Special-purpose mould for cross-linked polyethylene tube

A technology of cross-linked polyethylene and pipes, which can be used in household appliances, other household appliances, applications, etc., and can solve the problems that the quality of plastic pipes cannot be further improved, products are over-crosslinked or under-crosslinked, and mold cavity design problems, etc. , to achieve the effect of increasing the output of the main engine, simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

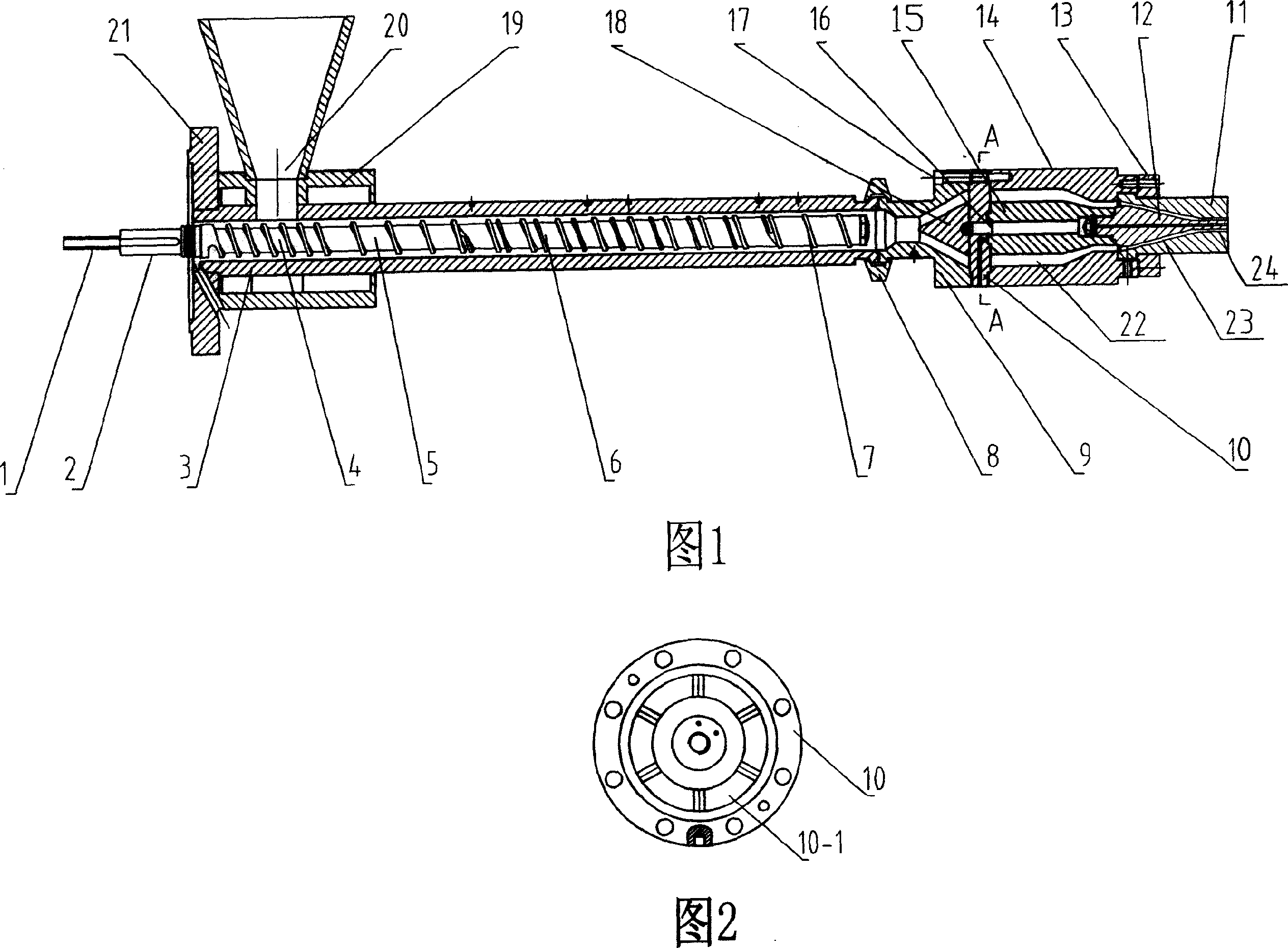

[0013] The present invention will be further described below in conjunction with accompanying drawing:

[0014] Referring to the accompanying drawings, this special mold for cross-linked polyethylene pipes includes an extruder and a molding die, wherein the extruder is composed of a screw barrel 3 and a screw 2 located in the screw barrel 3, and the screw barrel 3 has a discharge port 20. The screw 2 includes a feeding section 4, a compression section 5, a reaction section 6, and a homogenization section 7. The screw 2 adopts a small helix angle, a shallow screw groove, and a structure with equal pitch and unequal depth, and the helix angle is the standard screw angle. 1 / 2-1 / 4, the depth of the screw groove is 1 / 2-1 / 4 of the depth of the screw groove of the standard screw, the depth of the screw groove is from the feeding end to the other end from deep to shallow, and the change ratio is 1-2 . The standard screw lead angle is 17.65 degrees, and the standard screw groove dept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com