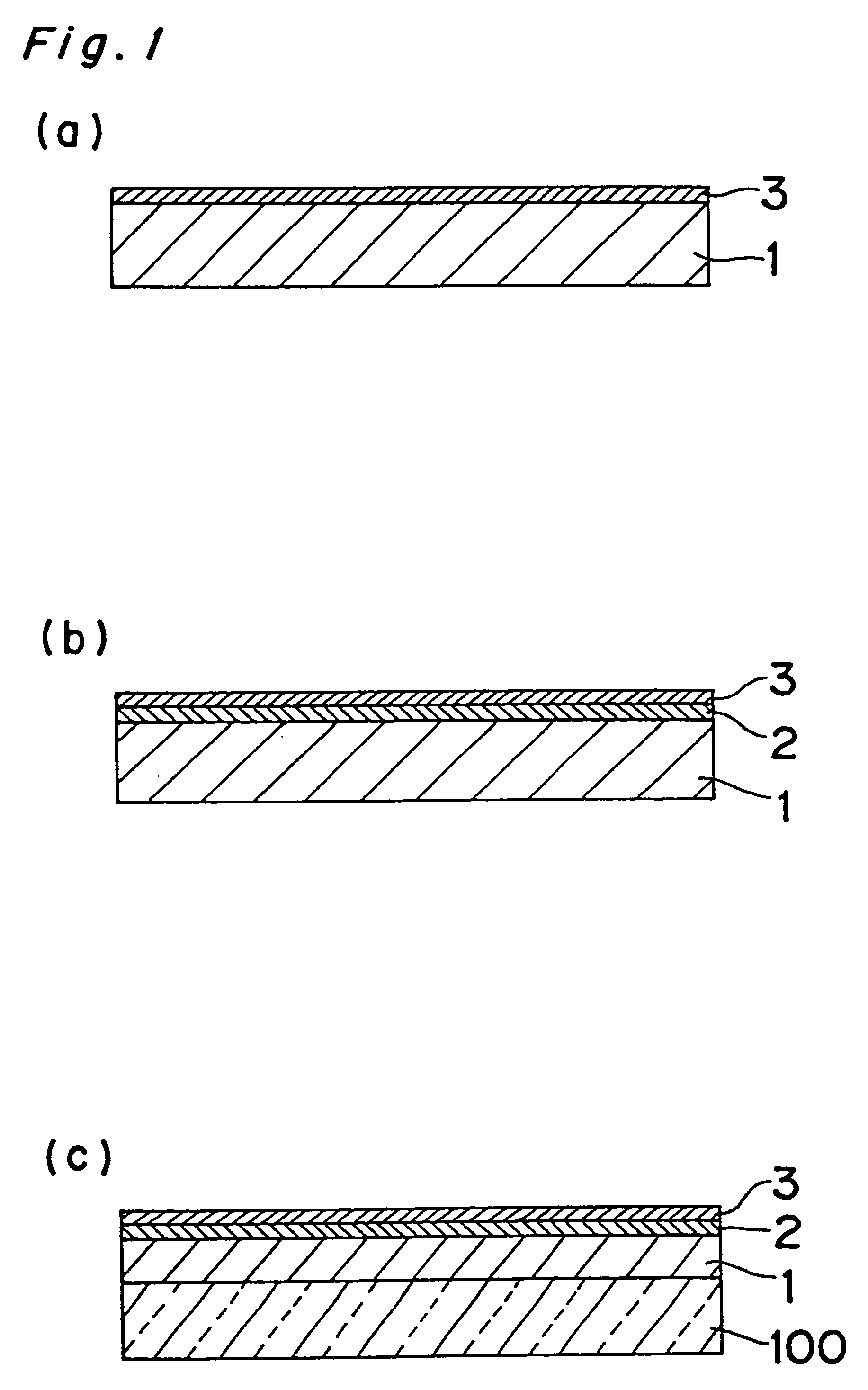

Aerogel substrate and method for preparing the same

InactiveUS6740416B1Uniformly formedLiquid surface applicatorsSolid-state devicesHydrophilizationInter layer

An aerogel substrate useful for an electrically conductive substrate, a heat insulating substrate, an optical waveguide substrate, a substrate for a light emitting device or a light emitting device is provided.The aerogel substrate is characterized by comprising a functional layer and an aerogel layer, and an intermediate layer formed between the functional layer and the aerogel layer to allow the functional layer to be formed uniformly thereon. The intermediate layer is formed on at least one surface of the aerogel layer by a gas phase method, by the Langmuir-Blodgett method or by adsorption of an inorganic layered compound; or formed by a hydrophilicizing treatment of at least one surface of the aerogel layer followed by coating and drying an aqueous coating fluid, by an annealing treatment of at least one surface of the aerogel layer, or by a hydrophilicizing treatment of at least one surface of the aerogel layer.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Method And Arrangement for Generating A Laser Beam Having A Differing Beam Profile Characteristic By Means Of A Multi-Clad Fiber

ActiveUS20130223792A1Little effortReduce complexityLaser detailsOptical fibre with multilayer core/claddingFiberLight beam

The invention concerns a method for generating a laser beam (3) with different beam profile characteristics, whereby a laser beam (2) is coupled into one fibre end (1a) of a multi-clad fibre (1), in particular a double-clad fibre, and emitted from the other fibre end (1b) of the multi-clad fibre (1) and whereby, to generate different beam profile characteristics of the output laser beam (3), the input laser beam (2) is electively coupled either at least into the inner fibre core (4) of the multi-clad fibre (1) or at least into at least one outer ring core (6) of the multi-clad fibre (1), as well as a corresponding arrangement (10).

