Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

236results about How to "Improve heat aging performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable material and method for preparing ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer from same

ActiveCN102153802AEnhanced cross-linking efficiencyIncreased uniform photocrosslinking depthPlastic/resin/waxes insulatorsInsulated cablesCross-linkPolyolefin

The invention relates to ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable material and a method for preparing an ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer from the same. The method comprises the following steps: adding a metal hydroxide flame retardant, a cationic photoinitiator, a free radical photoinitiator, a multi-functional cross-linking agent, a compound antioxidant, a flame-retardant synergist, a synergistic smoke suppressant and a processing aid to polyethylene or grafted and modified polyethylene and / or ethylene vinyl acetate or grafted and modified copolymer thereof which are used as base materials, compounding, mixing the materials uniformly according to the proportion, granulating, extruding to prepare the ultraviolet-light cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer, and immediately irradiating with a specific ultraviolet-light source to obtain the deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer. The cross-linking equipment used for preparing the novel material by using anovel technology has low investment, and the process is simple and environmental friendly, saves energy, ensures high production efficiency and low cost and good quality of product and can be widely used for producing high-performance special wire and cable products and the like.

Owner:HEILONGJIANG MINGXIANG TECH

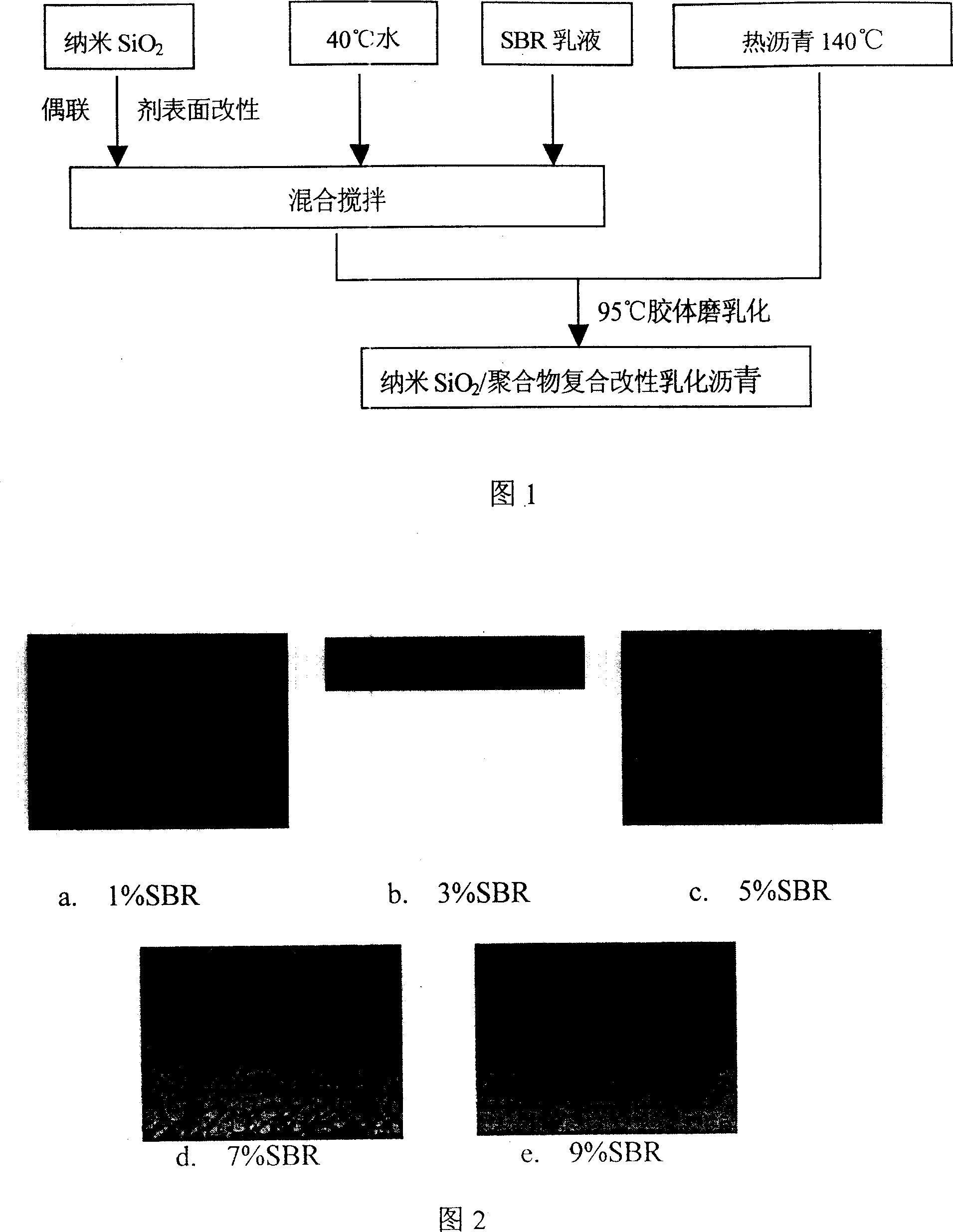

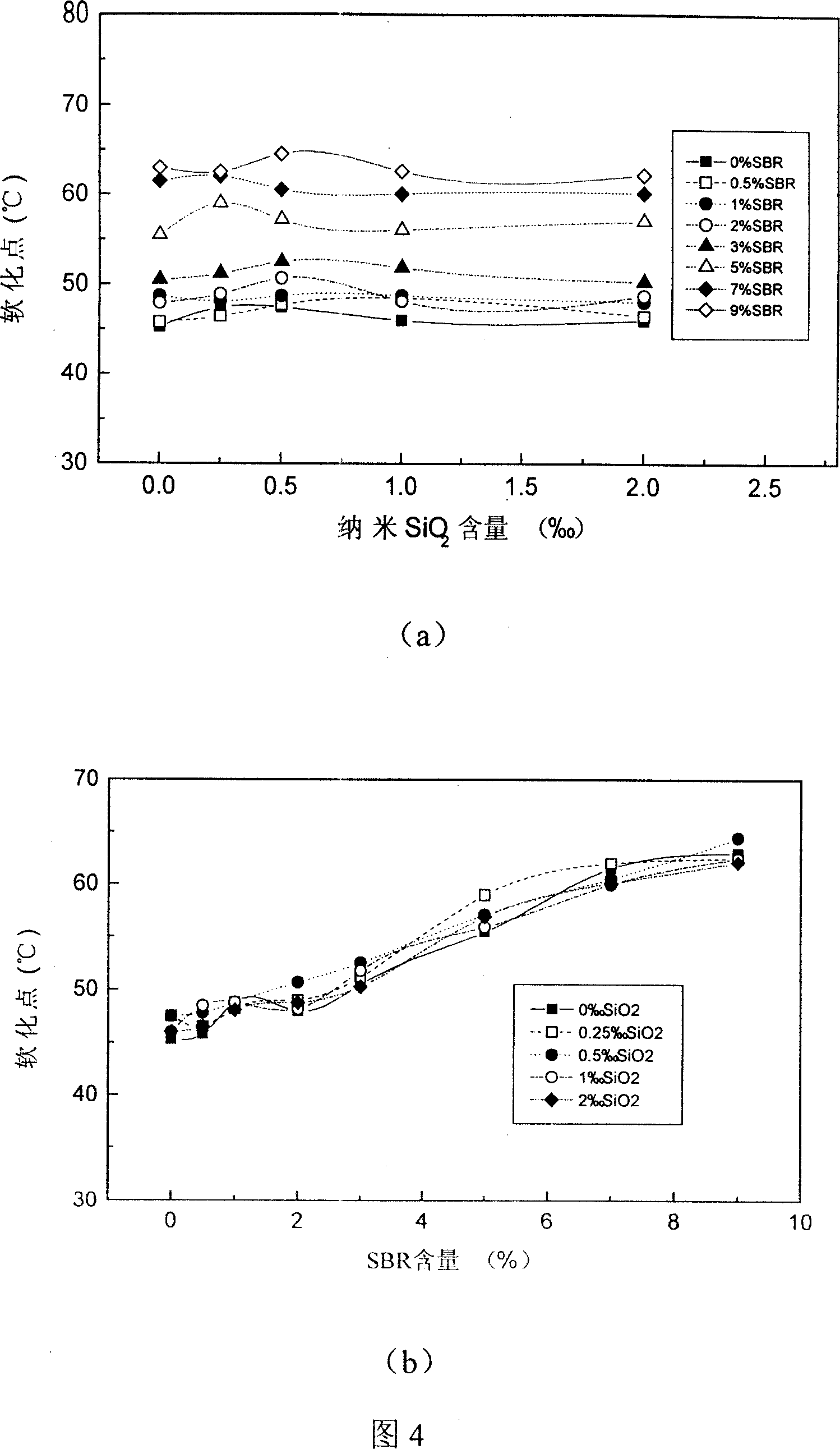

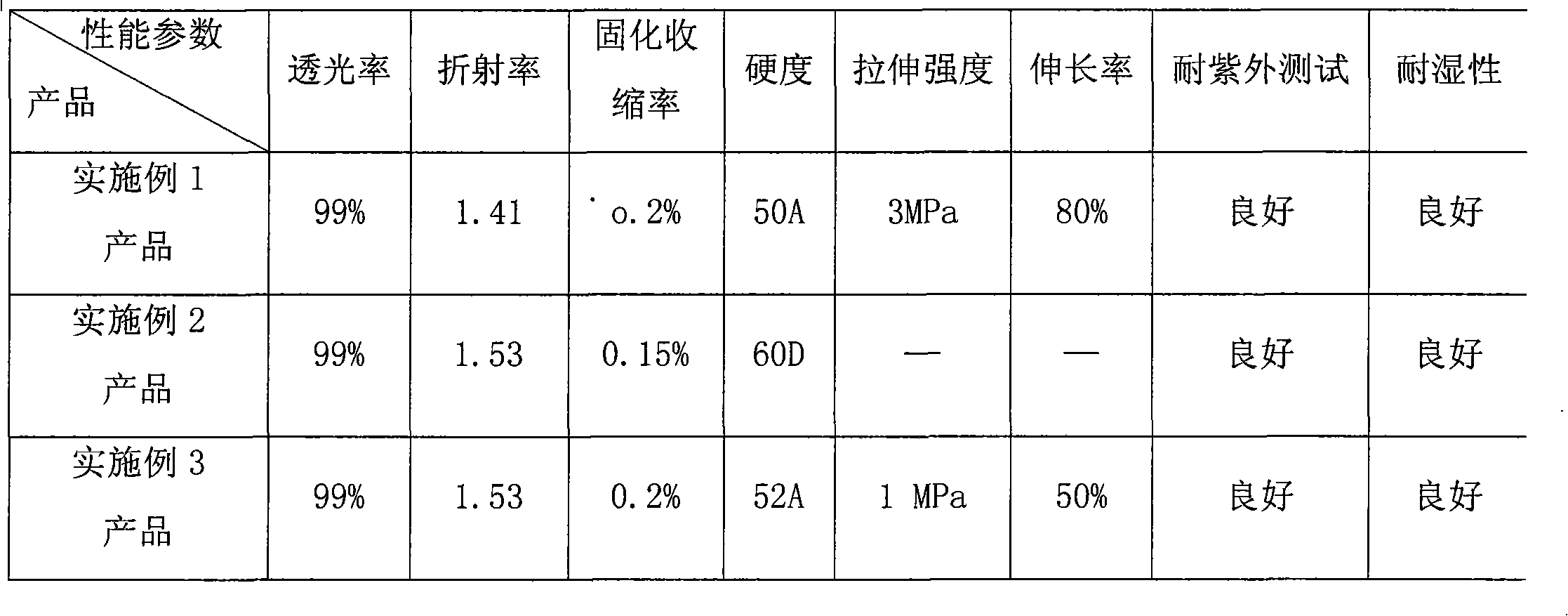

Inorganic nano particle and polymer composite modified emulsified asphalt

InactiveCN101143967AGood resistance to UV agingImprove heat aging performanceBuilding insulationsPolymer scienceButadiene-styrene rubber

A modified emulsion asphalt compounded by inorganic nano-particles and polymer contains 200-700 parts by weight of asphalt, 2-80 parts by weight of modified inorganic nano-particles, 5-50 parts by weight of styrene-butadiene rubber latex, and 170-793 parts by weight of water, wherein the modified inorganic nano-particles is prepared by mixing 95-98 parts by weight of inorganic nano-particles with 2-5 parts by weight of coupling agent, and each components are mixed, followed by normal emulsion treatment to get the emulsion asphalt. The invention utilizes unique surface effect, small size effect and macroscopic quantum tunneling effect etc. of the inorganic nano-particles to give the product comprehensive properties, such as good wear resistance, intensity sum, anti-aging property and fine waterproof effect etc. Using the invention can increase the road maintenance cycle and decrease the cost. Furthermore, the water-proof cost of construction industry is greatly decreased.

Owner:HUNAN UNIV

Organ silicon material for encapsulating power-type LED and synthetic method thereof

ActiveCN101608068AFully curedEven distribution of phenyl groupsSemiconductor devicesCross-linkMass ratio

The invention discloses an organ silicon material for encapsulating a power-type LED and a synthetic method thereof. The organ silicon material is mixed with a component A and a component B according to a mass ratio of 1:1 to 1:20, wherein the component A is a mixture of vinyl silicon polymer and a solidify catalyst, and the vinyl silicon polymer comprises vinyl silicon resin and polysiloxane with vinyl; and the component B comprises vinyl hydro silicon resin, poly hydro siloxane and an inhibitor. The organ silicon material has a higher refractive index, high transparency, excellent ultraviolet ageing resistance, good heat ageing resistance, and the like and is an ideal encapsulating material of the power type LED. The invention also discloses a synthetic method of an organ silicon material for encapsulating the power-type LED, the solidification of resin is more complete, and the light transmission and the hardness of the cross-link resin are effectively increased.

Owner:矽时代材料科技股份有限公司

Ultraviolet deep-crosslinked expansion flame-retardant polyolefine cable material, and preparation method of insulating or jacket layer thereof

ActiveCN102161793AImprove deep penetrating abilityImprove efficiencyInsulated cablesInsulated conductorsAntioxidantUltraviolet

