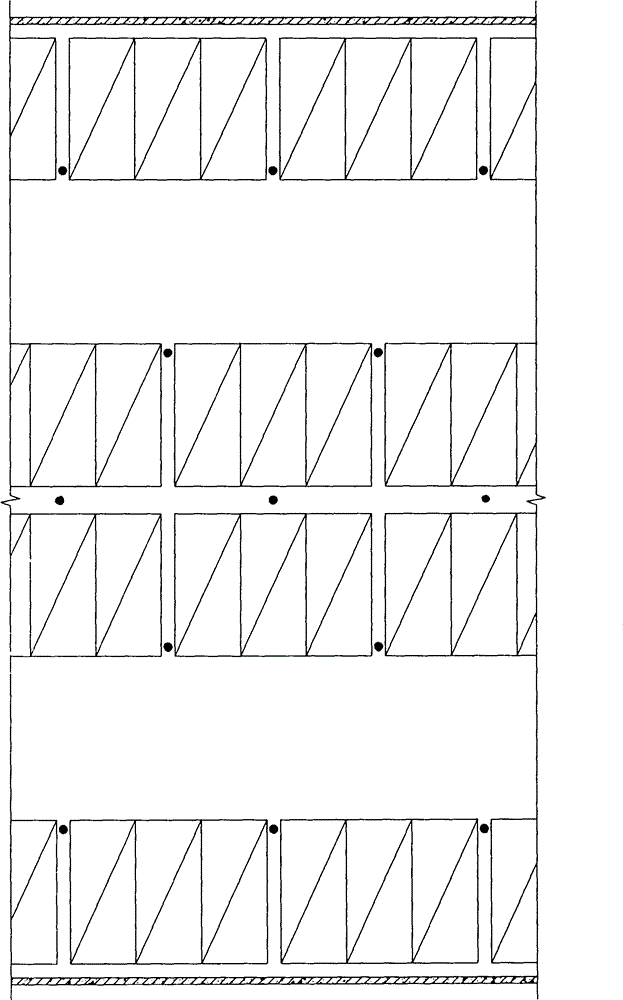

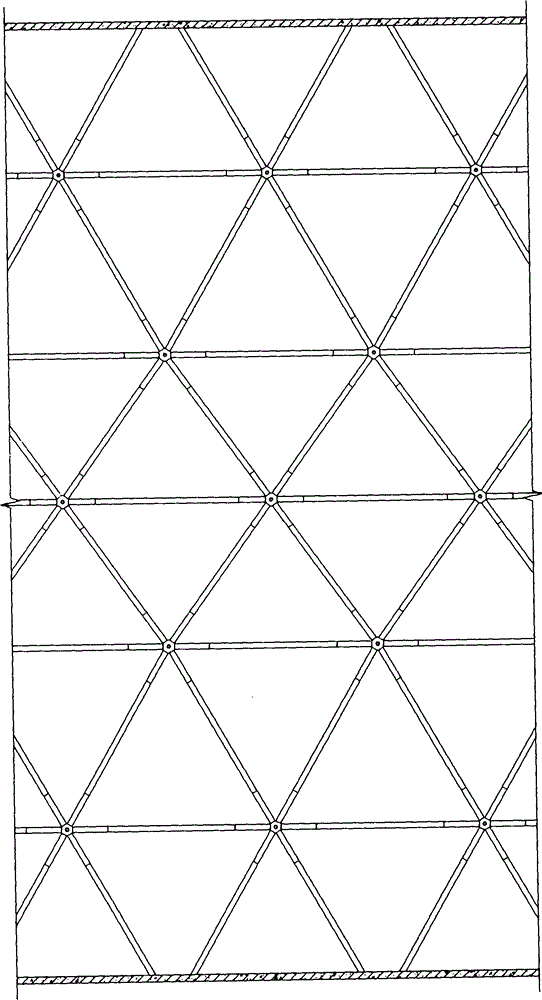

Garage arrangement mode and structure system thereof

A garage and system technology, which is applied in underwater structures, infrastructure engineering, building construction, etc., can solve the problems that the main components cannot be produced in a factory-standardized manner, and achieve the effects of shortening the construction period, easy recycling, and saving land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

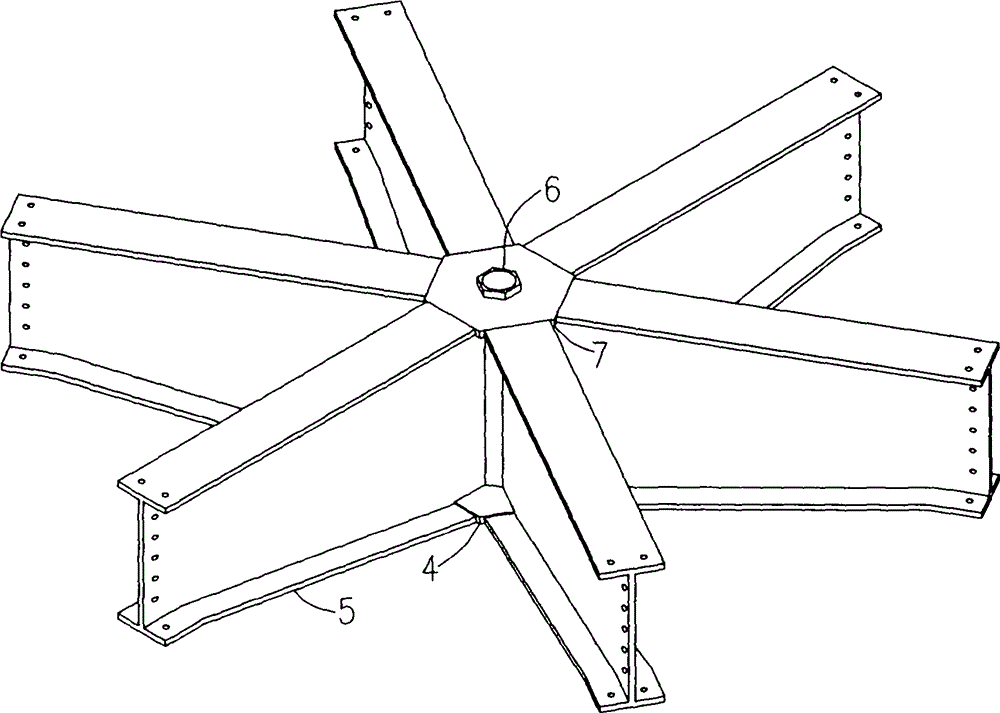

[0017] The steel pipe column (1) and concrete (2) are used to form a steel pipe concrete column, and the upper and lower connecting plates (7) and lower connecting plates (4) are respectively welded on the upper and lower sides of the central steel pipe (6), and the limit is welded under the lower connecting plate (4) Steel pipes (3), and then 6 H-shaped steel beams (5) are welded to the central steel pipe (6), the upper connecting plate (7) and the lower connecting plate (4) according to the angle of the column network. Figure 7 The outer diameter of the limiting steel pipe (3) is 1-2mm smaller than the inner diameter of the steel pipe column for easy installation, and holes are drilled on the lower connecting plate to facilitate pouring concrete into the steel pipe column, and composite floor slabs or reinforced truss concrete are laid on the steel beams The floor, the concrete in the steel pipe column and the floor concrete can be poured at the same time, and the steel comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com