Additive for pervious concrete and application thereof

A permeable concrete and admixture technology, which is applied in the field of concrete admixtures, can solve the problems of low strength, poor work performance, and poor durability in the later stage, and achieve the effects of improving fluidity, preventing drying and condensation, and improving durability and strength in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

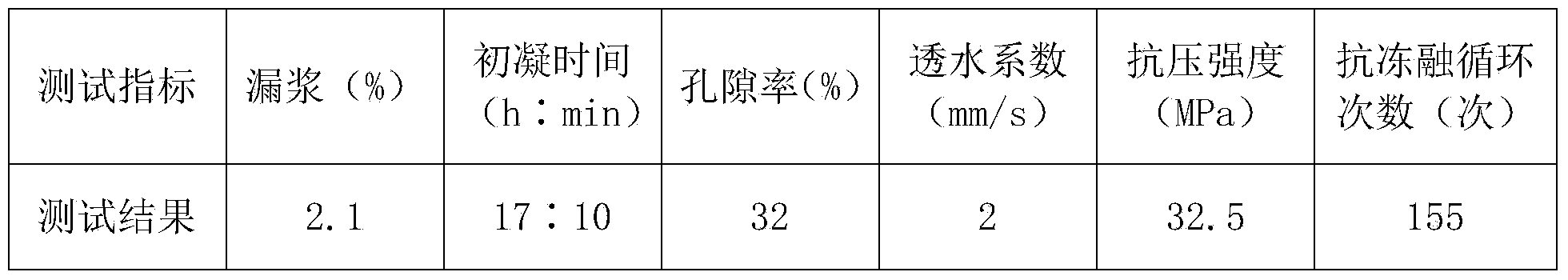

[0013] Example 1: (1) By mass ratio polyethylene glycol: butyl methacrylate: methyl methacrylate: vinyl ether-based polyoxyethylene: maleic anhydride: water = 2: 2: 5: 25: 5: Mix the components in a ratio of 61, and react at 70-100°C until a yellow-brown viscous liquid appears to prepare a polycarboxylate water-reducer; Melamine = 75:15:10 mixing the components to prepare the air-entraining agent; (3) by mass ratio polycarboxylate water reducer: aminotrimethylphosphoric acid: hydroxymethyl cellulose ether: air-entraining Agent: water = 40: 2.5: 1: 0.5: 56 Proportion of each component, mixing and stirring evenly to obtain the admixture for permeable concrete. When preparing concrete according to the construction mix ratio of C25 permeable concrete, the amount of the above-mentioned admixture is 1.8% of the mass of the cementitious material, and the performance test results of the permeable concrete added with the above-mentioned admixture are listed in the following table:

[...

Embodiment 2

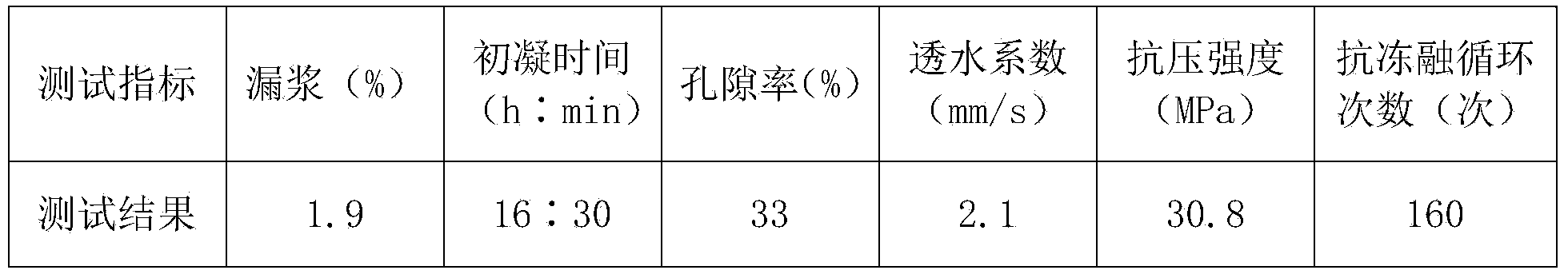

[0015] Example 2: (1) By mass ratio polyethylene glycol: butyl methacrylate: methyl methacrylate: vinyl ether-based polyoxyethylene: maleic anhydride: water = 2: 2: 5: 25: 5: Mix the components in a ratio of 61, and react at 70-100°C until a yellow-brown viscous liquid appears to prepare a polycarboxylate water-reducer; Melamine = 80:10:10 mixing the components to prepare the air-entraining agent; (3) by mass ratio polycarboxylate water reducer: phosphobutane tricarboxylic acid: polyacrylamide: air-entraining agent: water = 48: 2.3: 0.9: 0.8: 48 Proportion of each component, mixing and stirring evenly to obtain the admixture for permeable concrete. When preparing concrete according to the construction mix ratio of C25 permeable concrete, the amount of the above-mentioned admixture is 2.0% of the mass of the cementitious material, and the performance test results of the permeable concrete with the above-mentioned admixture are listed in the following table:

[0016]

Embodiment 3

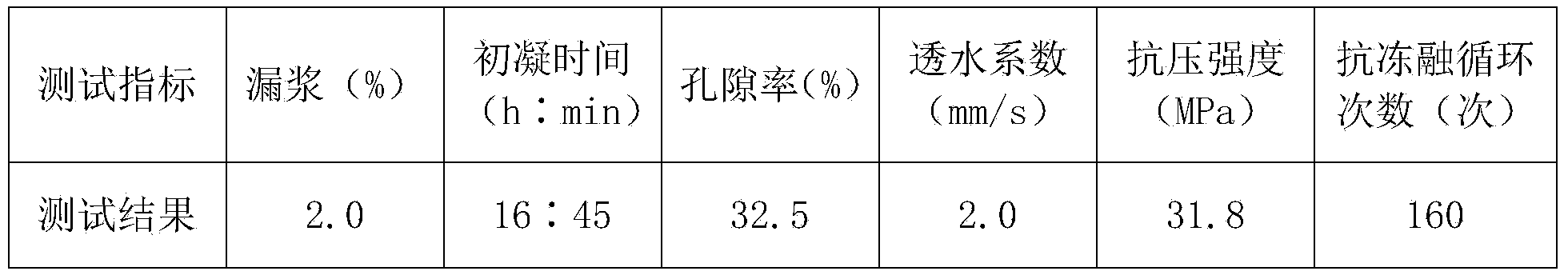

[0017] Example 3: (1) By mass ratio polyethylene glycol: butyl methacrylate: methyl methacrylate: vinyl ether-based polyoxyethylene: maleic anhydride: water = 2: 2: 5: 25: 5: Mix the components in a ratio of 61, and react at 70-100°C until a yellow-brown viscous liquid appears to prepare a polycarboxylate water-reducer; Melamine = 78: 12: 12 and mix the components to prepare the air-entraining agent; (3) by mass ratio, polycarboxylate water reducer: phosphobutane tricarboxylic acid: starch: air-entraining agent: water = 46 : 2.3: 1: 0.8: 48 Proportion of each component, mixing and stirring evenly to obtain the admixture for permeable concrete. When preparing concrete according to the construction mix ratio of C25 permeable concrete, the amount of the above-mentioned admixture is 2.0% of the mass of the cementitious material, and the performance test results of the permeable concrete with the above-mentioned admixture are listed in the following table:

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com