Owner:TRUMPF LASERSYST FOR SEMICON MFG

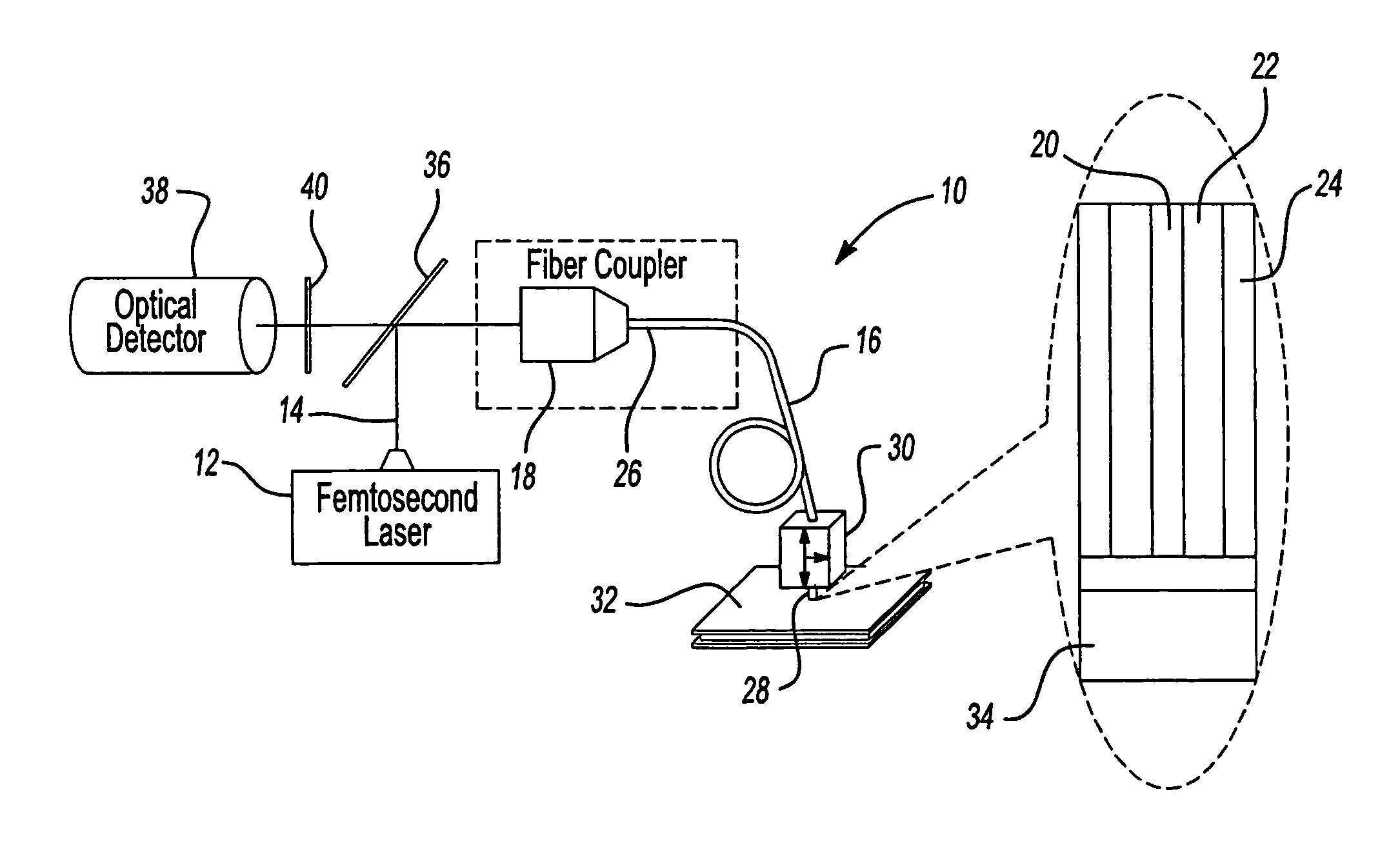

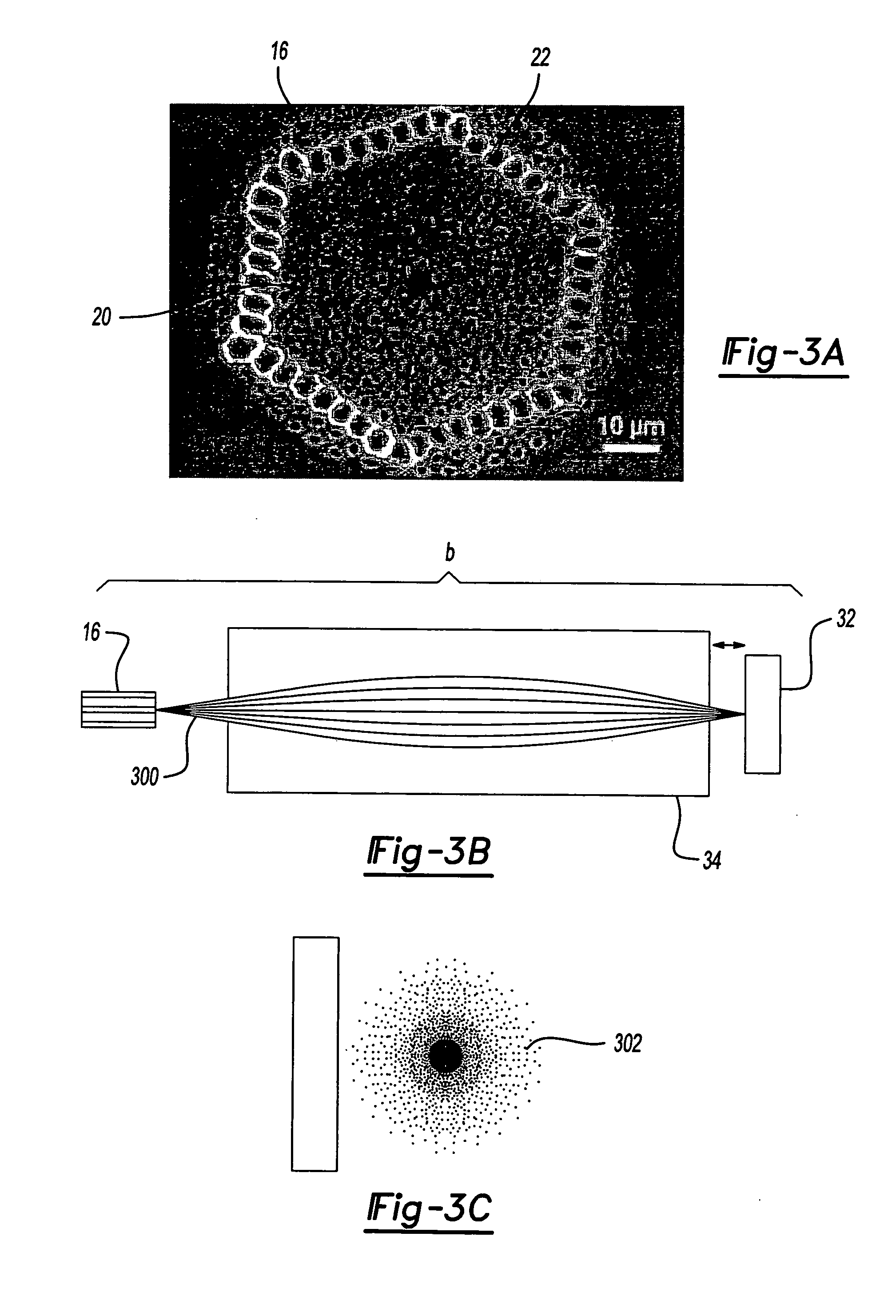

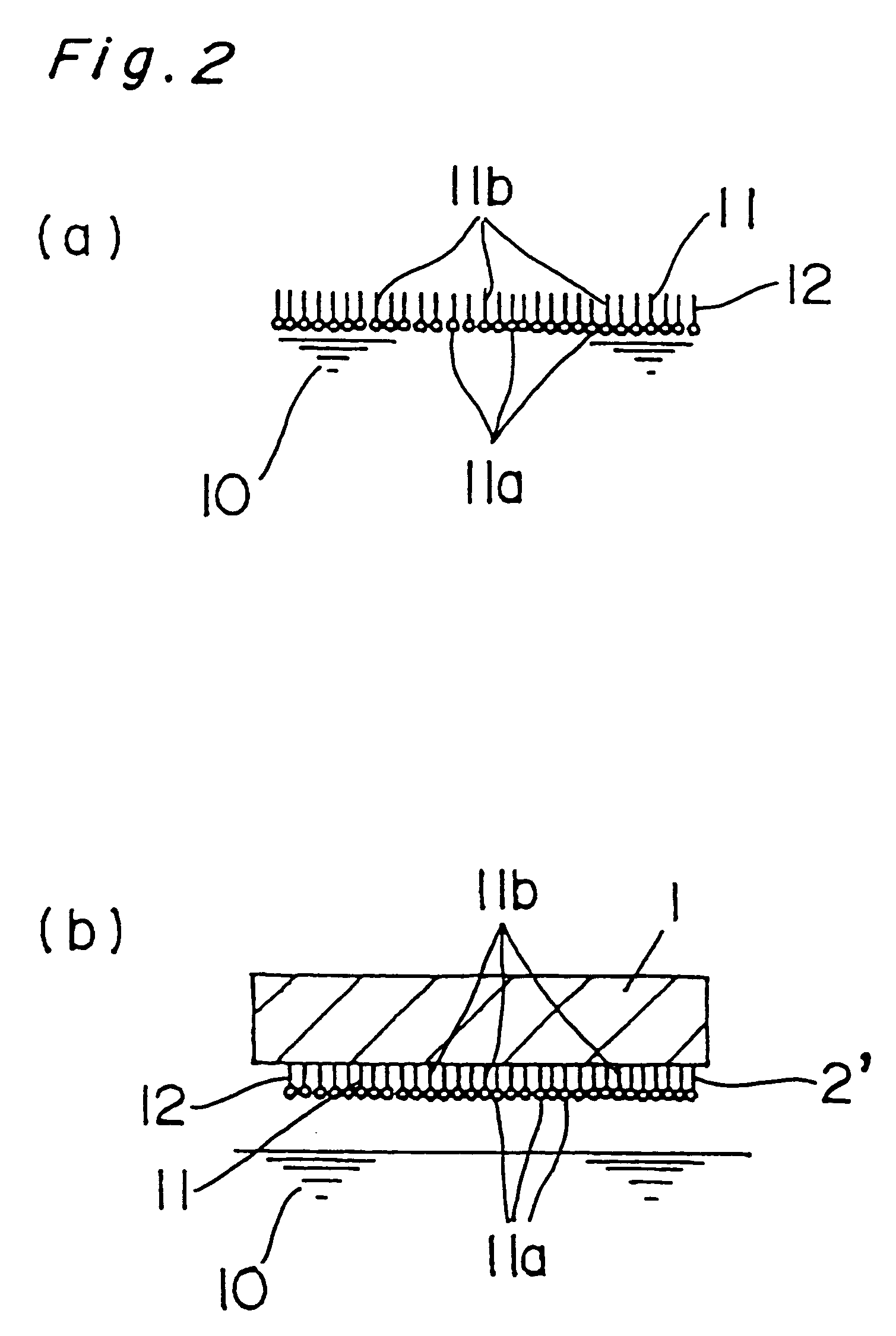

Multicore optical fiber with integral diffractive elements machined by ultrafast laser direct writing

InactiveUS20060215976A1Optical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingRefractive indexMulticore fiber

A multicore optical fiber with an integral diffractive element. The multicore optical fiber includes: a first optical fiber core formed of a non-photosensitive material having an initial index of refraction; and a second optical fiber core including a second longitudinal core axis substantially parallel to the first longitudinal axis. The first optical fiber core includes: a first longitudinal core axis; and a number of index-altered portions having an altered index of refraction which is different from the initial index of refraction. The index-altered portions are arranged within the non-photosensitive material of the first optical fiber core to form a diffractive structure of the integral diffractive element.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

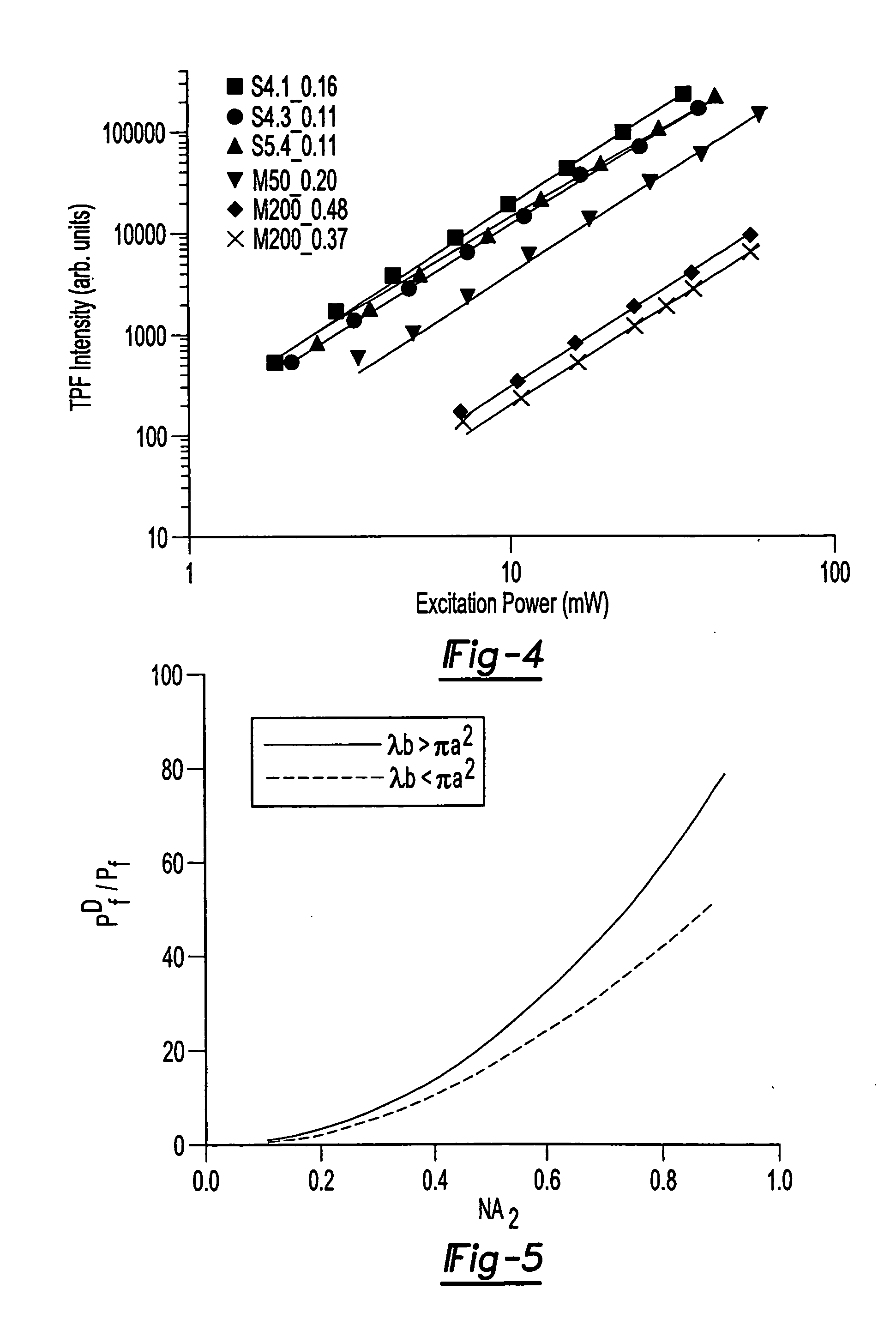

Enhancing fiber-optic sensing technique using a dual-core fiber

InactiveUS20060171647A1Improve detection efficiencyFluorescence/phosphorescenceMulticore optical fibreFiberSized small