The invention relates to an ultraviolet deep-crosslinked expansion phosphorus-nitrogen flame-retardant polyolefine cable material, and a preparation method of an insulating or jacket layer thereof. Polyethylene or graft-modified polyethylene and / or ethylene-vinyl acetate or graft-modified copolymer thereof are used as base materials, surface-modified expansion phosphorus-nitrogen halogen-free flame retardant, cation photoinitiator, free-radical photoinitiator, polyfunctional group crosslinking agent and composite antioxidant are added, and flame-retardant synergist, synergistic smoke suppressor and processing assistant are matched to obtain the ultraviolet deep-crosslinked expansion phosphorus-nitrogen flame-retardant polyolefine cable material. The preparation method comprises the following steps: proportionally and evenly mixing the materials to obtain granules, extruding to obtain an optical crosslinked expansion flame-retardant wire cable insulating layer or jacket layer, and radiating by a specific ultraviolet source for several seconds to obtain the deep-crosslinked insulating layer or jacket layer. The new material and new technology have the advantages of low investment required for crosslinking equipment, simple technique, energy saving, environmental protection, high production efficiency, low cost and good product quality, and can be widely used for manufacturing rail transportation cables, various mechanical wires, indoor assembly wires and the like.

Owner:HEILONGJIANG MINGXIANG TECH

Green tyre in composite structure between wheel track of polyurethane and tyre core of rubber, and fabricating method

ActiveCN1539628AReduce rolling resistanceImprove comfortOther chemical processesPolyureas/polyurethane adhesivesPolymer scienceSurface layer

A composite type composed of polyurethane surface layer and main body of rubber is prepared through treating the surface of main body, synthesizing and modifying the prepolymer of polyurethane, and casting the surface layer. Its advantages are high elasticity and antiwear nature, and low rolling resistance.

Owner:BESTIRE XINXING NEW MATERIAL TECH CO LTD

Optical conversion luminous film and preparation method thereof

ActiveCN101571235AGood luminous consistencyPrevent glareLuminescent paintsSynthetic resin layered productsChemistryColor rendering index

The invention relates to an optical conversion luminous film and a preparation method thereof. The optical conversion luminous film is formed by a diffusion film and a mixed paint layer on the diffusion film; the optical conversion luminous film has the thickness of 30-200mum, wherein, the thickness of the diffusion film is 20-70mum; the mixed paint layer is made of 10.000-30.000% of yellow luminous fluorescent material, 0.001-2.000% of red luminous fluorescent material, 60.000-89.000% of polymer resin, 1.000-5.000% of bi-amino silane, 0.000-20.000% of diluting agent and 0.000-5.000% of accessory ingredient. By combining the yellow luminous fluorescent material and the red luminous fluorescent material, the invention can realize the aim of regulating chromaticity coordinate, color temperature and color rendering index, thus preparing the optical conversion luminous film which is made of the fluorescent materials and has the advantages of high color rendering index of the photodiffusion effect, good property of uniform light, anti-dazzle, high light conversion efficiency, low cost, excellent aging characteristic and simple production technique.

Owner:DALIAN LUMINGLIGHT SCIENCE & TECHNOLOGY CO LTD

Carbon-nano-tube-reinforced polyethylene tube

The invention relates to a carbon-nano-tube-reinforced polyethylene tube which comprises, by weight, 70-100 parts of high-density polyethylene and 1-10 parts of carbon nano tubes. The carbon-nano-tube-reinforced polyethylene tube has the advantages that the carbon-nano-tube-reinforced polyethylene tube has excellent suppleness and formability; the carbon nano tubes are uniformly distributed and basically consistent in orientation in a polyethylene matrix so as to be firmly combined with the matrix, free from scattering and loss due to friction and good in durability; and the carbon nano tubes are conflict-free with other auxiliaries and good in synergy, and the antistatic performance, the mechanical strength and the thermal ageing performance are improved.

Owner:宁波风盛新材料科技有限公司

Reflective thermal-insulation exterior wall coating

InactiveCN103555102AKeep the decorative functionKeep the protection functionReflecting/signal paintsCelluloseThermal insulation

A reflective thermal-insulation exterior wall coating is characterized in that based on the total weight of the coating, components of the coating contain, by weight, 40-50% of waterborne acrylic resin, 10-20% of water, 10-15% of silica powder, 5-8% of expanded perlite, 3-5% of hollow ceramic microsphere, 2-5% of vermiculite powder, 3-5% of sericite powder, 5-8% of coal ash, 1-2% of an antifreeze agent, 4-6% of titanium dioxide, 4-6% of barium sulfate, 0.1-0.15% of aluminium titanate, 0.1-0.15% of silicon carbide, 0.1-0.15% of cordierite, 0.3-0.8% of an antifoaming agent, 0.1-0.15% of a bactericide, 0.1-0.4% of a dispersant, 1-1.5% of an alkali swelling thickener, 0.1-0.2% of a cellulose thickener, 0.1-0.15% of a wetting agent and 0.5-1% of an film-forming additive.

