Heat-resistant and wear-resistant composite material and preparation method and application thereof

A technology of composite materials and wear-resistant materials, which is applied in the field of polymer wear-resistant materials, can solve the problems of heavy specific gravity and easy corrosion manufacturing cost, and achieve the effects of light specific gravity, improved wear resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

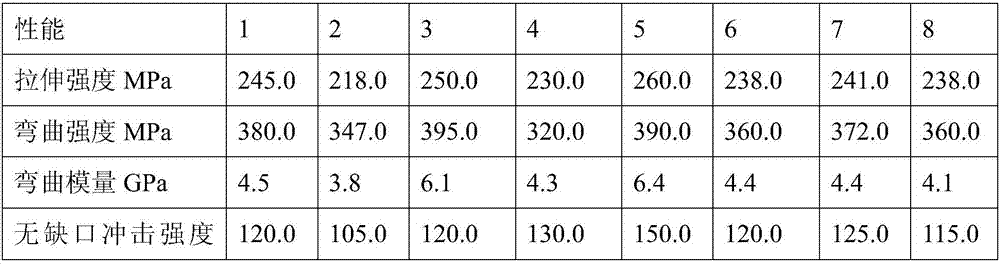

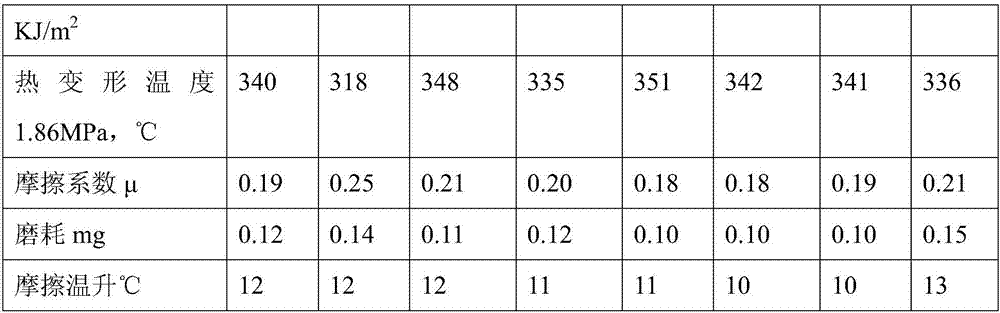

Examples

Embodiment 1

[0043] A high temperature and wear-resistant composite material, including the following raw materials and parts by weight: 2.0kg PEEK, 0.6kg carbon fiber, 1.0kg alumina whiskers, 0.2kg silicon carbide whiskers, 3.0g graphene nanomaterials, 12g coupling agent KH550, 6.0g primary antioxidant 412S, 4g secondary antioxidant HostaoxP-EPQ, 10g lubricant polytetrafluoroethylene, 10g molybdenum disulfide (MoS 2 ).

[0044] The preparation method comprises the following steps:

[0045] (1) Add wear-resistant materials alumina whiskers, silicon carbide whiskers, and graphene nanomaterials into the mixer in proportion and mix them, add coupling agent KH550 under heating and stirring, stir at 60°C for 6 minutes, and control the stirring speed at 150rpm;

[0046] (2) Add thermoplastic resin PEEK, lubricant polytetrafluoroethylene and molybdenum disulfide, antioxidant to the compound of step (1), stir 6min;

[0047] (3) Add carbon fiber to the mixture in step (2), adjust the stirring spe...

Embodiment 2

[0053] A high temperature and wear-resistant composite material, including the following raw materials and parts by weight: 2.0kg polyethersulfone, 0.2kg carbon fiber, 0.8kg alumina whisker, 0.2kg silicon nitride whisker, 2.0g graphene nanomaterial, 20g Coupling agent KH550, 2.4g primary antioxidant 412S, 1.6g secondary antioxidant HostaoxP-EPQ, 6g lubricant silicone, 24g molybdenum disulfide (MoS 2 ).

[0054] The preparation method comprises the following steps:

[0055] (1) Add wear-resistant materials alumina whiskers, silicon nitride whiskers, and graphene nanomaterials into the mixer in proportion to mix, add coupling agent KH 550 under heating and stirring, stir at 80°C for 5 minutes, and control the stirring speed at 100rpm ;

[0056] (2) Add thermoplastic resin polyethersulfone, lubricant polysilicone and molybdenum disulfide, antioxidant to the mixture of step (1), and stir for 5 minutes;

[0057] (3) Add carbon fiber to the mixture in step (2), adjust the stirrin...

Embodiment 3

[0063] A high temperature and wear-resistant composite material, including the following raw materials and parts by weight: 2.0kg polysulfone, 0.8kg carbon fiber, 1.5kg alumina whiskers, 0.5kg silicon carbide whiskers, 10g graphene nanomaterials, 40g coupling agent KH560, 12g primary antioxidant 412S, 8g secondary antioxidant HostaoxP-EPQ, 5g lubricant polytetrafluoroethylene, 5g graphite.

[0064] The preparation method comprises the following steps:

[0065] (1) Add wear-resistant materials alumina whiskers, silicon carbide whiskers, and graphene nanomaterials into the mixer in proportion and mix them, add coupling agent KH560 under heating and stirring, stir at 40°C for 10 minutes, and control the stirring speed at 500rpm;

[0066] (2) Add thermoplastic resin polysulfone, lubricant polytetrafluoroethylene and graphite, antioxidant to the compound of step (1), stir 10min;

[0067] (3) Add carbon fiber to the mixture in step (2), adjust the stirring speed to 50rpm, and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com