Owner:RGT UNIV OF MICHIGAN

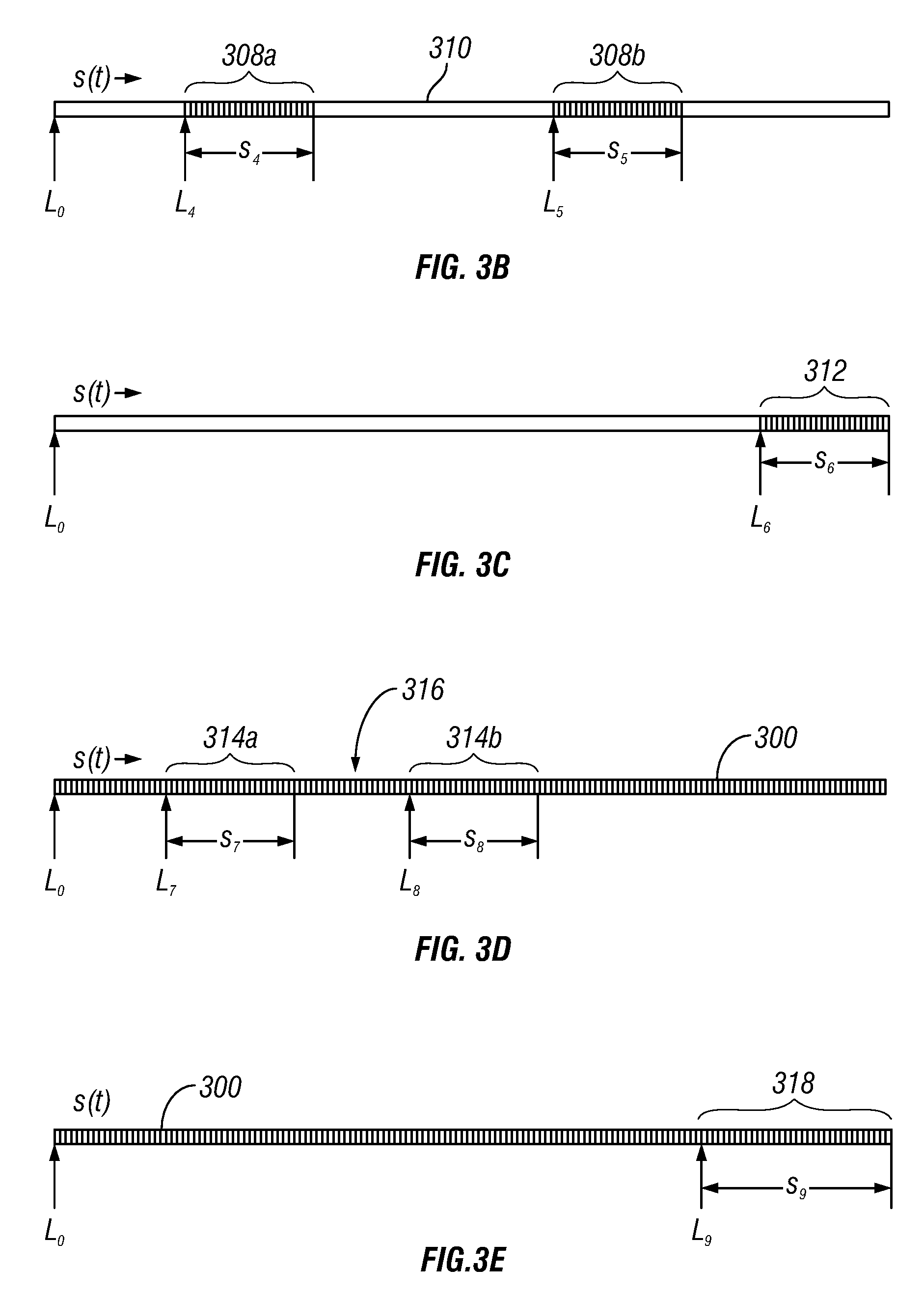

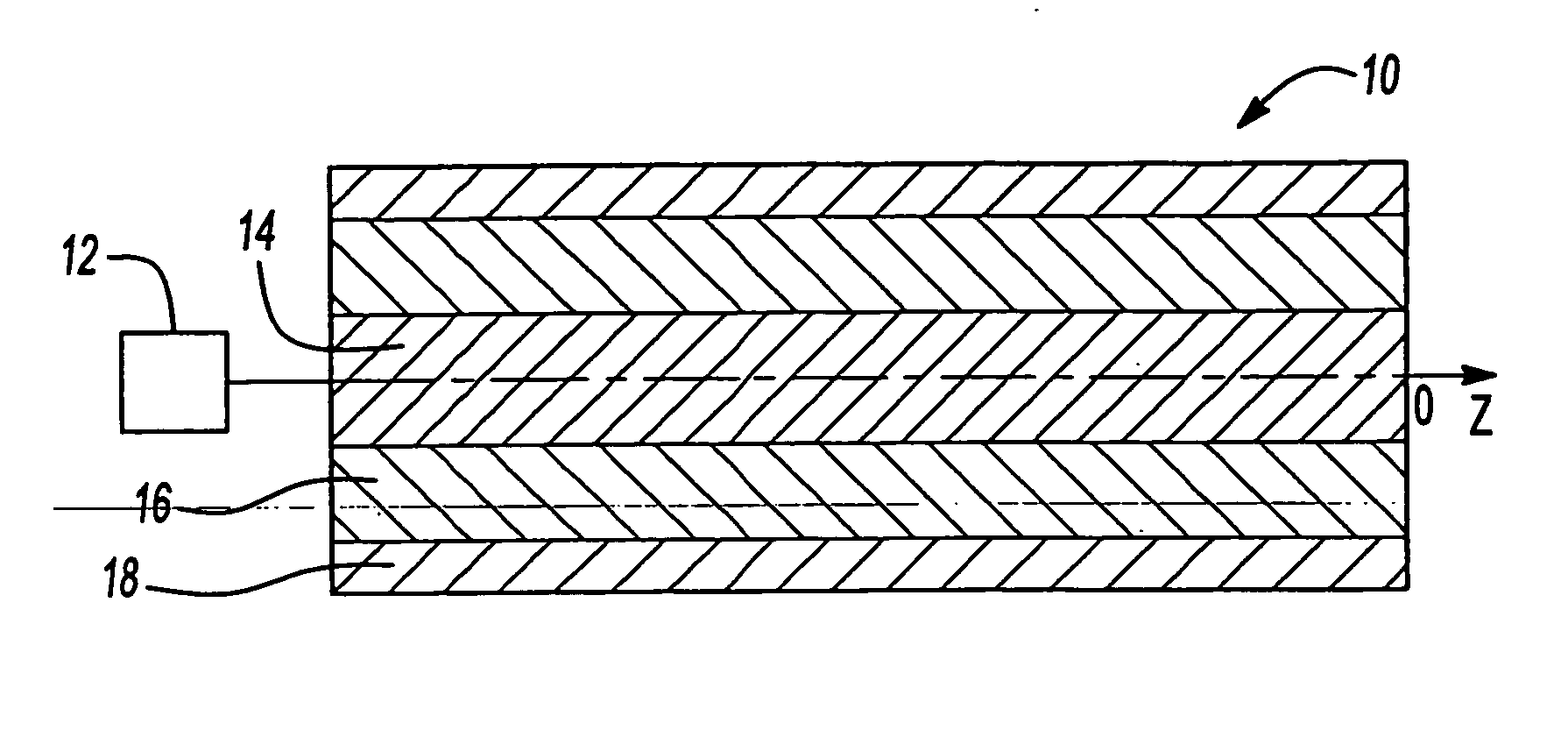

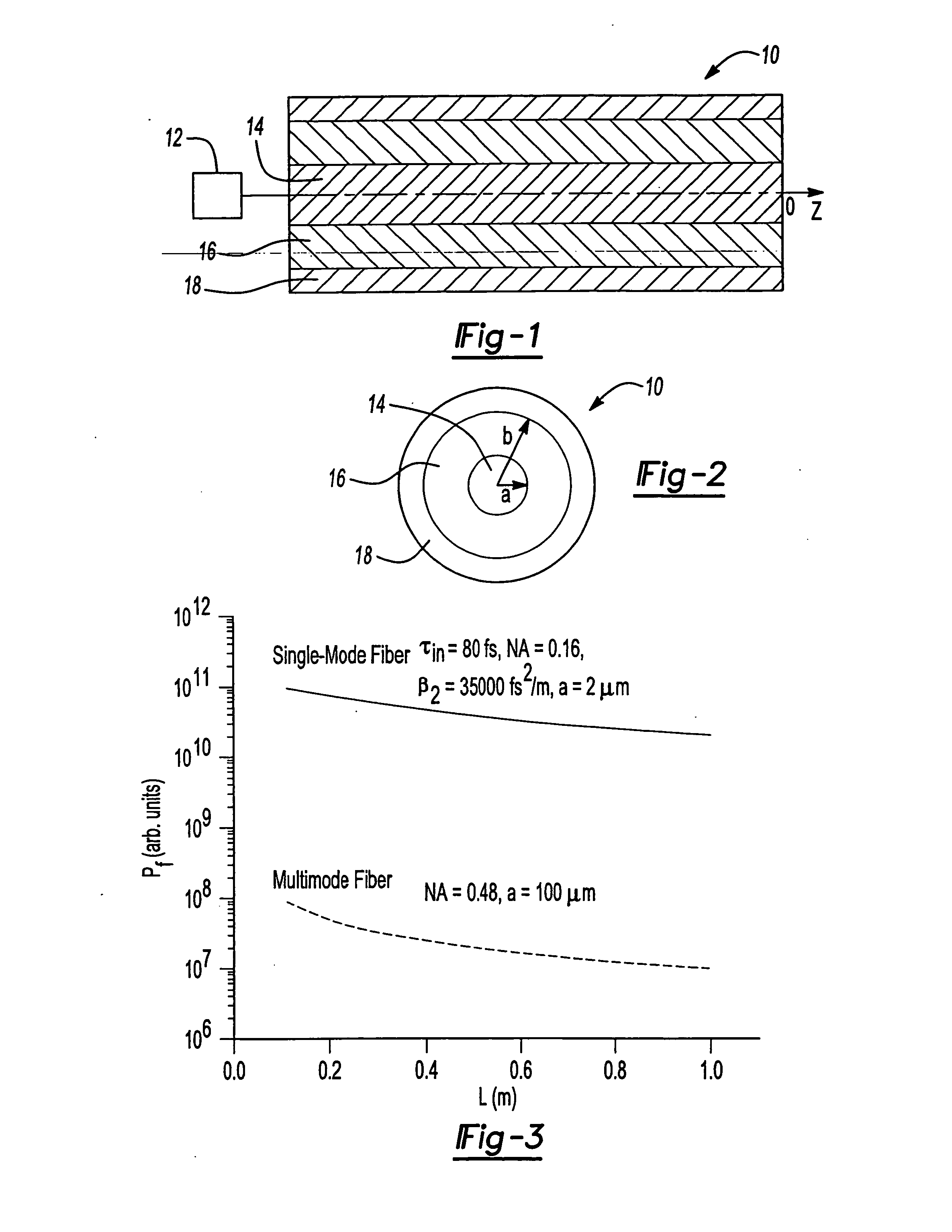

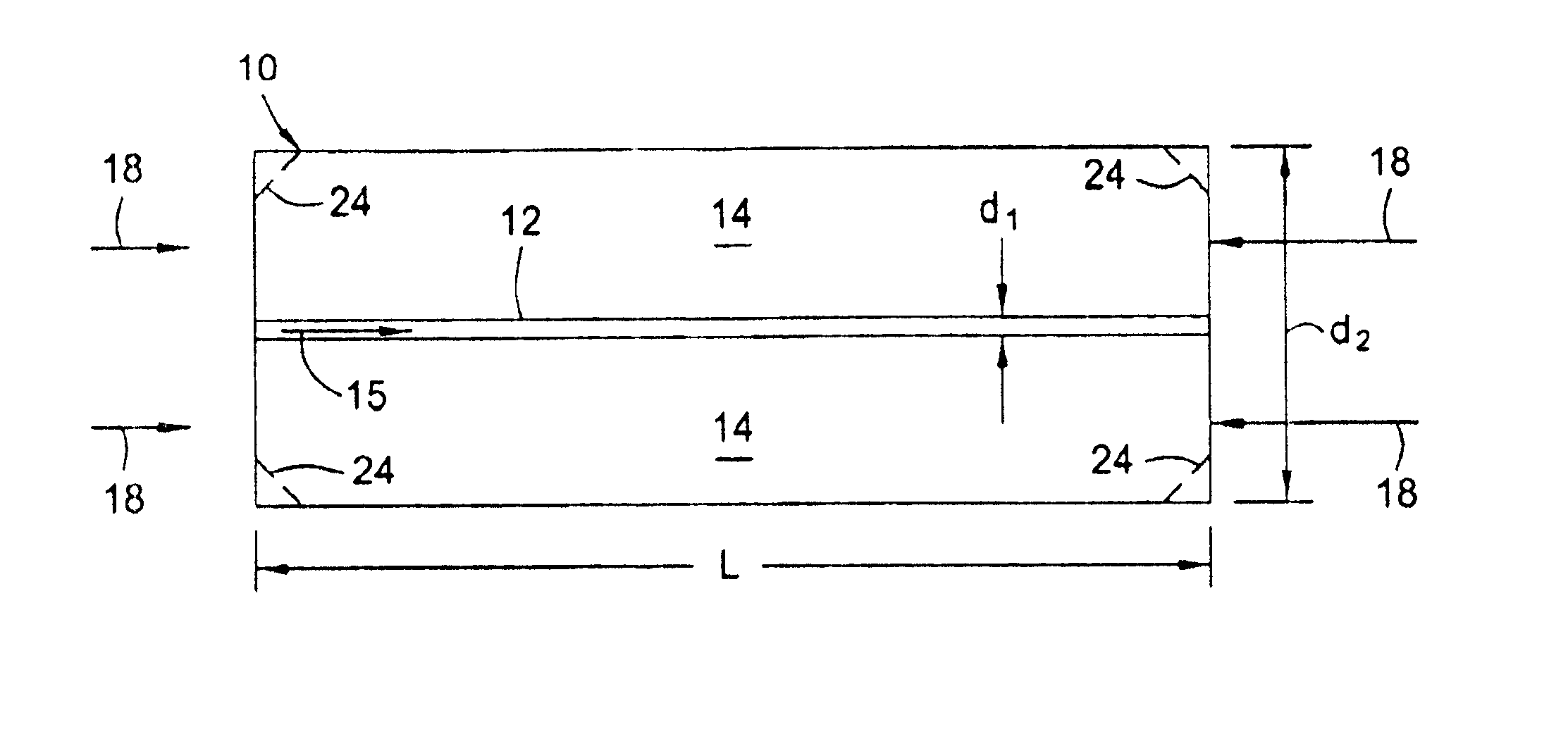

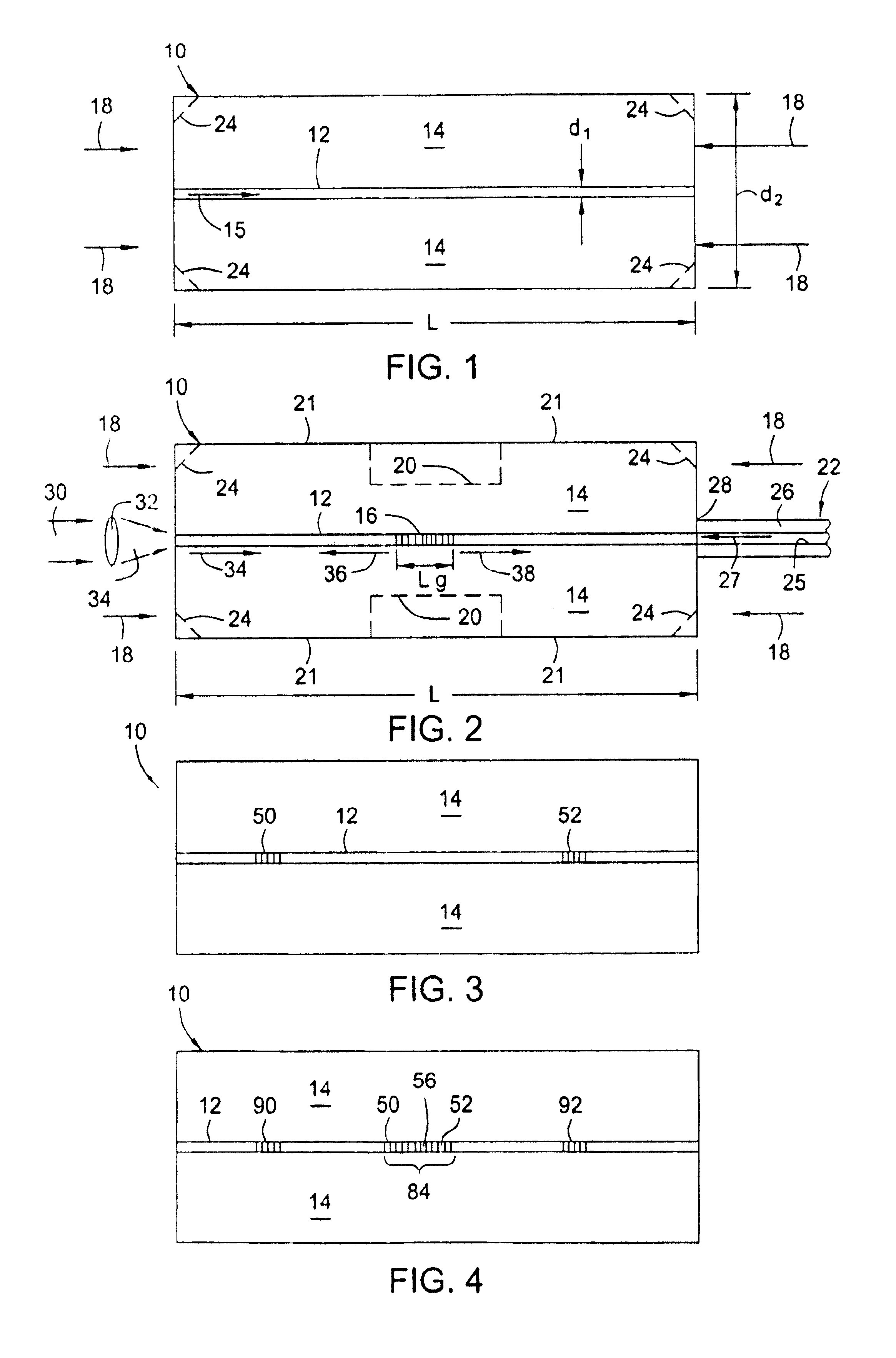

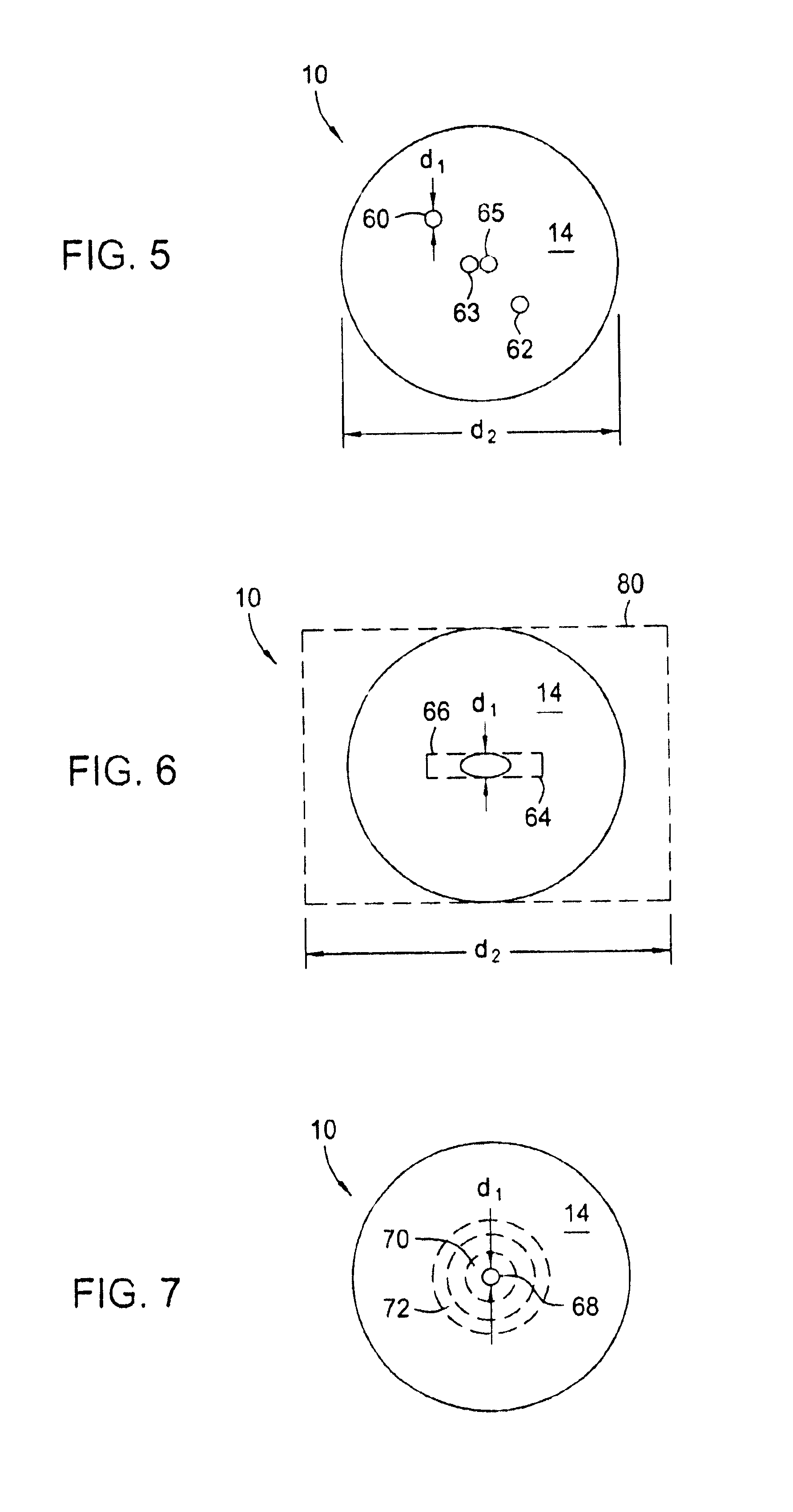

Large diameter optical waveguide, grating, and laser

InactiveUS6982996B1Reducing core to cladding couplingIncrease optical powerLaser using scattering effectsActive medium shape and constructionDopantGrating

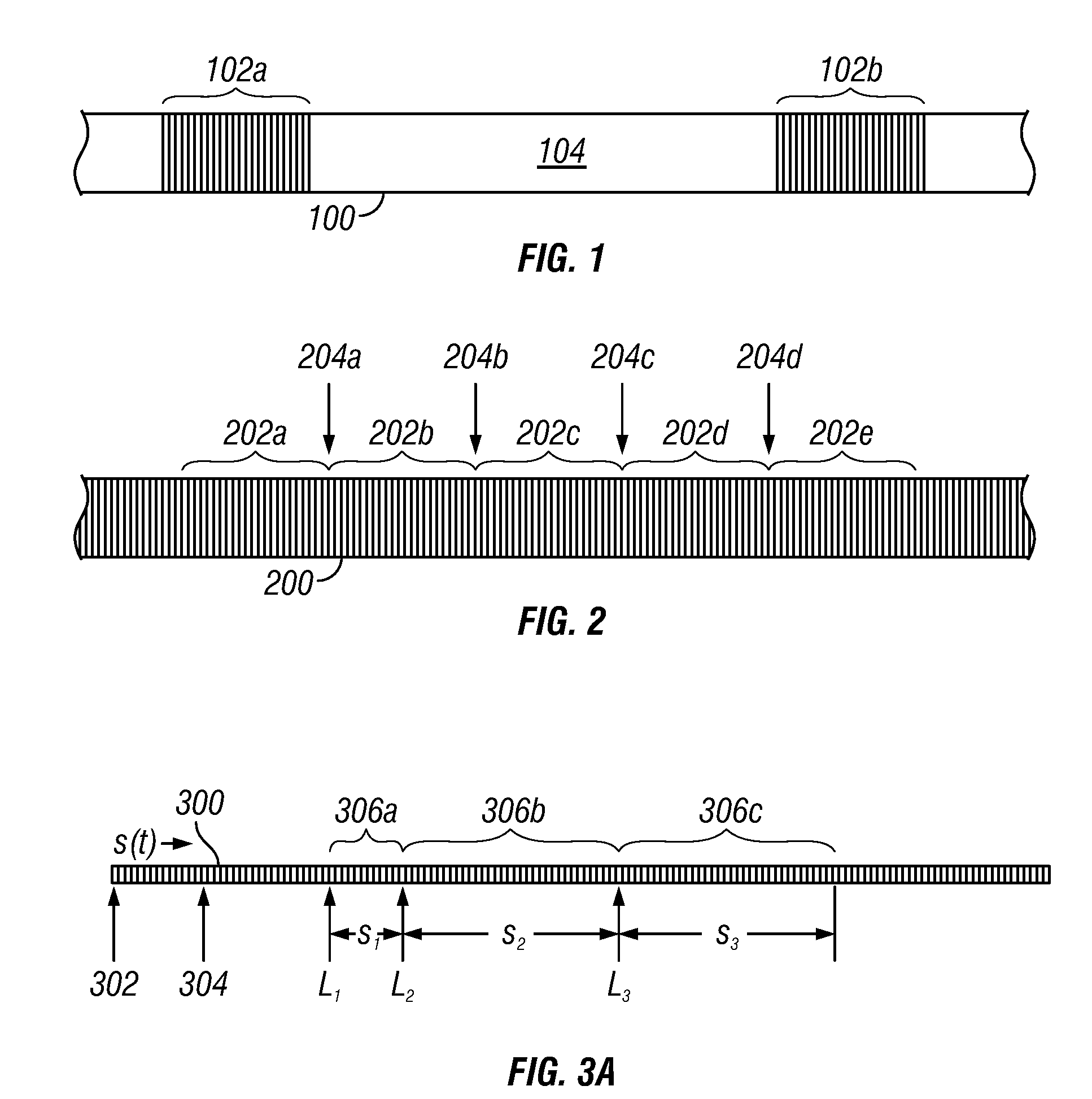

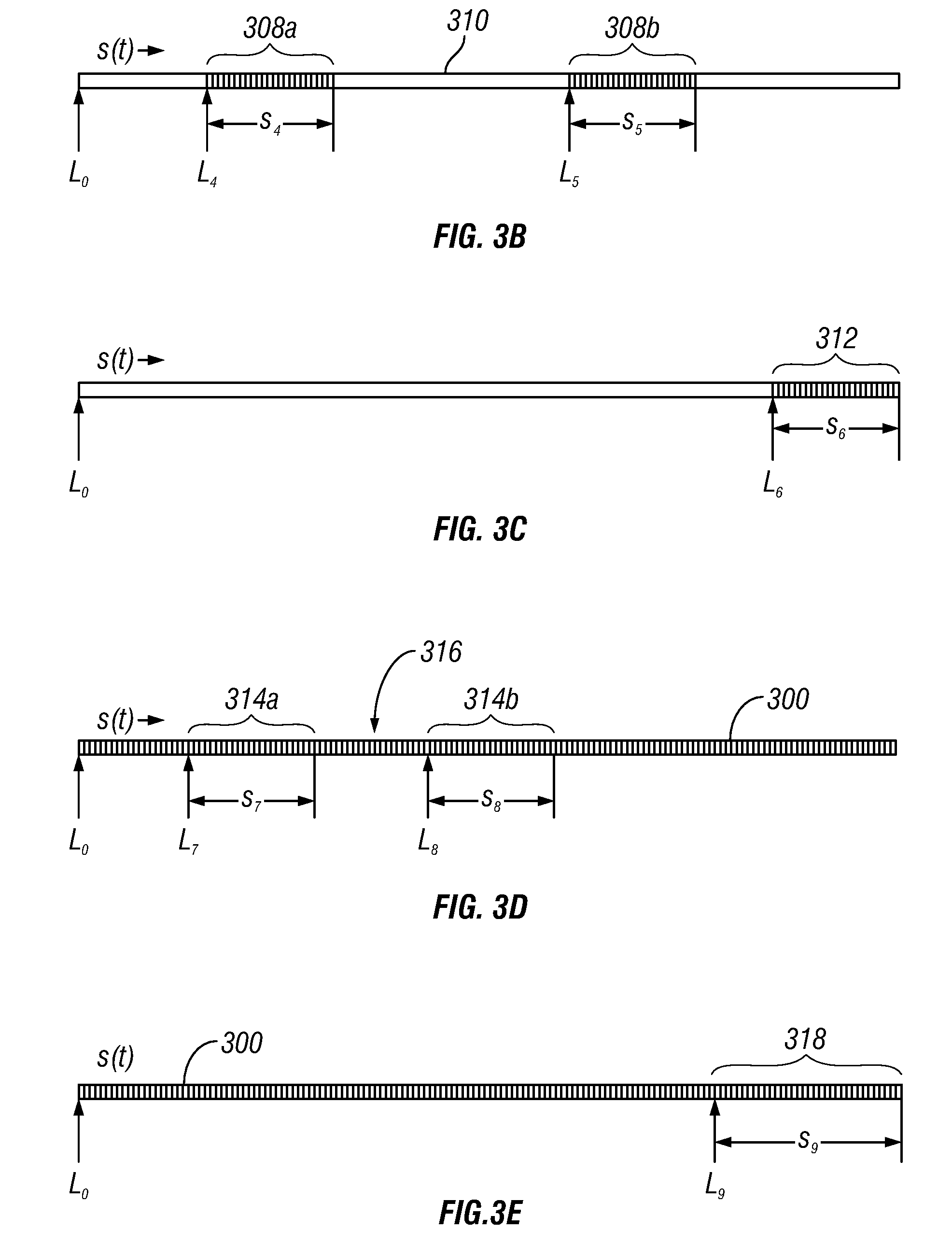

A large diameter optical waveguide, grating, and laser includes a waveguide 10 having at least one core 12 surrounded by a cladding 14, the core propagating light in substantially a few transverse spatial modes; and having an outer waveguide dimension d2 of said waveguide being greater than about 0.3 mm. At least one Bragg grating 16 may be impressed in the waveguide 10. The waveguide 10 may be axially compressed which causes the length L of the waveguide 10 to decrease without buckling. The waveguide 10 may be used for any application where a waveguide needs to be compression tuned, e.g., compression-tuned fiber gratings and lasers or other applications. Also, the waveguide 10 exhibits lower mode coupling from the core 12 to the cladding 14 and allows for higher optical power to be used when writing gratings 16 without damaging the waveguide 10. The shape of the waveguide 10 may have other geometries (e.g., a “dogbone” shape) and / or more than one grating or pair of gratings may be used and more than one core may be used. The core and / or cladding 12,14 may be doped with a rare-earth dopant and / or may be photosensitive. At least a portion of the core 12 may be doped between a pair of gratings 50,52 to form a fiber laser or the grating 16 or may be constructed as a tunable DFB fiber laser or an interactive fiber laser within the waveguide 10. The waveguide may resemble a short “block” or a longer “cane” type, depending on the application and dimensions used.