Owner:苏州富莱希涂料有限公司

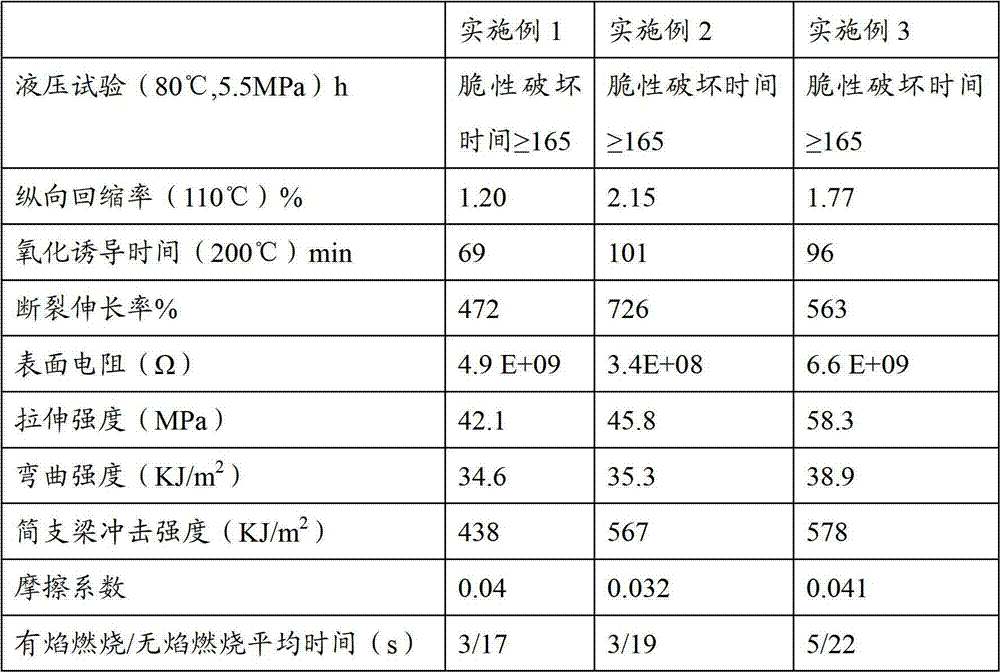

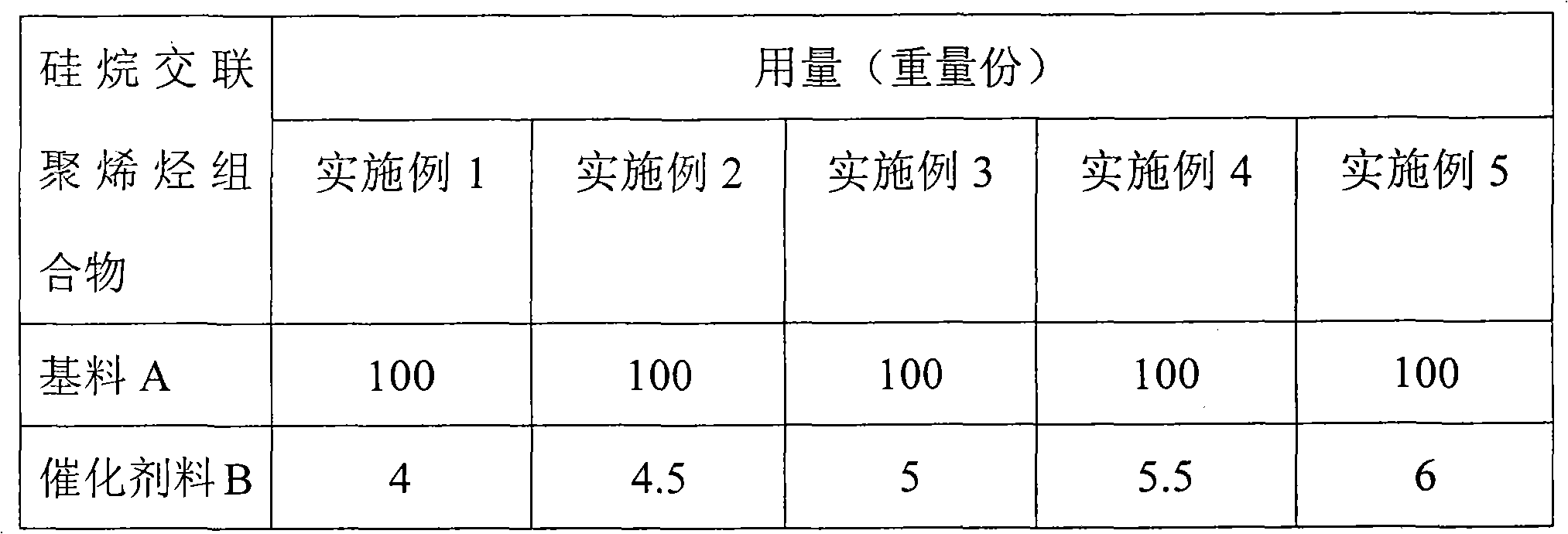

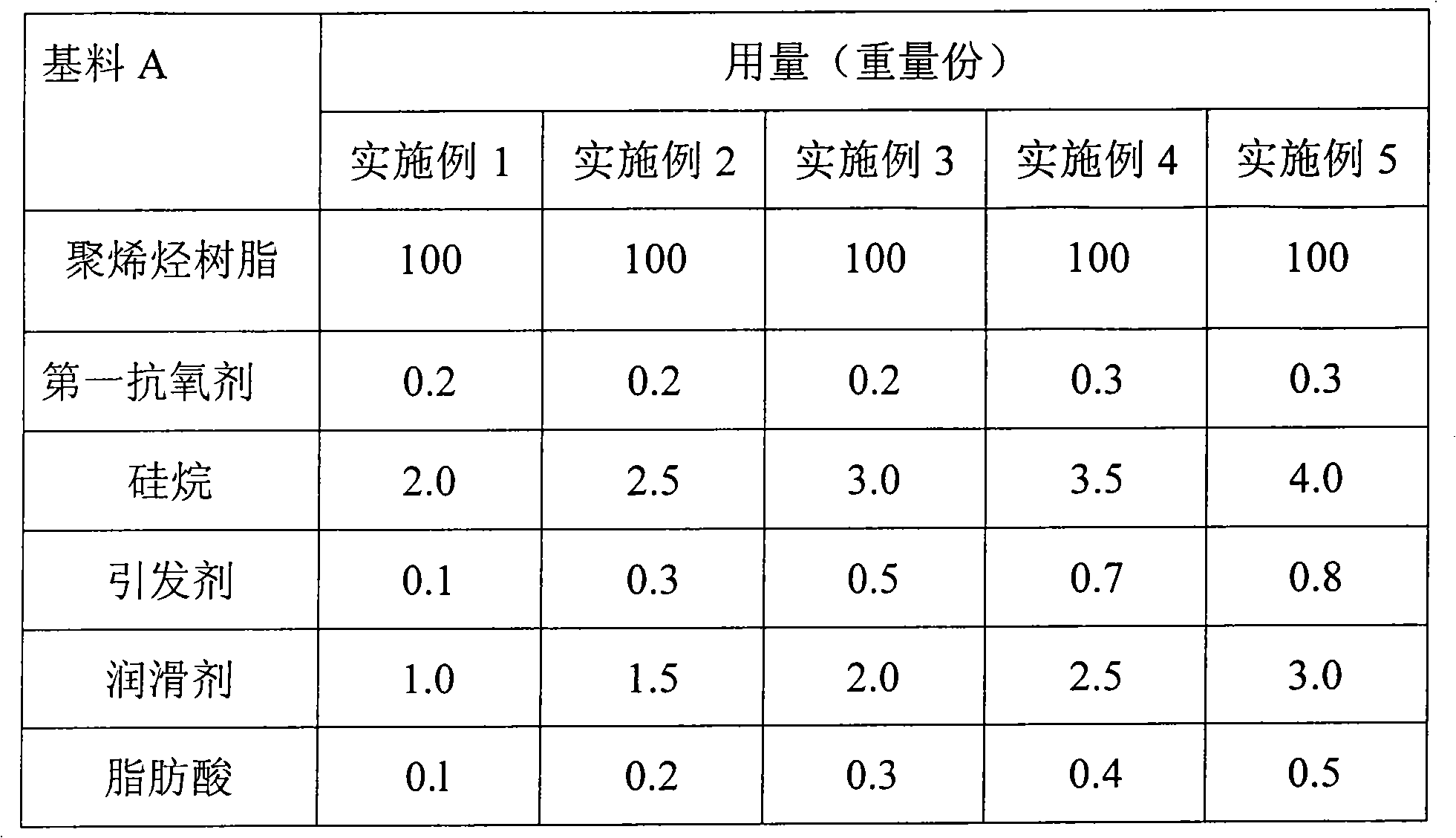

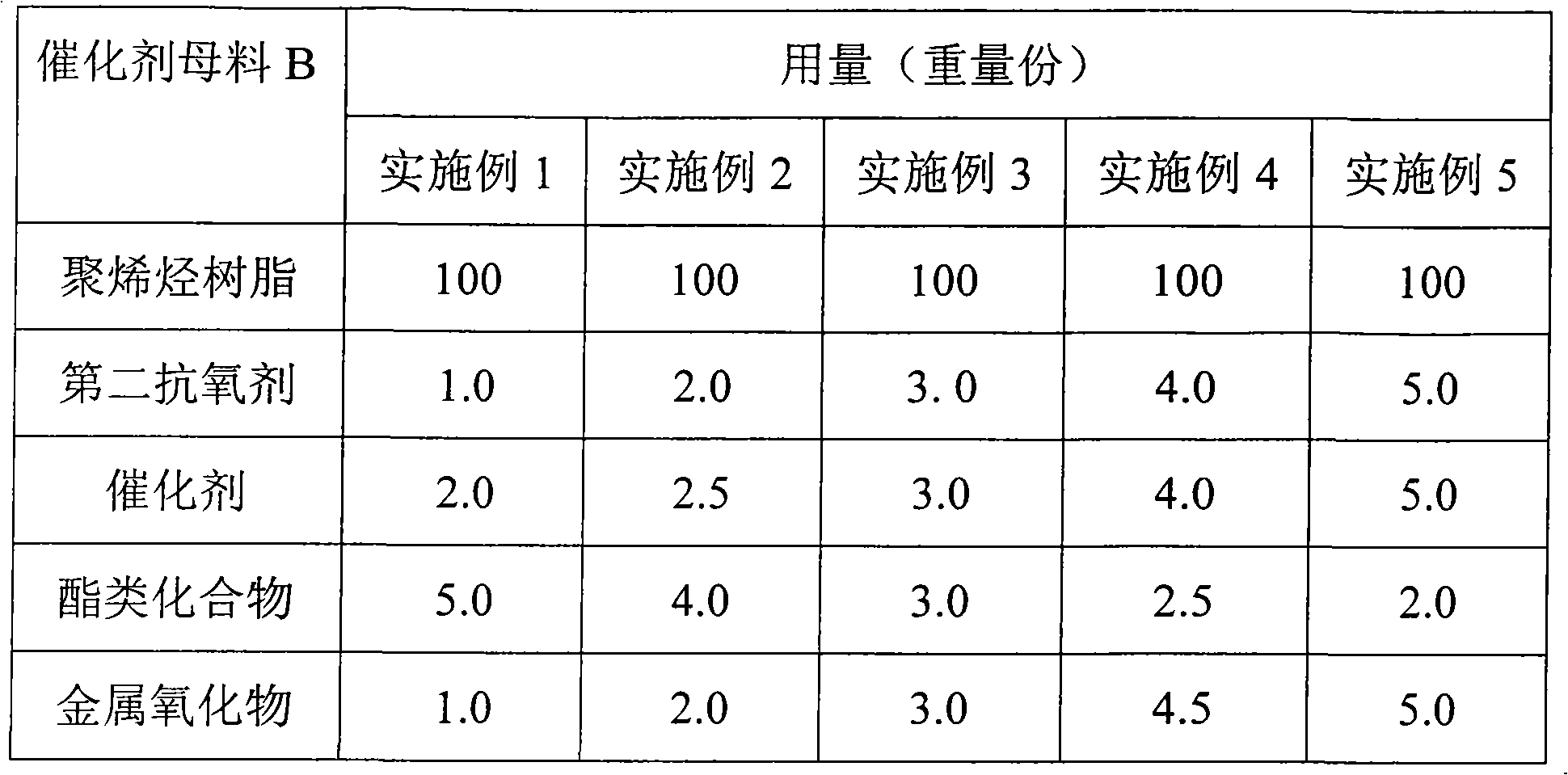

Boiling-free silicane cross-linking polyolefin composition

The invention provides a warm-water-free silane crosslinking polyolefines composition, comprising base material A and catalyst parent material B, the weight ratio thereof being :100:4-6, wherein the base material A is composed of (by weight parts): polyolefine rsin 100 parts, first antioxidant 0.2-0.3 parts, silicane 2.0-4.0 parts, initiator 0.1-1.0 parts, lubricant 1.0-3.0 parts, fatty acid 0.1-0.5 parts, the catalyst parent material B is composed of (by weight parts): polyolefine resin 100 parts, second antioxidant 1.0-5.0 parts, catalyst 2.0-5.0 parts, ester compound 2.0-5.0 parts, metal oxide 2.0-5.0 parts. The preparation method is uniformly mixing the above material. The silane crosslinking polyolefines composition can be linkable under natural conditions not through boiling or vapor bathing, with property corresponding the operational requirement, especially silane crosslinking polyolefines cable material .

Owner:JIANGSU DEWEI ADVANCED MATERIALS +1

Production method of high refractive index nano modified organosilicon encapsulating material

InactiveCN101457022AHigh transparencyHigh refractive indexOther chemical processesSemiconductor/solid-state device detailsRefractive indexCaking

A producing method for a high-refractive index modified organic silicon sealing material adopts a two-pack route and uses a plurality kinds of organic silicon polymer bodies provided with special function genes and produces ropy nanometer modified organic silicon polymer sealing solution together with the inorganic nanometer oxide sol through a certain technique; a thick coat on the chip is produced in a simple method before the solidification and the sealing coat with the needed performance is gained after a certain temperature process. The gained sealing material is provided with the performances of high refractive index, high transmittance, high-temperature resistance, being UV resistant and aging resistant and strong caking, thus can be applied in the sealing of the power typed LED lighting fittings.

Owner:SHENZHEN UNIV

Aging-resistant PC (Polycarbonate) - ABS (Acrylonitrile Butadiene Styrene) plastic alloy

