Mothproof and fireproof plasterboard with glass fiber surface and manufacturing method thereof

A technology of gypsum board and glass fiber surface, which is applied in the field of architectural decorative boards, can solve the problems of the board's flexural strength drop, and achieve the effect of simple shape, light weight and good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

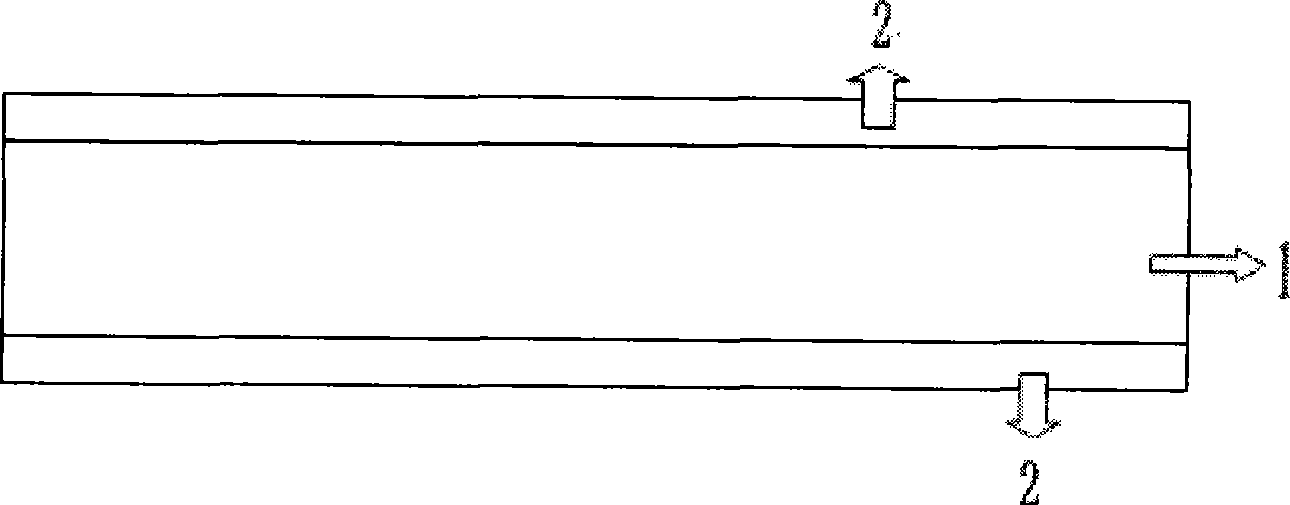

[0024] Embodiment 1; as figure 1 As shown, a moth-proof and fireproof glass fiber surface gypsum board includes an intermediate base 2 made of gypsum cementitious material, and a glass fiber surface formed by glass fiber mesh cloth woven with glass fibers on the outside of the intermediate base 2 2.

Embodiment 2

[0025] Embodiment 2; A kind of preparation method of mothproof, fireproof glass fiber gypsum board comprises the following steps: step 1, to a kind of mothproof, fireproof glass fiber gypsum board batching, the content of each composition is respectively weight ( number of copies):

[0026] Hemihydrate gypsum powder 1000 parts

[0027] Adhesive 30 parts

[0028] 20 parts glass fiber

[0029] Glass fiber mesh cloth 75 parts

[0030] 730 parts of water;

[0031] The above-mentioned hemihydrate gypsum powder is one or more mixtures of 80 mesh hemihydrate gypsum powder, 120 mesh hemihydrate gypsum powder or 160 mesh hemihydrate gypsum powder;

[0032] The above glass fiber length is 300mm;

[0033] Glass fiber mesh cloth with a specification of 2mm×2mm;

[0034] Above-mentioned sizing agent is cornstarch;

[0035] Step 2, batching according to the above weight percentage; add water and stir and mix according to the conventional process;

[0036] Step 3, forming;

[0037] ...

Embodiment 3

[0040] Embodiment 3; A kind of preparation method of moth-proof, fireproof glass fiber gypsum board comprises the following steps: step 1, to a kind of moth-proof, fireproof glass fiber gypsum board batching, the content of each component is respectively weight ( number of copies):

[0041] Hemihydrate gypsum powder 1000 parts

[0042] Adhesive 35 parts

[0043] 45 parts glass fiber

[0044] Fiberglass mesh 90 parts

[0045] 850 parts of water;

[0046] The above-mentioned hemihydrate gypsum powder is one or more mixtures of 100 mesh hemihydrate gypsum powder, 120 mesh hemihydrate gypsum powder or 160 mesh hemihydrate gypsum powder;

[0047] The above glass fiber length is 800mm;

[0048] Glass fiber mesh cloth with a specification of 3mm×2mm;

[0049] Above-mentioned sizing agent is cornstarch;

[0050] Step 2, batching according to the above weight percentage; add water and stir and mix according to the conventional process;

[0051] Step 3, molding;

[0052] Step 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com