Owner:WEATHERFORD TECH HLDG LLC

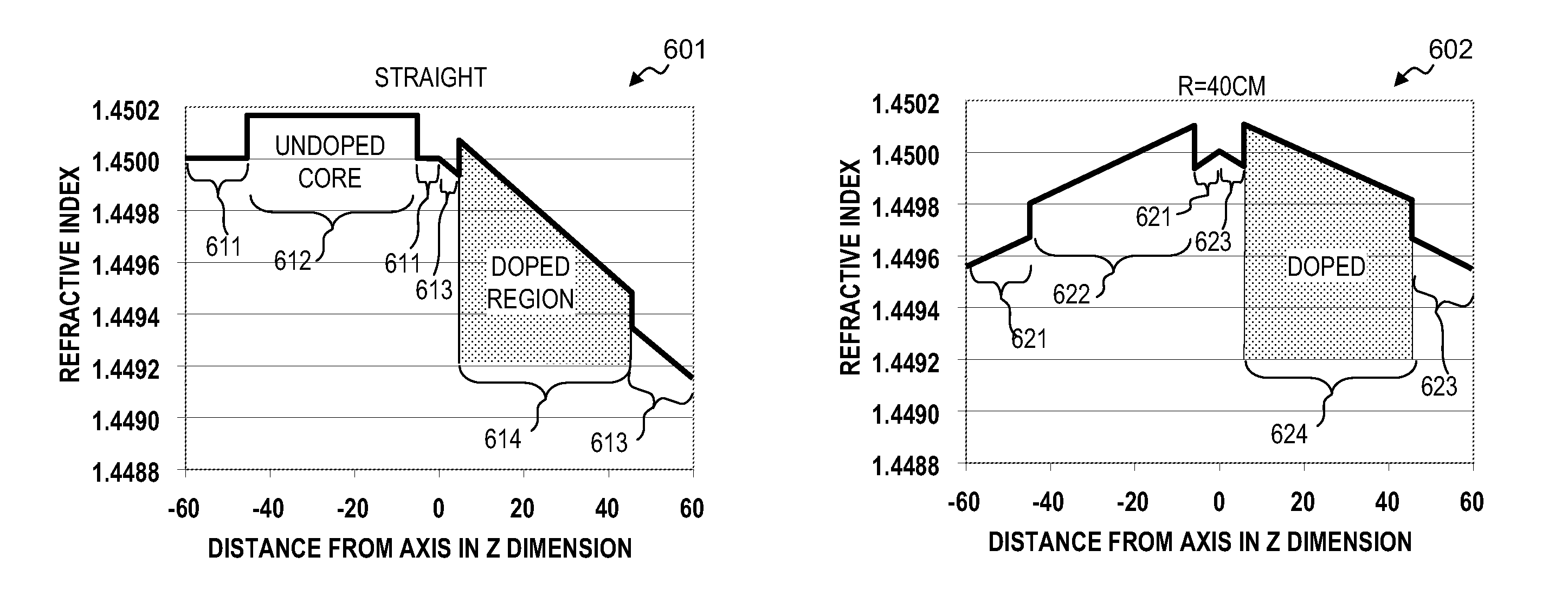

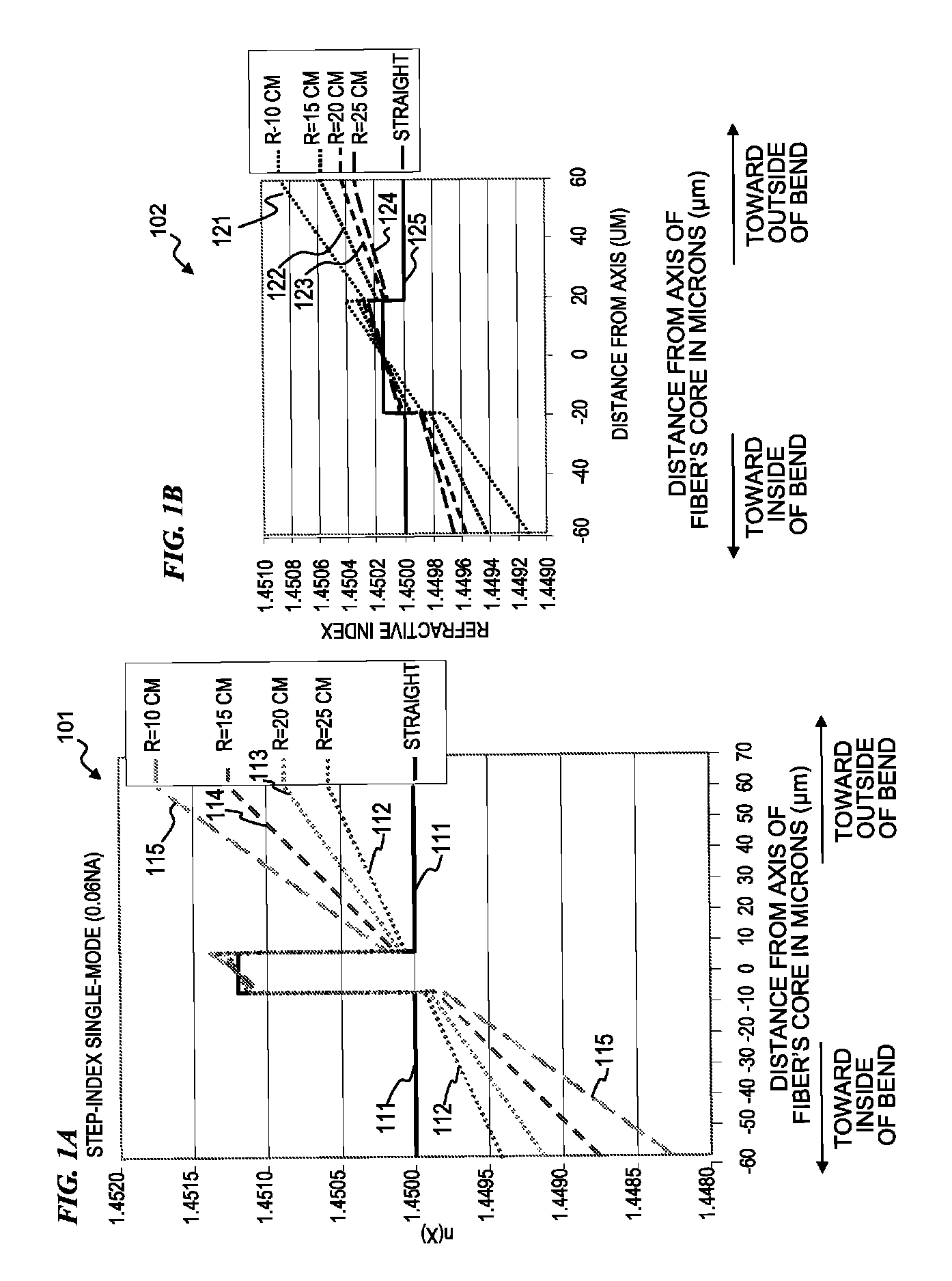

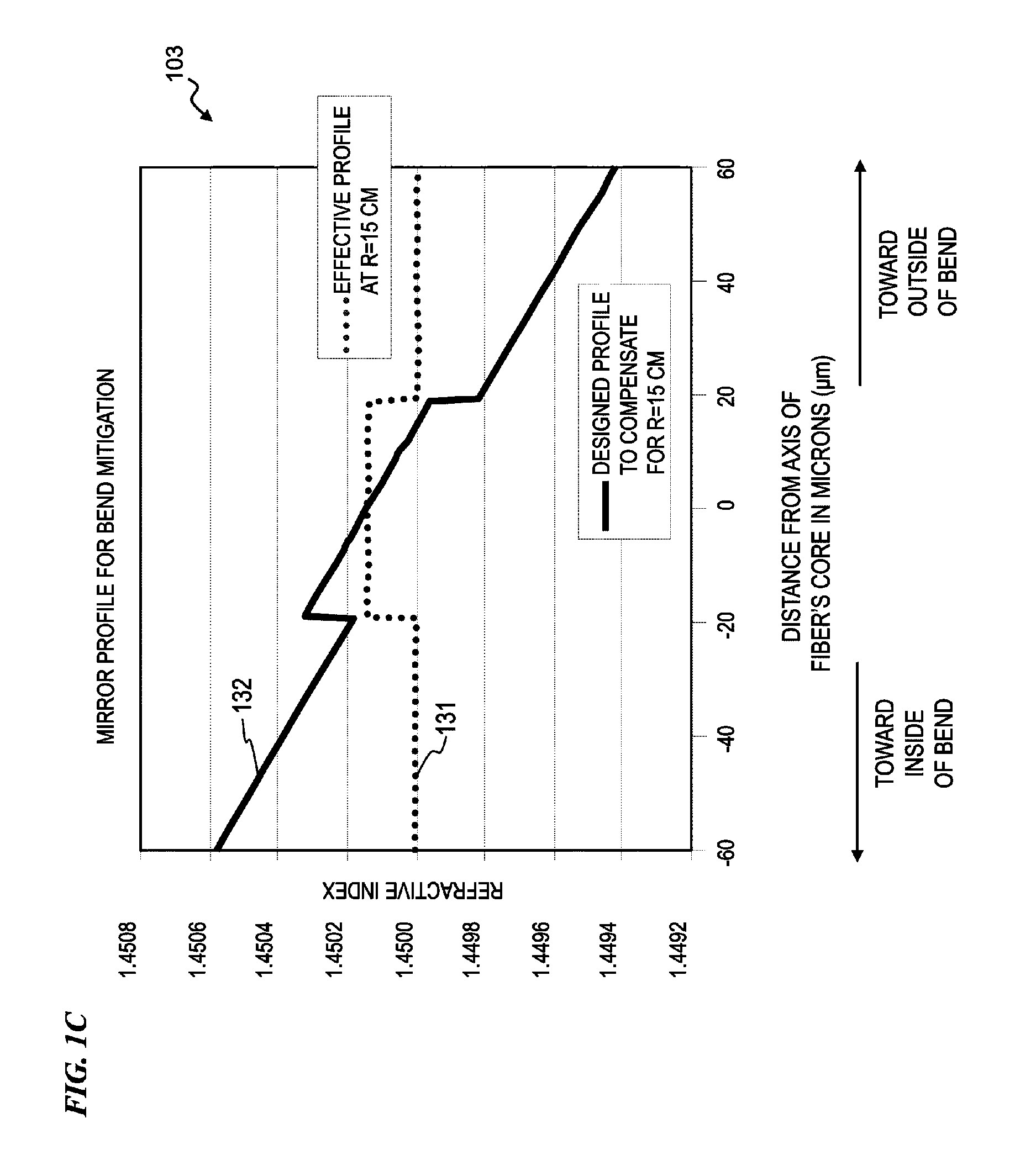

Apparatus and method for compensating for and using mode-profile distortions caused by bending optical fibers