ActiveCN103351592AExcellent heat aging performanceImprove heat aging performancePolycarbonateAging property

The invention discloses an aging-resistant PC-ABS plastic alloy, which is composed of the following components in weight part: 40-60 parts of PC, 20-40 parts of ABS, 2-4 parts of compatibilizer and 0.5-1.5 parts of age resister. The PC-ABS plastic alloy disclosed by the invention combines excellent properties of two materials, namely formability of the ABS material and mechanical property, impact strength, temperature resistance, uv resistance and the like of the PC material, and has excellent thermal aging property, thereby being suitable for use in the extremely high temperature environment.

Owner:东莞市优特美工程塑料有限公司

Polyamide composition

InactiveUS6846868B2Improve heat aging performanceImprove the heating effectConductive materialOrganic conductorsPolymer sciencePolyamide

A polyamide composition comprising 100 parts by weight of (A) a semiaromatic polyamide having dicarboxylic acid units mainly composed of aromatic dicarboxylic acid units and diamine units mainly composed of aliphatic diamine units having 4 to 14 carbon atoms and containing not more than 15 μeq / g of terminal amino groups; and 0.01 to 5 parts by weight of (B) a copper compound.

Owner:KURARAY CO LTD

Heat-resistant and wear-resistant composite material and preparation method and application thereof

The invention discloses a heat-resistant and wear-resistant composite material and a preparation method and an application thereof and belongs to the field of high polymer wear-resistant materials. The heat-resistant and wear-resistant composite material is prepared from the following raw materials in parts by weight: 100 parts of thermoplastic resin, 10-40 parts of carbon fiber, 40-100 parts of a wear-resistant material, 0.1-1.0 part of a heat conduction material, 0.5-2.0 parts of a coupling agent, 0.2-1.0 part of an antioxidant and 0.5-5.0 parts of a lubricant. The heat-resistant and wear-resistant composite material has the characteristics of light specific gravity and high strength, the properties, such as the wear resistance, the corrosion resistance and the ageing resistance, are improved, and the heat-resistant and wear-resistant composite material is a composite material with excellent overall performance and can effectively replace metal alloy and ceramic materials.

Owner:长沙五犇新材料科技有限公司

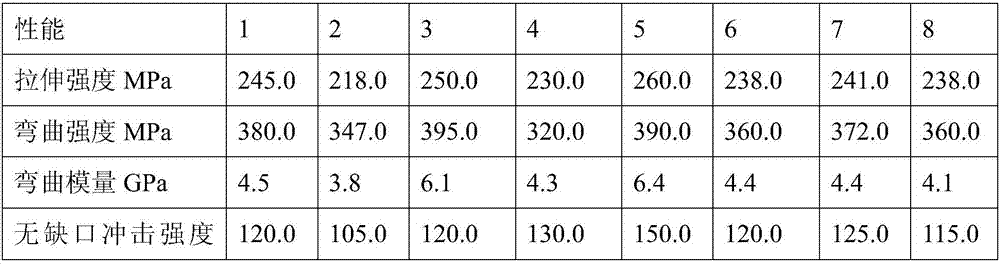

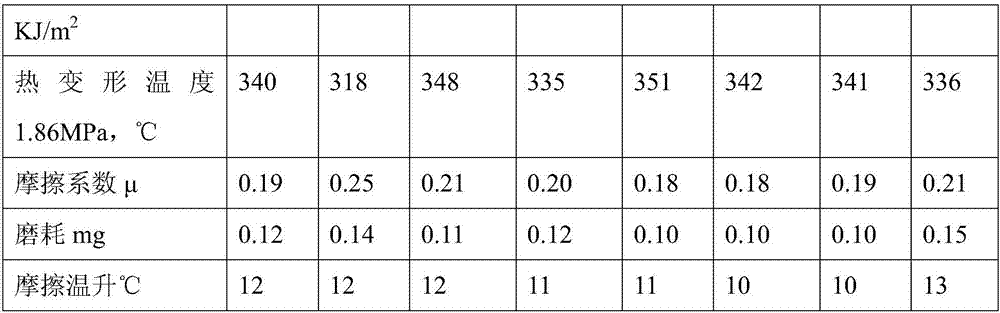

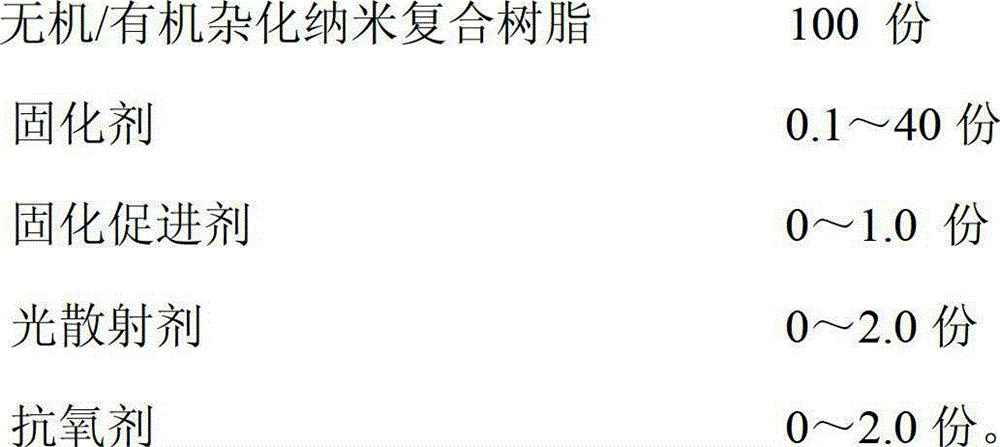

Inorganic/organic hybridization nanometer composite resin and light-emitting diode (LED) packaging materials prepared by the same

The invention belongs to the field of optical semiconductor device packaging materials, and discloses inorganic / organic hybridization nanometer composite resin and light-emitting diode (LED) packaging materials prepared by the same. The inorganic / organic hybridization nanometer composite resin is prepared by epoxy group phenyl group oligomerization siloxane and inorganic nanometer materials in a composite and hybridization mode. The LED packaging materials are prepared by raw materials of the inorganic / organic hybridization nanometer composite resin. The preparation steps comprise that 100 parts by weight of the inorganic / organic hybridization nanometer composite resin, 0.1-40 parts by weight of curing agents, 0-1.0 part by weight of curing accelerator, 0-2.0 parts by weight of light scattering agents and 0-2.0 parts of antioxidants are mixed uniformly, procured for 1-3 hours at the temperature of 60-90 DEG C, then cured for 2-4 hours at the temperature of 120-140 DEG C, and finally cured for 2-6 hours at the temperature of 160-180 DEG C, and the LED packaging materials are obtained.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Ultraviolet deep crosslinked halogen-free flame-retardant ethylene propylene rubber cable material and preparation method of insulating or sheathing layer thereof

ActiveCN102181099AEnhanced cross-linking efficiency induced by UV lightEnhanced cross-linking efficiencyInsulated cablesInorganic insulatorsPolymer scienceUltraviolet

The invention relates to an ultraviolet deep crosslinked halogen-free flame-retardant ethylene-propylene-diene monomer (EPDM) rubber cable material and a preparation method of an insulating or sheathing layer thereof. The method is characterized by comprising the following steps of: mixing and extruding to form the cable material by using EPDM rubber and graft modified EPDM rubber as base materials and compounding a metal hydroxide flame retardant, light initiating bodies of a cationic photoinitiator and a free radical photoinitiator and the like; and then performing molten on-line continuousultraviolet irradiation on a coated cable insulating or sheathing layer in ultraviolet irradiation cross-linking equipment provided with a thermal electronic excited medium-voltage mercury arc lamp or a microwave excited H-shaped, D-shaped or V-shaped electrodeless lamp serving as a specific light source to prepare the ultraviolet deep crosslinked halogen-free flame-retardant EPDM rubber cable insulating or sheathing layer. The technology has unique advantages that: the required cross-linking equipment is low in investment; the process is simple and high in production efficiency; the product has low cost and good quality; and the method is energy-saving and environment-friendly, and is widely used for manufacturing high-performance crosslinked flame-retardant rubber wire and cable products.

Owner:HONGLONGJIANG ORIENT SCI & TECH

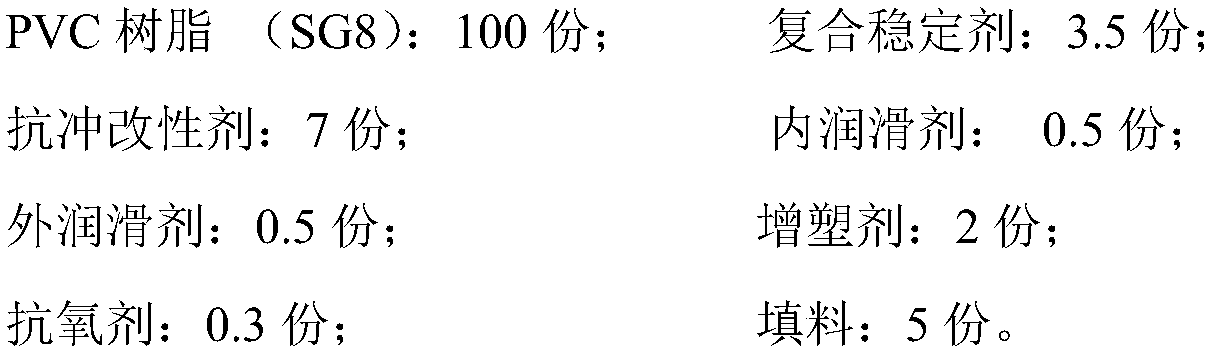

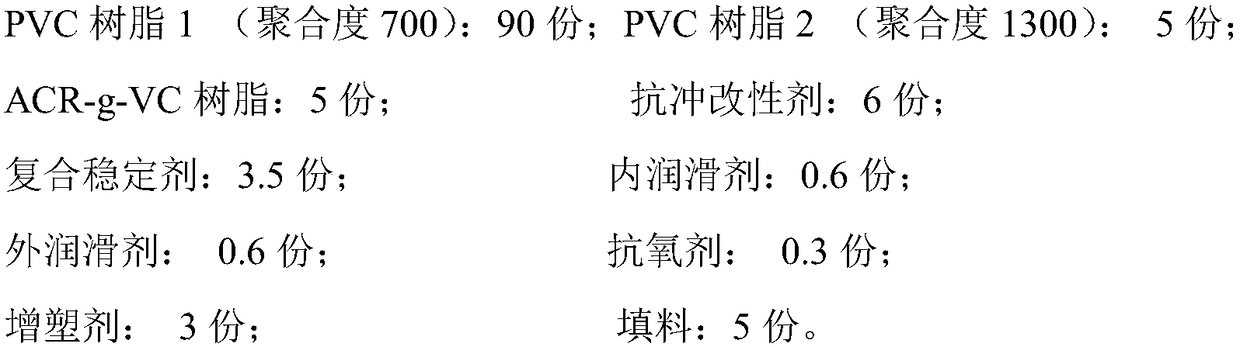

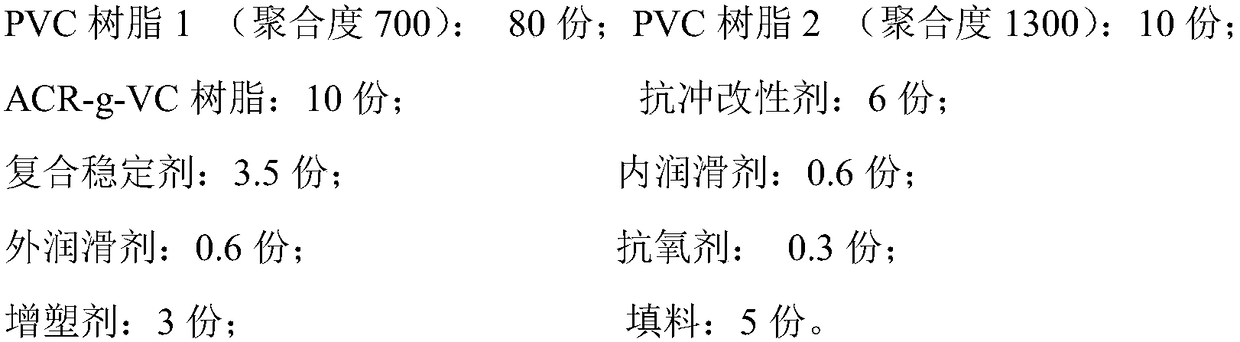

High-strength and high-toughness polyvinyl chloride injection molded composition and preparation method thereof

The invention discloses a high-strength and high-toughness polyvinyl chloride injection molded composition and a preparation method thereof. The composition comprises, by weight, 50-90 parts of PVC (polyvinyl chloride) resin 1, 5-20 parts of PVC resin 2, 5-40 parts of ACR-g-VC (acrylic graft vinyl chloride) resin, 3-10 parts of parts of impact modifier, 4-6 parts of compound stabilizer, 0.5-2 parts of internal lubricant, 0.5-1.2 parts of external lubricant, 1-5 parts of fillers, 1-3 parts of plasticizer and 0.1-1 part of antioxygen. The preparation method includes: weighing the ingredients according to a formula about weight ratios, placing in a high-speed mixer, mixing to obtain a polyvinyl chloride mixture, adding the polyvinyl chloride mixture into a tapered double-screw extruder, melting, extruding, pelletizing and packaging. Compared with a product prepared according to a formula adopting normal SG8 type PVC resin, the high-strength and high-toughness polyvinyl chloride injectionmolded composition has the advantages that plasticizing time can be shortened by more than 20%, and impact strength can be enhanced by more than 10 times.