An apparatus and method for compensating for mode-profile distortions caused by bending optical fibers having large mode areas. In various embodiments, the invention micro-structures the index of refraction in the core and surrounding areas of the inner cladding from the inner bend radius to the outer bend radius in a manner that compensates for the index changes that are otherwise induced in the index profile by the geometry and / or stresses to the fiber caused by the bending. Some embodiments of an apparatus and method include a fiber having a plurality of substantially parallel cores, the fiber including a straight section and a curved section; guiding signal light primarily in a second core in the straight section; guiding the signal light from the second core into a first core between the straight section and the curved section; and guiding the signal light primarily in the first core in the curved section.

Owner:LOCKHEED MARTIN CORP

Fiber optic tracking system and method for tracking

ActiveUS20090314925A1Photometry using reference valueInstruments for comonautical navigationFiberEngineering

A fiber optic tracking system for tracking substantially rigid object(s) is described. The fiber optic tracking system includes a light source, an optical fiber having a sensing component configured to modify optical signals from the light source, the optical fiber being configured to attach to the substantially rigid object, a detection unit arranged to receive the modified optical signals from the sensing component, and a calculation unit configured to determine a pose of the substantially rigid object in six degrees of freedom based on the modified optical signals.

Owner:MAKO SURGICAL CORP

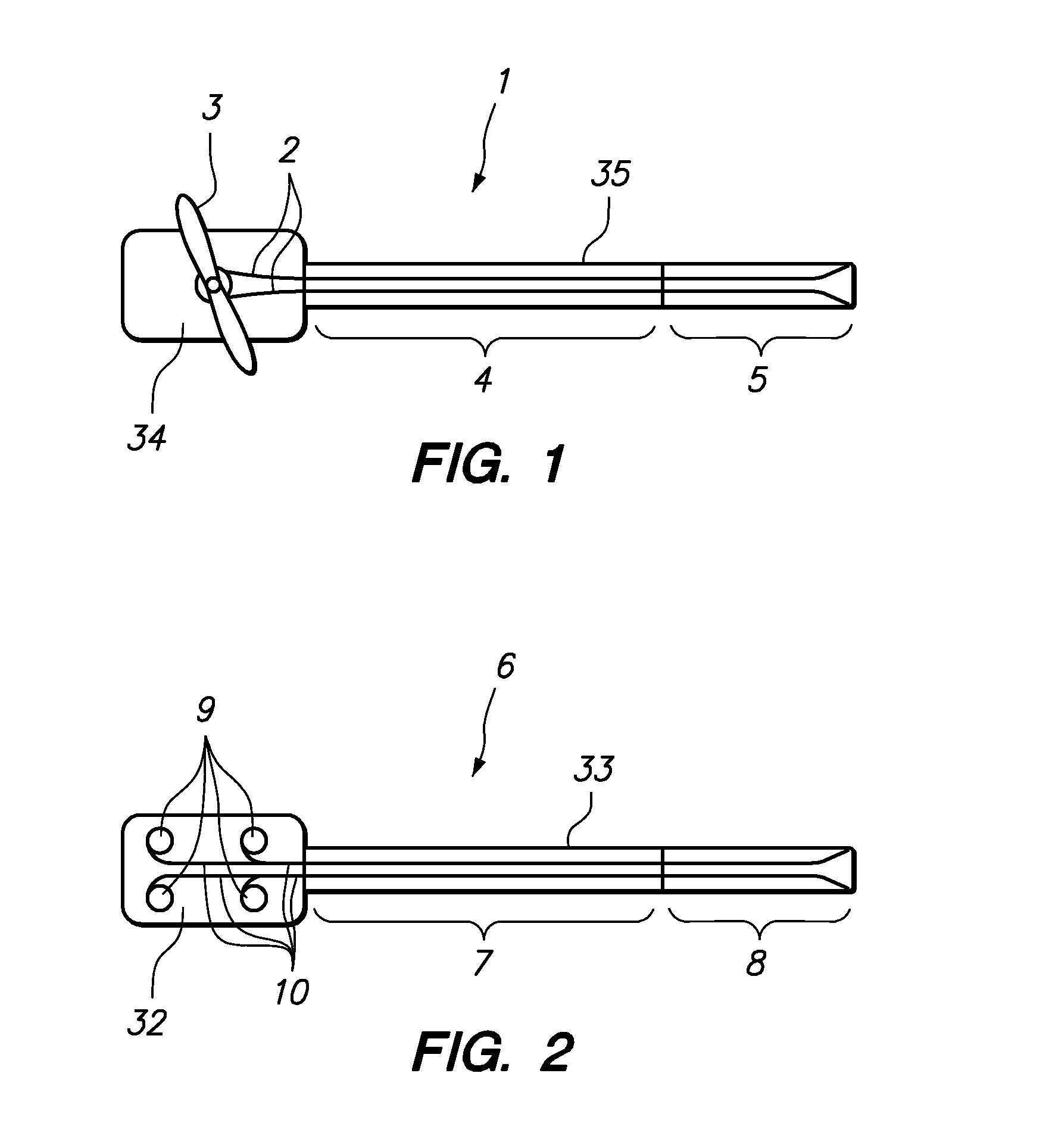

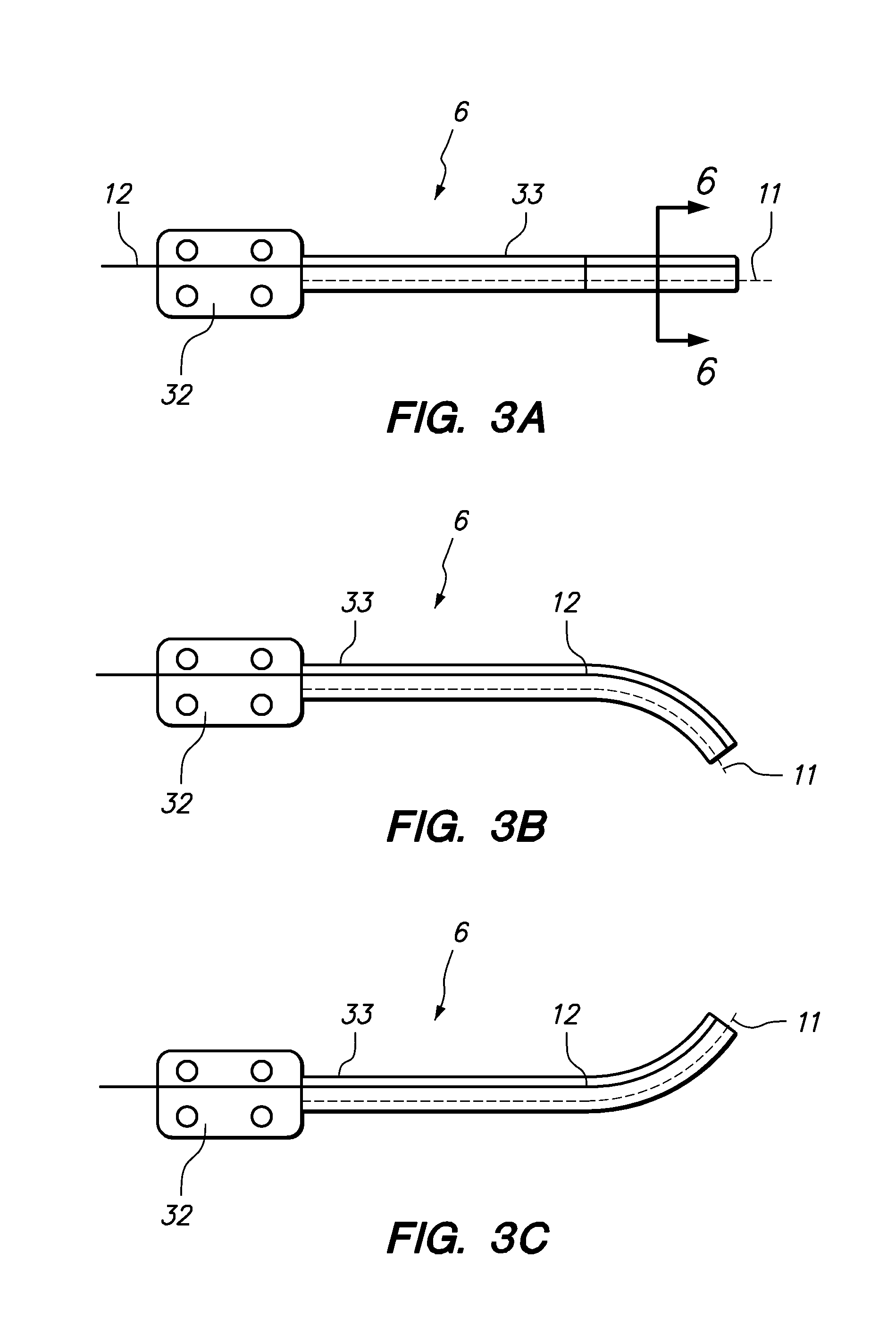

Multi-core low reflection lateral output fiber probe

InactiveUS20120099112A1Added fabricationEndoscopesUsing optical meansLight propagationCore (optical fiber)

Multi-core optical fiber probe includes a multi-core optical fiber (and method of manufacturing the probe) including a plurality of cores adjacent a cladding material, and a plurality of angled reflectors disposed at a distal end of the cores. An angled reflector of the plurality of angled reflectors deflects light propagating in the core at a deflection angle that is different from an axis of light propagation in the core. Light propagating toward a distal end of the core of the multi-core probe is emitted, after reflection by the corresponding reflector, out of the multi-core optical fiber probe.