Owner:YIBIN TIANYUAN GRP CO LTD

Preparation and application of silica gel for LED packaging

InactiveCN101619170AHigh transparencyExcellent UV aging resistanceOther chemical processesSilanesMoisture resistance

The invention relates to preparation of bi-component organic silica gel, which comprises the following steps: firstly, preparing a component A by the co-hydrolysis of vinyl-containing silane and chlorine-containing silane; secondly, preparing a component B by the co-hydrolysis of hydrogen-containing silane and the chlorine-containing silane; and finally, mixing the two components according to certain proportion to obtain a colorless and transparent LED packaging material with heat resistance and low water absorption and without color change under the action of a catalyst C. The material solves the problems of color change, light attenuation and the like caused by poor heat resistance of the conventional thermoplastic packaging materials, plays a role of mechanical support, environment sealing and chip protection to a certain extent, and has good light transmission, adhesiveness, moisture resistance and heat resistance. In addition, the hardness, the adhesion and the heat resistance of the material can be regulated according to the demand of application. The material not only is suitable for LED packaging, but also can be applied to the fields of optical lenses, solar cell substrates, touch screens and the like.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

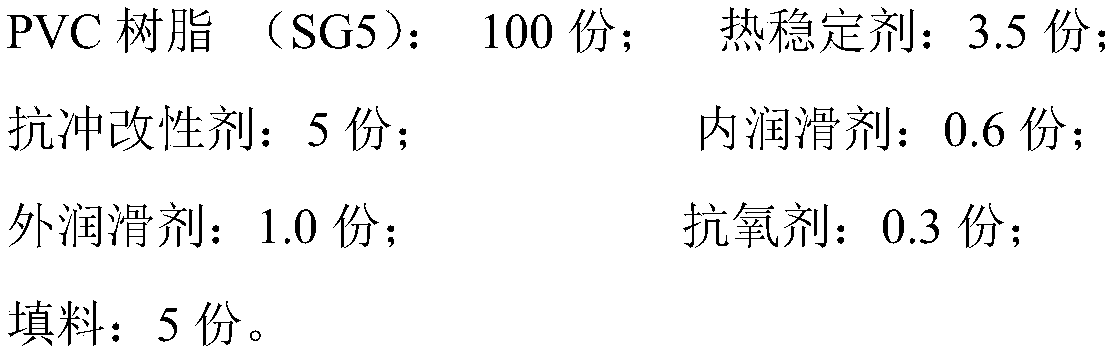

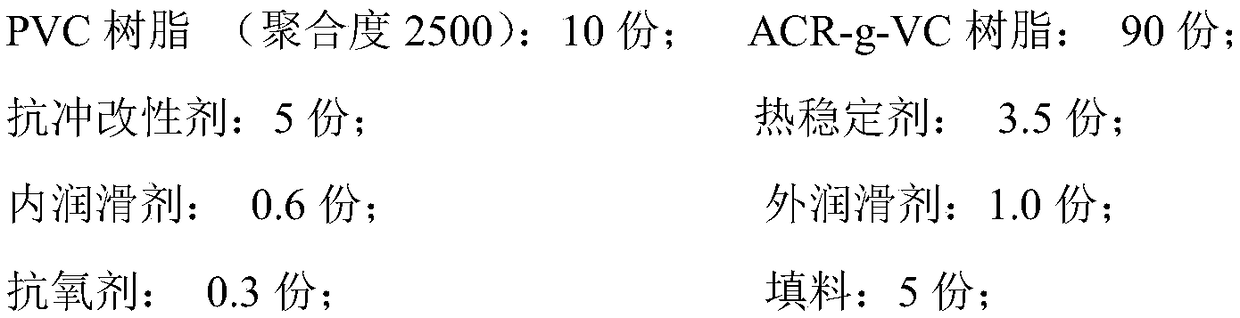

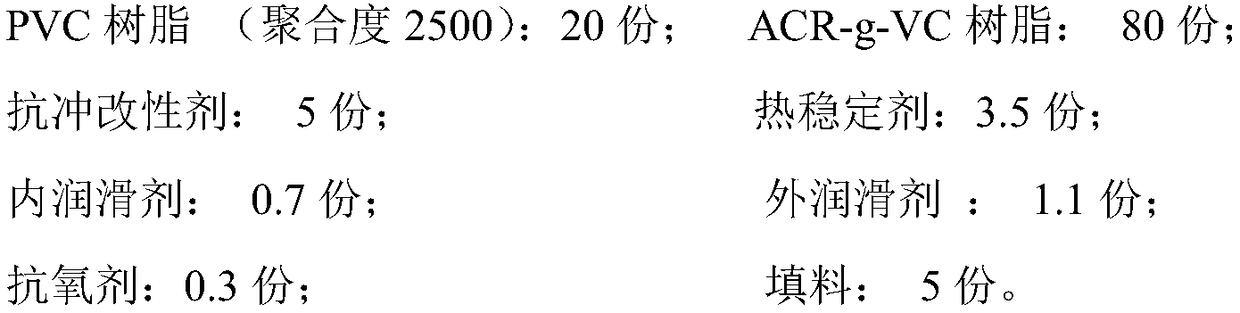

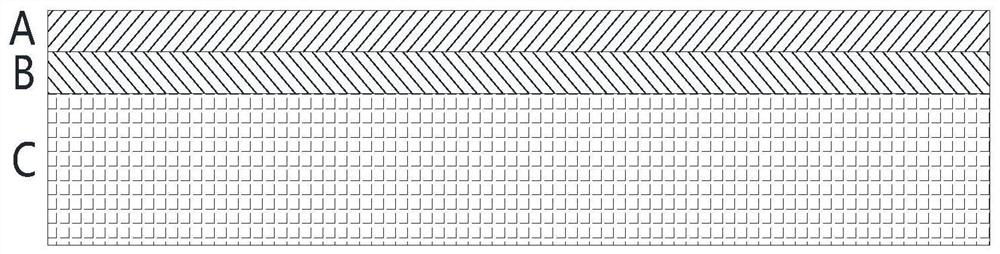

Formula and preparation method of high-strength and high-toughness polyvinyl chloride pipe material

The invention discloses a formula and a preparation method of a high-strength and high-toughness polyvinyl chloride pipe material. According to the formula, the high-strength and high-toughness polyvinyl chloride pipe material comprises, by weight, 10-40 parts of PVC (polyvinyl chloride) resin, 60-90 parts of ACR-g-VC (acrylic graft vinyl chloride) resin, 2-10 parts of impact modifier, 2-5 parts of heat stabilizer, 0.5-2 parts of internal lubricant, 0.5-1.2 parts of external lubricant, 1-20 parts of fillers and 0.1-1 part of antioxygen. The preparation method includes: weighing the ingredientsaccording to the formula, placing in a high-speed stirrer, mixing to obtain a polyvinyl chloride mixture, melting, extruding and pelletizing. A pipe material product prepared by the preparation method has the advantages of high plasticizing speed, high processability, great surface color, high impact resistance, high tensile strength, high weather resistance and the like.

Owner:YIBIN TIANYUAN GRP CO LTD

Aging-resistant PC (Polycarbonate) -PBT (Polybutylene Terephthalate) plastic alloy

InactiveCN103351593AImprove heat resistanceImprove wear resistanceCrack resistancePolyethylene terephthalate

The invention discloses an aging-resistant PC-PBT plastic alloy, which is composed of the following components in weight part: 100 parts of PC, 20-40 parts of PBT, 4-8 parts of compatibilizer and 0.5-1.5 parts of age resister. The PC-PBT plastic alloy disclosed by the invention has the advantages of good thermal tolerance, good stress cracking resistance, excellent abrasive resistance, excellent chemical corrosive resistance, high low-temperature impact strength, easiness in machining and good coating property, and is mainly applied to bumpers, chassis and panels of superior quality cars, fenders of motorcycles and the like. The aging-resistant PC-PBT plastic alloy also has excellent thermal aging property, thereby being suitable for use in the extremely high temperature environment.

Owner:深圳市高科塑化有限公司

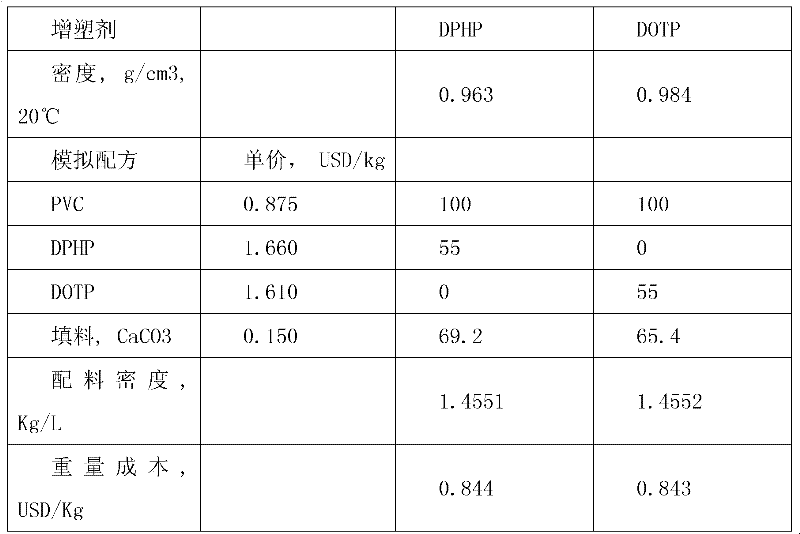

Preparation method and application of phthalic acid diester (2-propyl group heptanol)

InactiveCN102531903AImprove stabilityImprove migration resistanceOrganic compound preparationCarboxylic acid esters preparationThermal ageingPlasticizer

The invention provides a preparation method and application of phthalic acid diester (2-propyl group heptanol), which obtain the phthalic acid diester (2-propyl group heptanol) (DPHP) through a one-step reaction with phthalic anhydride and the 2-propyl group heptanol serving as raw materials. The raw materials selected by in the preparation method and the application are easy to obtain and mild in reaction condition, the postprocessing after reaction is simple, operation is simple and convenient, chemical yield coefficient is high and the like. The preparation method is convenient in operation, saves energy, and is less in environmental contamination. Obtained products have low volatility, good thermal ageing performance, good weather fastness and good anti-mobility, and can serve as a plasticizer in the polrvinyl chloride processing process.

Owner:CHAOHU XIANGFENG PLASTIC AIDS

Radiation crosslinked polyethylene thermally-shrinkable cladded sheet materials and preparation method therefor

InactiveCN1970677AGood waterproof sealingIncrease stressOther chemical processesCorrosion preventionNuclear radiationCompound (substance)

The invention discloses a water-proof radiating crosslinking polyethylene heat-condensing clad piece of oil, chemical and insulating pipe, which is composed of polyethylene base and fusing gel layer, wherein the polyethylene, carbon black and chlorcosane are fused and crosslinked to mould, which are extended transversely through nuclear radiation; the fused gel is coated on the inner surface or inner periphery of base evenly; each hole is opened on the clad piece along two sides intervally, which fixes the interface of clad piece.

Owner:吉林石油集团有限责任公司 +1

Pt-containing catalyst suitable for gasoline vehicle tail gas purification, and preparation method thereof

PendingCN112221494AGood anti-aging performanceImprove heat aging abilityExhaust apparatusHeterogenous catalyst chemical elementsComposite oxideOxide

The invention discloses a Pt-containing catalyst suitable for gasoline vehicle tail gas purification, and a preparation method of the Pt-containing catalyst. The catalyst is composed of a honeycomb carrier and a coating coated on the pore wall of the carrier, wherein the coating comprises a bottom coating coated on the surface of the pore wall of the carrier and an upper coating coated on the surface of the bottom coating, the bottom coating comprises noble metals Pt and Pd, an auxiliary agent CeO2, an alkaline earth metal oxide, modified aluminum oxide and a cerium-zirconium composite oxide,and the upper coating comprises a noble metal Rh, an auxiliary agent Nd2O3, modified aluminum oxide and a cerium-zirconium composite oxide. According to the invention, Pt, Pd, Ce and the like are co-impregnated in a cerium-zirconium composite oxide in equal volume, a large amount of CeO2 is formed around Pt to form a Pt-O bond or a Pt-O-Ce bond, the oxidation state of Pt can be maintained so as tostabilize Pt, and a small amount of Pd can improve the catalytic performance of Pt; and Pt, Pd and alkaline-earth metal oxide are adopted to be co-impregnated in modified aluminum oxide in an isopyknic manner, the thermal aging capacity of the catalyst can be improved by adding the alkaline-earth metal oxide, and the catalytic performance of Pd can be improved by a small amount of Pt.

Owner:SINOCAT ENVIRONMENTAL TECH

Material of polyolefin elastomer dedicated to skins of instruments decorated inside auto car

This invention discloses an automobile inner decoration material of polyolefin elastomer. The material comprises: ternary ethylene-propylene rubber 30-60 wt.%, polyethylene 10-35 wt.%, polypropylene 6-35 wt.%, silane coupling agent 3-7 wt.%, organic Sn 0.5-3.5 wt.%, perfluorodibenylethane 5-8 wt.%, Ti2O3 1.5-3 wt.%, antioxidant-1010 0.3-0.5 wt.%, and zinc stearate 0.3-0.8 wt.%. The material can be produced by traditional ABS / PVC resin production process and apparatus. The material has such advantages as good physical properties, light weight, high elasticity, and good permanent deformation performance, high scrape resistance, and high heat and cold resistance, and can be used for automobile inner decoration.

Owner:双嘉新材料科技(浙江)有限公司

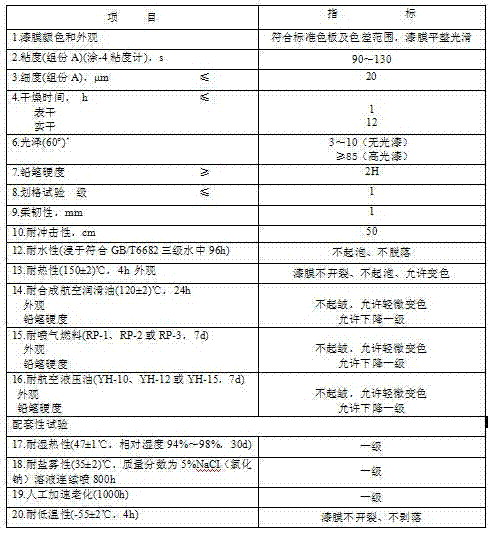

Nanometer enamel used for aircraft skin and preparing method thereof

ActiveCN104119751AImproves resistance to UV agingImprove heat aging performanceMagnetic paintsPolyester coatingsSolventThermal ageing

The invention discloses nanometer enamel used for aircraft skin and a preparing method thereof, and belongs to the technical field of paint, mainly solving the technical problems that enamel at present has unsatisfactory ultraviolet radiation aging resistance and thermal ageing resistance and cannot meet requirements of long-term flight of aircrafts. The nanometer enamel comprises following components by weight: 3-5 parts of modified polyester resin, 30-35 parts of acrylic resin, 20-25 parts of titanium dioxide, 3-4 parts of nanometer silicon dioxide, 3-6 parts of a dispersant, 0.5-1 part of a silane coupling agent, 8-10 parts of precipitated barium sulphate, 10-15 parts of a curing agent, 15-36 parts of a mixed solvent, 0.2-0.3 part of a leveling agent, 0.2-0.3 part of a defoaming agent and 0.1-0.3 part of a catalyst. The preparing method includes steps of nanometer material pretreatment, mill base dispersion, paint mixing, filtration, and the like. The nanometer enamel has excellent ultraviolet radiation aging resistance and thermal ageing resistance at the same time of meeting common performance requirements, and can meet requirements of long-term flight of aircrafts.

Owner:西安经建油漆有限责任公司

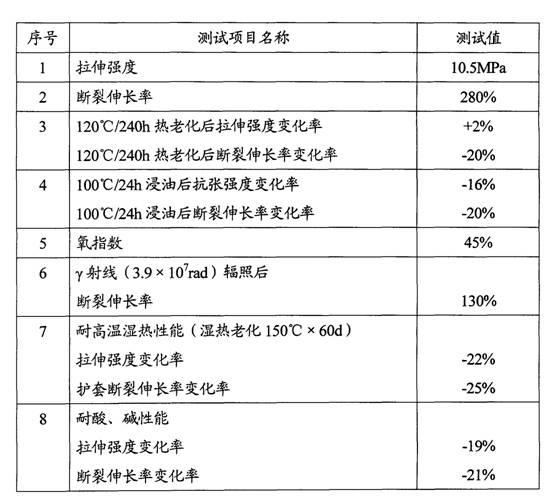

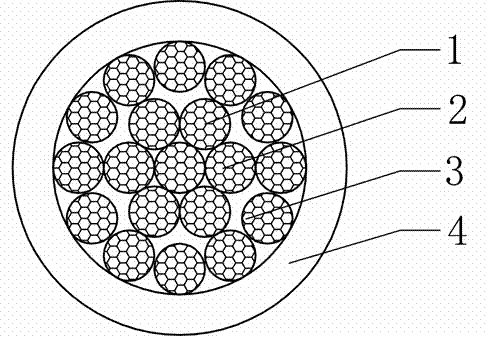

Cable jacket material for nuclear power station of third generation and preparation method for cable jacket material

InactiveCN102604196AImprove radiation resistanceExtended service lifeInsulated cablesInsulated conductorsCross-linkNuclear power

The invention relates to a cable jacket material for a nuclear power station of the third generation and a preparation method for the cable jacket material. A raw material formula of the cable jacket material comprises, by weight, 100 parts of ethylene-vinyl acetate copolymers, 105-180 parts of flame retardants, 3-4 parts of antioxidants, 2.5-3 parts of stabilizers, 3-5 parts of lubricants, 2.5-4 parts of coupling agents, 2.5-3 parts of cross-linking agents and 0.5-1.5 parts of crosslinking auxiliaries, wherein the ethylene-vinyl acetate copolymers are made of ethylene and vinyl acetate by means of copolymerization. The preparation method includes the steps: mixing the ethylene-vinyl acetate copolymers, the antioxidants, the lubricants, the stabilizers, the cross-linking agents and the flame retardants by a banbury mixer, then feeding the mixture into a double-screw extruder for extrusion, granulating by granulation equipment prior to adsorbing dicumyl peroxide serving as the cross-linking agents and triallyl isocyanurate serving as the crosslinking auxiliaries, and obtaining the cable jacket material for the nuclear power station of the third generation after cooling. The cable jacket material is fine in performance, and the service life of the cable jacket material is longer than 60 years.