Owner:ALPHONSE GERARD ARGANT +1

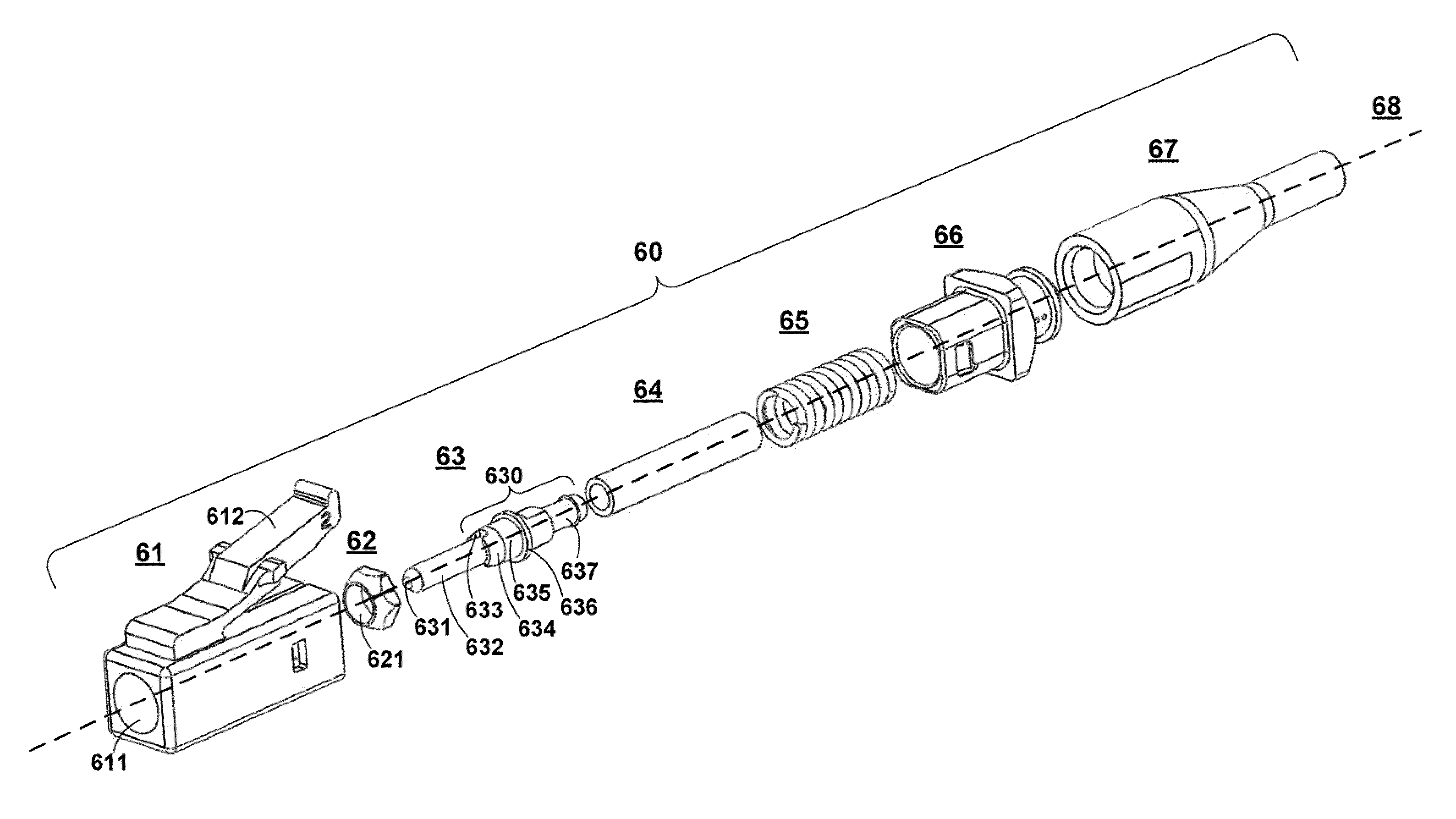

Simplex connectors for multicore optical fiber cables

ActiveUS20110229085A1Accurate rotational alignmentPrecise alignmentLine/current collector detailsCoupling light guidesEngineeringOptical fiber cable

An optical fiber cable connector includes a ferrule subassembly, in which a ferrule is mounted into a receptacle including a barrel section having a flange at its base. The ferrule subassembly is loaded into an enclosure having a plug housing at its lead end. The plug housing is configured to provide a connection between an endface of a multicore fiber mounted into the ferrule and a corresponding surface in a mating socket. A collar is rotatably mounted onto the barrel section of the ferrule subassembly such that it butts up against the flange. The collar has an opening that fits around the barrel section, and an outer perimeter that fits into a receiving cavity with the plug housing. The ferrule, receptacle, receptacle barrel section, mounted multicore fiber, enclosure, and plug housing have a common longitudinal axis. As a result, the ferrule, receptacle, receptacle barrel section, and mounted multicore fiber are continuously rotatable with respect to the enclosure and plug housing, thereby enabling a precise rotational alignment of the multicore fiber within the enclosure.

Owner:OFS FITEL LLC

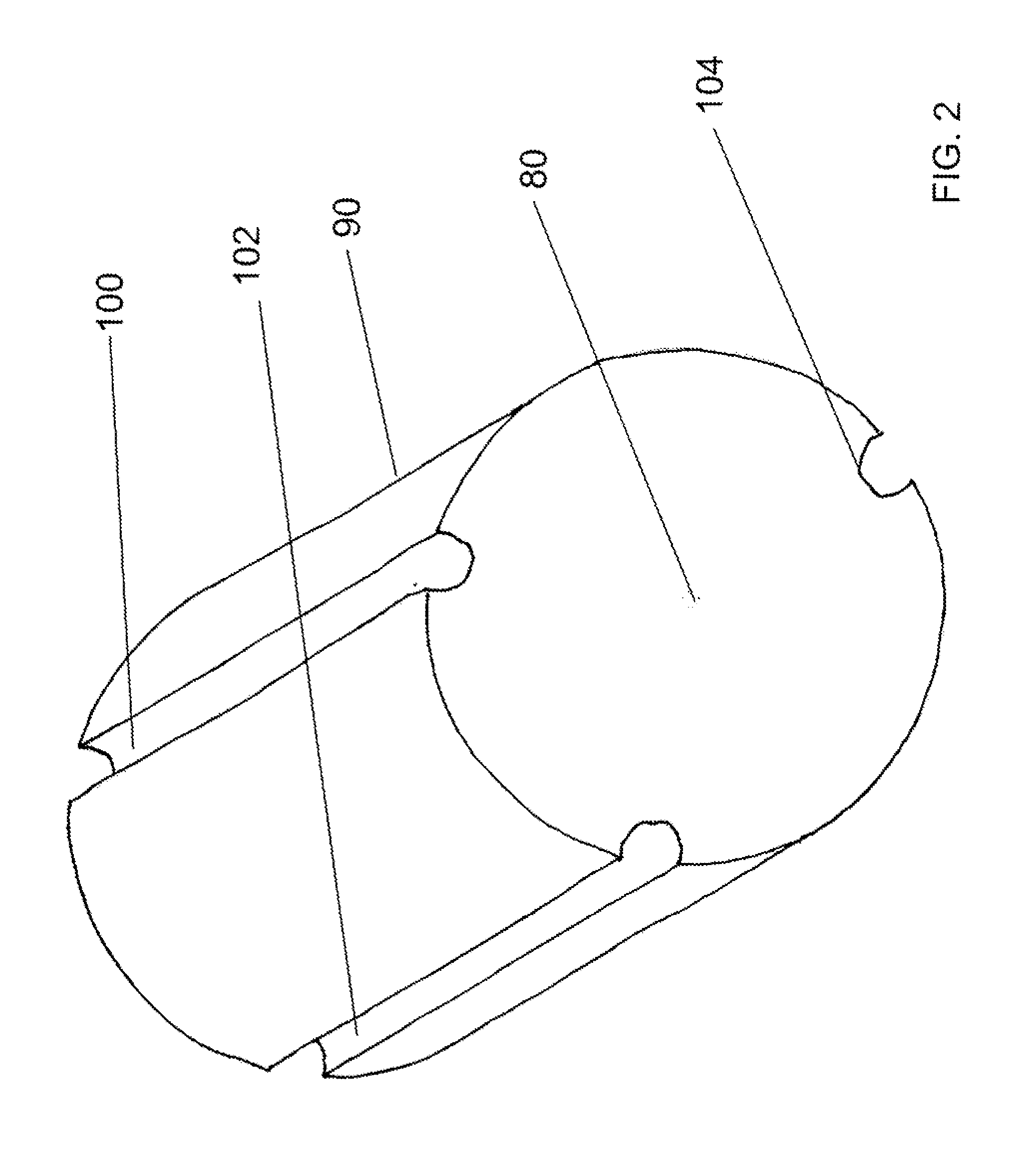

Compensating for non-ideal multi-core optical fiber structure

ActiveUS20120069347A1Accurately determineWithout loss in positional accuracyForce measurementMaterial analysis by optical meansEngineeringMechanical engineering

An interferometric measurement system includes a spun optical fiber including multiple optical waveguides configured in the fiber. Interferometric detection circuitry detects measurement interferometric pattern data associated with each of the multiple optical waveguides when the optical fiber is placed into a bend. Data processing circuitry determines compensation parameters that compensate for variations between an optimal configuration of the multiple optical waveguides in the fiber and an actual configuration of multiple optical waveguides in the fiber. The compensation parameters are stored in memory for compensating subsequently-obtained measurement interferometric pattern data for the fiber. The compensation parameters are applied to the subsequently-obtained measurement interferometric pattern data in order to distinguish between axial strain, bend strain, and twist strain on the fiber and to accurately determine one or more strain values for the fiber corresponding to one or more of the axial strain, bend strain, or twist strain on the fiber.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Multifiber connectors for multicore optical fiber cables

ActiveUS20110229086A1Accurate rotational alignmentCoupling light guidesMulticore optical fibreMulticore fiberEngineering

Structures and techniques are described relating to the alignment of multicore fibers within a multifiber connector. These structures and techniques include: multicore fibers having a number of different shapes, including, for example, circular, elliptical, D-shaped, double D-shaped, and polygonal; multifiber ferrules, having a plurality of fiber guide holes therein of various shapes; alignment fixtures for aligning multicore fibers within multifiber ferrules; and various multicore fiber alignment techniques.

Owner:OFS FITEL LLC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com