Owner:JIANGSUSNGSHANG CABLE GROUP

Preparation method of super-soft cable and external coating material of super-soft cable

ActiveCN104761909AWill not deformSmall bending radiusFlexible cablesCable/conductor manufactureYarnSesquioxide

The invention discloses a preparation method of a super-soft cable and an external coating material of the super-soft cable. The super-soft cable comprises a conductive core stranded by 7-61 groups of folded yarns and the external coating material of the conductive core, wherein each of the folded yarns is stranded by a plurality of tinned copper wires; the conductive core is coated with super-soft high-strength silicon rubber for insulation; the high-strength silicon rubber comprises the following components: methyl vinyl silicone rubber, precipitated white carbon, iron sesquioxide, chlorinated paraffin, magnesium hydrate, an anti-aging agent N-isopropyl benzene-N'-phenyl p-phenylenediamine, hydroxyl silicone oil, silicone oil containing hydrogen, dioctyl phthalate, a surfactant gamma-thiopropyl triethoxy silane, a silane coupling agent and a bis-2, 5 vulcanizing agent. The super-soft cable has the characteristics of bending resistance, corrosion resistance, wear resistance and the like, is relatively high in using temperature and relatively long in service life, and can be used for various types of equipment which is small in cable laying space and great in number of round trips.

Owner:西安飞机工业(集团)亨通航空电子有限公司

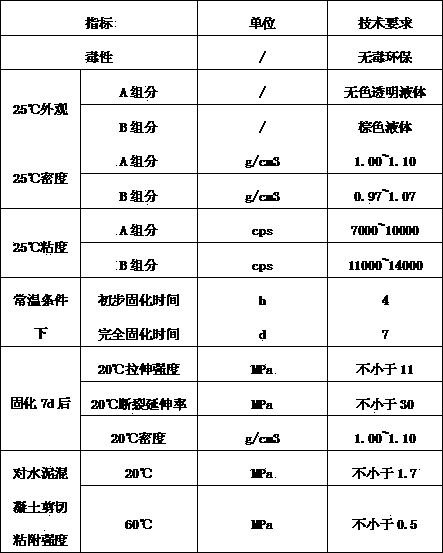

Construction process of colored pavement epoxy non-slip wearing layer structure

ActiveCN103938513ASimple construction processEasy constructionIn situ pavingsPaving detailsEpoxyRoad surface

The invention discloses a construction process of a colored pavement epoxy non-slip wearing layer structure. The construction process comprises the following steps: (1) pavement patching; (2) pavement shot blasting; (3) epoxy resin stirring; (4) paving of epoxy resin; (5) spreading of aggregates; (6) curing and recovering of the aggregates; and (7) opening of transit. Compared with the prior art, the construction process has the advantages that the wearing layer structure is simple in process, easy to operate, good in non-slip performance, high in bonding strength, small in thickness, convenient in construction, rapid in curing and high in material water resistance; running noise of vehicles is lowered; driving conditions are improved; the wearing layer structure is excellent in corrosion resistance, high in flame retardant property, high in ductility, uniform in expansion, high in low-temperature resistance, low in low-temperature brittleness, excellent in thermal ageing resistance, high in high-temperature stability and high in wear resistance, the surface aggregate is high in wear resistance, a conventional road elevation and the conventional clear height of a bridge are not changed, existing various structural and non-structural pavement diseases can be repaired at a time, the maintenance cost is saved, and the service life of a pavement is greatly prolonged.

Owner:上海仁路科技有限公司

Anti-aging PC-PET (poly carbonate-polyethylene terephthalate) plastic alloy

ActiveCN103360741AImprove low temperature resistanceImprove impact performanceHeat deflection temperaturePolyethylene terephthalate glycol

The invention discloses an anti-aging PC-PET (poly carbonate-polyethylene terephthalate) plastic alloy which consists of the following components in parts by weight: 60-80 parts of PC, 15-25 parts of PET, 2-4 parts of compatilizer and 0.5-1.5 parts of anti-aging agent. The anti-aging PC-PET plastic alloy disclosed by the invention has the characteristics of excellent low-temperature resistance, high impact strength and thermal deformation temperature and good stability in mechanical property and size, and can be widely applied to the fields such as home appliances, electronics, building materials, automobiles and the like; and moreover, the anti-aging PC-PET plastic alloy has excellent thermal aging performance and is applicable to an extreme high-temperature environment.

Owner:SHANTOU LONGQI PLASTIC PROD

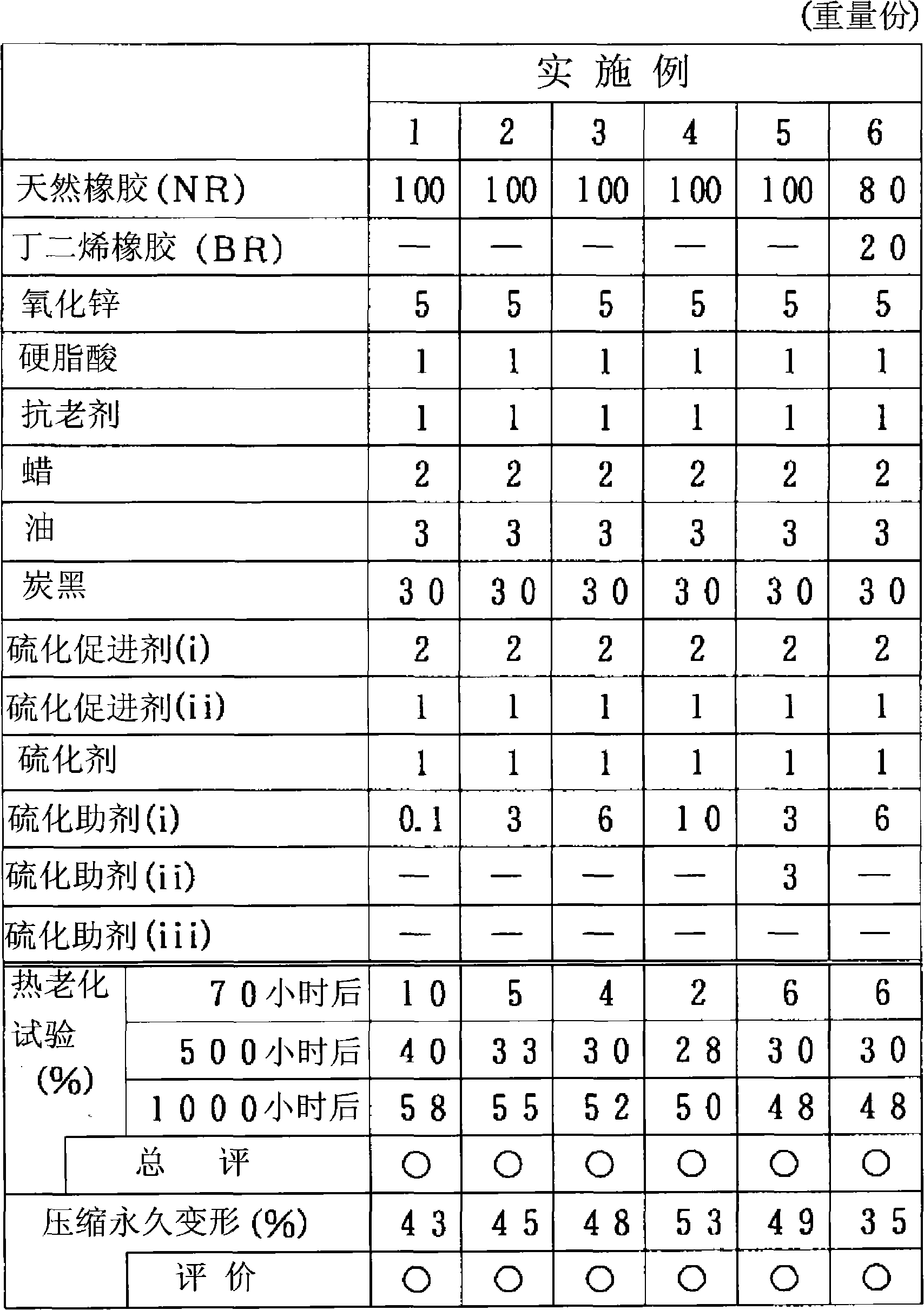

Vibration-damping rubber composition

InactiveCN102341451AImprove the anti-vibration effectImprove fatigue resistanceOther chemical processesPolymer scienceZinc

A vibration-damping rubber composition which comprises (A) natural rubber (NR) as the main component and contains (B) zinc monomethacrylate and (C) a sulfur-containing vulcanizing agent, wherein the content of the component (B) is set within the range of 0.1 to 10 parts by weight with respect to 100 parts by weight of the component (A). The vibration-damping rubber composition exhibits excellent vibration-damping properties and has excellent heat aging resistance over a long period.

Owner:SUMITOMO RIKO CO LTD

Prepn process of anti-fouling metallic paint

ActiveCN1847339AGood hygroscopicityGood anti-aging performanceAntifouling/underwater paintsPaints with biocidesSolventSurface finishing

The present invention relates to modified polymer paint technology, and is especially one kind of composite anti-fouling metallic paint with nanometer particle and its preparation process. The preparation process of the composite anti-fouling metallic paint includes the following steps: 1. dissolving room temperature vulcanized silicon rubber in organic solvent xylene to form glue liquid; 2. preparing nanometer powder of silica, magnesia, titania and barium sulfate in certain weight proportion and treated with sodium laurate as organic surface treating agent, and adding the nanometer powder into the glue liquid gradually while vibrating; 3. adding small amount of dispersant, coupling agent and organic tin catalyst; and 4. setting the glue liquid and vibrating beads into vibrating bottle, adding silica, magnesia, titania and barium sulfate successively, vibrating, and filtering to obtain the slurry as the anti-fouling metallic paint.

Owner:SHANGHAI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com